Patents

Literature

48results about How to "Not easy to gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

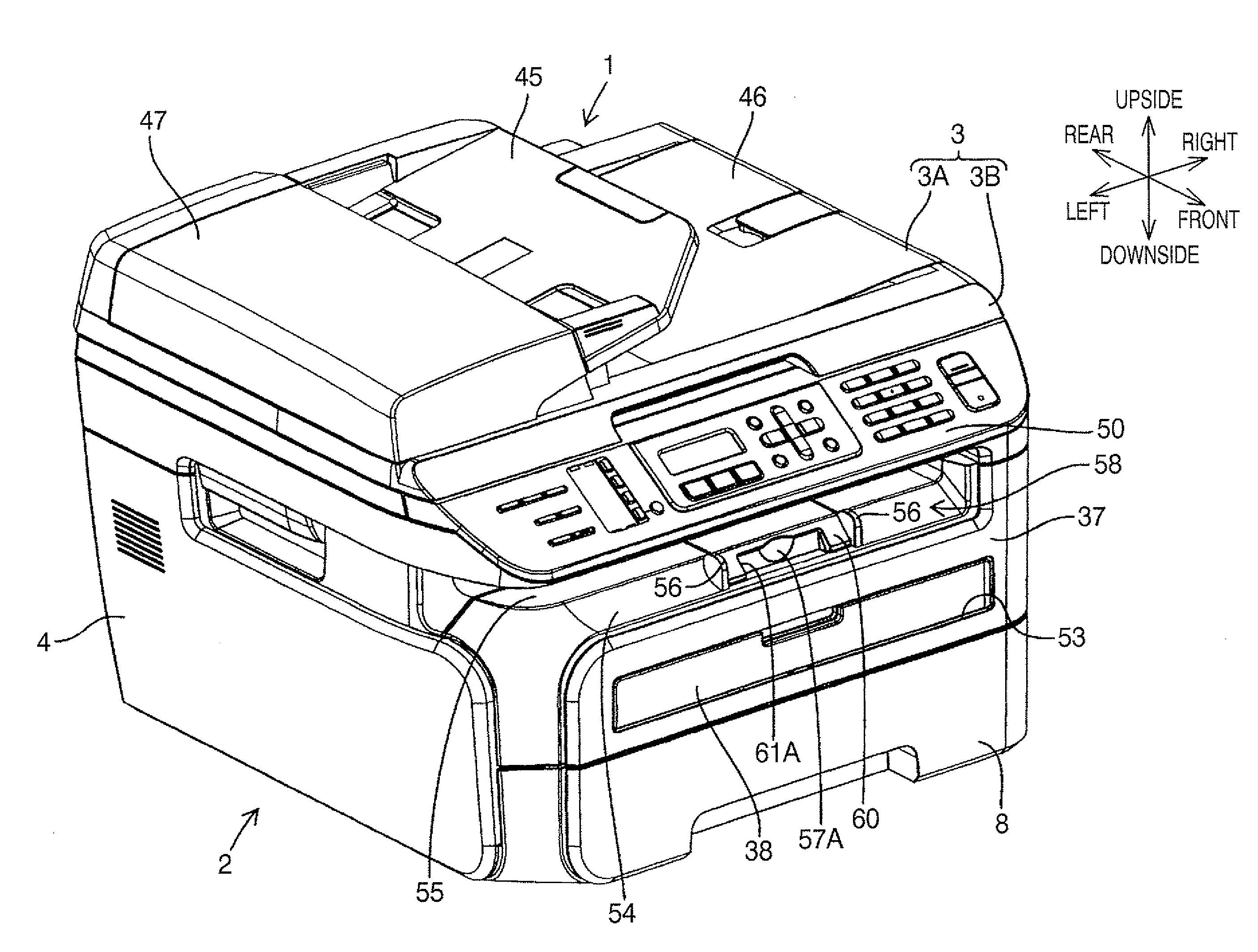

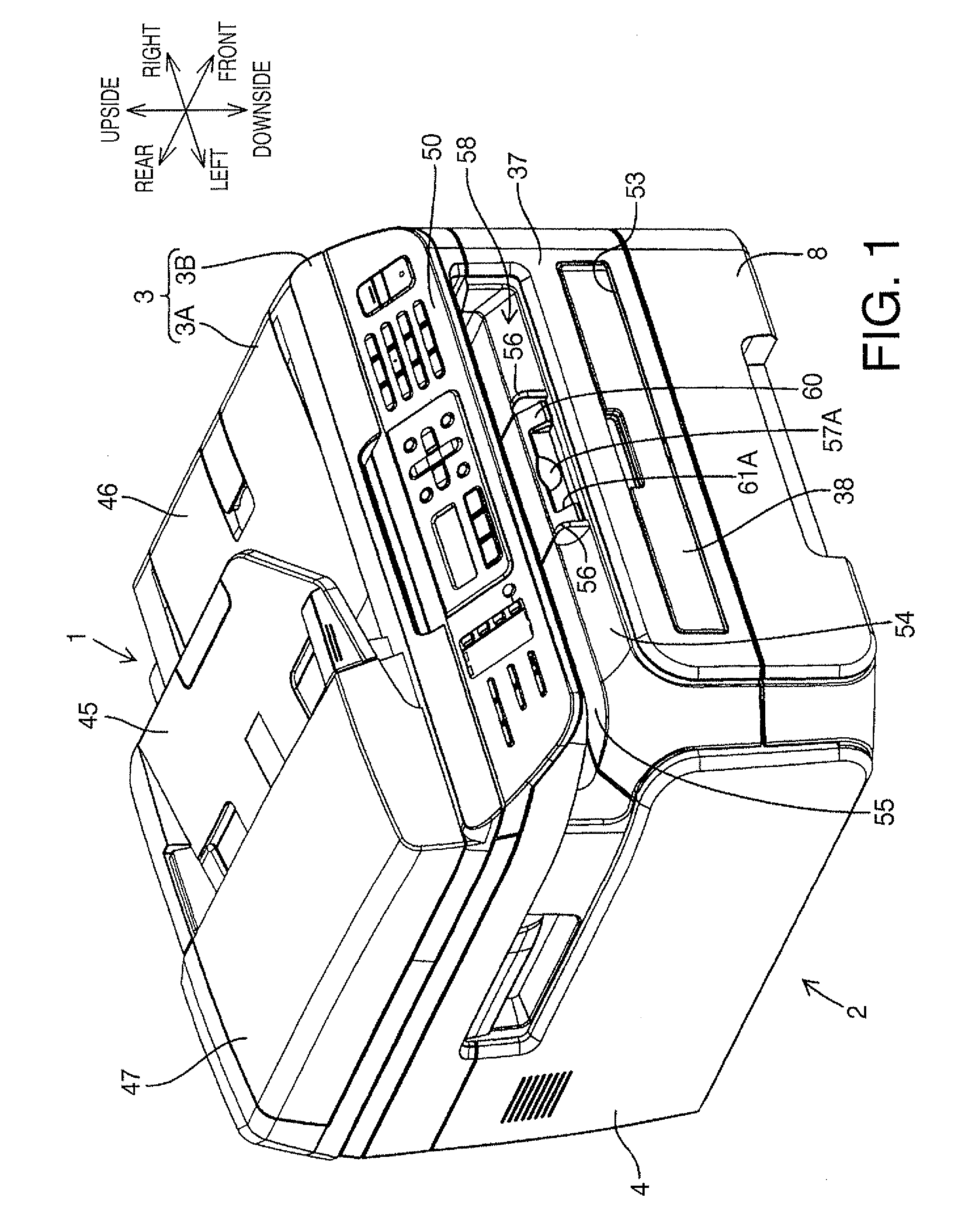

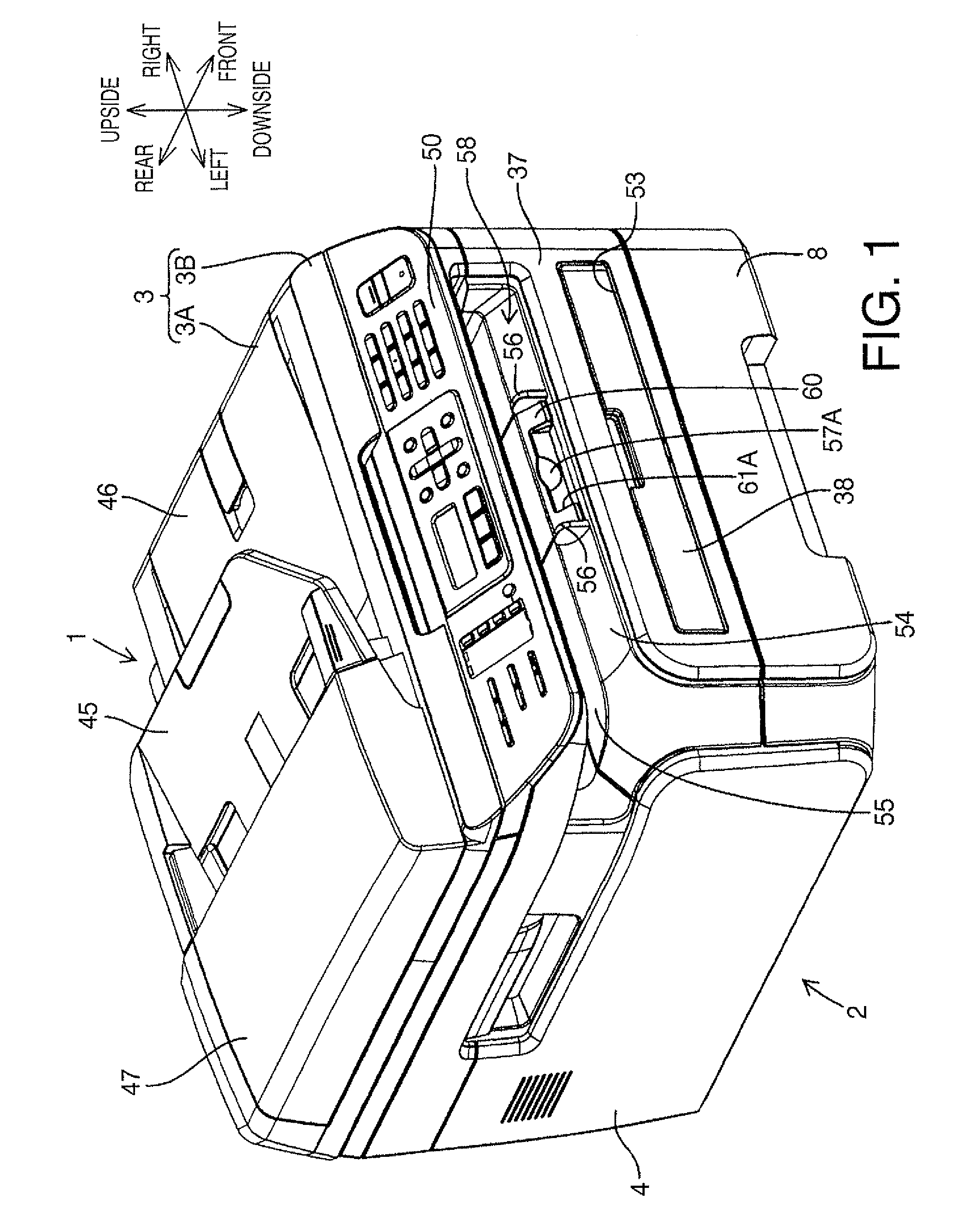

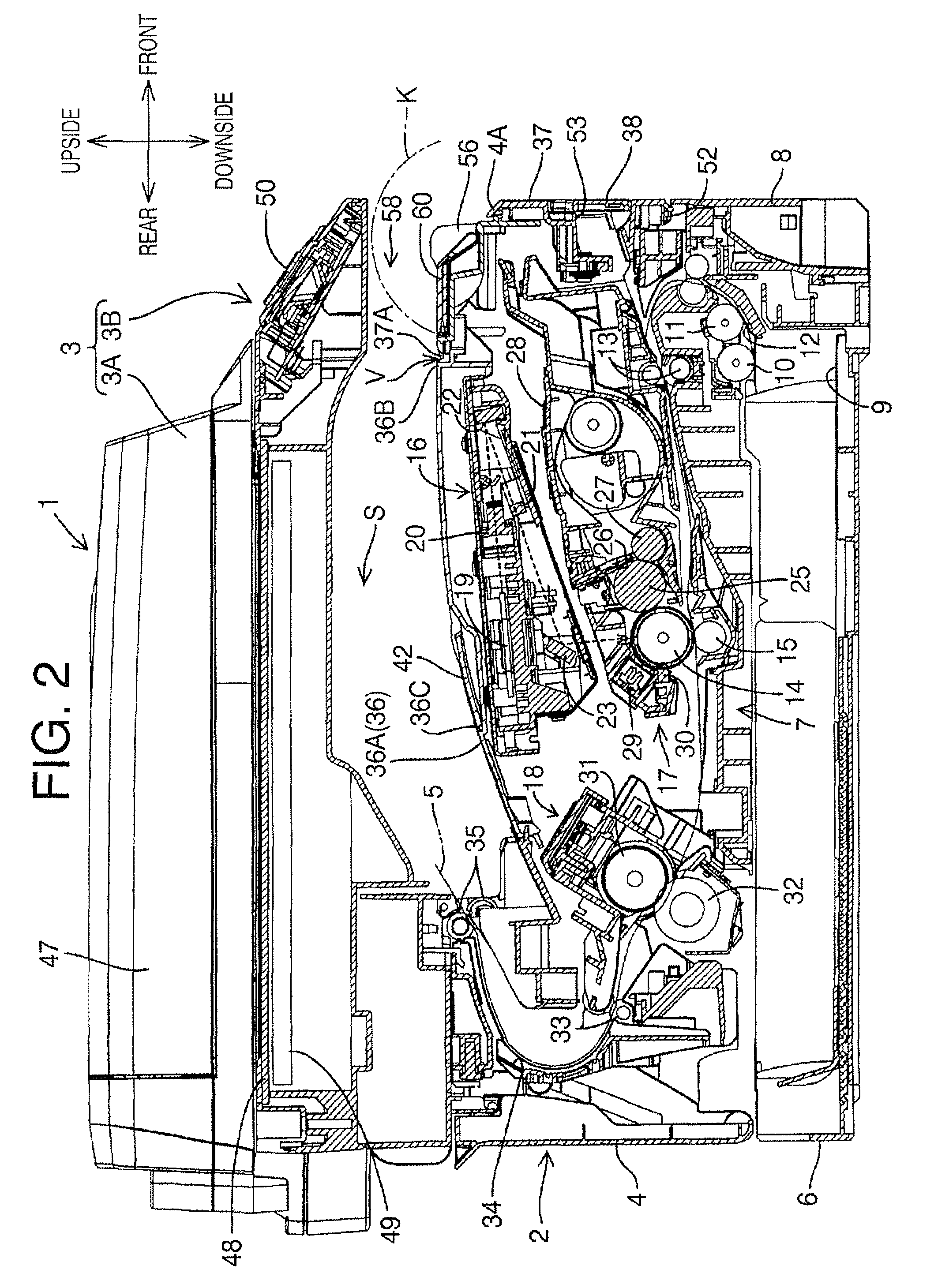

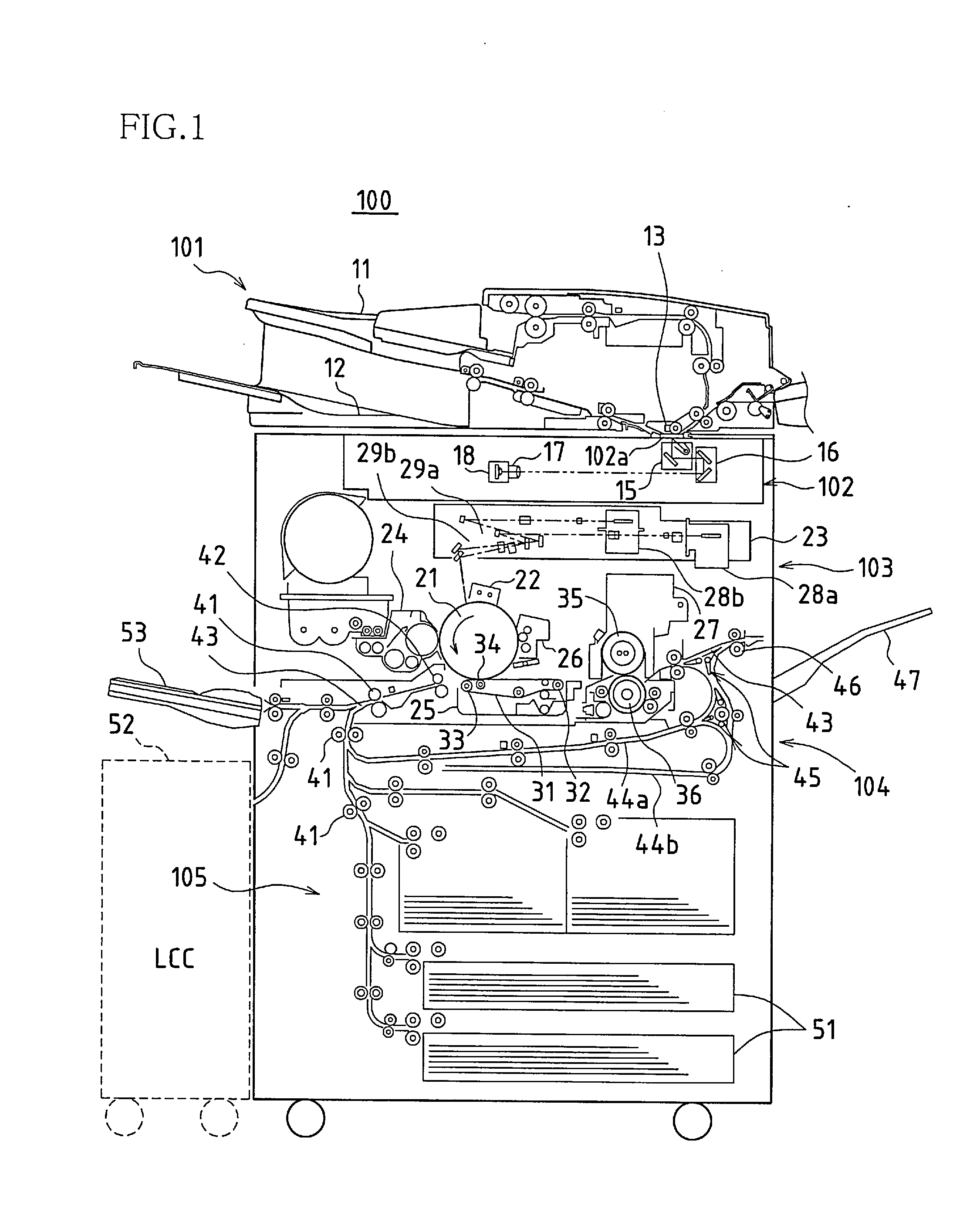

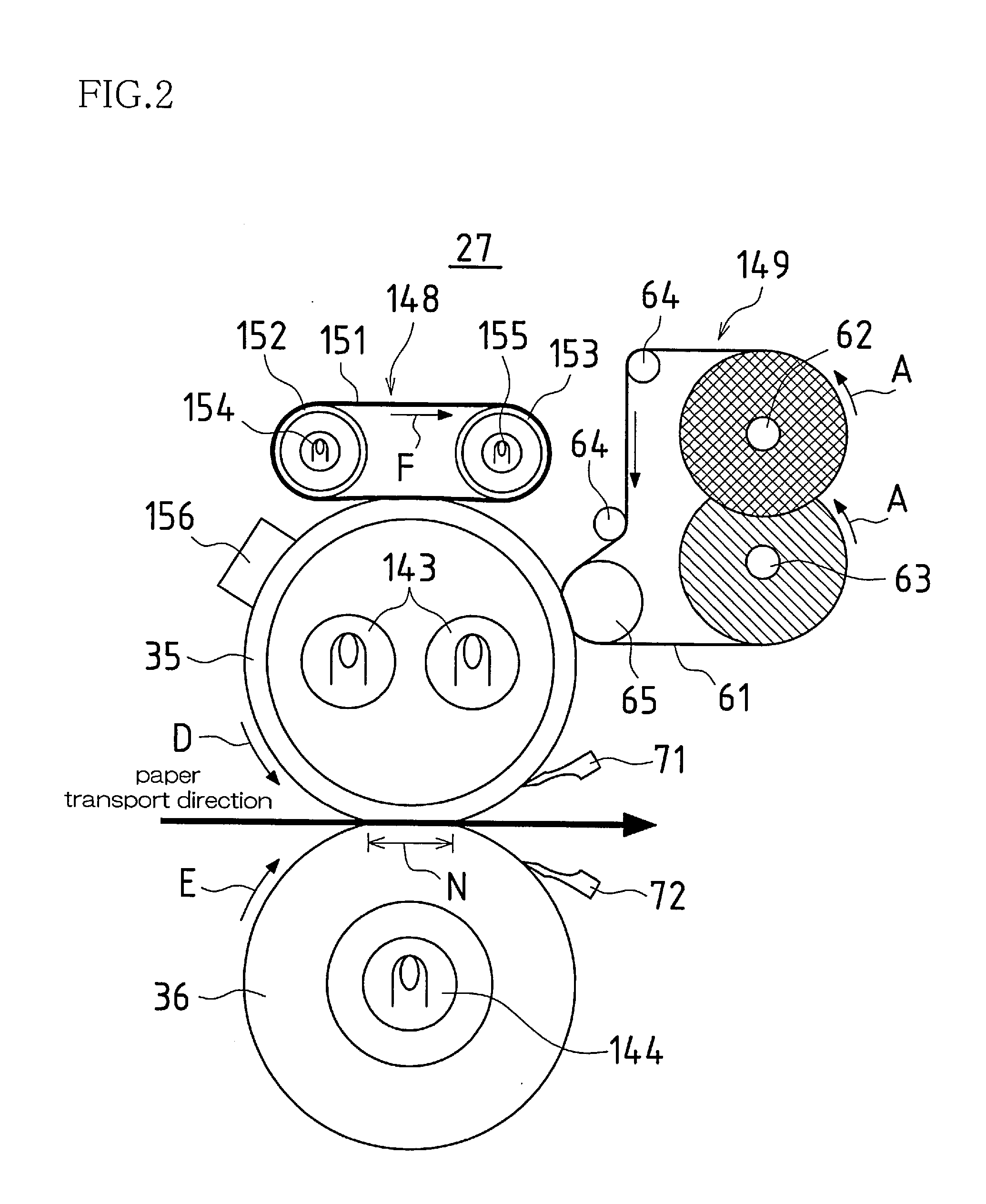

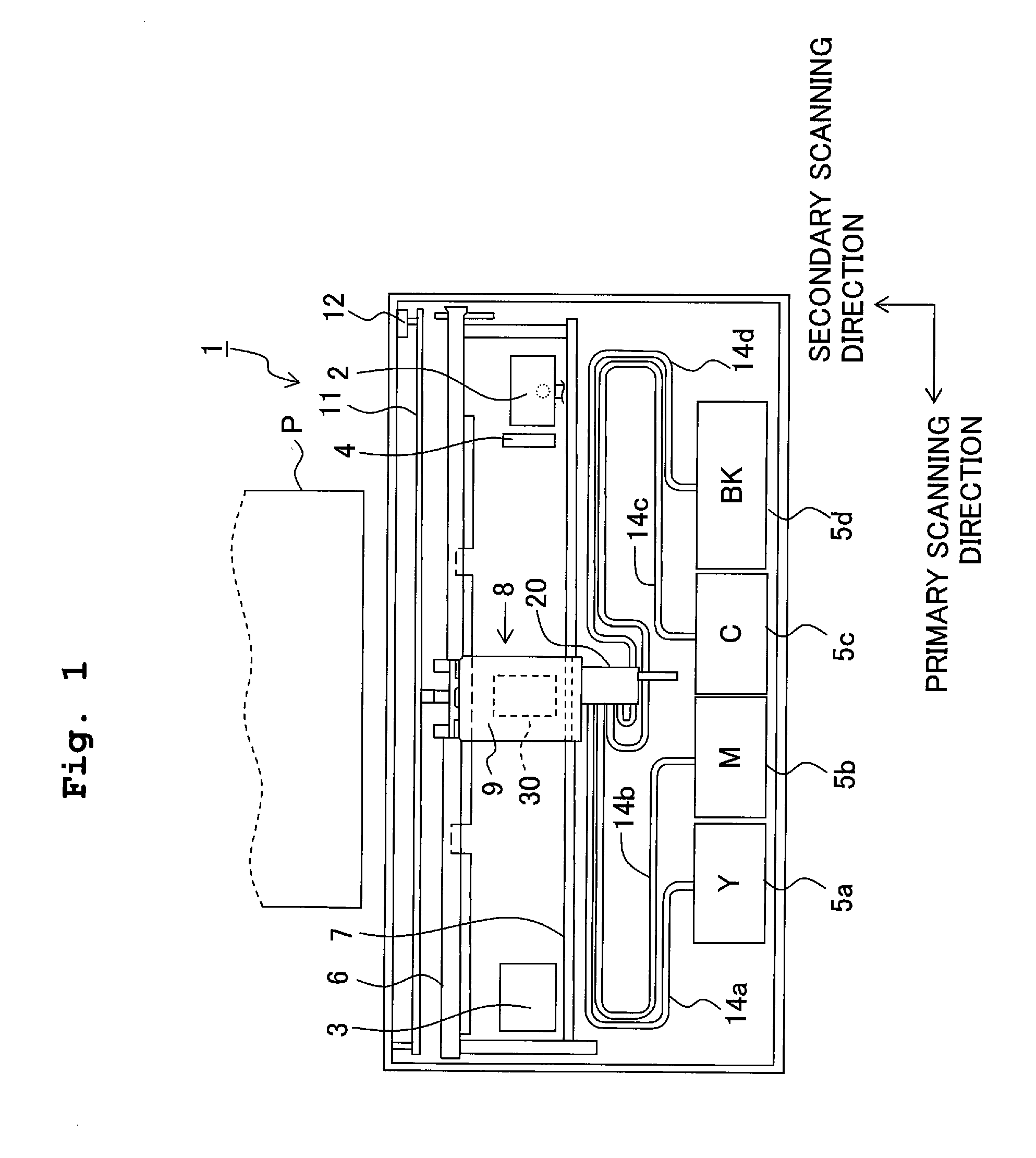

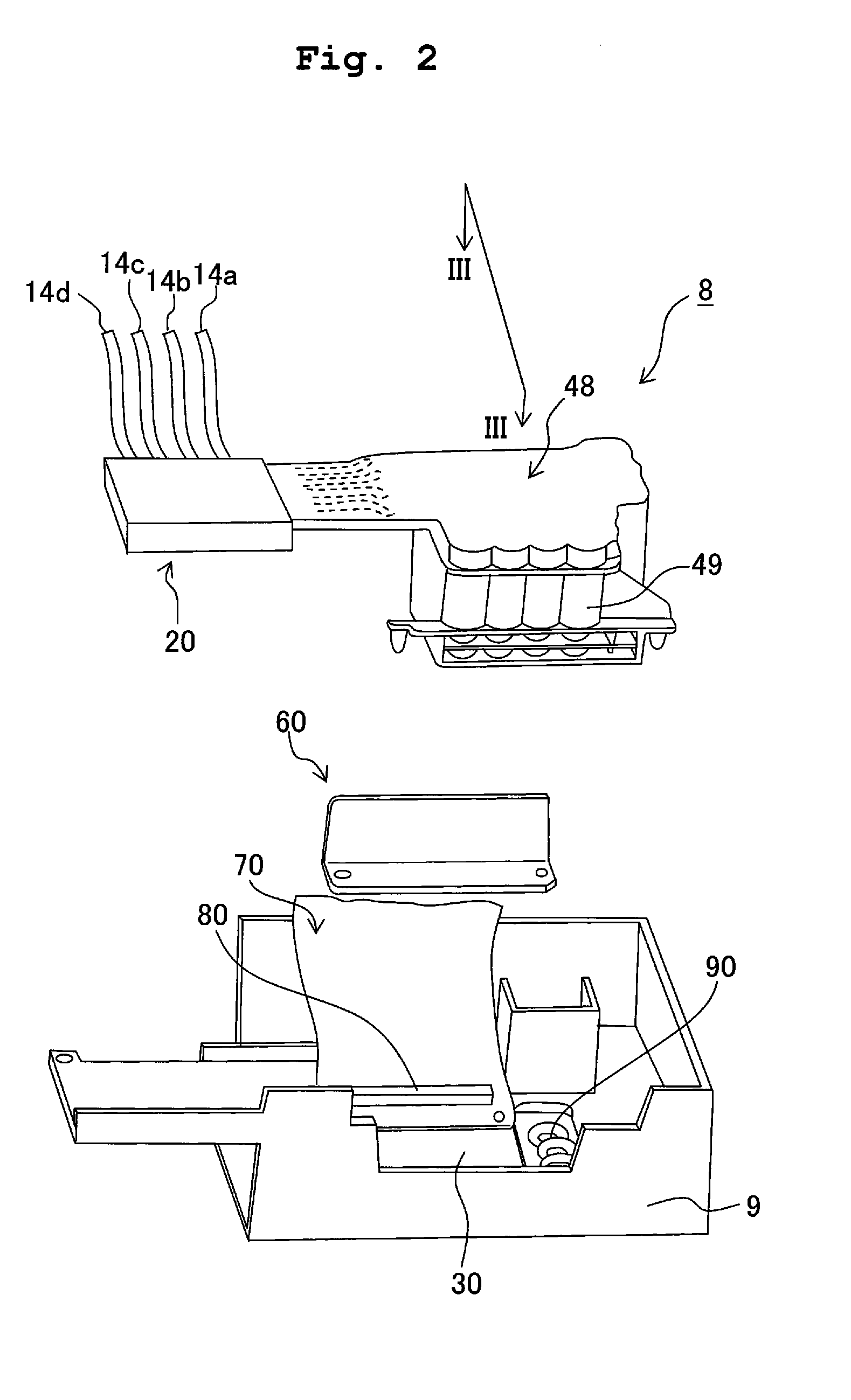

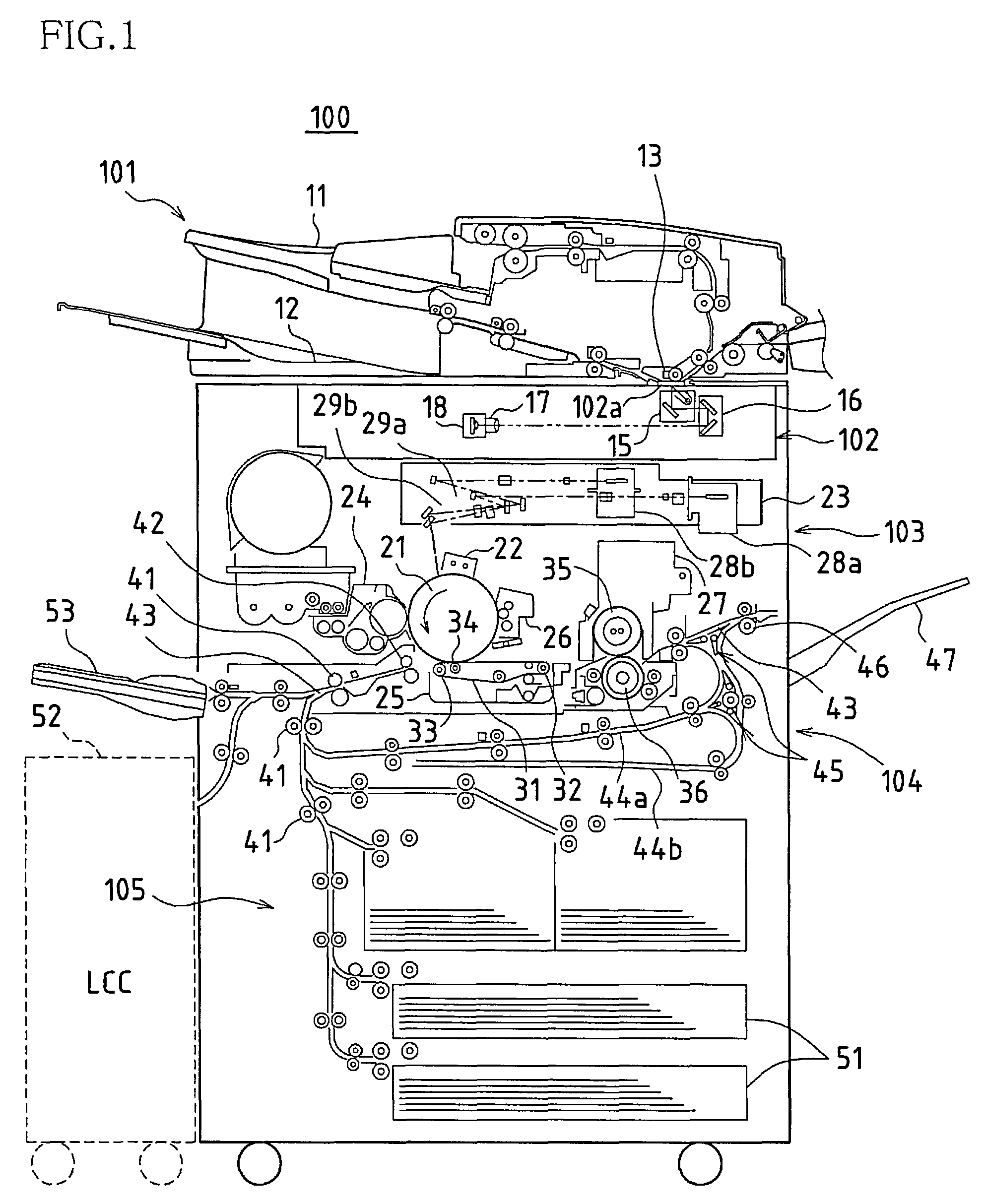

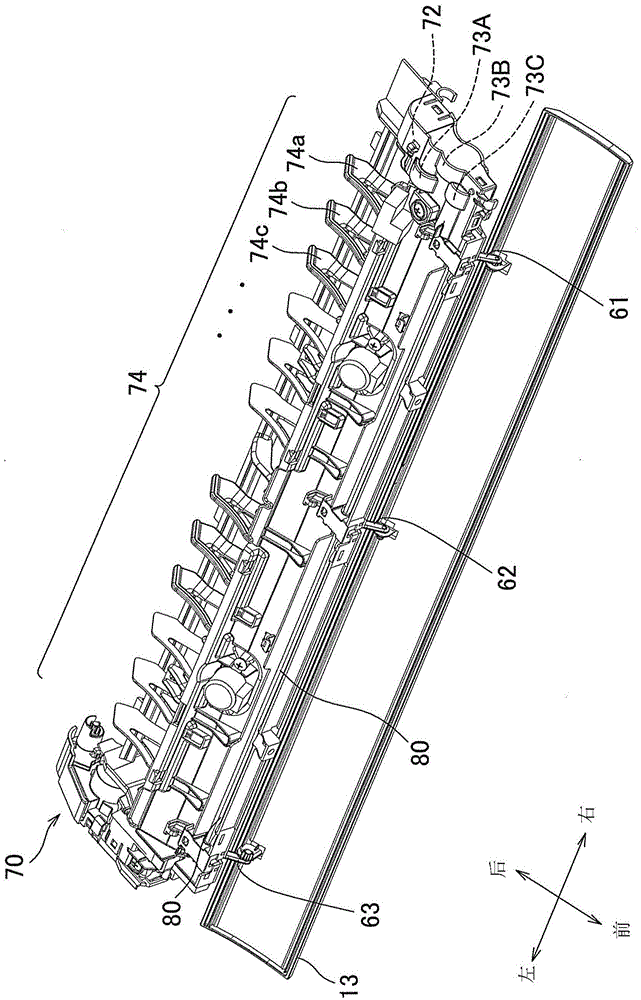

Image forming device

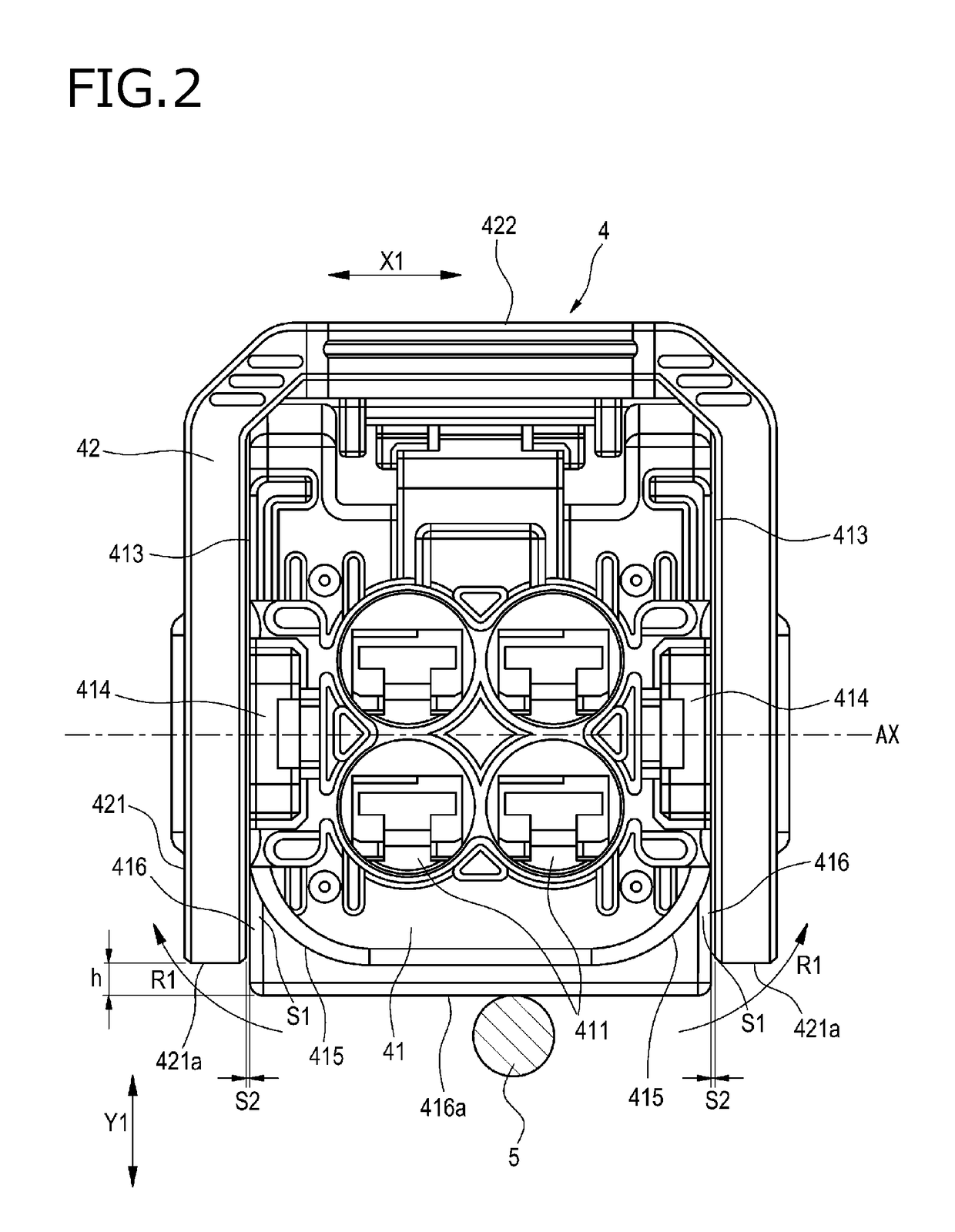

ActiveUS20090121414A1Smooth dischargeNot easy to gapElectrographic process apparatusPile receiversImage formationEngineering

Owner:BROTHER KOGYO KK

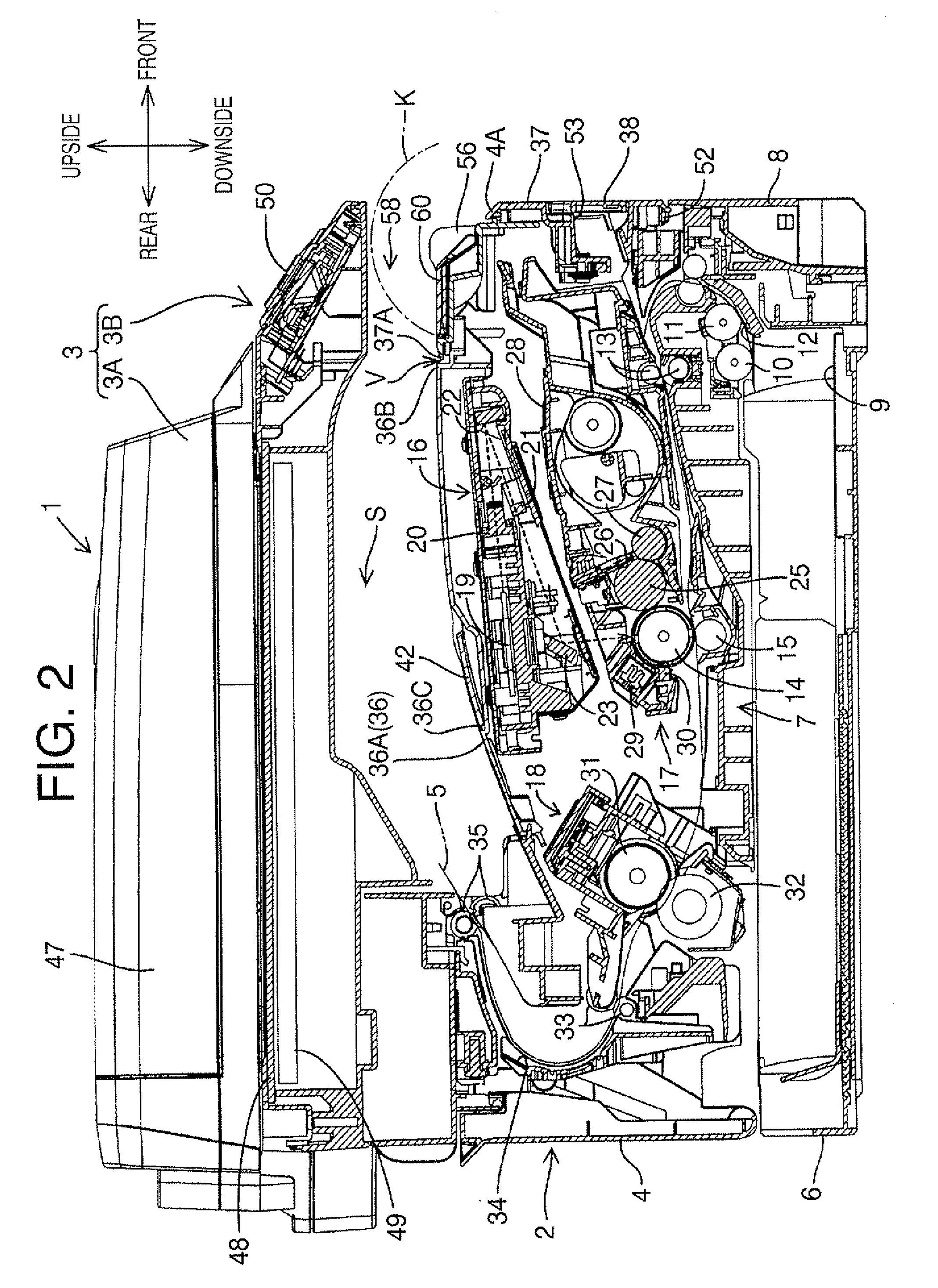

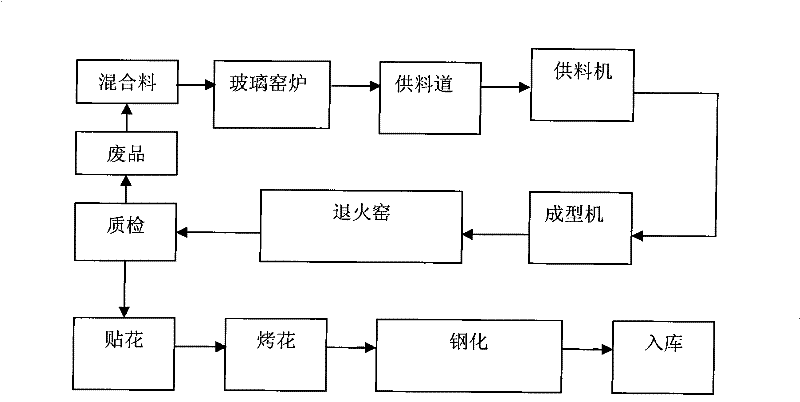

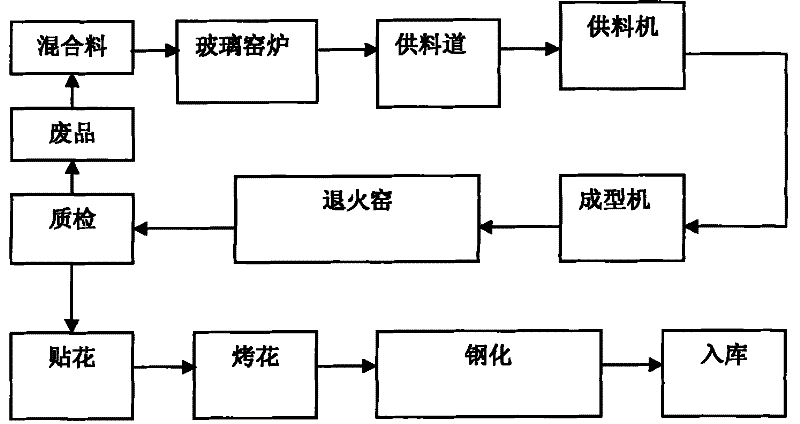

Glass ceramic and preparation method thereof

The invention relates to a glass ceramic and a preparation method thereof, comprising the following raw materials by weight parts: 75-100 weight parts of quartz sands, 10-30 weight parts of lithium feldspar, 30-60 weight parts of feldspar, 25-45 weight parts of sodium carbonate, 2-8 weight parts of sodium nitrate, 2-6 weight parts of barium carbonate, 5-15 weight parts of fluorite powders, 5-10 weight parts of borax, 10-30 weight parts of sodium fluosilicate and 10-20 weight parts of calcite; the method comprises the following steps of: mixing the raw materials and sending the mixture in a glass furnace; melting the mixture as glass melt at the temperature of 1400-1600 DEG C; sending the glass melt into a material supply machine by a material supply passage; sending the glass melt into a forming machine for forming by the material supply machine; sending the formed product into an annealing furnace for annealing; subsequently inspecting the quality of the annealed product; returning the unqualified product to the raw material; and conducting the operations of applique, enamel firing and steeling to the qualified product so as to prepare the finished products. Compared with the prior art, the method has the advantages of low expansion heat-resistance performance, high hardness, being not easy to be scraped or cracked, environmental protection and the like.

