Golf ball which includes fast-chemical-reaction-produced component and method of making same

a technology of fast reaction and golf ball, which is applied in the field of golf balls, can solve the problems of high cost, achieve the effects of improving gloss retention uv light stability, thermal stability hydrolytic stability, and low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

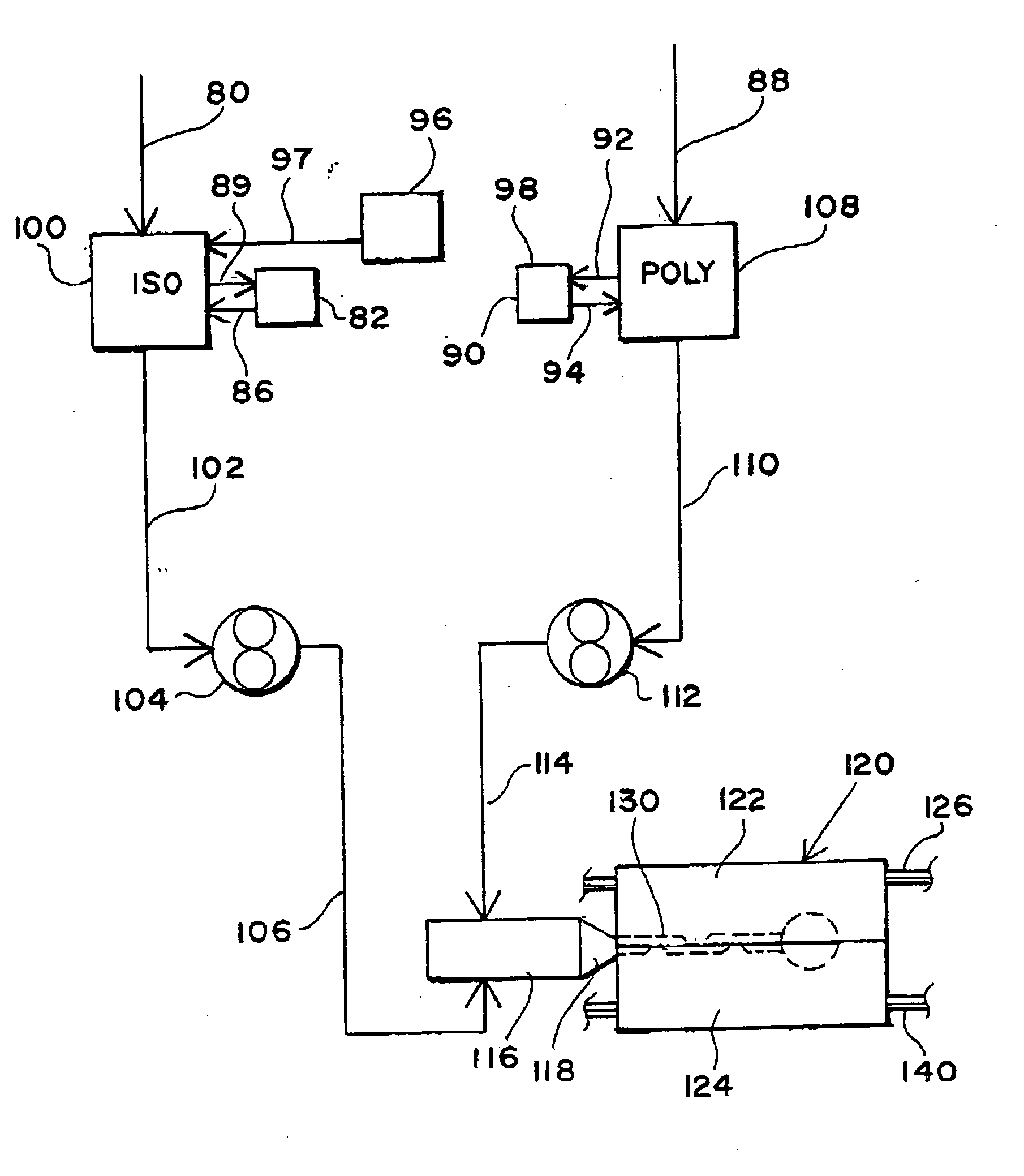

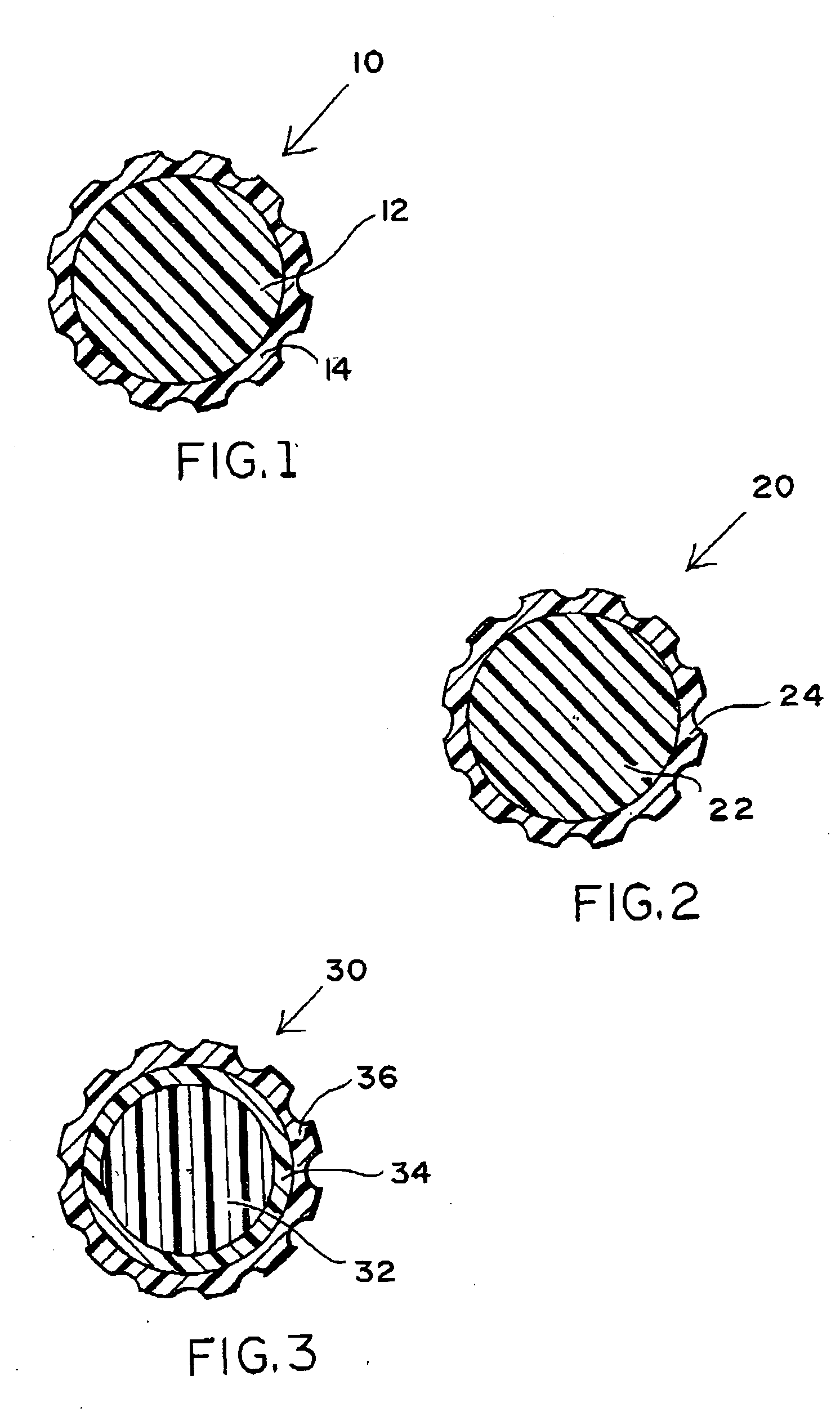

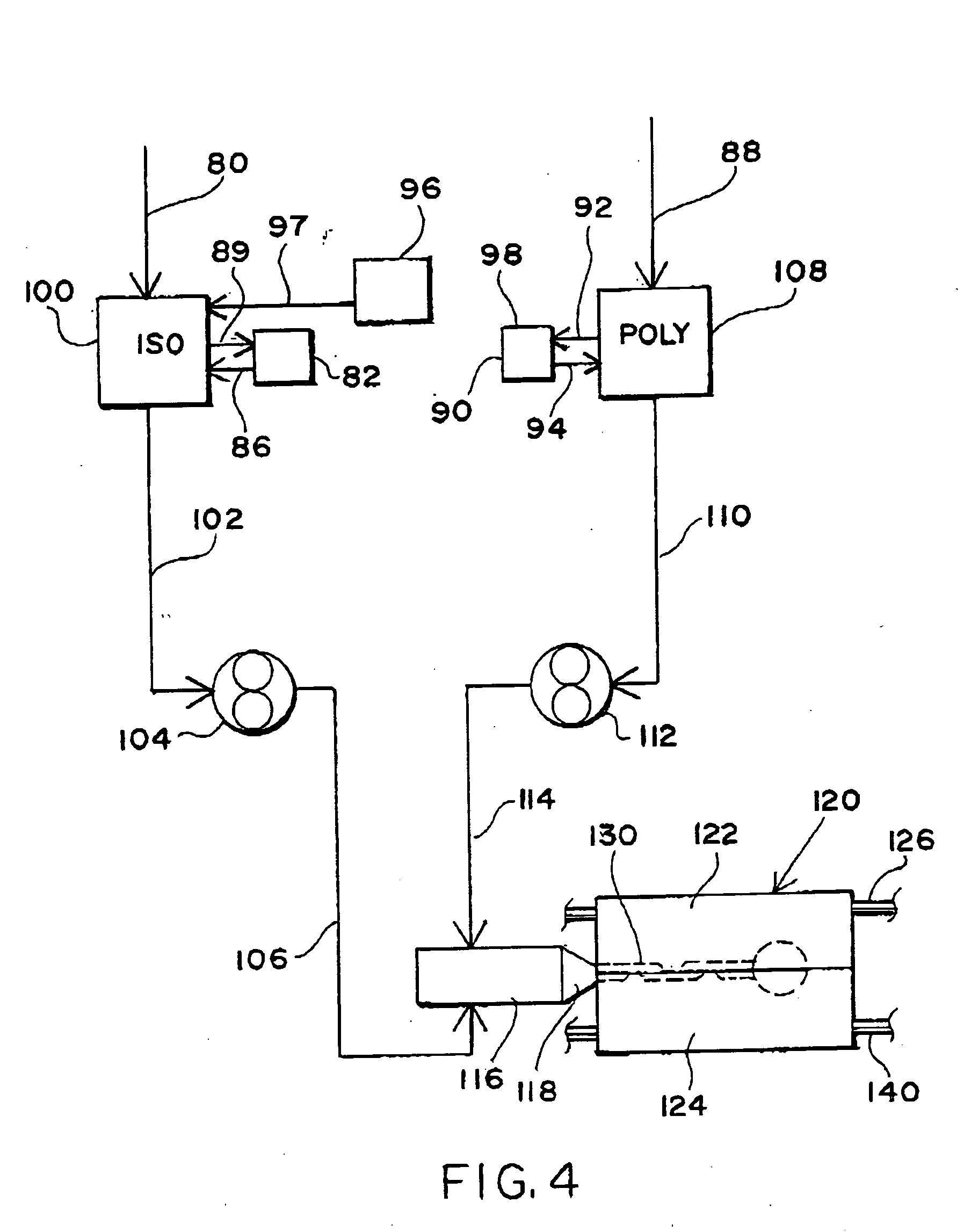

Method used

Image

Examples

example 1

[0065] A polybutadiene golf ball core having a diameter of 1.545″, a PGA compression of about 65 and a coefficient of restitution of about 0.770 was obtained. A dimpled cover having a thickness of 0.0675″ was reaction