High strength spring steel and production method thereof

A production method and technology of spring steel, applied in the field of metallurgy, can solve problems such as complete fracture and insufficient strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

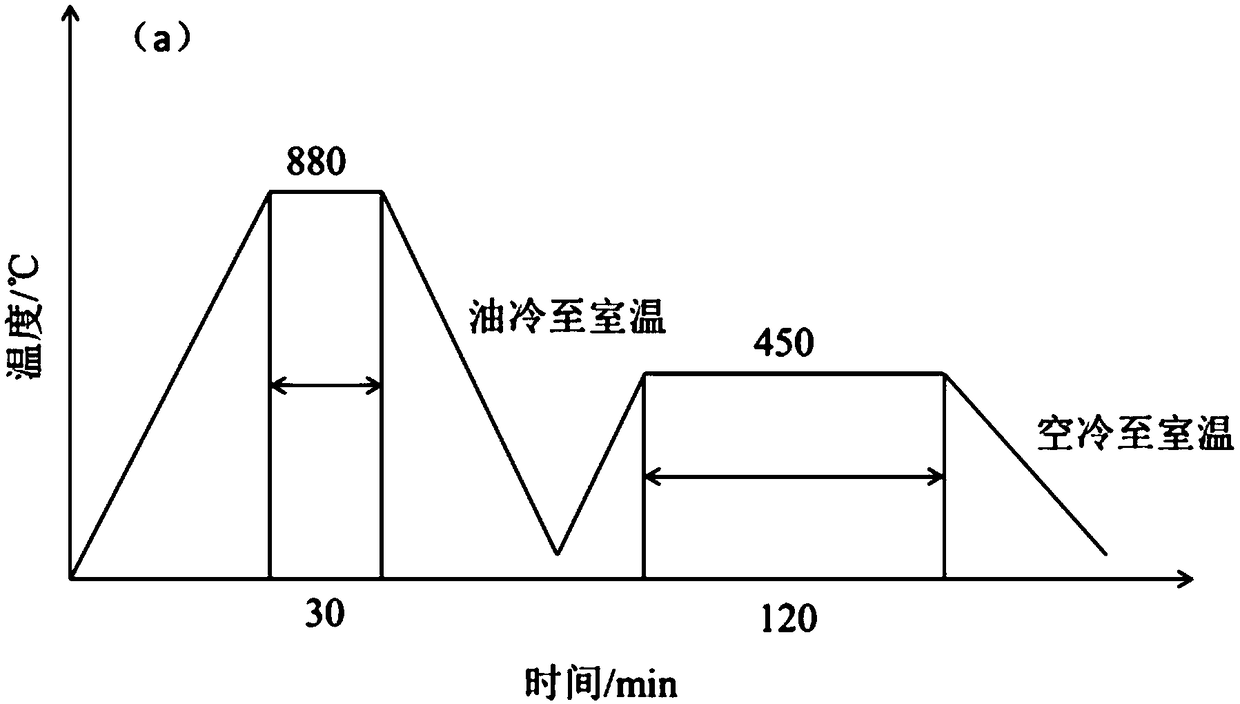

Embodiment 1

[0053] This embodiment provides a high-strength spring steel. The weight percentage of each chemical component of the high-strength spring steel is shown in Table 1, wherein the weight percentage of V is controlled to 0.16%.

[0054] In addition, this embodiment also provides the above-mentioned production method of high-strength spring steel. The high-strength spring steel is smelted in a 25kg vacuum induction furnace. The specific steps are as follows:

[0055] S1. Ingredients: According to the weight percentage of each chemical composition of the spring steel of Example 1 in Table 1, prepare raw materials required for smelting, including pure iron, metallic chromium, ferrovanadium, electrolytic manganese, industrial silicon, and graphite blocks.

[0056] S2. Smelting: Put the crucible containing pure iron and 80% graphite block in a 25kg vacuum induction furnace. The order of external silo charging is: industrial silicon, metallic chromium, graphite block, vanadium iron and electro...