Owner:JINGDEZHEN COKING IND GRP CO LTD

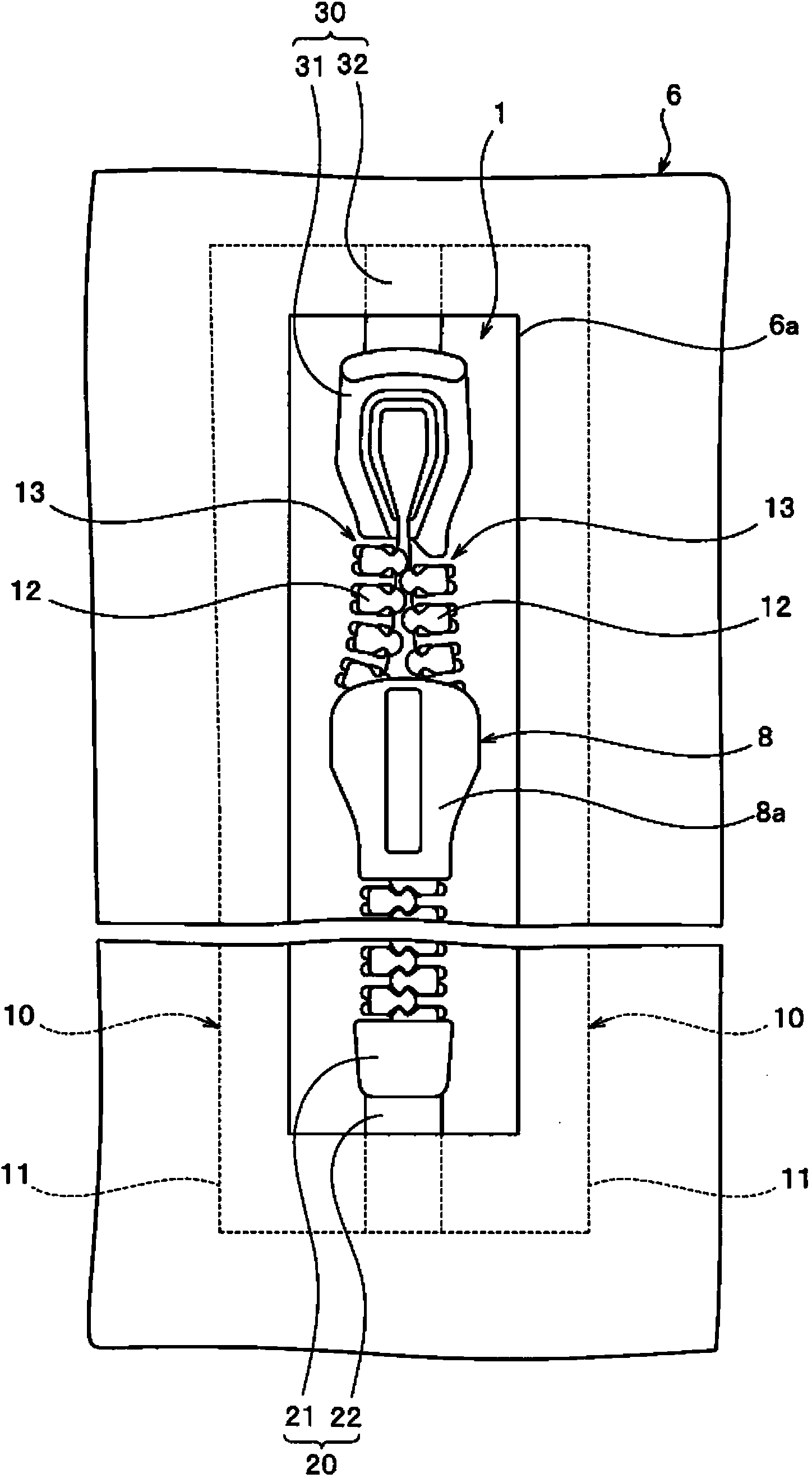

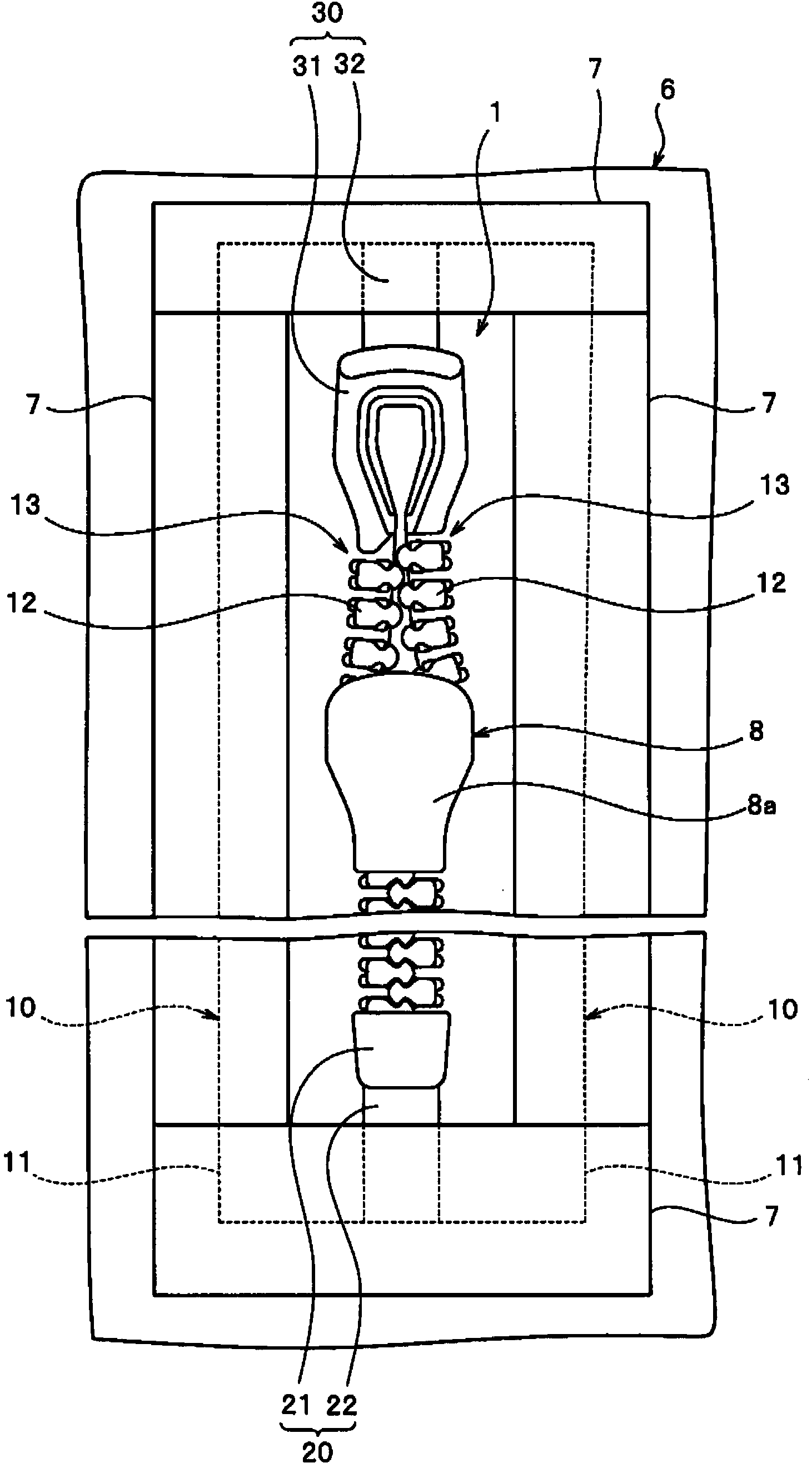

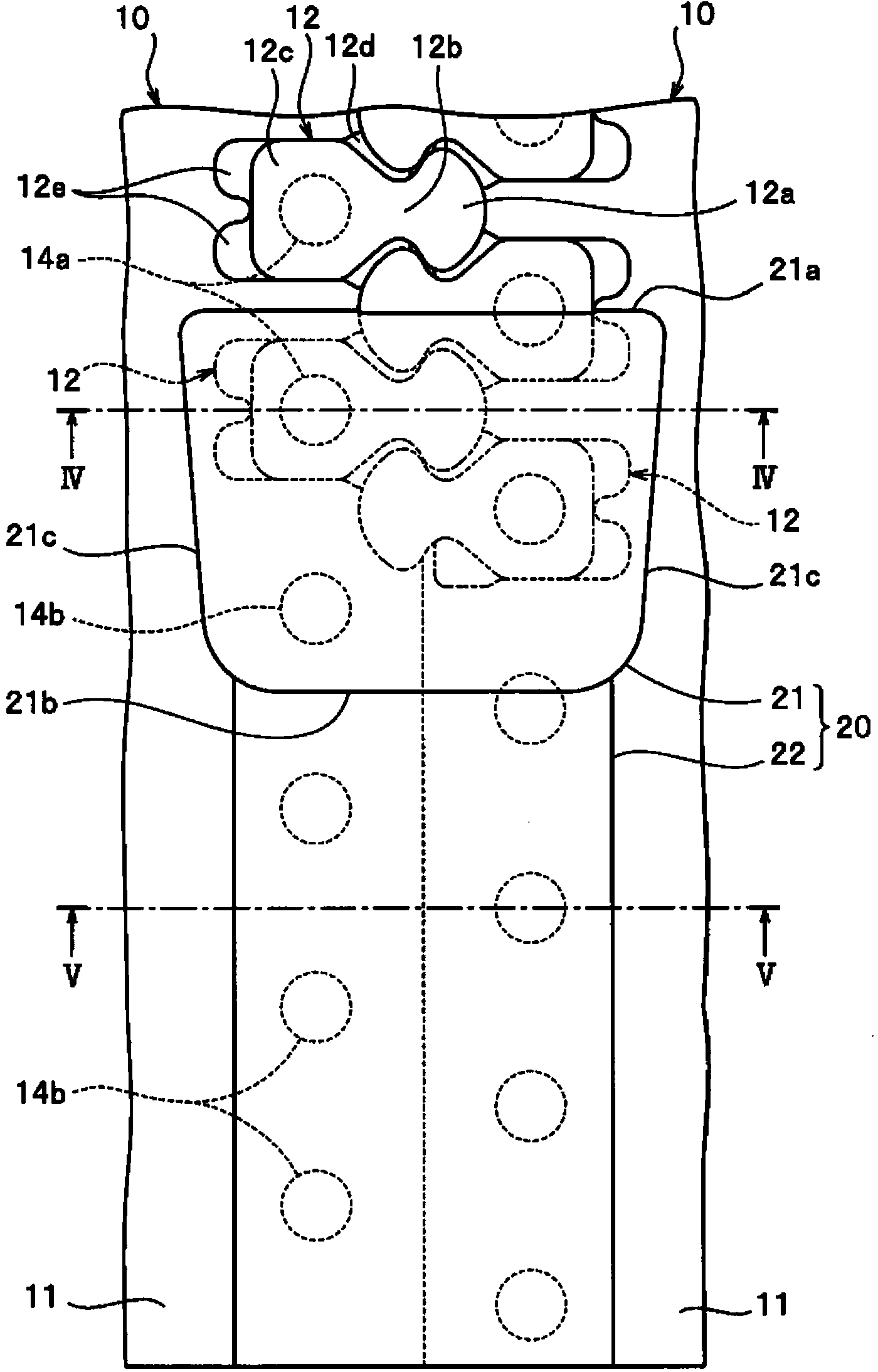

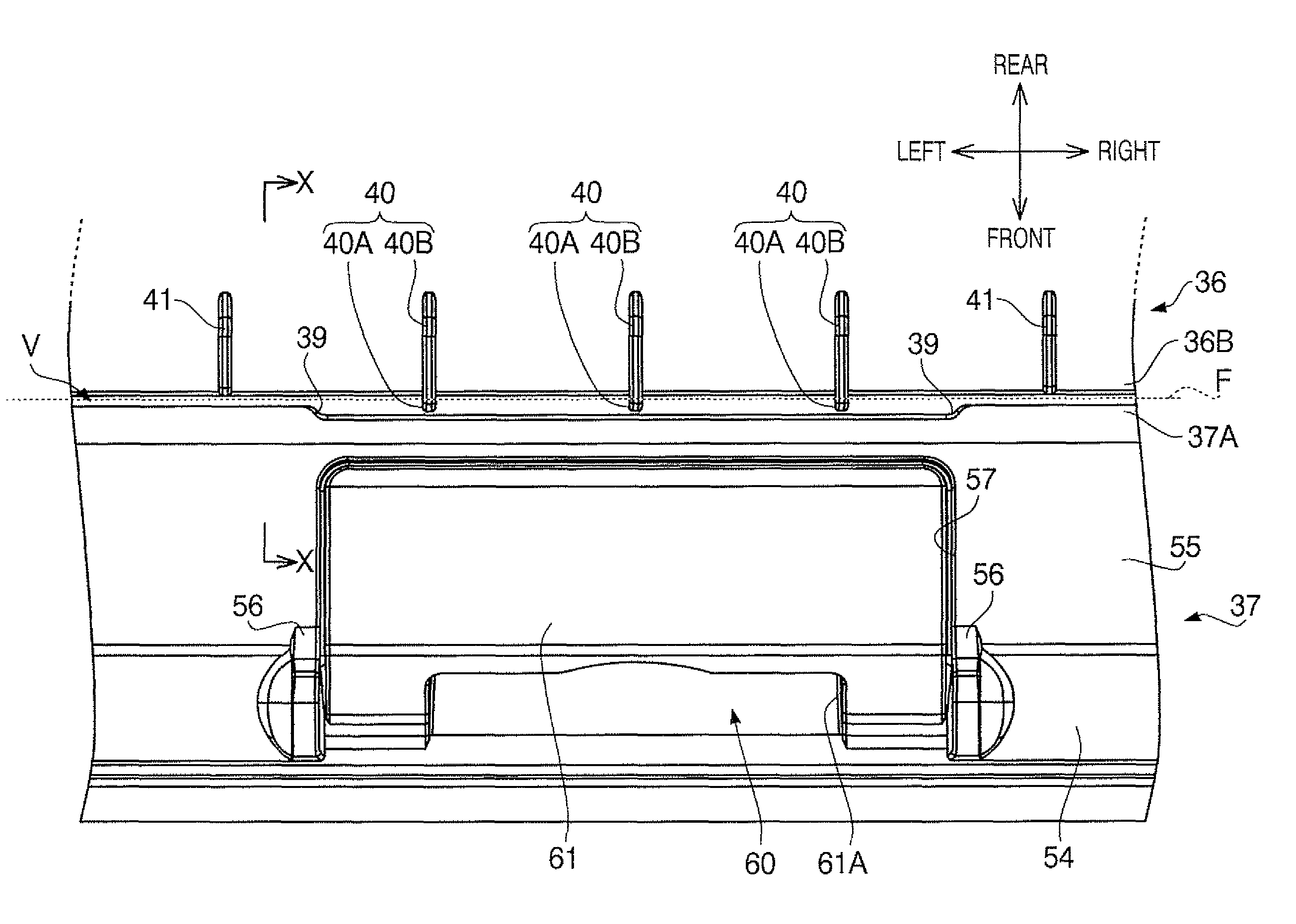

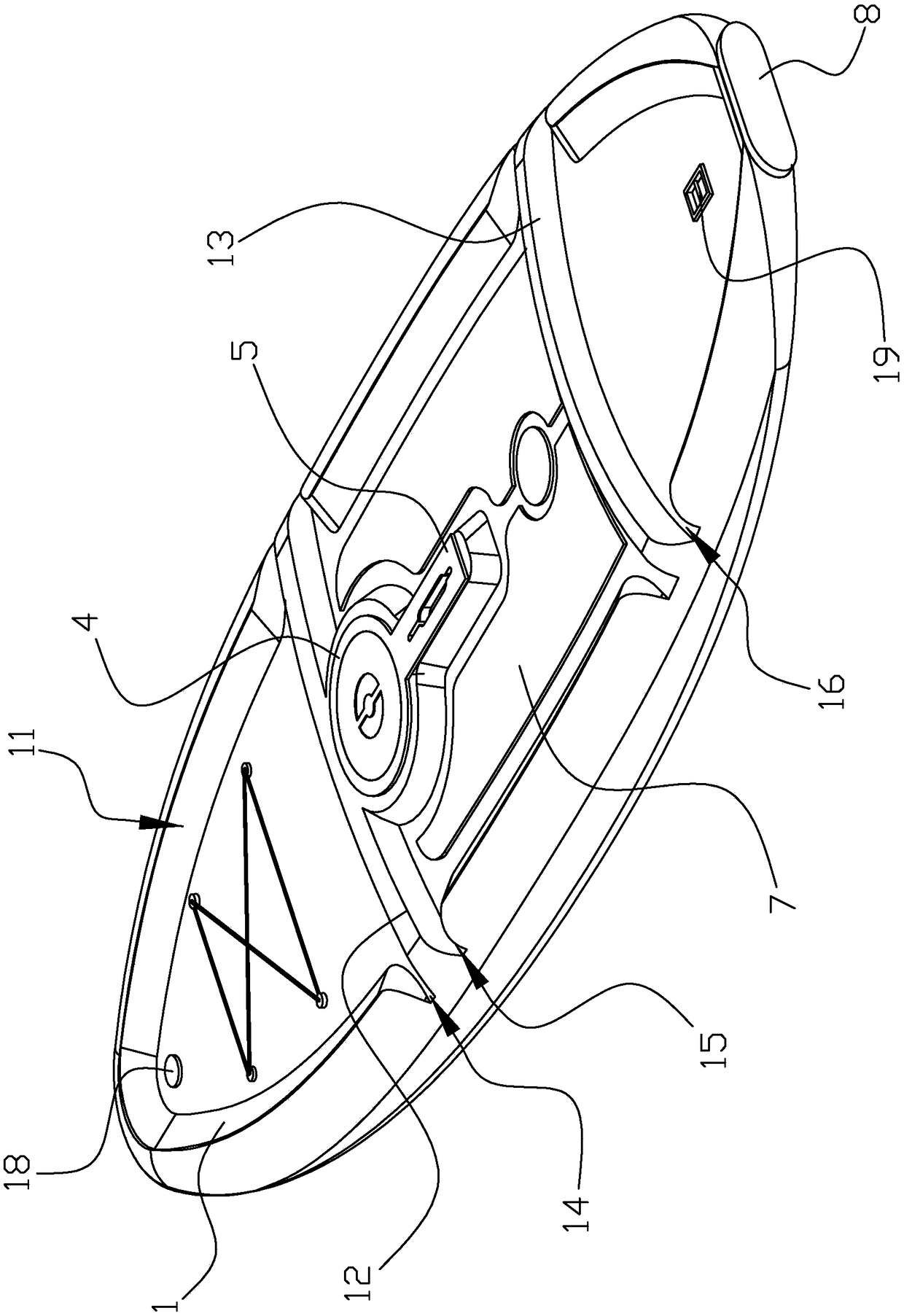

Waterproof slide fastener

ActiveCN104053378ASimplify the manufacturing processPrevent infiltrationSlide fastenersPull forceEngineering

This waterproof slide fastener (1, 2, 3, 4) is configured so that first and second through-holes (14a, 14b) are formed at specific intervals in tape side edges of waterproof tapes (11), and so that first and second halves (15, 16) of fastener elements (12) are connected and integrated together through the first through-holes (14a). A stopper (20, 30, 40, 50, 60) has a body section (21, 31, 41, 51, 61) and an extension section (22, 32, 42, 52, 62) which extends from the body section (21, 31, 41, 51, 61). First and second halves (23, 24) of the stopper (20, 30, 40, 50, 60) are disposed so as to straddle the pair of waterproof tapes (11) and are connected and integrated together through the second through-holes (14b). As a result of this configuration, the manufacturing step of the waterproof slide fastener (1, 2, 3, 4) is simplified, and water is prevented from entering even if the slide fastener (1, 2, 3, 4) is subjected to a lateral pulling force.

Owner:YKK CORP

Image forming device

InactiveUS7971873B2Smooth dischargeNot easy to gapElectrographic process apparatusPile receiversImage formationEngineering

Owner:BROTHER KOGYO KK

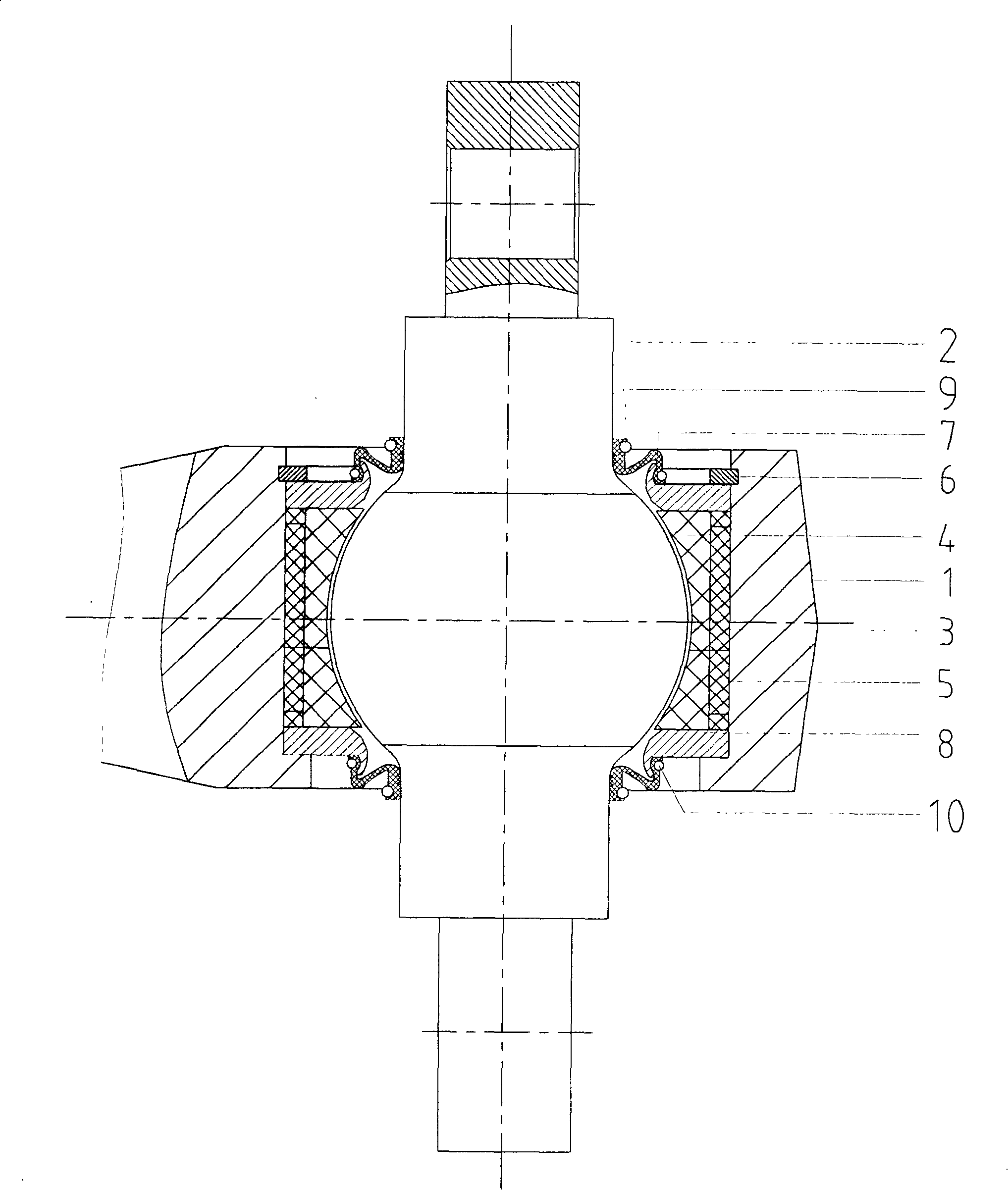

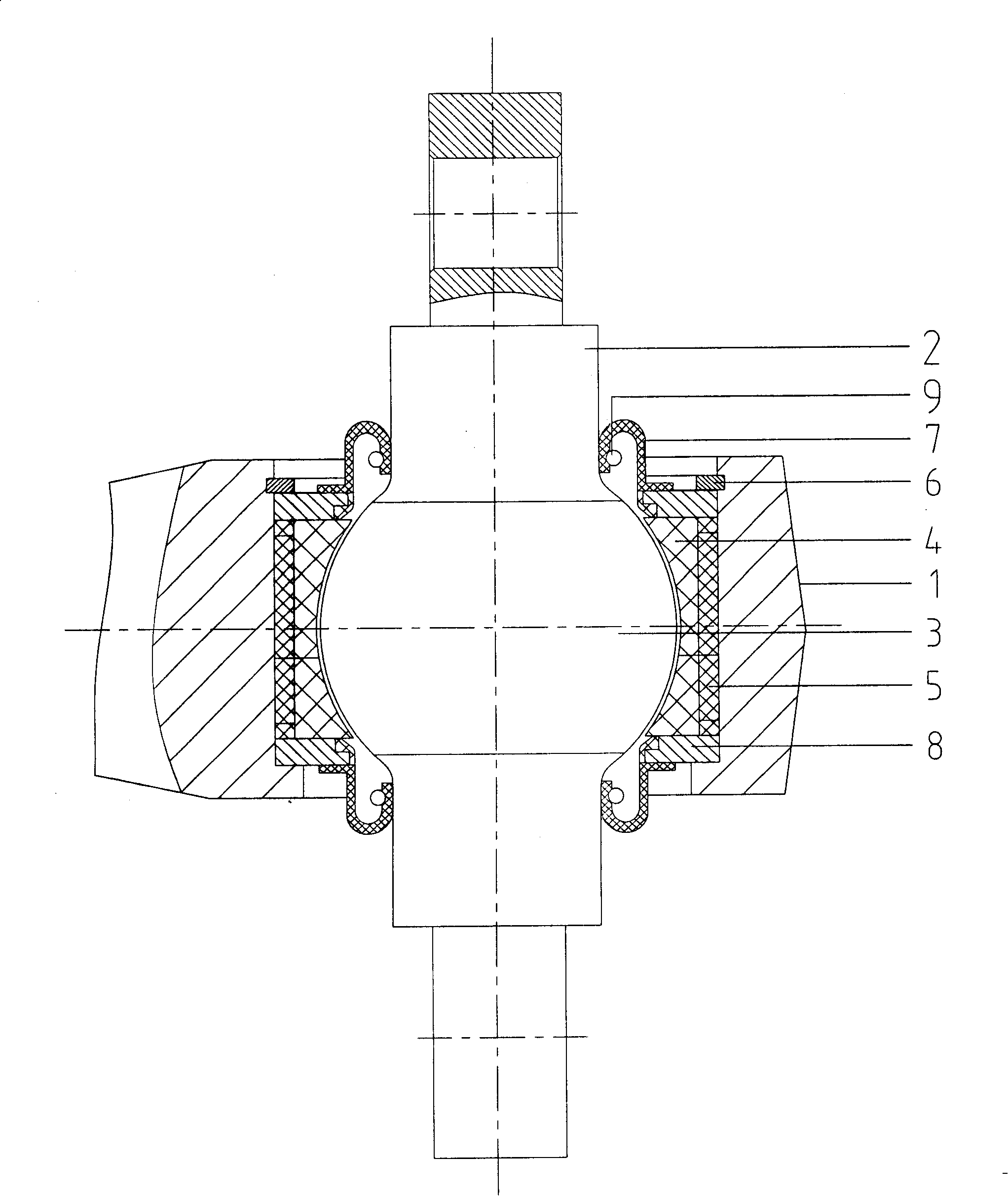

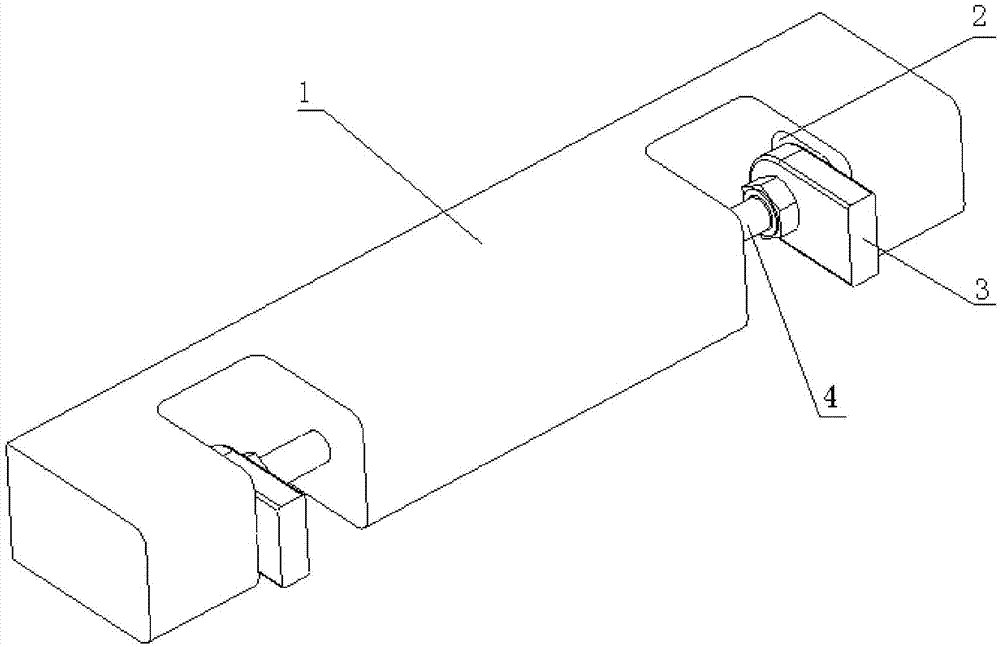

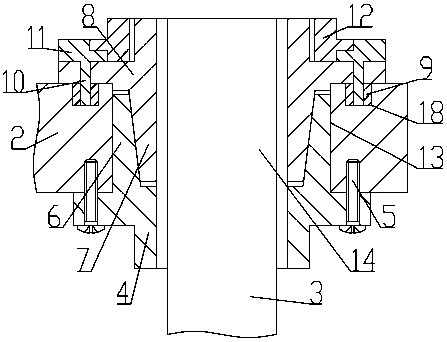

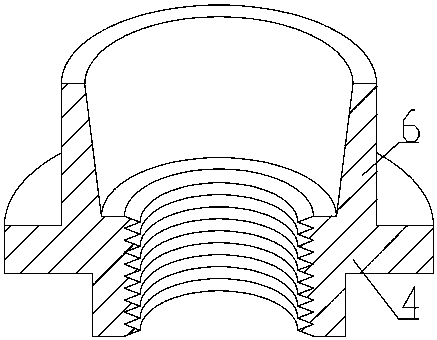

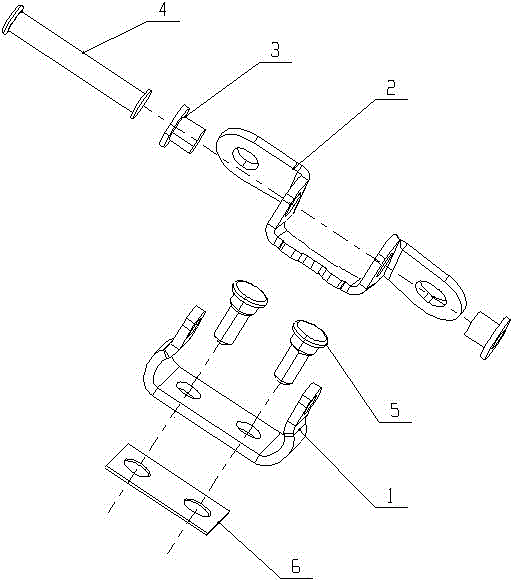

Automobile torque rod assembly

InactiveCN101240811ANot easy to gapImprove sealingPivotal connectionsPivoted suspension armsEngineering

The present invention discloses a vehicle torque rod assembly, which includes body of rod, lever head (1) of rod end with pin (2), pin (2) with spherical surface body (3), ball bowl (4) matching with spherical surface body is placed between spherical surface body (3) and lever head (1), outer of ball bowl (4) with resilient support body (5), end of spherical surface body (3) with elastic collar (6), dirt guard (7) and washer (8), and the special part is that a elastic ring (9) clips inner edge of dirt guard (7) on pin (2). Vehicle torque rod assembly of the present invention whose inner edge of cover is not easy to form gap with pin has good advantage of sealing property.