injection molded over the core. The cover comprised Bayflex MP 10000 resin (Bayer). The resulting ball had a PGA compression of 78, a COR of 0.720 and a Shore D cover hardness of 39. The ball met standard durability tests and had an excellent scuff resistance rating of 1. It is expected that this cover also has an excellent cut resistance rating.

example 2

(Prophetic)

[0066] A golf ball core formed from high cis polybutadiene, zinc diacrylate, zinc oxide, zinc stearate, and peroxide initiator is obtained. The core has a diameter of 1.49″.

[0067] The core is covered with a 0.04″ thick mantle layer of RIM polyurethane which has a plaque Shore D hardness of 58, namely Bayflex® 110-50 unfilled (Bayer Corp.). The mantle layer is covered with a 0.055″ thick dimpled outer cover layer of Iotek 8000, 7510 and 7030, and a whitener package. The formulation and properties of the golf ball are shown below on Table 1.

example 3

(Prophetic)

[0068] A golf ball core formed from high-cis polybutadiene, zinc diacrylate, zinc oxide, zinc stearate and peroxide imitator is obtained. The core has a diameter of 1.49″.

[0069] The core is covered with a 0.040″ thick mantle layer of RIM polyurethane having a plaque Shore A hardness of about 90, namely Bayflex® MP 10000 unfilled (Bayer Corp.). The mantle layer is covered with a 0.055″ thick dimpled outer cover layer of Ex 1006 and 1007 (Exxon Corp.) and Iotek 7030 (Exxon Corp.). The formulations and properties of the golf ball are shown below in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com