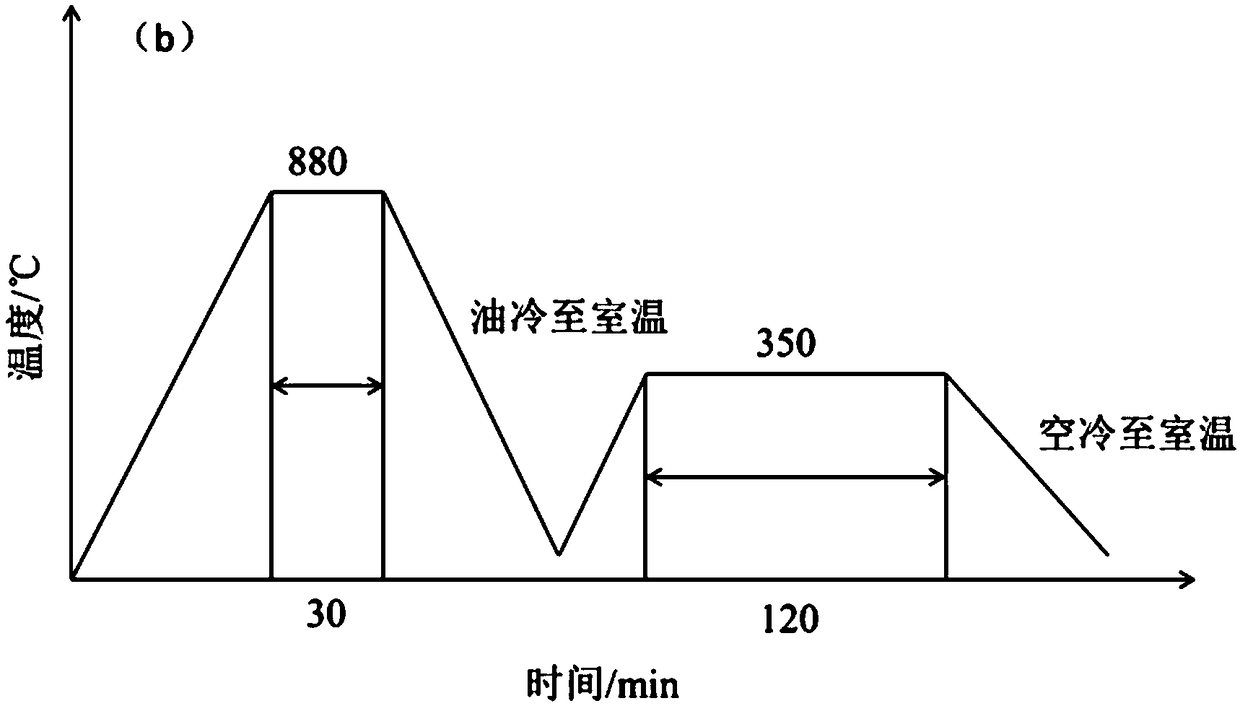

Embodiment 2

[0061] This embodiment provides a high-strength spring steel. The weight percentage of each chemical component of the high-strength spring steel is shown in Table 1, wherein the weight percentage of V is controlled to 0.21%.

[0062] In addition, this embodiment also provides the above-mentioned production method of high-strength spring steel. The high-strength spring steel is smelted in a 25kg vacuum induction furnace. The specific steps are as follows:

[0063] S1. Ingredients: According to the weight percentages of the chemical components of the spring steel of Example 2 in Table 1, prepare raw materials required for smelting, including pure iron, metallic chromium, ferrovanadium, electrolytic manganese, industrial silicon, and graphite blocks.

[0064] S2. Smelting: Put the crucible containing pure iron and 80% graphite block in a 25kg vacuum induction furnace. The order of external silo charging is: industrial silicon, metallic chromium, graphite block, vanadium iron and electrol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com