Owner:王加宏

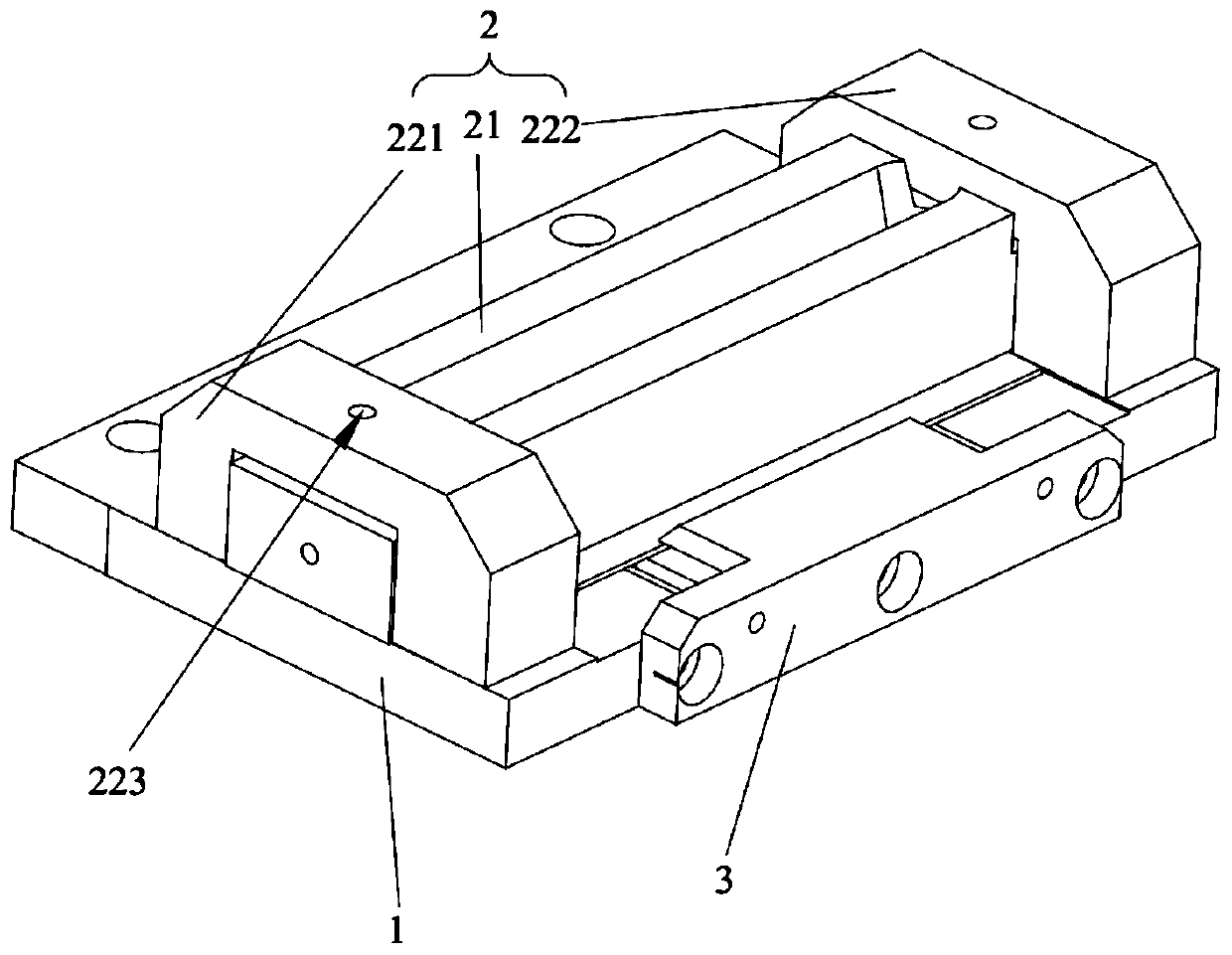

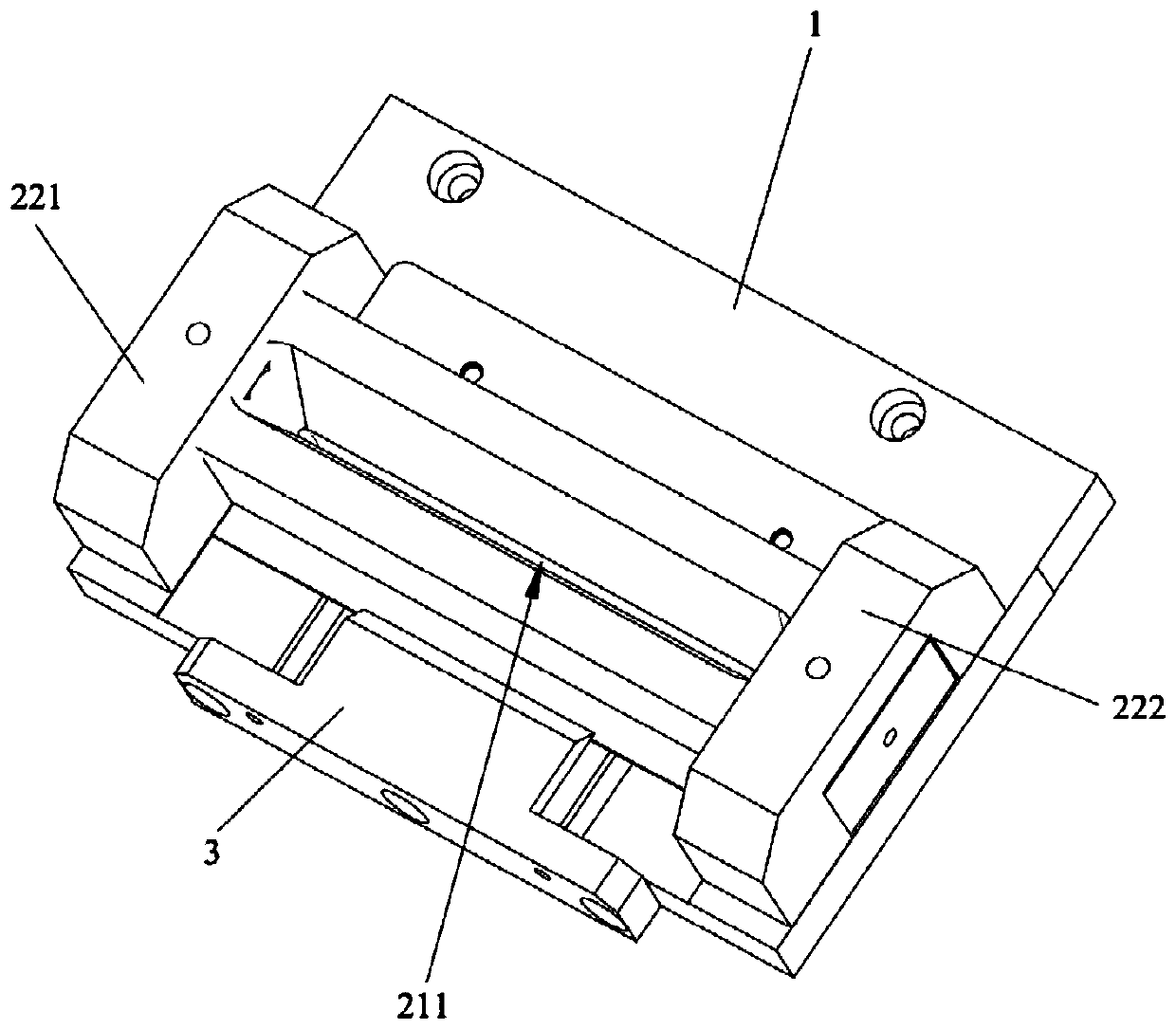

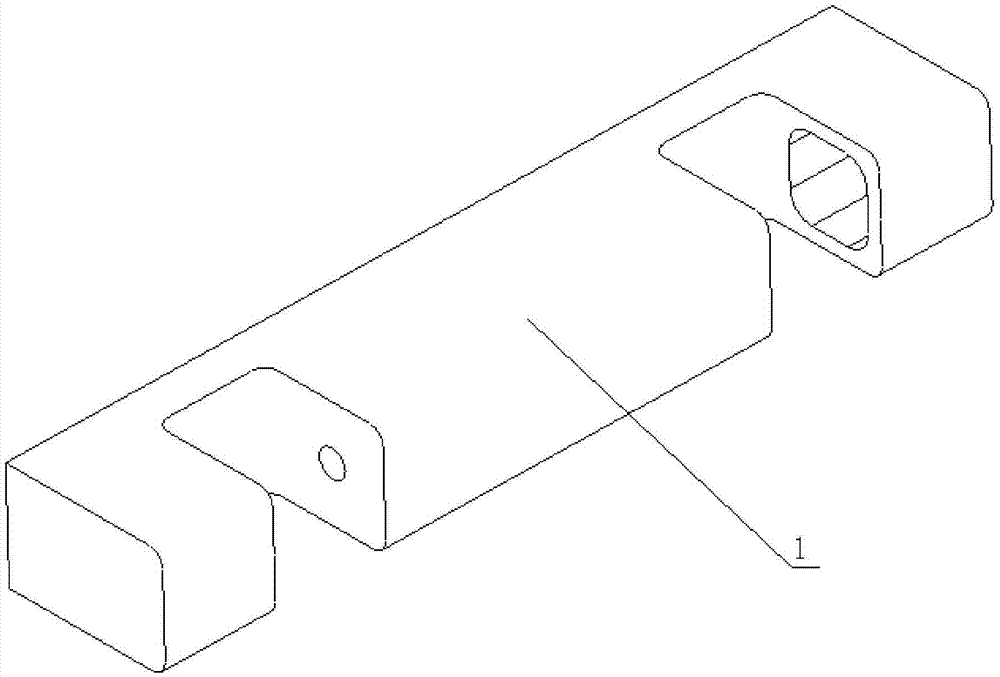

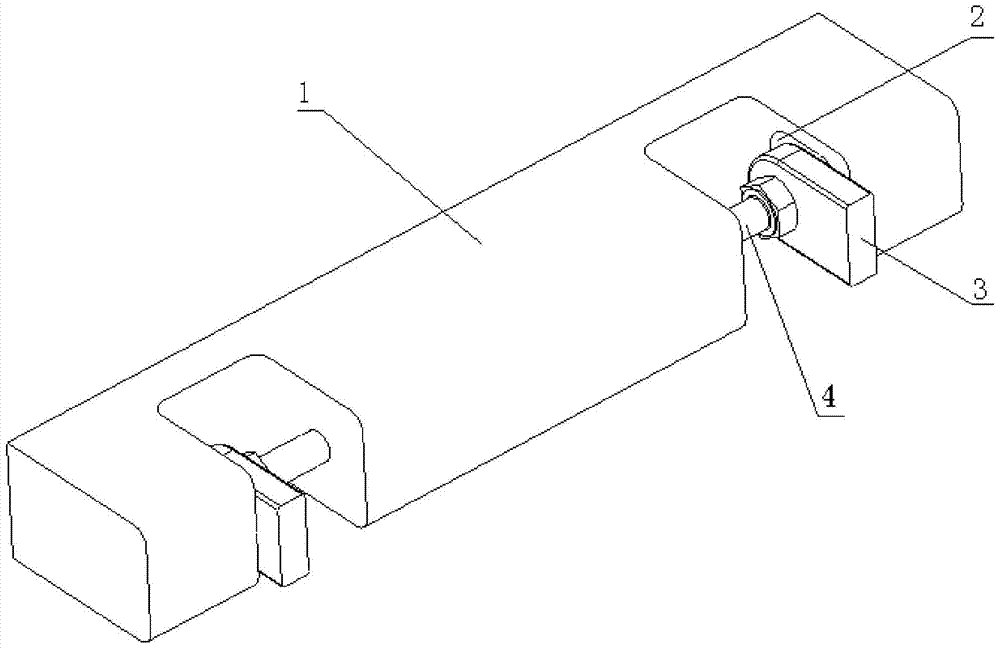

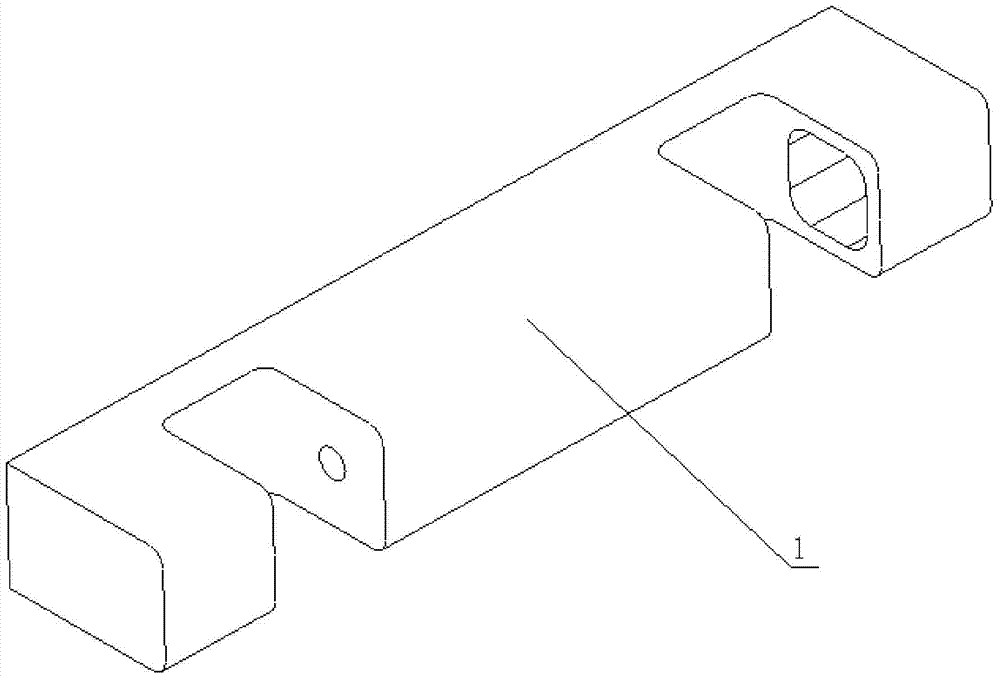

Laser welding clamp and welding method

InactiveCN110091087AQuality assuranceNo gapWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser

The invention relates to the technical field of laser welding, and discloses a laser welding clamp and a welding method. The laser welding clamp comprises a bottom plate, a pressing unit and a clamping unit, the pressing unit is used for pressing a workpiece on the bottom plate, the pressing unit comprises a pressing block, the pressing block is configured to be capable of moving relative to the bottom plate, so as to compress or get away from the workpiece, a welding groove is formed in the pressing block and is used for welding a joint on the workpiece, and the clamping unit comprises a first clamping part and a second clamping part which are arranged on the bottom plate and used for clamping the workpiece in a plane parallel to the bottom plate. By arranging the bottom plate and the pressing unit, the pressing unit is used for pressing the workpiece on the bottom plate so as to limit the position of the workpiece in the direction perpendicular to the bottom plate; the clamping unitis arranged, the clamping unit is used for clamping the workpiece in a plane parallel to the bottom plate so as to limit the position of the workpiece in the direction parallel to the bottom plate, then the joint of the workpiece is completely attached, no gap exists, and the quality of the welded workpiece is ensured.

Owner:深圳力星激光智能装备有限公司

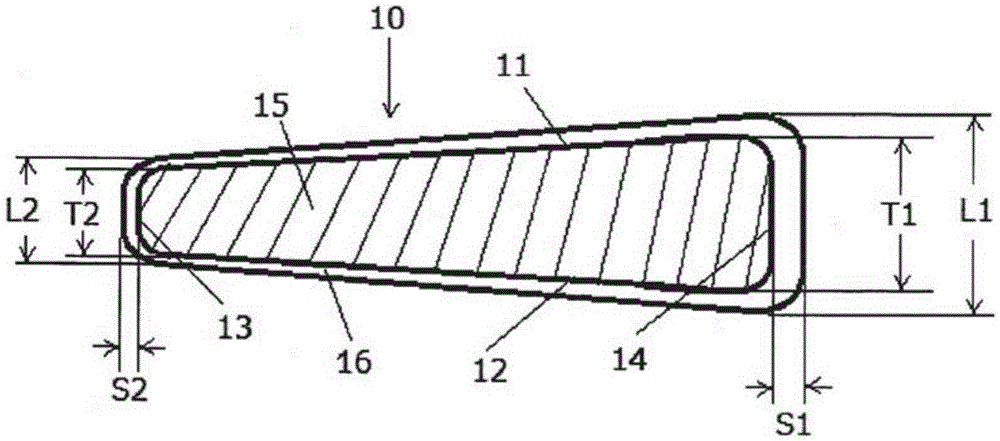

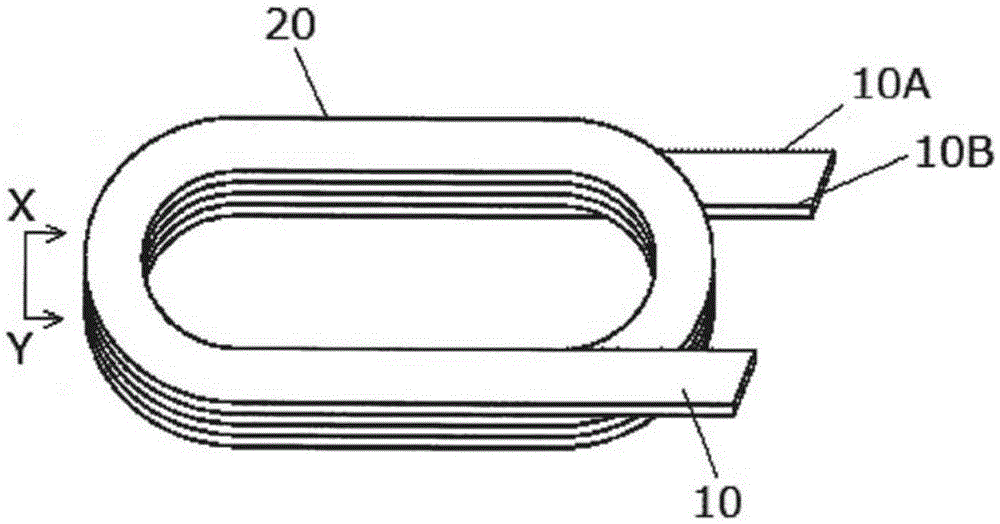

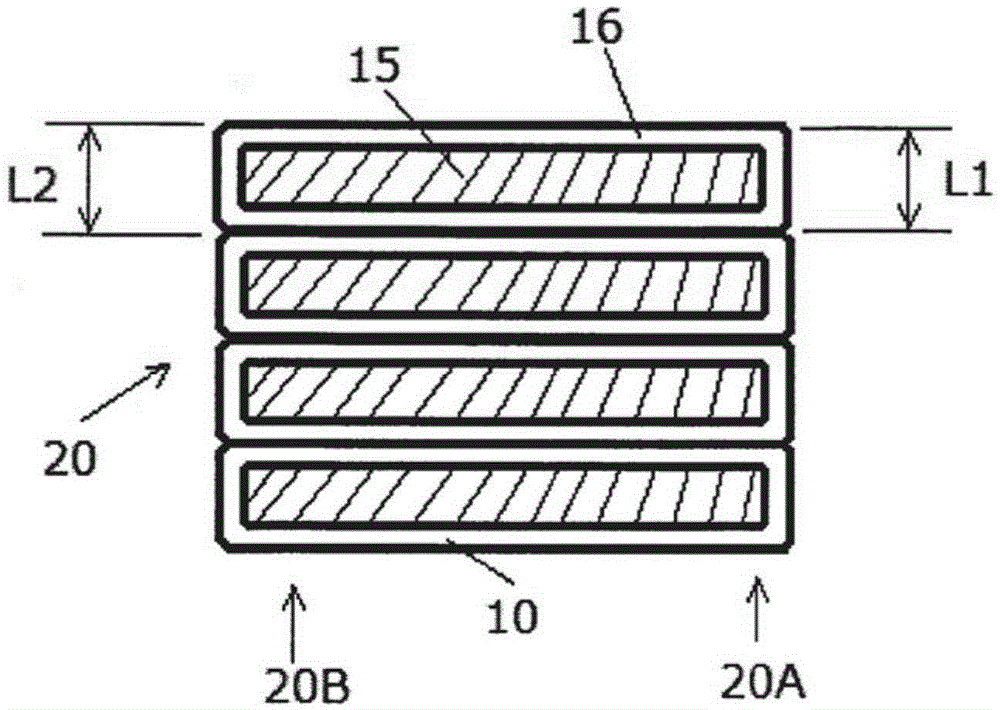

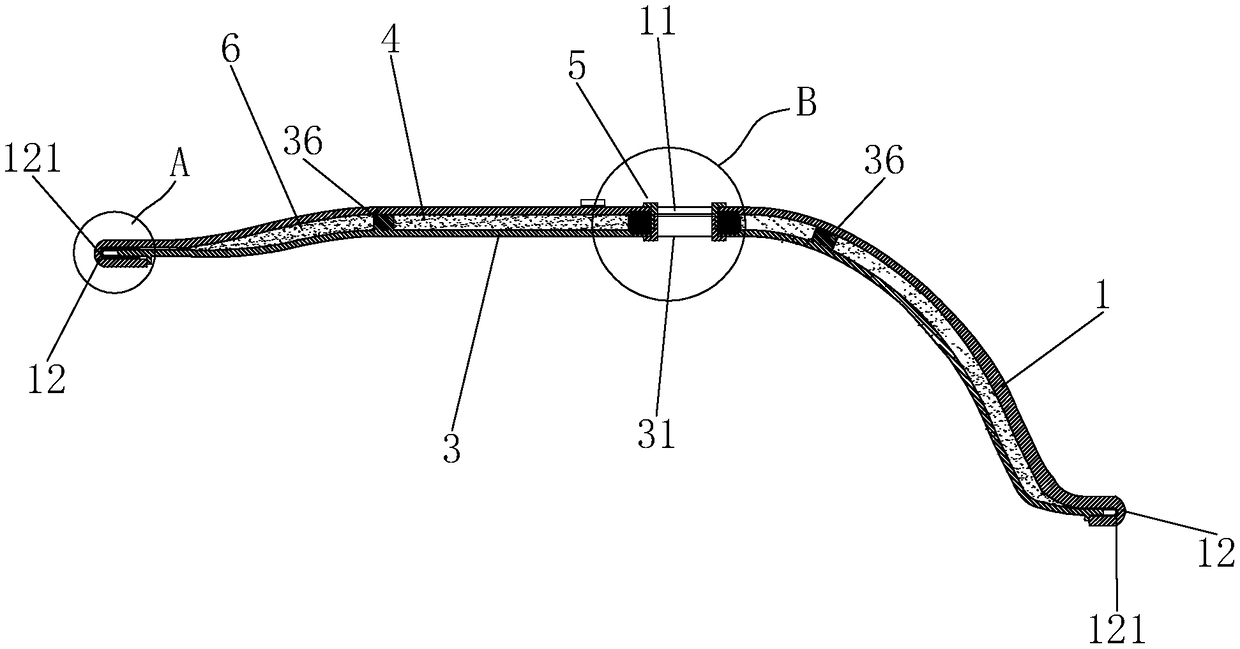

Flat coil flat insulated electric wire and manufacturing method for same

ActiveCN105551583ANot easy to gapReduced insulation performanceTransformers/inductances coils/windings/connectionsInsulated cablesEngineeringElectric wire

The invention provides a flat coil flat insulated electric wire and a manufacturing method for the same. The flat insulated electric wire is characterized in that the wall thickness of a conductive wire rod on the bend external peripheral part is greater than the wall thickness of the conductive wire rod on the bend internal peripheral part; the insulated coating thickness of the bend external peripheral part is greater than the insulated coating thickness of the bend internal peripheral part; preferentially, the insulated coating thickness of the external peripheral part is more than 1.5 times of the insulated coating thickness of the internal peripheral part; and the wall thickness of the conductive wire rod and the insulated coating part of the external peripheral part is 1.2 to 1.7 times of the wall thickness of the conductive wire rod and the insulated coating part of the internal peripheral part.

