Sinter-hardening powder and their sintered compacts

a technology of sinter-hardening powder and compacts, which is applied in the field of sinter-hardening powders, can solve the problems of inability to meet the requirements of heat treatment on the components, inability to meet the requirements of heat treatment, and inability to achieve the effect of reducing the number of sinter-hardening powders, and reducing the number of sinter-hardening powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0043]To the Fe-0.8Mo-0.8Cr mixed powder, different amounts of elemental Ni powder are added. The base iron powder selected is carbonyl iron powder. The Mo powder is added in the elemental powder form. The Cr is added in the form of Fe-16 wt % Cr ferroalloy powder. The chemical compositions are shown in Table 3. The admixed powder is doped with 7 wt % of the binder, kneaded in a high shear rate mixer at 150° C. for 1 hour, and then cooled to room temperature to obtain the granulated feedstock. Thereafter, the granulated feedstock is filled into the injection molding machine to produce the tensile test bar (e.g. the standard tensile bar from the MPIF-50 standard). The tensile bar is debound under the procedure applied from the known arts in the industry to remove the binder, subsequently heated in the vacuum furnace at 1200° C. for two hours, and then furnace-cooled at a cooling rate of about 6° C. / minute between 600° C. and 300° C. After sintering, the specimen is tempered at 200° C...

example 2

[0045]To the Fe-8Ni-0.8Cr mixed powders, different amounts of elemental Mo powder are added. The base iron powder selected is carbonyl iron powder. The Cr is added in the form of Fe-16 wt % Cr ferroalloy powder, while the Ni is added in the elemental powder form. The chemical compositions are shown in Table 4. The mixed powder is processed following those procedures described in EXAMPLE 1. The carbon content thus obtained is about 0.45 wt %, and the sintered density is about 95.7%. As shown in Table 4, the hardness increases as the Mo content increases, reaching a maximum at about 0.8 wt % Mo. When the Mo content is 6 wt %, the hardness decreases to HRC35.

[0046]Table 4 shows the effect of Mo content on the hardness of sinter-hardened Fe-8Ni-0.8Cr-0.45C compact.

TABLE 4Sample No.Mo (wt %)Hardness (HRC)10040110.142120.546130.848142431543916635

example 3

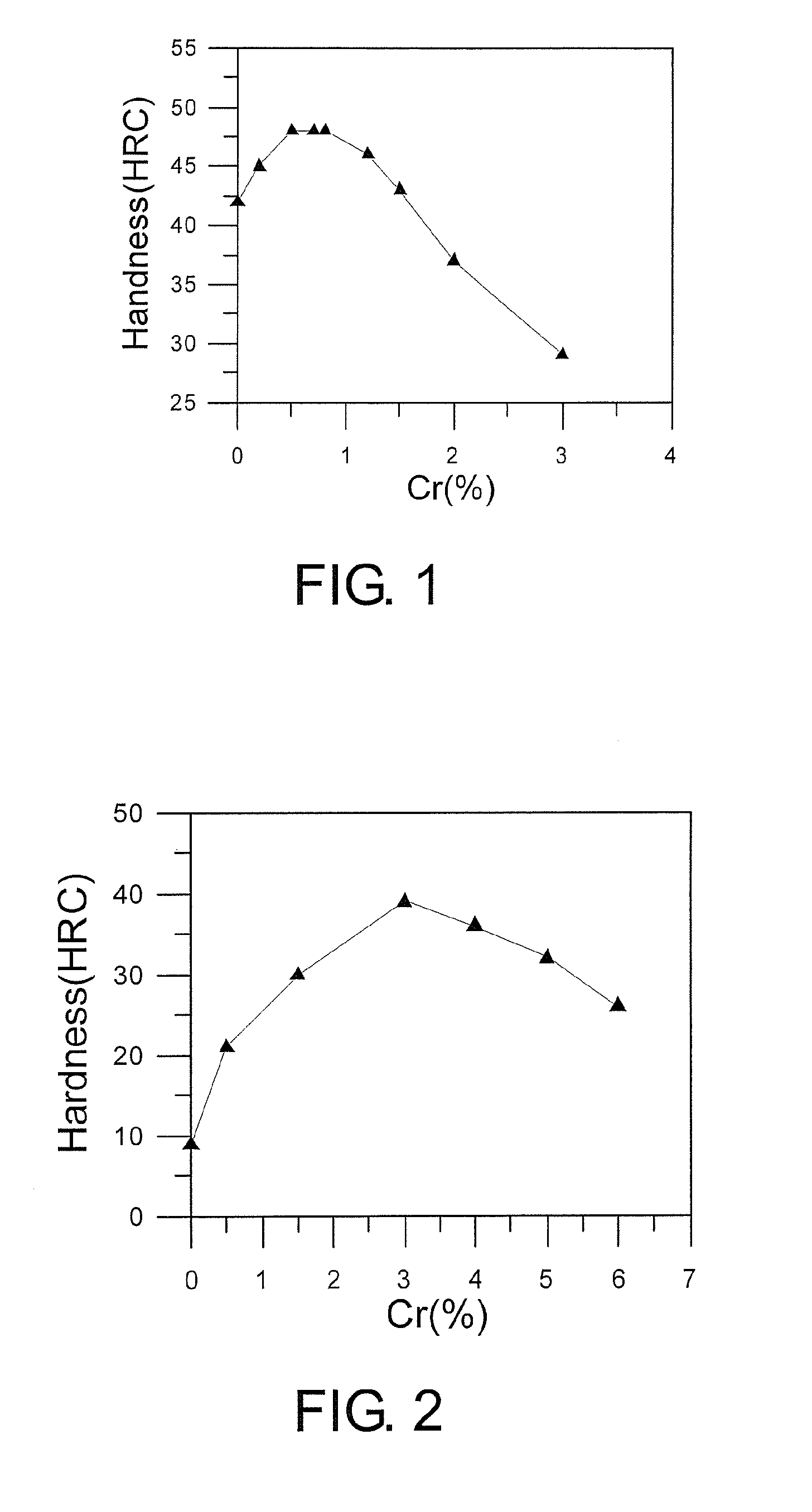

[0047]To the Fe-8Ni-0.8Mo mixed powder, different amounts of Cr are added in the form of Fe-16 wt % Cr ferroalloy powder. The base iron powder selected is carbonyl iron powder. Both Ni and Mo are added in the elemental powder form. The chemical compositions are shown in Table 5. The mixed powder is processed the same way as that described in EXAMPLE 1. The carbon content obtained is about 0.43 wt % and the sintered density is about 95.6%. As shown in Table 5, the hardness increases as the Cr content increases, reaching a maximum at about 0.8 wt % Cr. When the Cr content is 6 wt %, the hardness is lower than HRC35.

[0048]Table 5 shows the effect of Cr content on the hardness of sinter-hardened Fe-8Ni-0.8Mo-0.43C compact.

TABLE 5Sample No.Cr (wt %)Hardness (HRC)17042180.143190.245200.548210.848221.546232.042243.037256.030

[0049]The benefits of adding Cr is shown above in Table 5. However, such benefits can be seen only when there is a good combination of alloying elements. For example, F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com