Owner:MITSUBISHI MATERIALS CORP

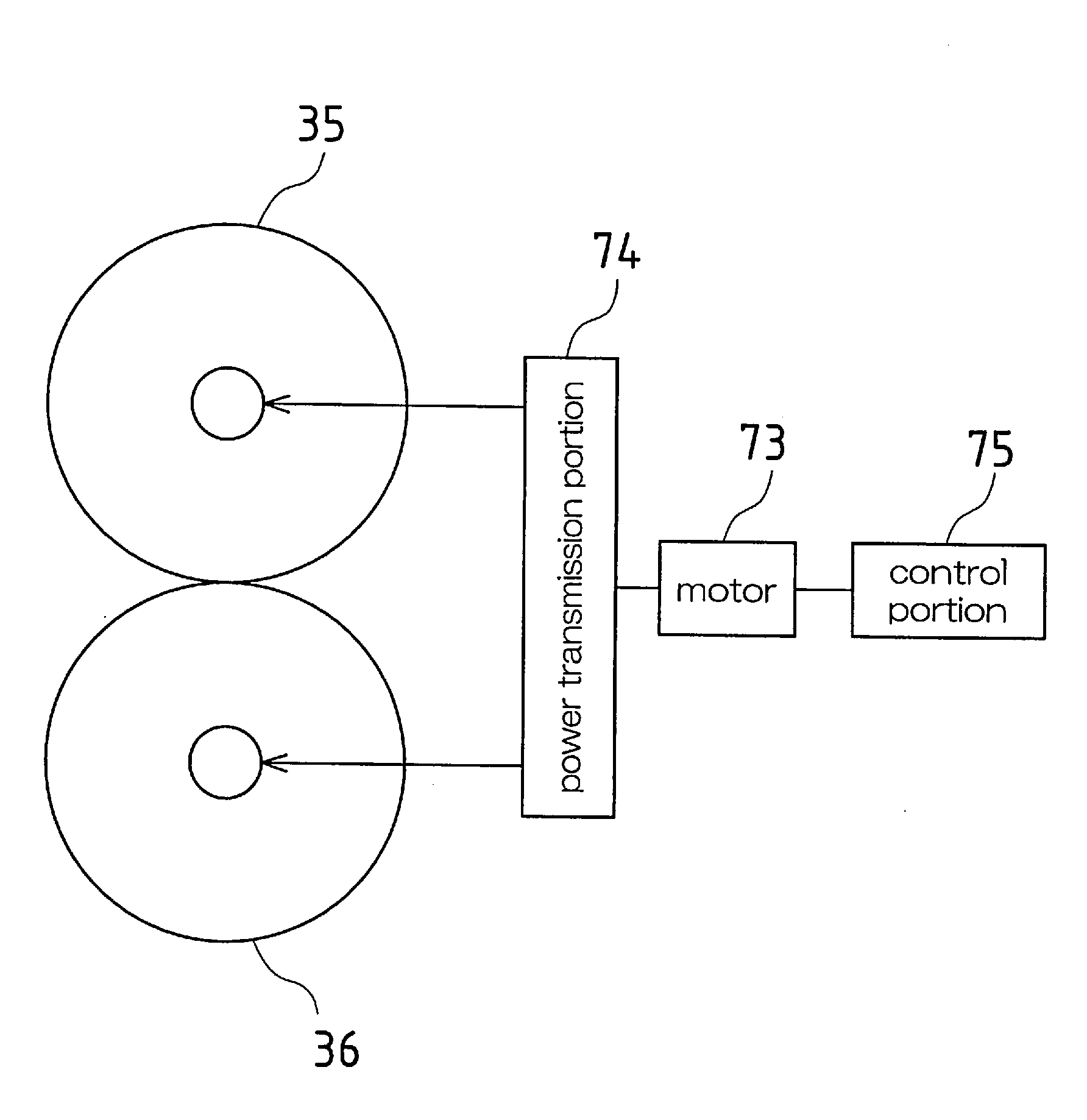

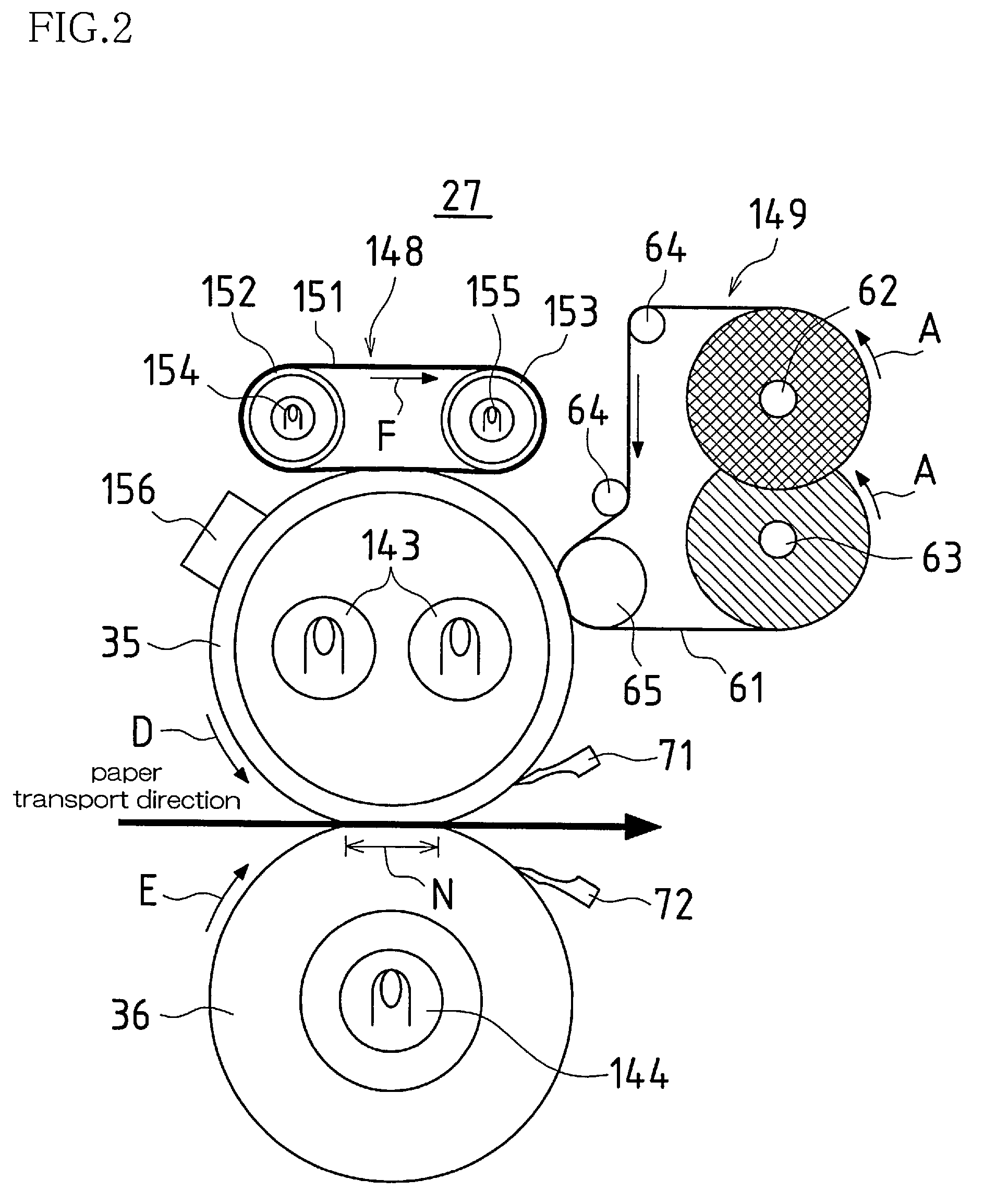

Roller drive control method of fixing apparatus and fixing apparatus

InactiveUS20080253790A1Improve vibrationNot easy to gapElectrographic process apparatusControl engineeringProcess engineering

Owner:SHARP KK

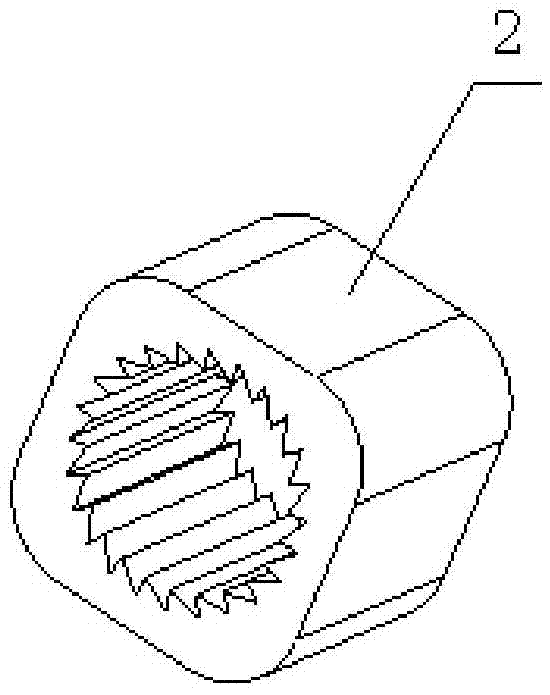

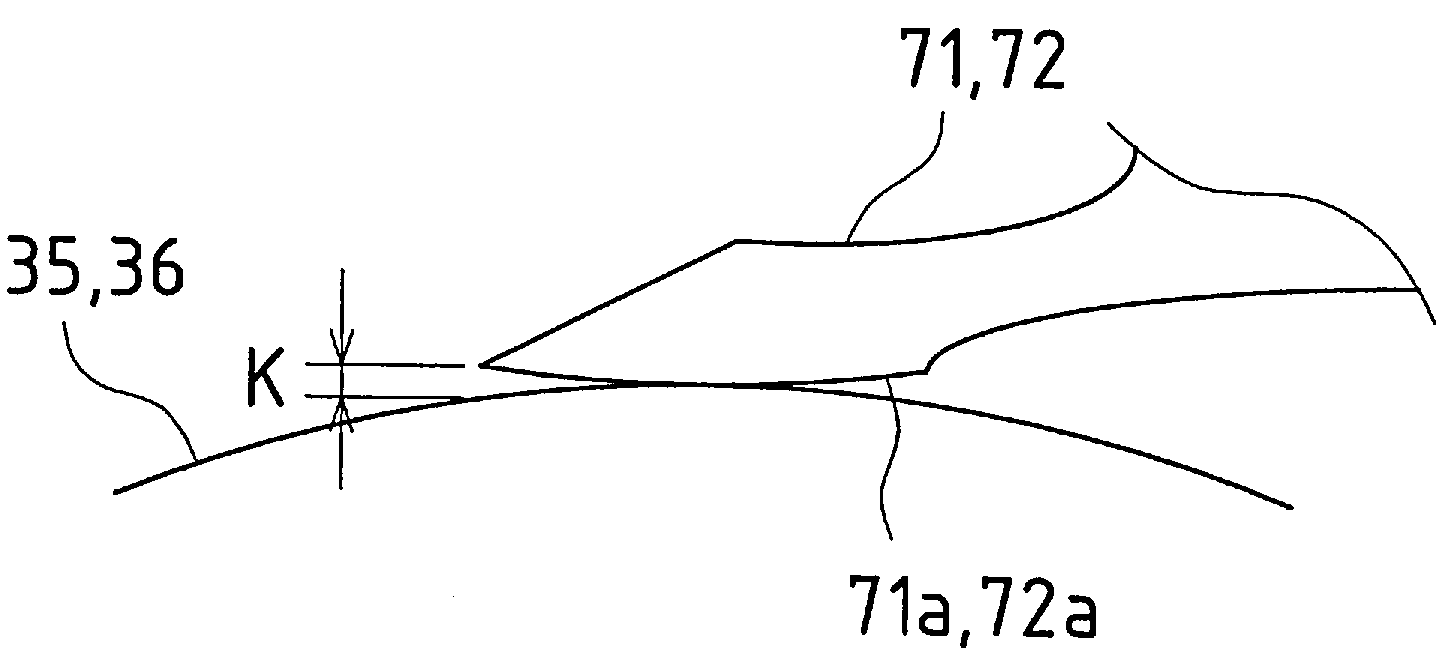

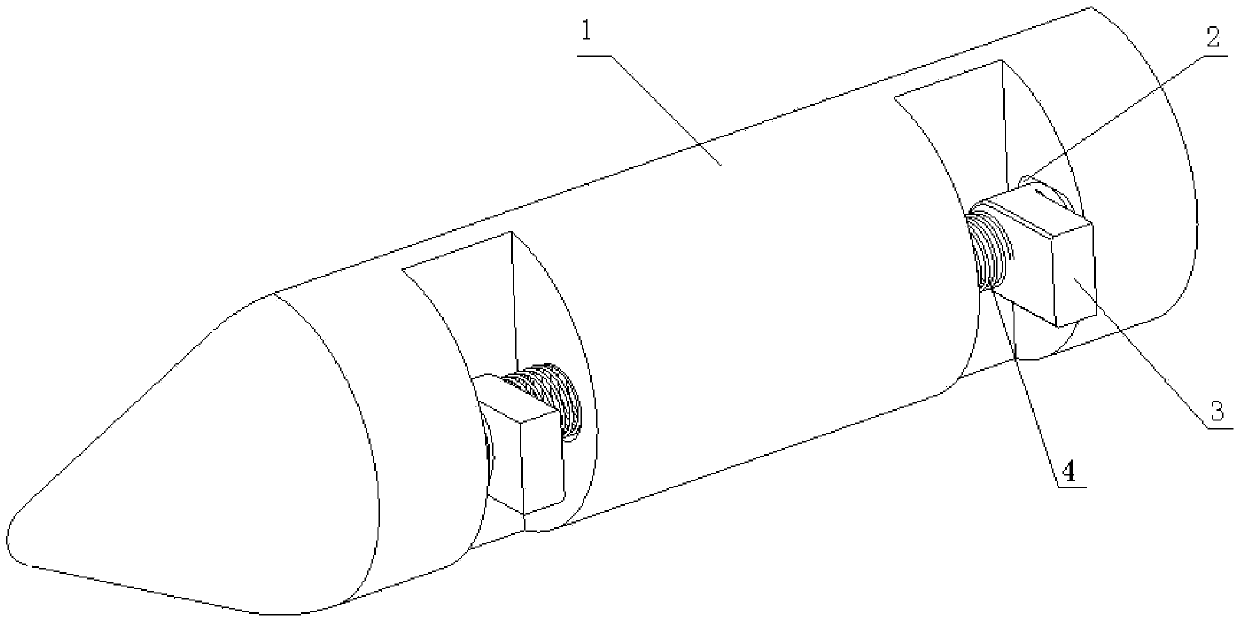

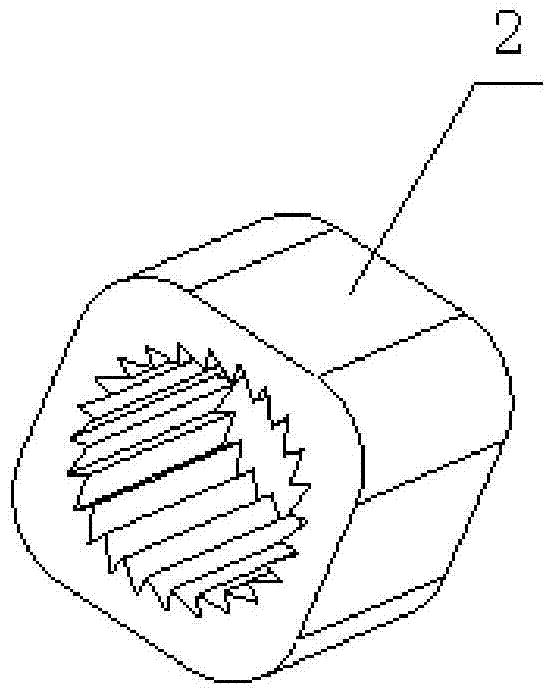

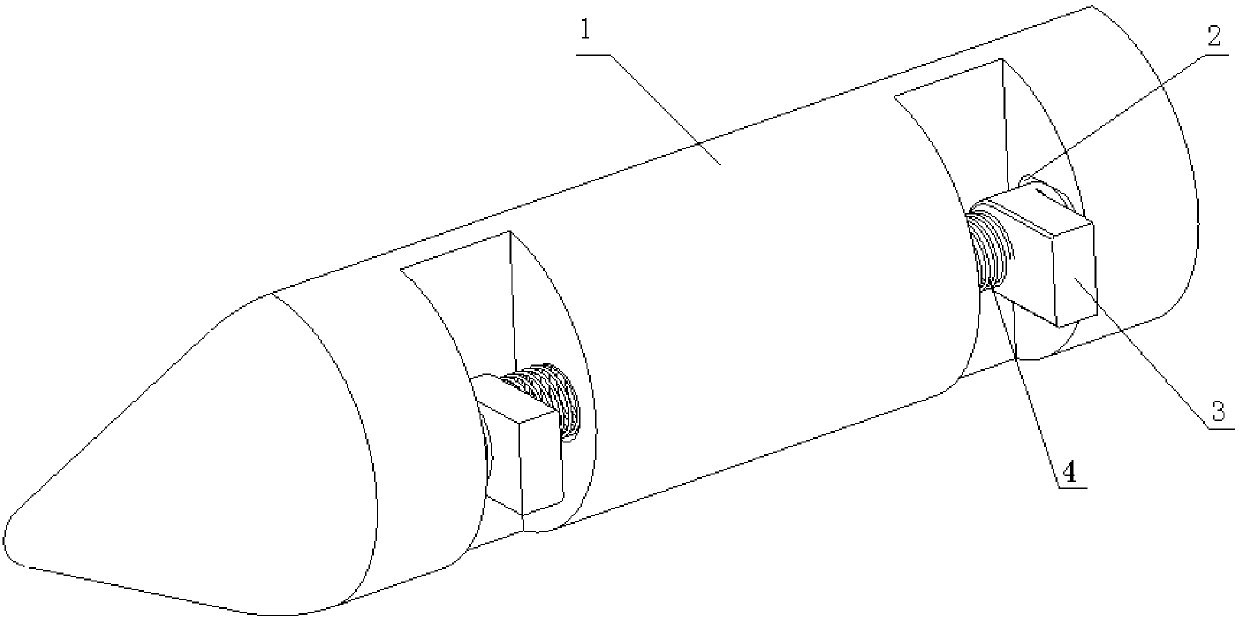

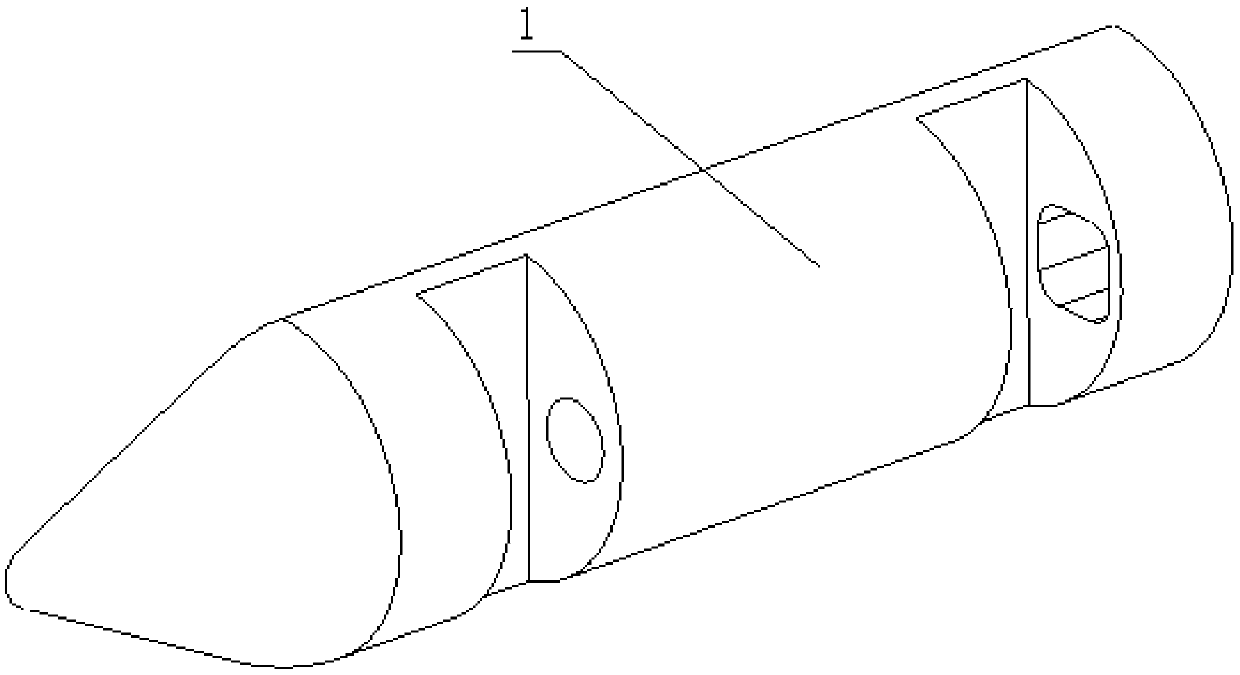

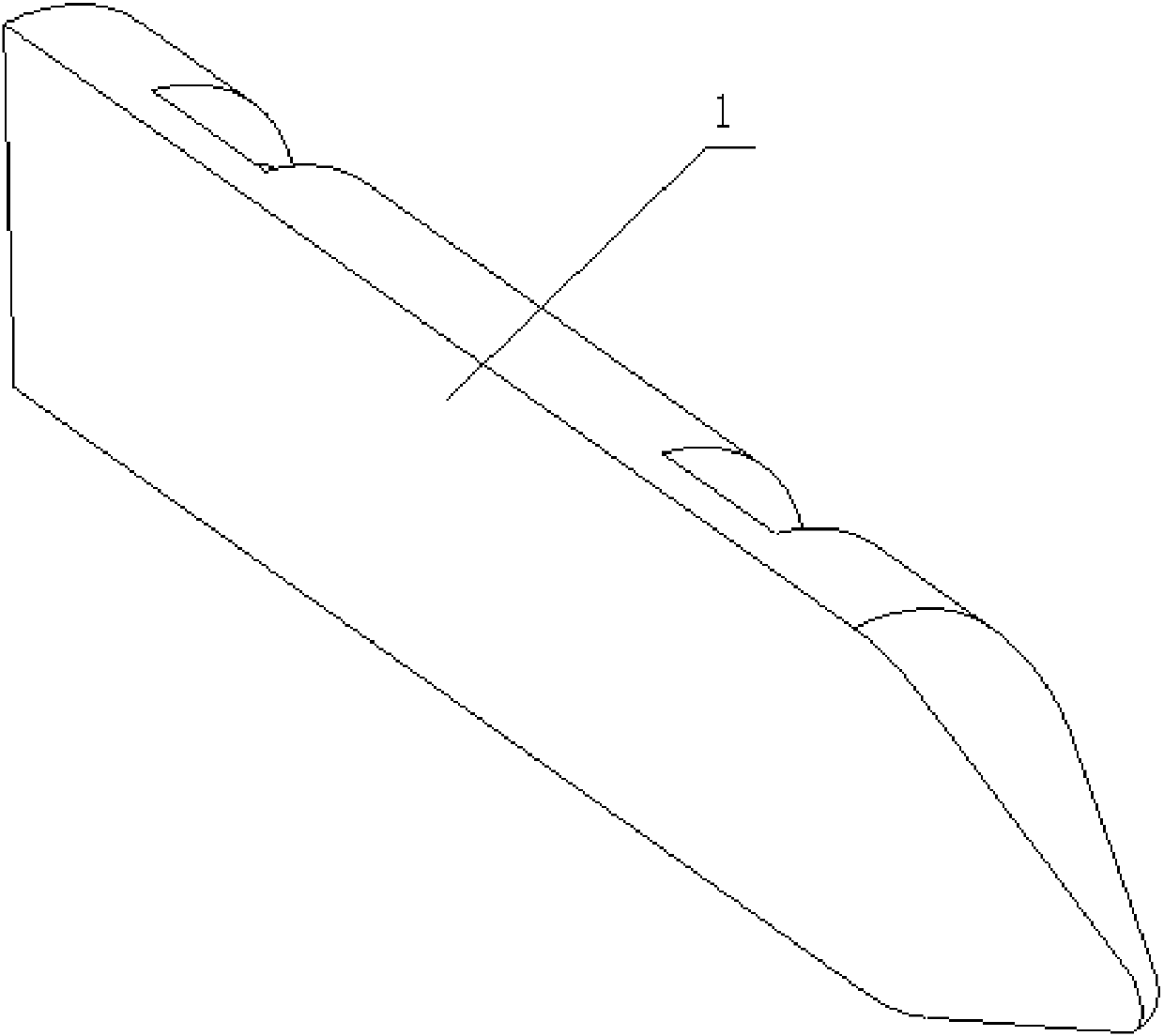

Winglet device

ActiveCN105438441ASmall footprintReduce weightWing adjustmentsHeat reducing structuresMechanical engineeringEngineering

The invention discloses a winglet device which comprises a wingtip connecting part (1), ratchet wheel sleeves (2), ratchet wheel rods (3) and pressing bolts (4), wherein the wingtip connecting part (1) is connected to a wingtip of a wing; one side of the wingtip connecting part (1) is provided with two or more U-shaped grooves; two inner end surfaces of each U-shaped groove are respectively provided with a ratchet wheel groove in the shape of a non-revolving body and a threaded hole; the ratchet wheel sleeve (2) is arranged in the ratchet wheel groove, the shape of each ratchet wheel sleeve is consistent with that of the corresponding ratchet wheel groove, and a ratchet-wheel-shaped through hole is formed in each ratchet wheel sleeve; each ratchet wheel rod (3) comprises a ratchet wheel part and a connecting part, wherein the connecting part is connected to the winglet, the periphery of the ratchet wheel part is consistent with the through hole in shape, and the ratchet wheel part is arranged in the through hole of the ratchet wheel sleeve (2) in a sleeved mode; a threaded end of each pressing bolt (4) is screwed in the corresponding threaded hole, and the other end of each pressing bolt (4) axially presses one end surface of the corresponding ratchet wheel rod (3) connecting part to limit axial movement of the corresponding ratchet wheel rod (3). According to the winglet device, the ratchet wheel structure is relatively small in space occupancy, lighter in weight and highly adjustable in angle.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

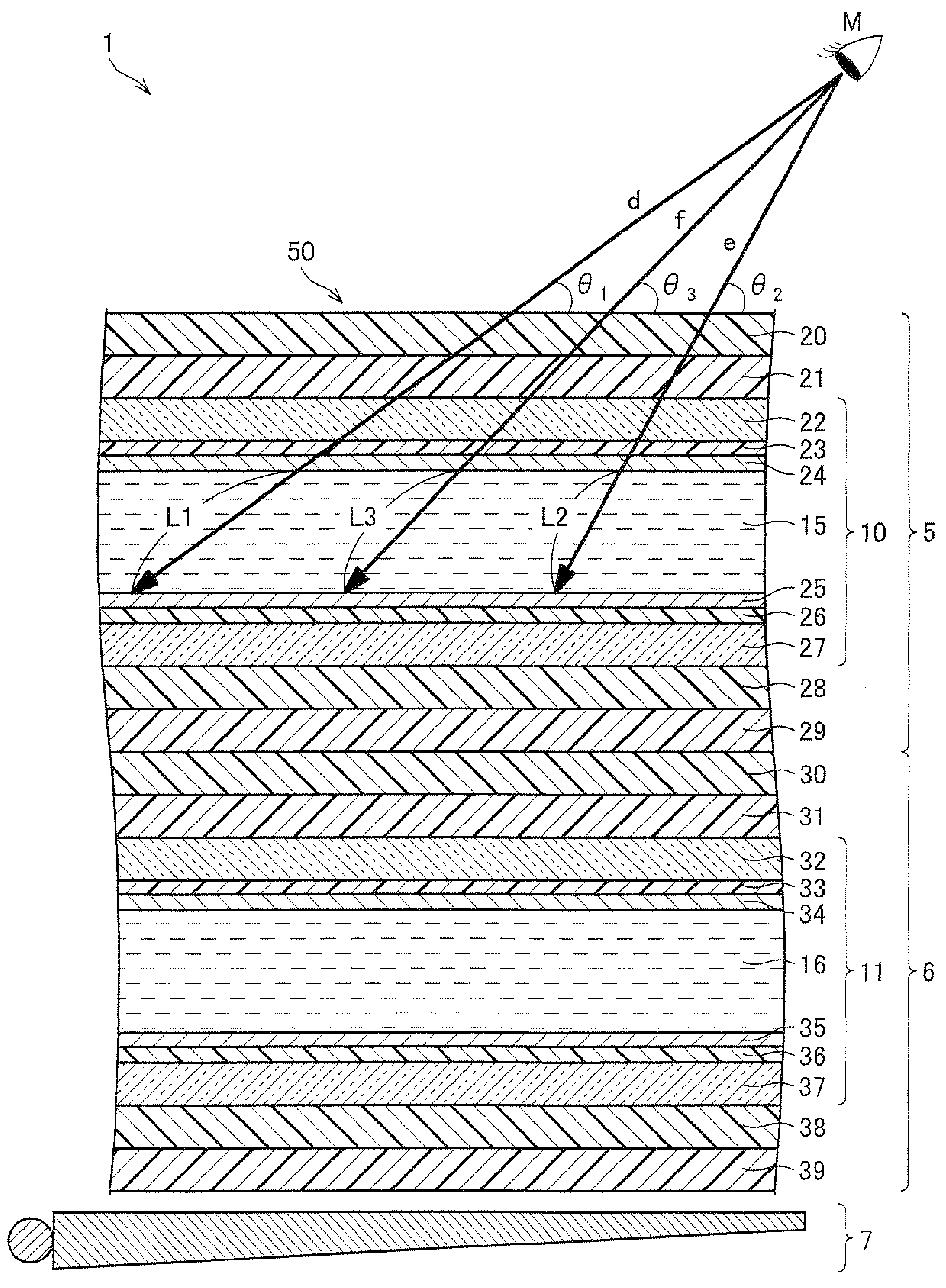

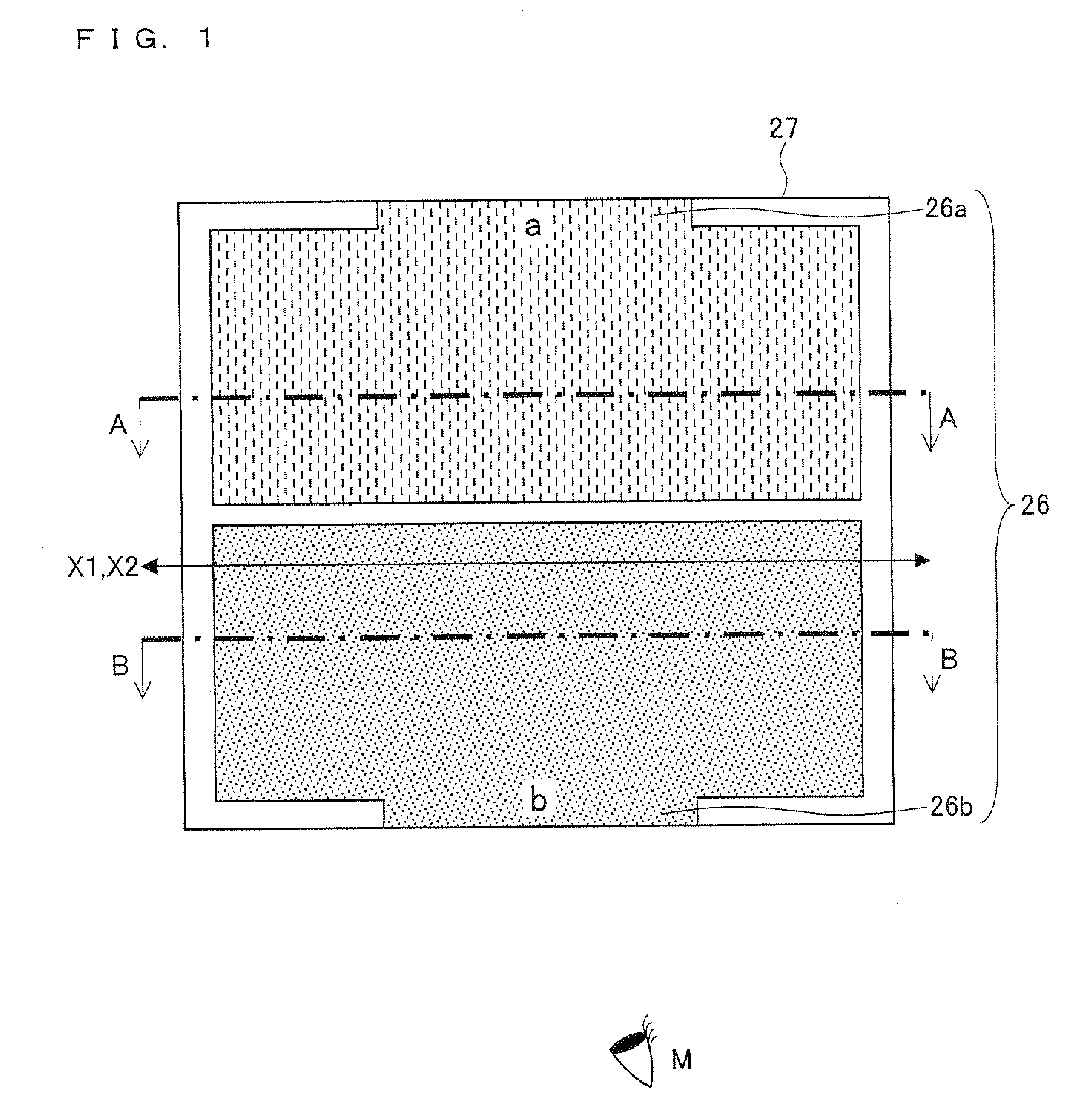

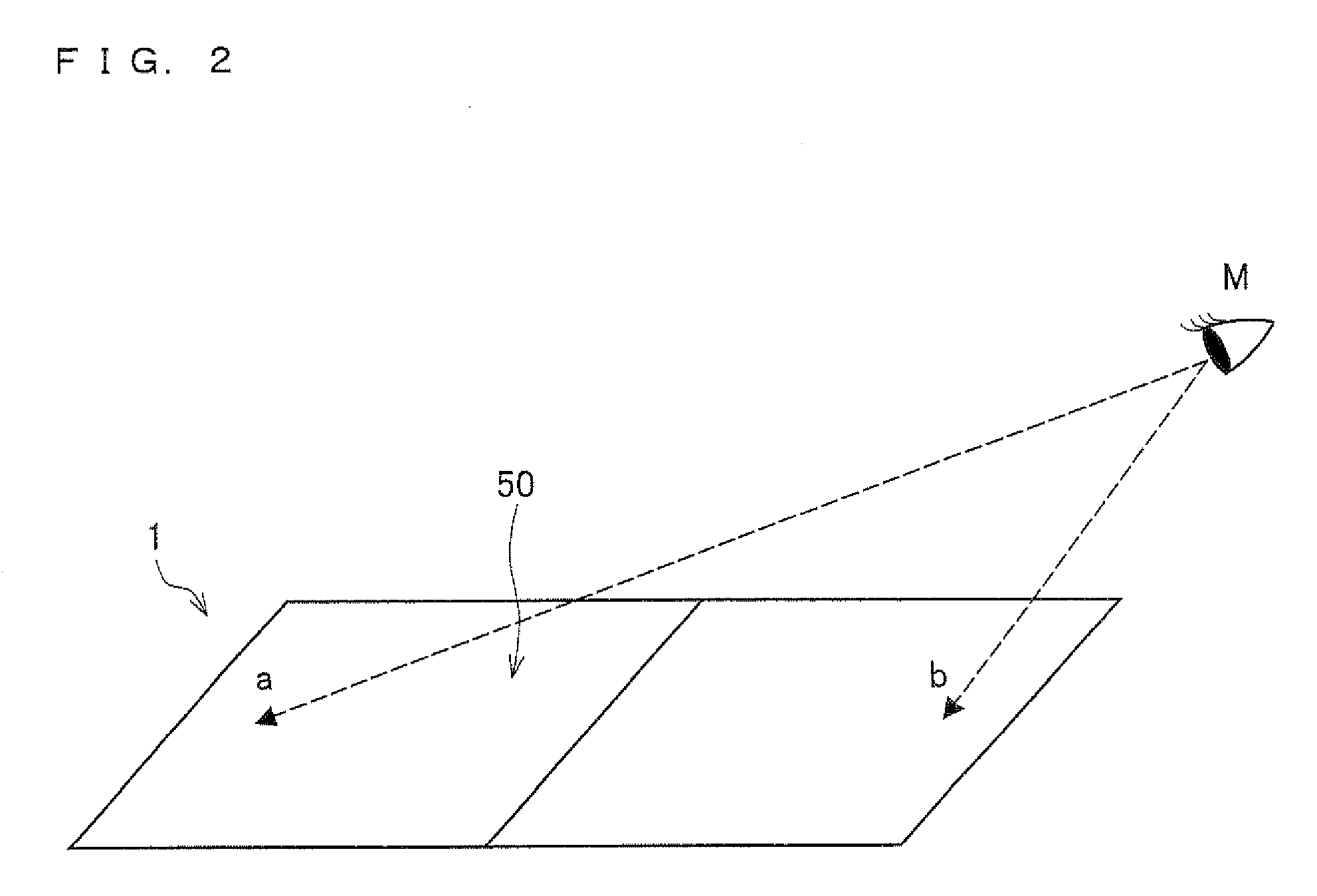

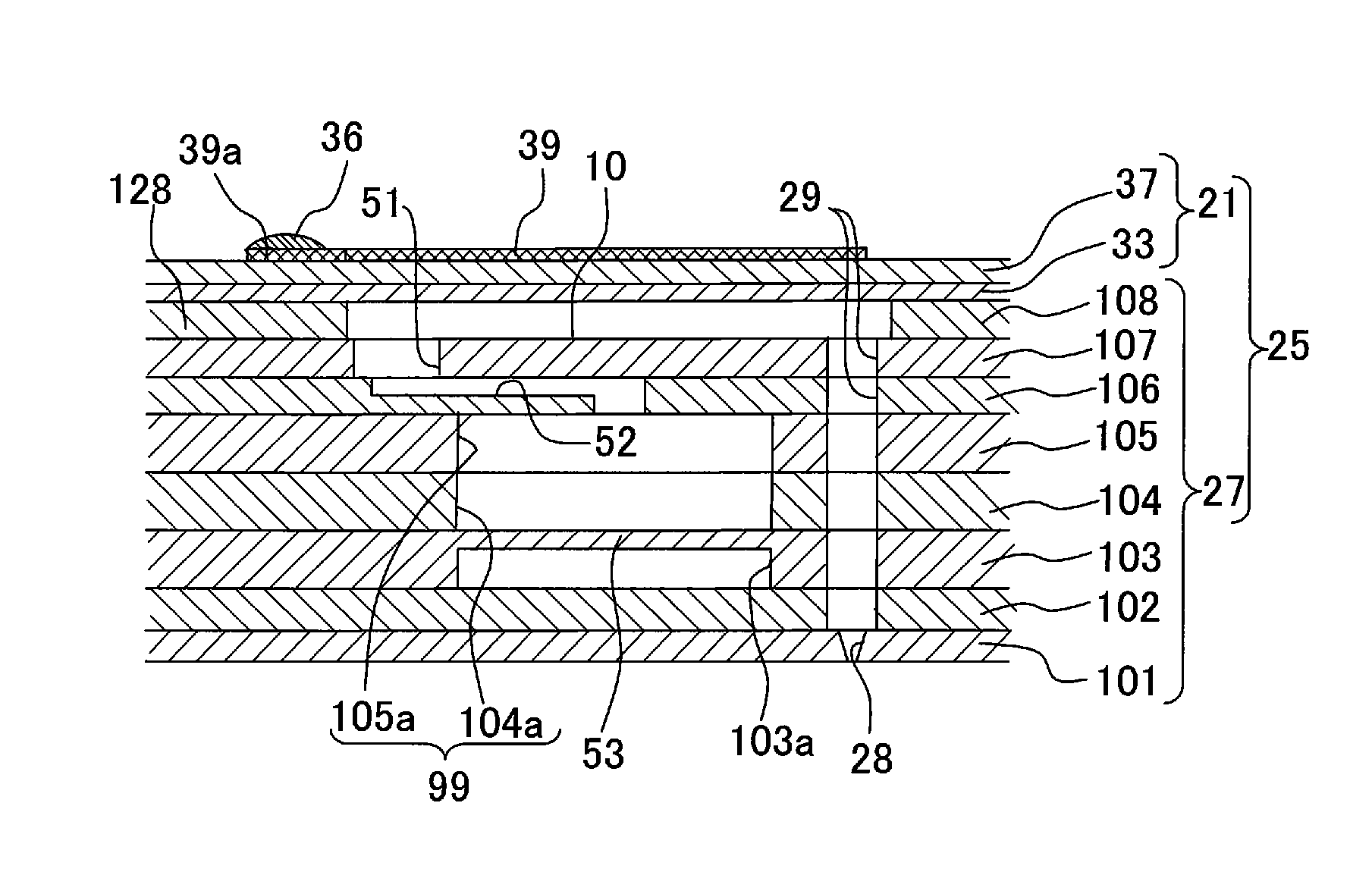

Viewing angle controlling liquid crystal panel and display device

A viewing angle controlling liquid crystal panel in which uniformity of a shielding effect in a screen is further improved is provided. Linearly polarized light enters a liquid crystal layer. Further, the liquid crystal layer is provided, on a light exit side of the liquid crystal layer, with a polarizing plate transmitting only a component of light having exited from the liquid crystal layer which component is parallel to a polarization axis of the linearly polarized light having entered the liquid crystal layer. Liquid crystal molecules contained in the liquid crystal layer are tilted in a direction parallel to or perpendicular to the polarization axis of the linearly polarized light having entered the liquid crystal layer. In addition, an electrode (26) is provided so that two or more different voltages can be applied to the liquid crystal layer simultaneously.

Owner:SHARP KK

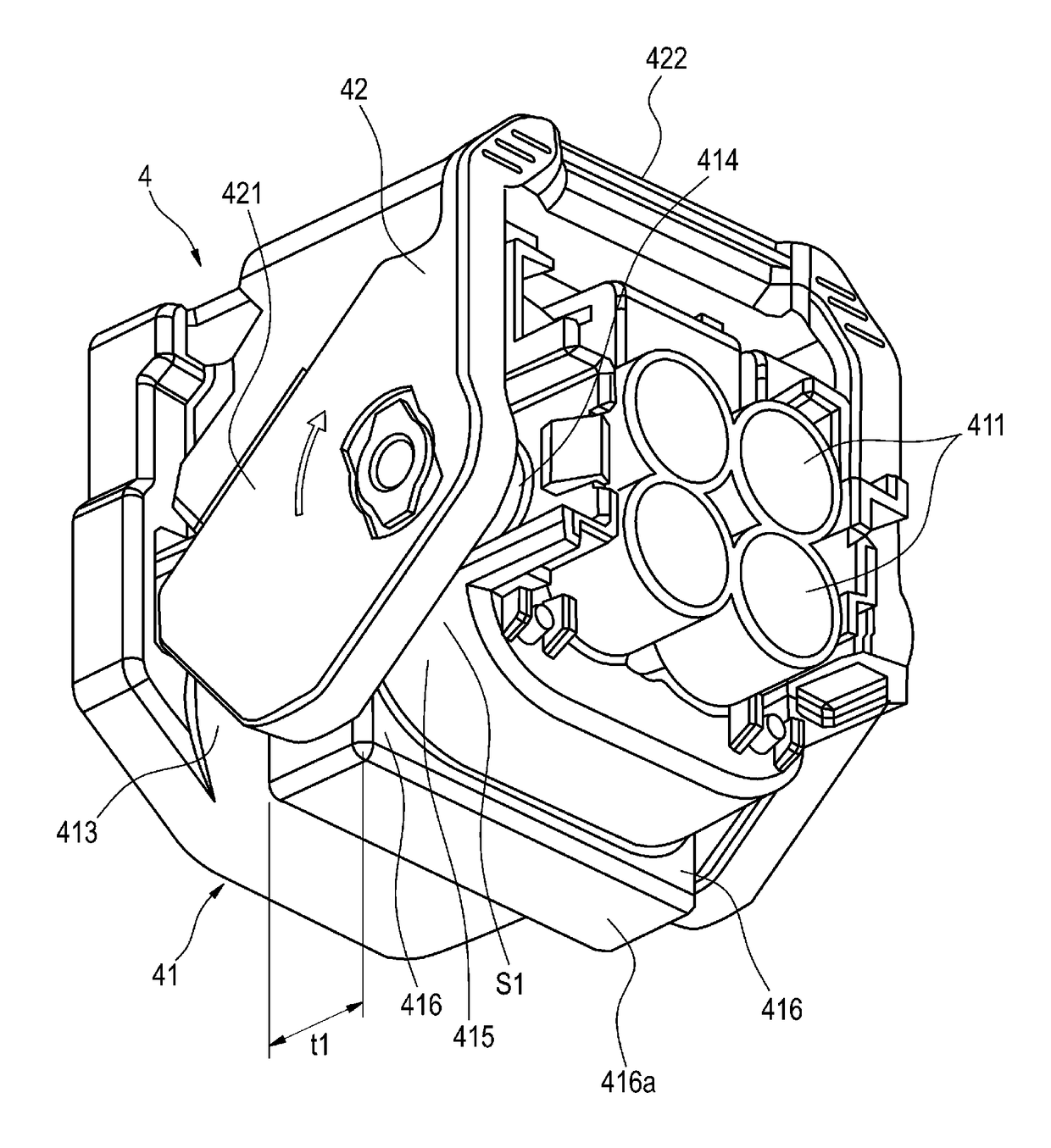

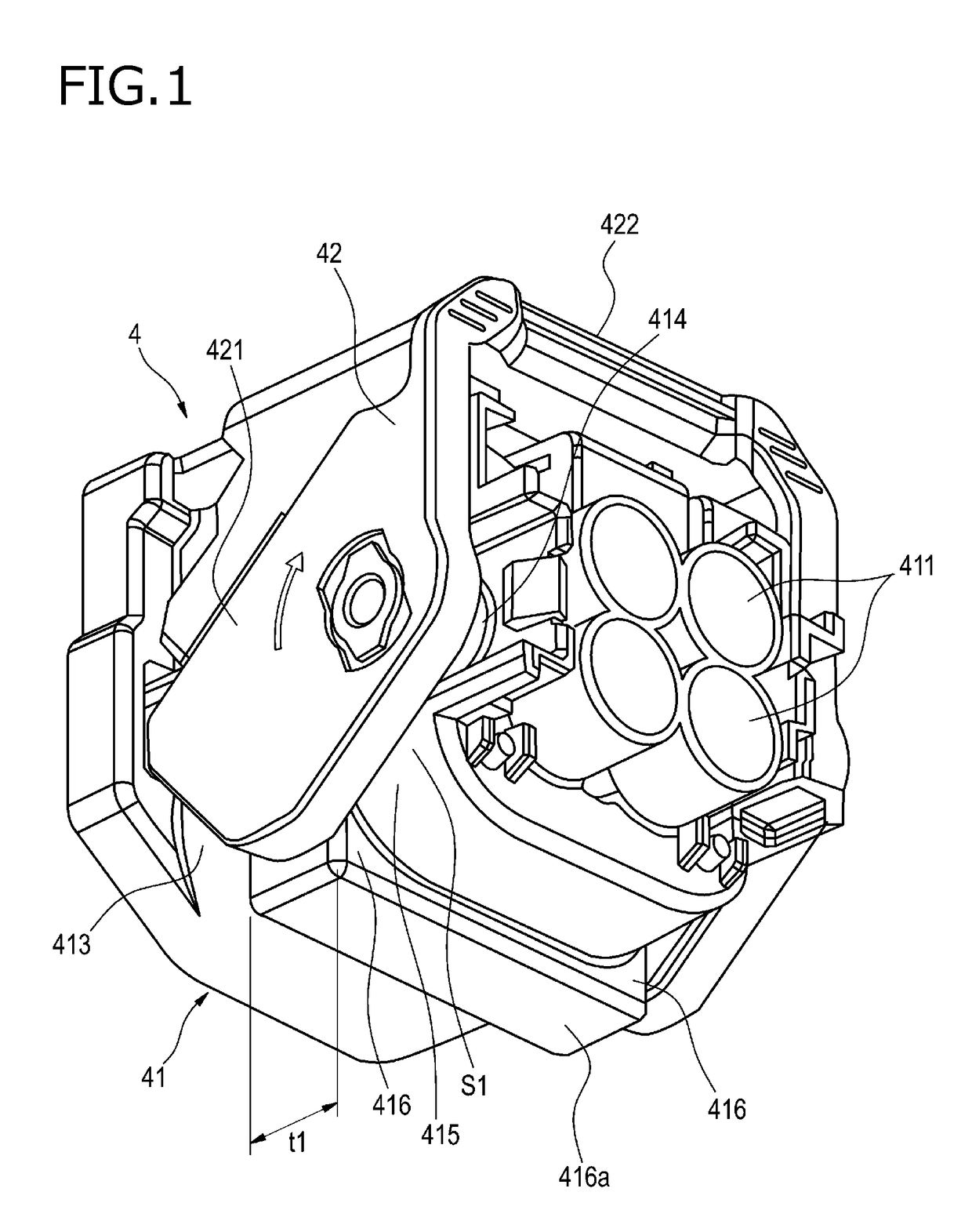

Liquid jetting head and method for producing the same

An ink-jet head includes a channel unit and a piezoelectric actuator. The channel unit has a plurality of plates made of metal and including a cavity plate which is made of metal and in which a plurality of pressure chambers are formed and a supply plate which is made of metal and in which holes communicating with the pressure chambers respectively are formed, and the plates are diffusion-bonded with each other. The piezoelectric actuator has a vibration plate which is diffusion-bonded with the cavity plate. A groove is formed in a partition wall defining the pressure chambers or in an area overlapping the partition wall of the vibration plate, the cavity plate, and the supply plate. There is provided a liquid jetting head in which air hardly remains in the pressure chambers, and deterioration of jetting performance by the air is suppressed.

Owner:BROTHER KOGYO KK

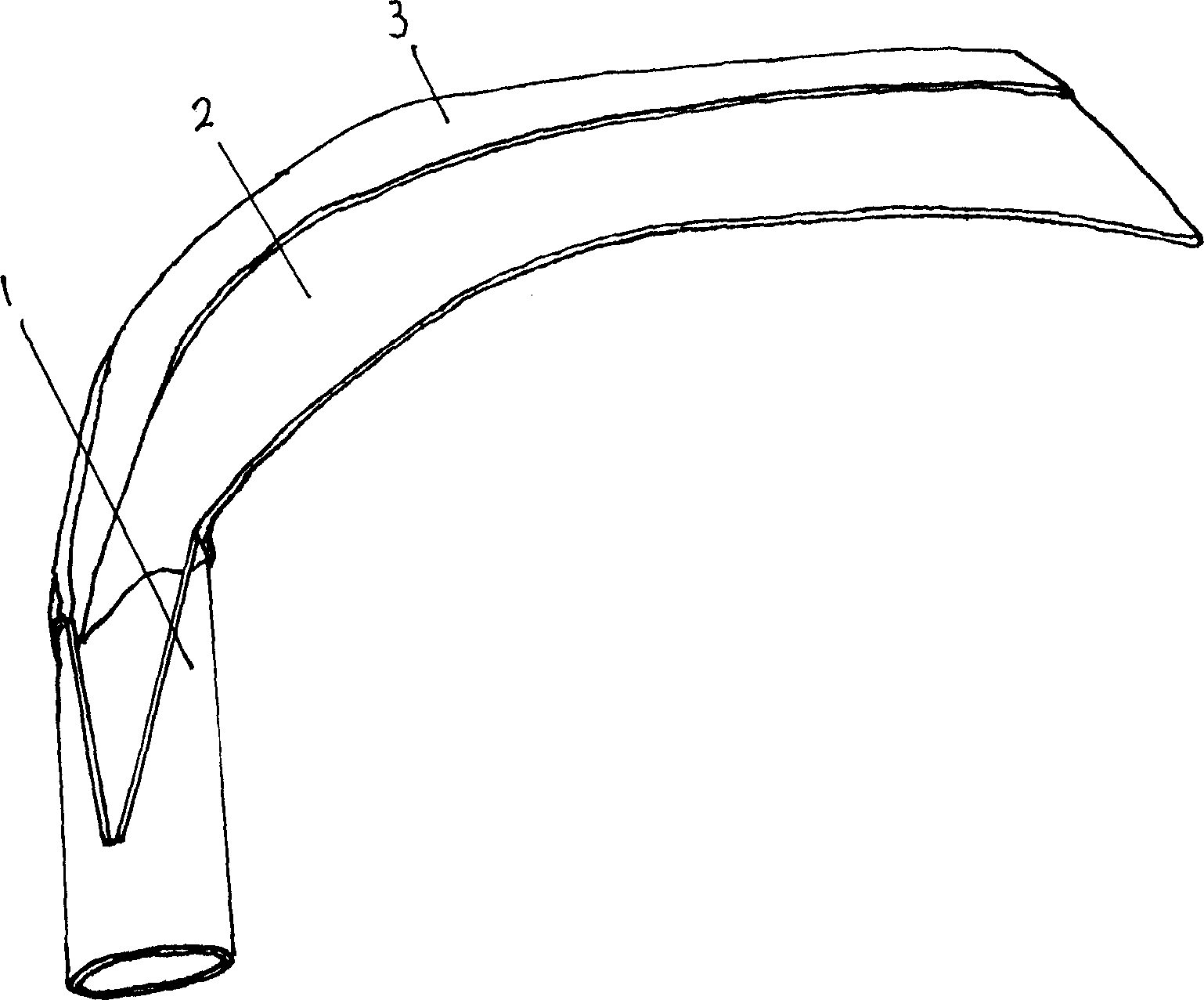

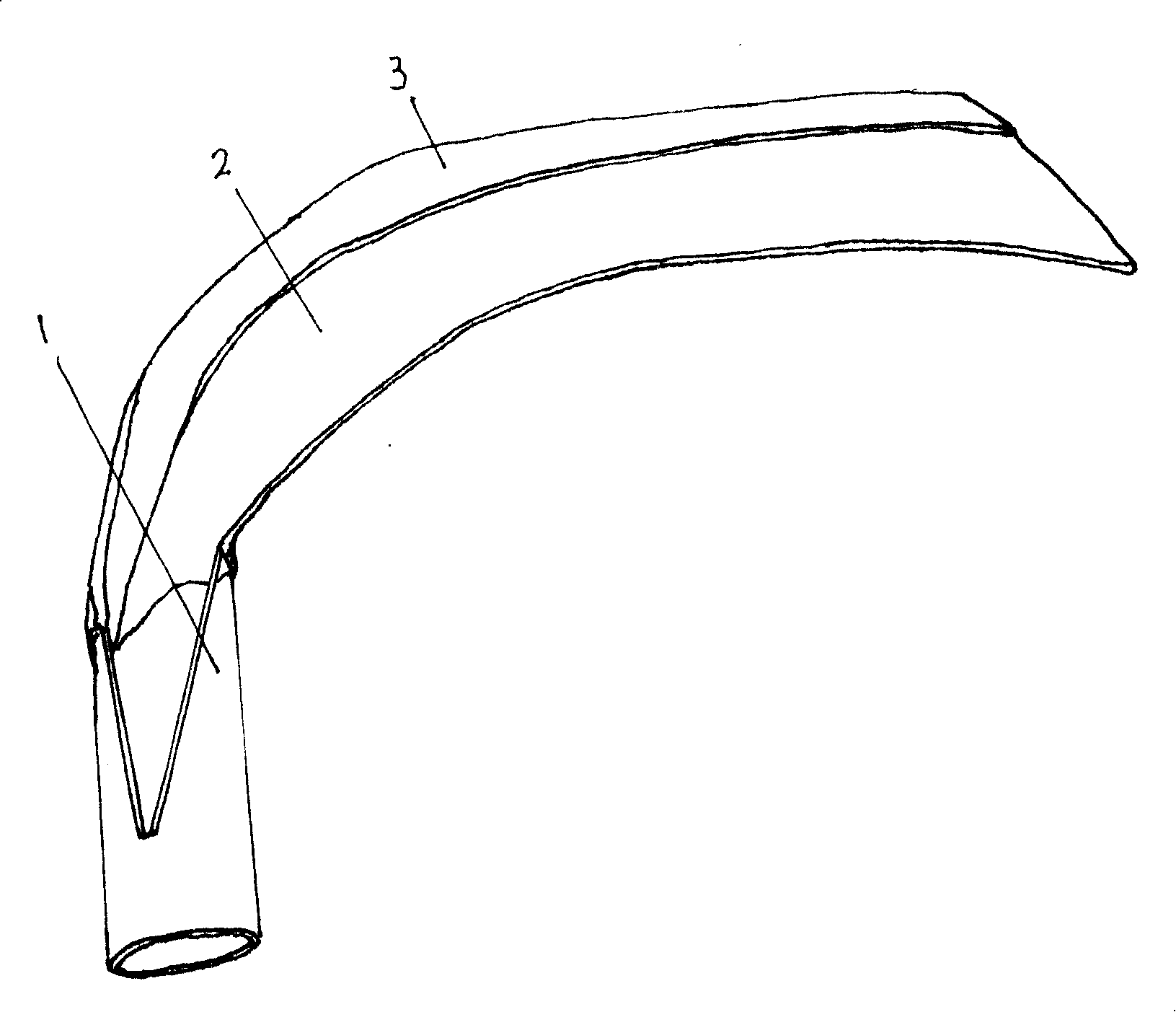

Sickle production and processing method

InactiveCN1736657AHigh strengthAvoid deformationOther manufacturing equipments/toolsChemical treatmentBlade plate

The invention relates to a method for preparation of sickle. It contains the following steps: cutting the metallic sheet, folding the back, welding the seam, coating one face of the knife plate with a masking paste and then with chemical treatment, welding the trouser- part material with the knife plate, punching the trouser-part material to mould, whole grinding, quenching, tempering, aligning, coarse grinding, and correct grinding to prepare the product. The sickle is intense and not easy to be out of shape or to break; and the sickle can be produced by industrialization.

Owner:高百洋

Roller drive control method of fixing apparatus and fixing apparatus

InactiveUS7783220B2Fast meltingSoften fastElectrographic process apparatusMechanical engineeringEngineering

Owner:SHARP KK

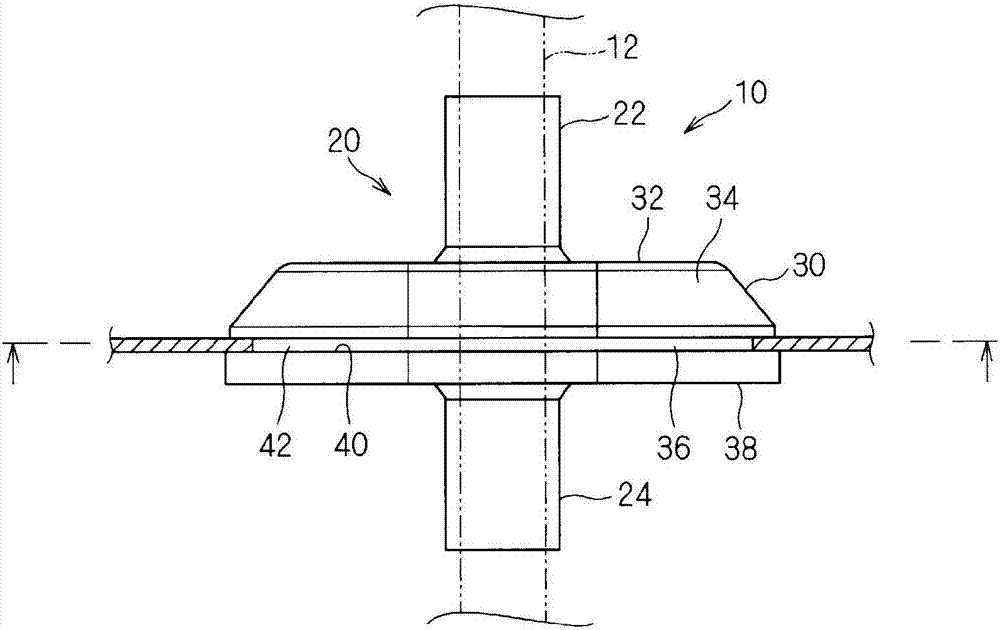

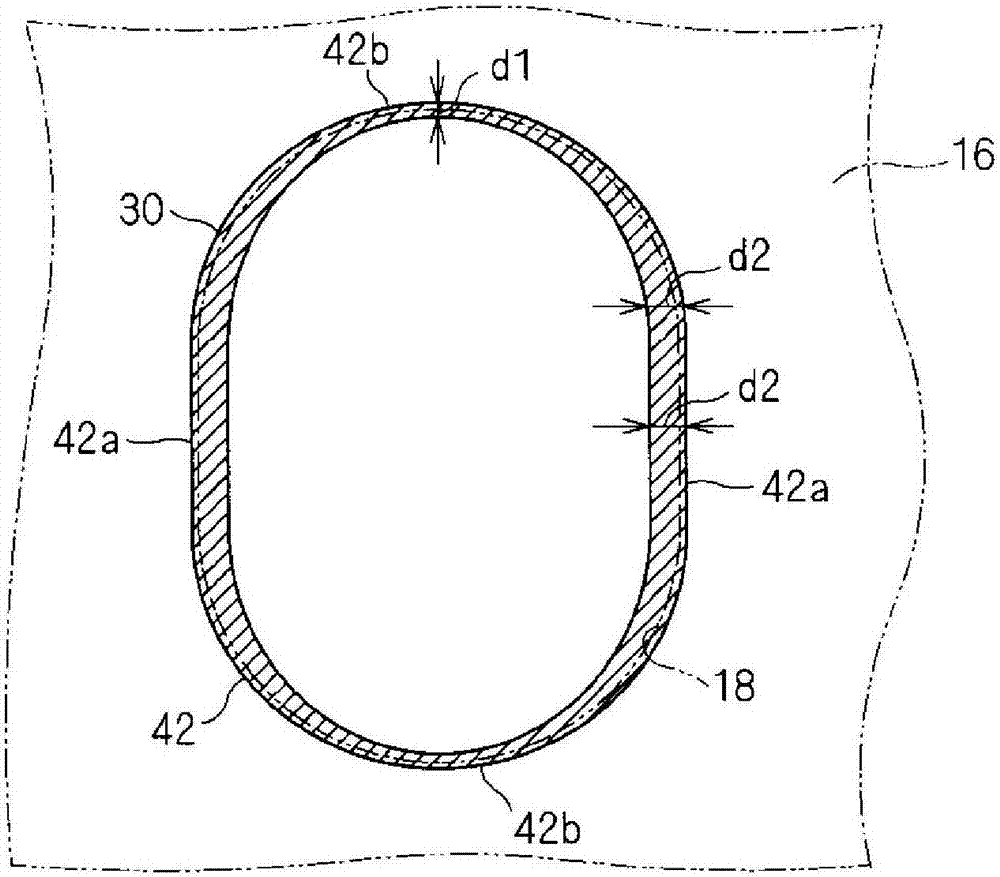

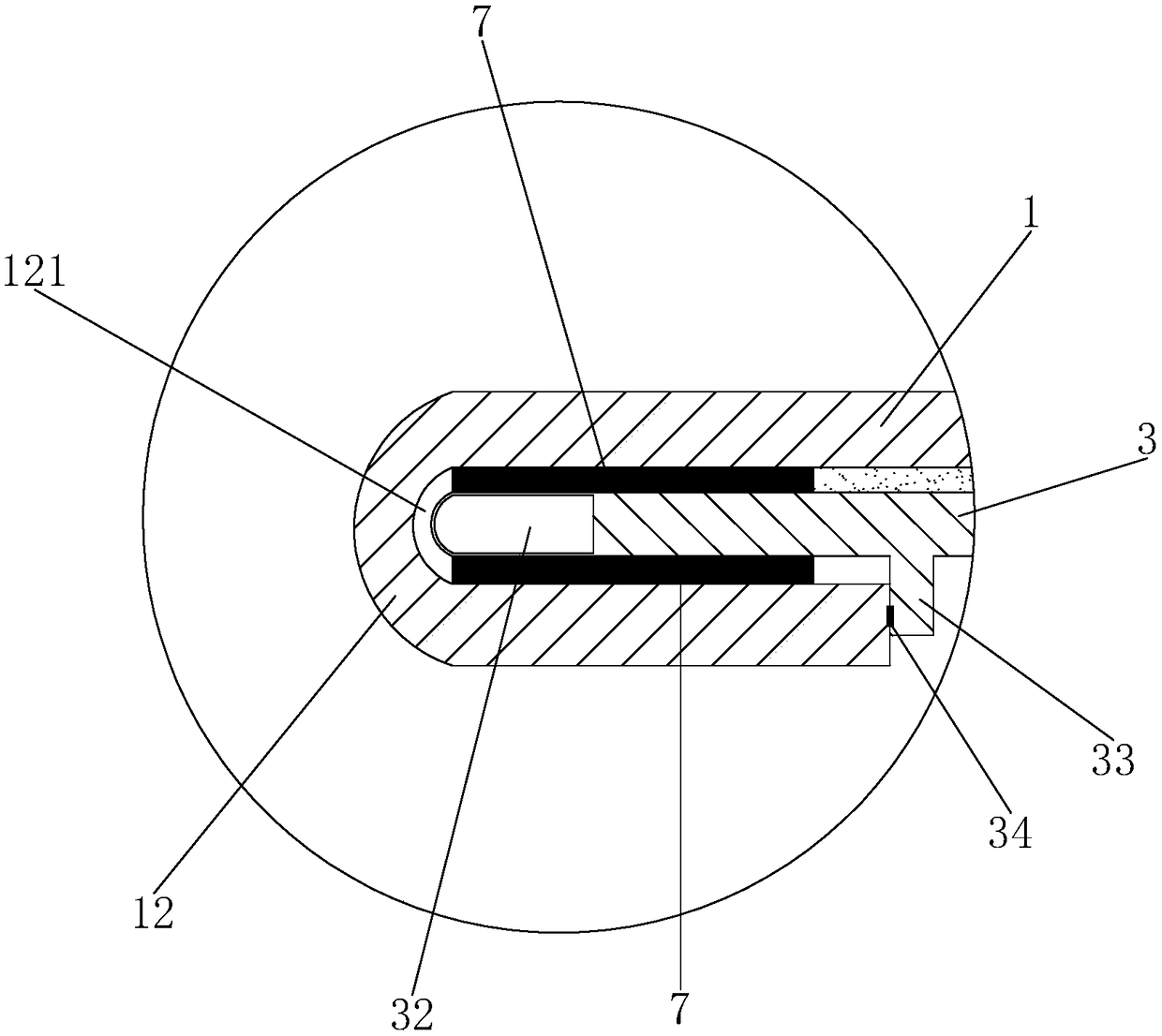

Grommet and electric wire with grommet

The purpose of the present invention is to improve, in a grommet to be fitted into a track-shaped through hole, a water-stopping property between an inner circumferential edge of the through hole and a bottom surface of a ring-shaped groove of the grommet. A grommet of the present invention comprises: a cylindrical part; and a fitting part that is formed so as to protrude to an outer circumferential part of the cylindrical part and that has formed, in an outer circumferential part thereof, a ring-shaped groove into which the inner circumferential edge of the through hole can be inserted. A bottom surface of the ring-shaped groove is formed in a track shape that has a pair of straight-line portions and a pair of arc-shaped portions that are each formed in an outwardly convex arc shape and that connect the two ends on one side of the pair of straight-line portions and the two ends on the other side of the pair of straight-line portions. An inner circumferential part of each arc-shaped portion includes a part having a thickness that gradually increases from the center thereof toward connecting parts between the arc-shaped portions and the straight-line portions.

Owner:SUMITOMO WIRING SYST LTD

Plastic reinforcing cap for detonating cap

The invention relates to the manufacturing field of explosive materials and providing a plastic reinforcing cap for a detonating cap. The plastic reinforcing cap is used for solving the problems that the existing plastic reinforcing cap is deformed and cracked under high pressure, easy to chap under an extreme environment and melt and block a flash hole when the eruption of the first fire composition of the detonating cap is delayed, and easy to tear and smash during explosion. The plastic reinforcing cap can be suitable for detonating cap shells made from various materials, is convenient for static electricity guiding and further reducing the frictional force between the reinforcing cap and the inner wall of the tube, and easy to popularize and use.

Owner:SICHUAN YIBIN WEILI CHEM CO LED

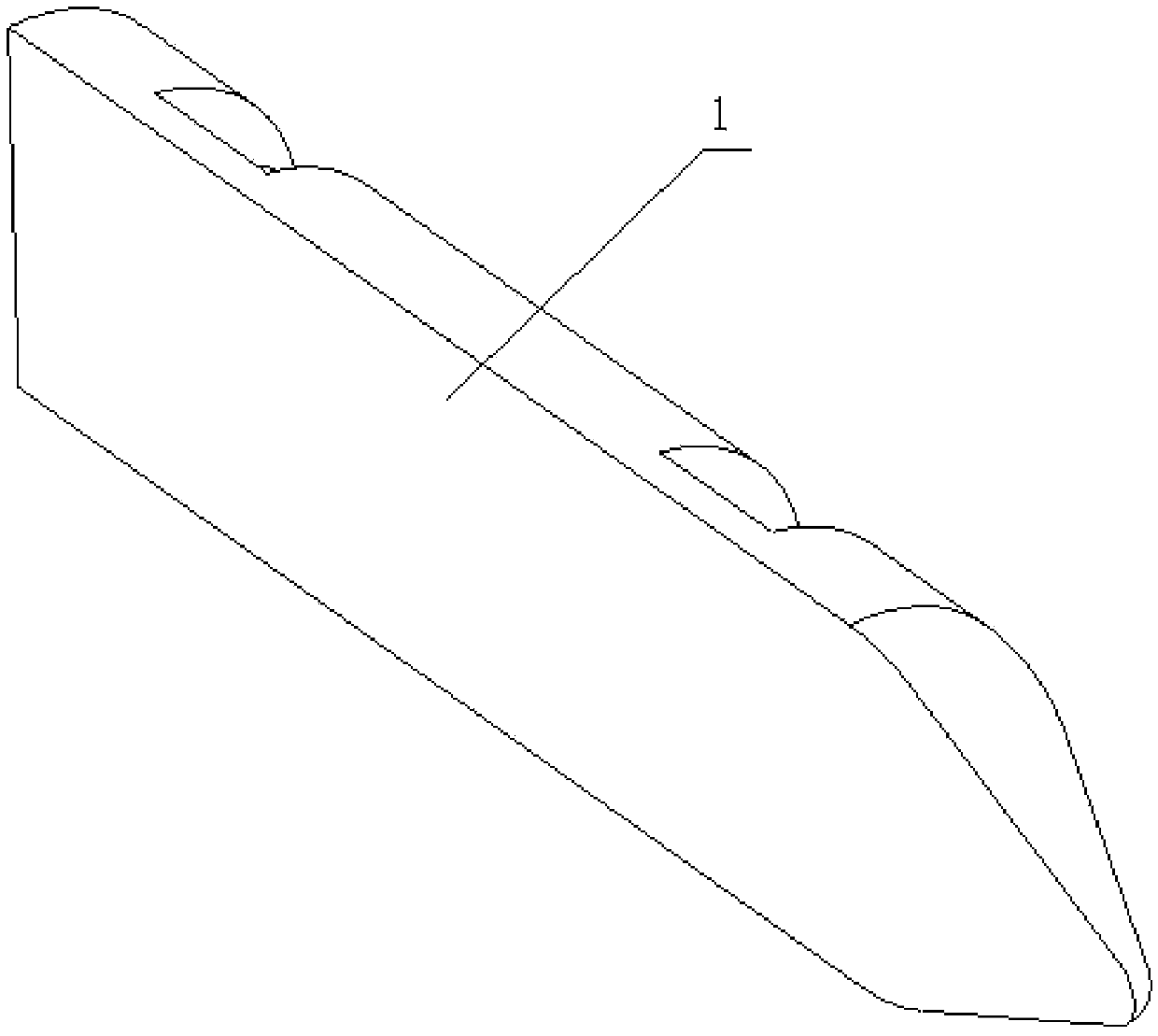

Winglet device with adjustable angle

InactiveCN105366031ASmall footprintReduce weightWing adjustmentsHeat reducing structuresEngineeringBlind hole

A winglet device with adjustable angle includes a wingtip holder (1), insert blocks (2), connecting rods (3) and compression springs (4). The wingtip holder (1) is connected with the wingtip; one side of the wingtip holder (1) is provided with two or more grooves; both ends of each groove are respectively provided an insert block groove in a non-rotating shape and a blind hole; the shape of the insert blocks (2) is consistent with the shape of the insert block grooves, and the insert blocks are inserted into the insert block grooves; the outer end face of each insert block (2) is provided with a ring of adjustment grooves circumferentially arranged, and each adjustment groove forms a centrosymmetric figure along the center of the circumference; one end of each connecting rod (3) is provided with a ring of projections matching with the adjustment grooves, the projections are in the adjustment grooves, and the connecting rods (3) are connected with the winglet; and one end of each compression spring (4) is arranged in the blind hole, and the other end of each compression spring abuts against the other end face of the connecting rod (3) and is axially compresses the connecting rod (3). The winglet device has the advantages of small space occupation, light weight, and the many adjustable angles.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

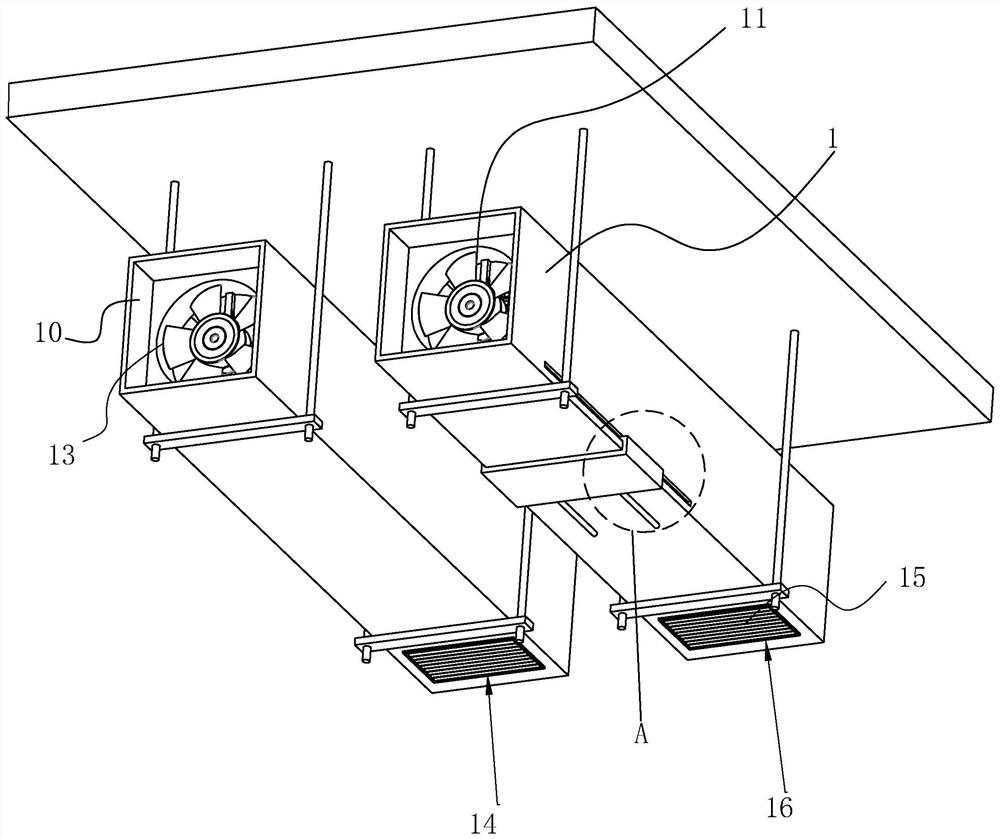

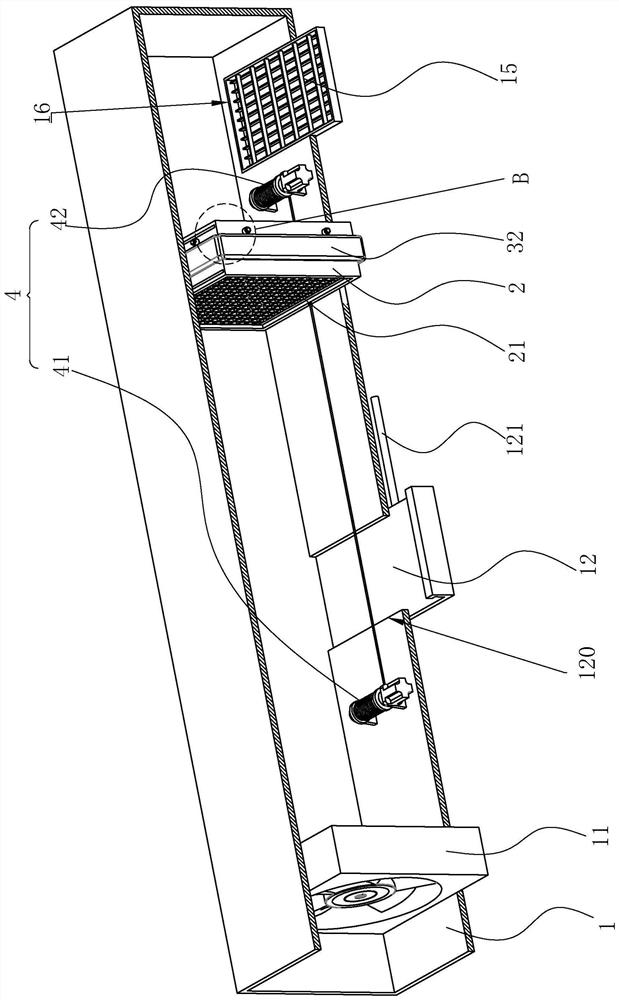

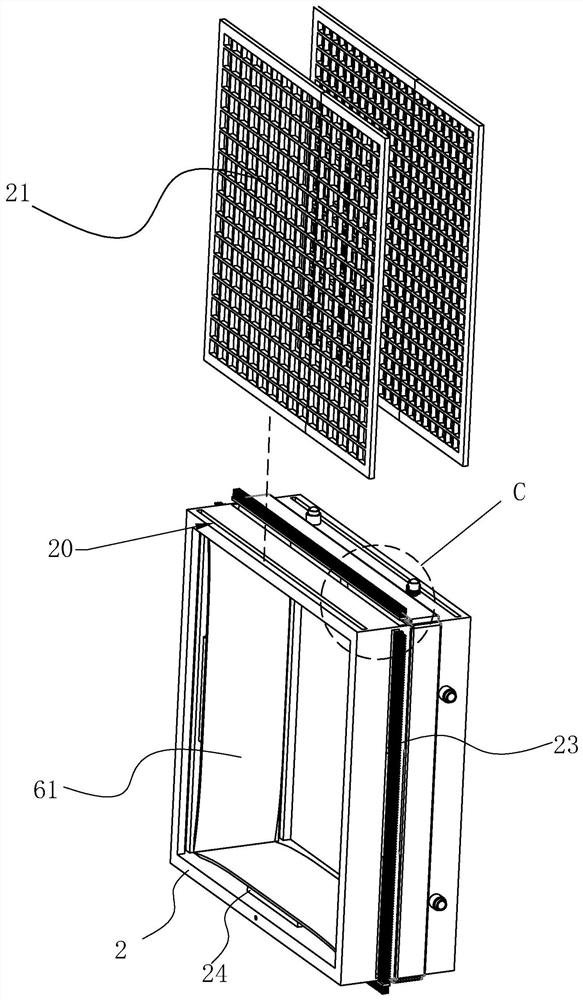

Indoor ventilation circulation system for green building

ActiveCN113757869AEasy to removeNot easy to gapMechanical apparatusLighting and heating apparatusActivated carbonEnvironmental engineering

The invention relates to the technical field of ventilation circulation systems, and provides an indoor ventilation circulation system for a green building. Aiming at the problem that dust in an air inlet pipe of a traditional ventilation circulation system is inconvenient to clean, the indoor ventilation circulation system comprises an air inlet pipe and an air outlet pipe, and an air inlet fan and an exhaust fan are arranged at pipe openings of the air inlet pipe and the air outlet pipe respectively; a purification box used for loading activated carbon particles is further slidably connected into the air inlet pipe; an access hole and an air supply port are also formed in the bottom wall of the air inlet pipe, and the access hole is used for inserting the purification box into the air inlet pipe; the air inlet fan, the access hole, the purification box and the air supply port are sequentially arranged in the air inlet direction of the air inlet pipe; brushes are arranged on the outer side walls of the purification box, and the air inlet pipe is further detachably connected with a sealing plate used for sealing the access hole; and the air inlet pipe is further provided with a driving assembly used for driving the purification box to move in the air inlet direction of the air inlet pipe. The indoor ventilation circulation system has the effect of reducing the dust cleaning difficulty of the air inlet pipe.

Owner:广东省第十一建设有限公司

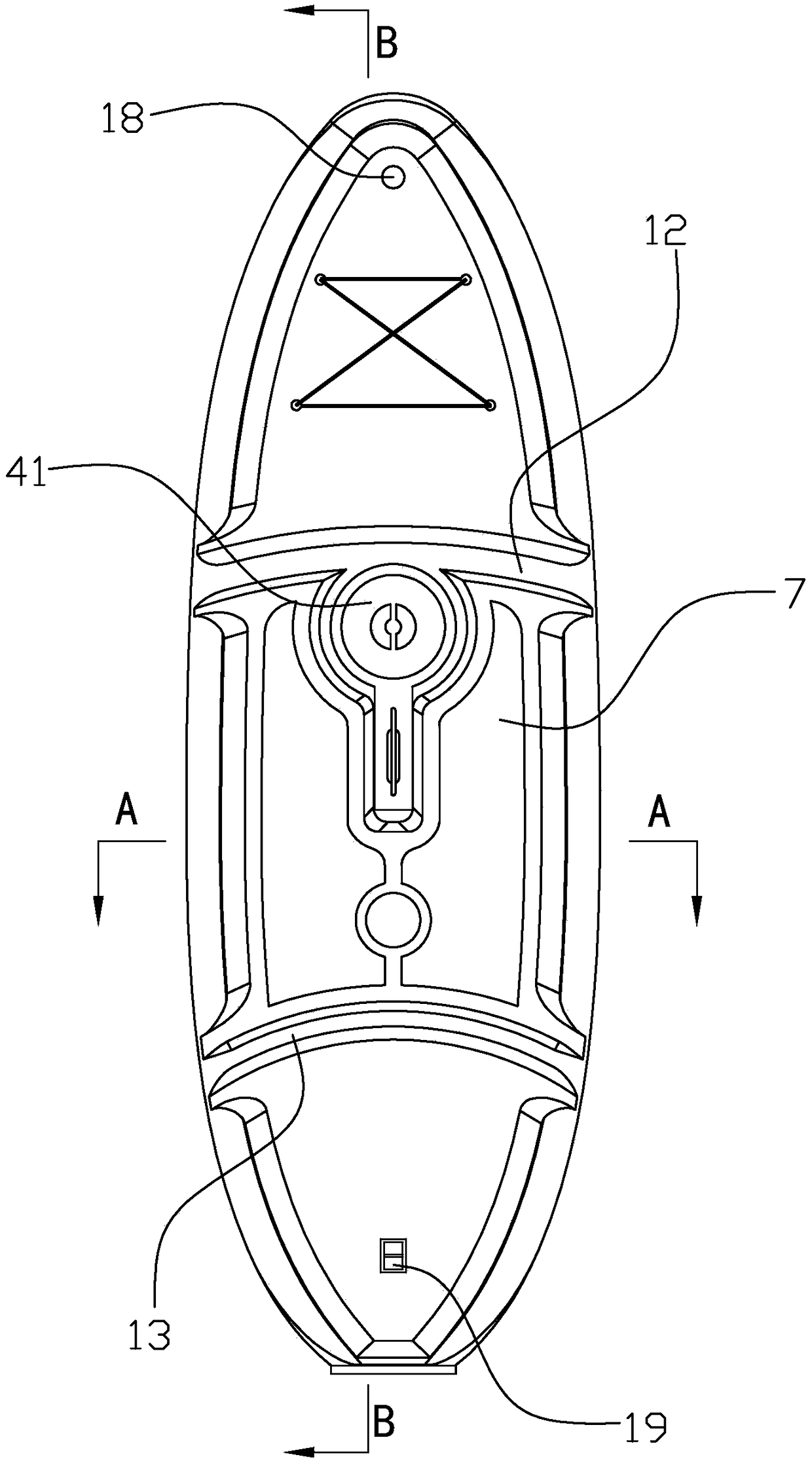

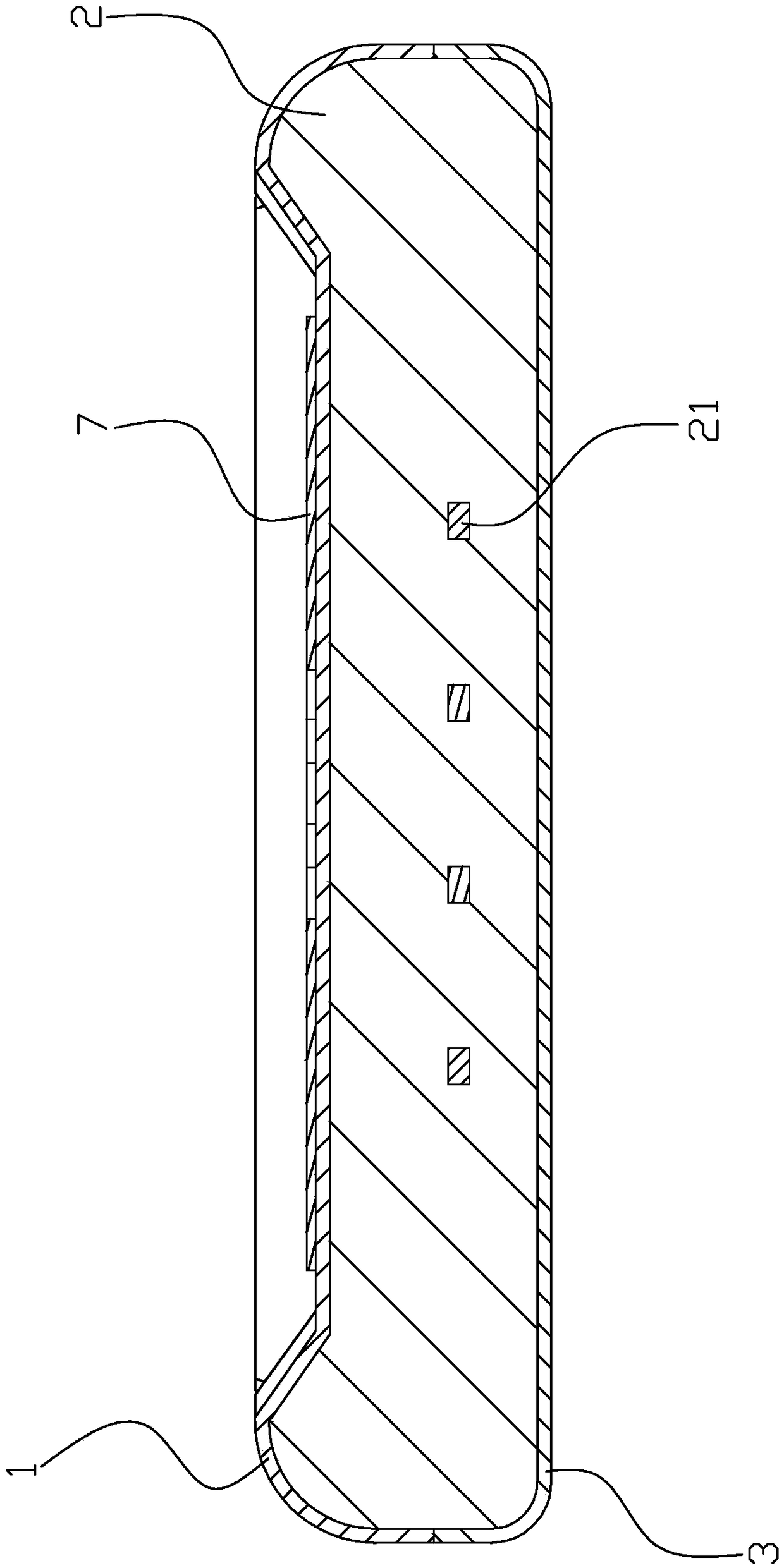

Making method of concave and convex surface of water sports skateboard

ActiveCN109263822AWeight optimizationReduce weightWaterborne vesselsSpecial purpose vesselsPulp and paper industryConcave surface

Owner:宁波市甬陵轻工实业有限公司

A winglet device

ActiveCN105438441BSmall footprintReduce weightWing adjustmentsHeat reducing structuresEngineeringMechanical engineering

The invention discloses a winglet device which comprises a wingtip connecting part (1), ratchet wheel sleeves (2), ratchet wheel rods (3) and pressing bolts (4), wherein the wingtip connecting part (1) is connected to a wingtip of a wing; one side of the wingtip connecting part (1) is provided with two or more U-shaped grooves; two inner end surfaces of each U-shaped groove are respectively provided with a ratchet wheel groove in the shape of a non-revolving body and a threaded hole; the ratchet wheel sleeve (2) is arranged in the ratchet wheel groove, the shape of each ratchet wheel sleeve is consistent with that of the corresponding ratchet wheel groove, and a ratchet-wheel-shaped through hole is formed in each ratchet wheel sleeve; each ratchet wheel rod (3) comprises a ratchet wheel part and a connecting part, wherein the connecting part is connected to the winglet, the periphery of the ratchet wheel part is consistent with the through hole in shape, and the ratchet wheel part is arranged in the through hole of the ratchet wheel sleeve (2) in a sleeved mode; a threaded end of each pressing bolt (4) is screwed in the corresponding threaded hole, and the other end of each pressing bolt (4) axially presses one end surface of the corresponding ratchet wheel rod (3) connecting part to limit axial movement of the corresponding ratchet wheel rod (3). According to the winglet device, the ratchet wheel structure is relatively small in space occupancy, lighter in weight and highly adjustable in angle.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Sickle production and processing method

InactiveCN100398258CHigh strengthAvoid deformationOther manufacturing equipments/toolsChemical treatmentBlade plate

The invention relates to a method for preparation of sickle. It contains the following steps: cutting the metallic sheet, folding the back, welding the seam, coating one face of the knife plate with a masking paste and then with chemical treatment, welding the trouser- part material with the knife plate, punching the trouser-part material to mould, whole grinding, quenching, tempering, aligning, coarse grinding, and correct grinding to prepare the product. The sickle is intense and not easy to be out of shape or to break; and the sickle can be produced by industrialization.

Owner:高百洋

Ripple type automobile thermal shield with efficient heat dissipation

PendingCN109441604AIncrease surface areaImprove cooling effectExhaust apparatusSilencing apparatusEngineering

The invention relates to the field of auto parts and discloses a ripple type automobile thermal shield with efficient heat dissipation. The ripple type automobile thermal shield comprises a first thermal shield body. A first connecting hole is formed in the first thermal shield body; a ripple type surface recessed towards the inner surface of the first thermal shield body is formed on the outer surface of the first thermal shield body; an edge folding portion uncovered by the ripple type surface is arranged on the margin of the first thermal shield body. The ripple type automobile thermal shield has the following advantages and effects that the surface of the first thermal shield body is enabled to be accidented through the arrangement of the ripple type surface positioned on the surface of the first thermal shield body, the superficial area of the first thermal shield body can be enlarged, the heat dissipation effect of the first thermal shield body can be improved, and the edge folding portion can increase the structural strength of the edge of the first thermal shield body, and thus the first thermal shield body is not prone to being deformed.

Owner:浙江正鼎汽车零部件有限公司

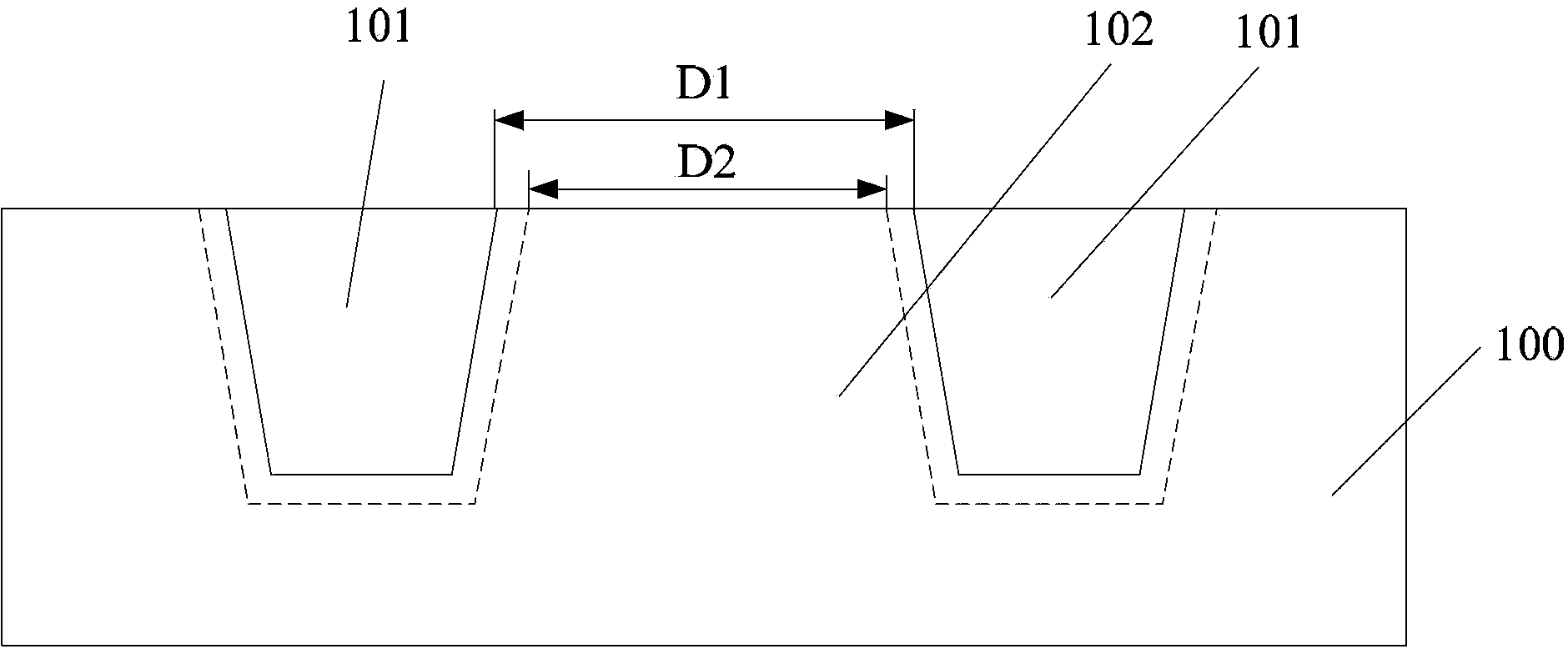

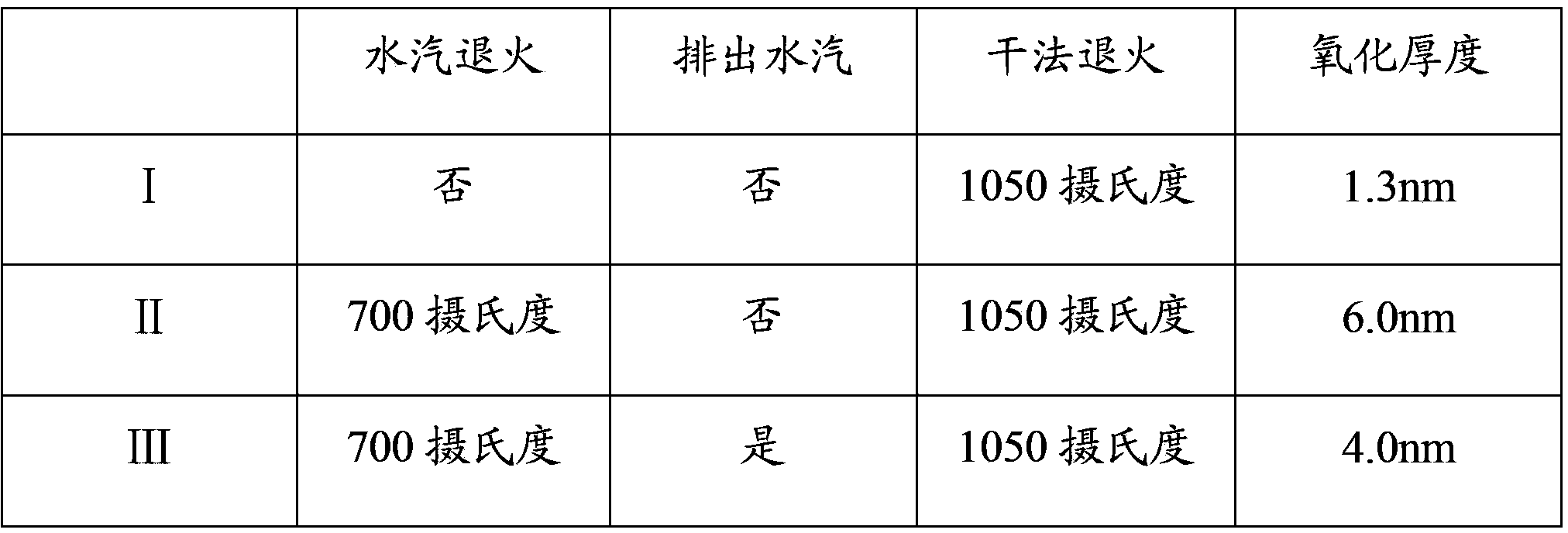

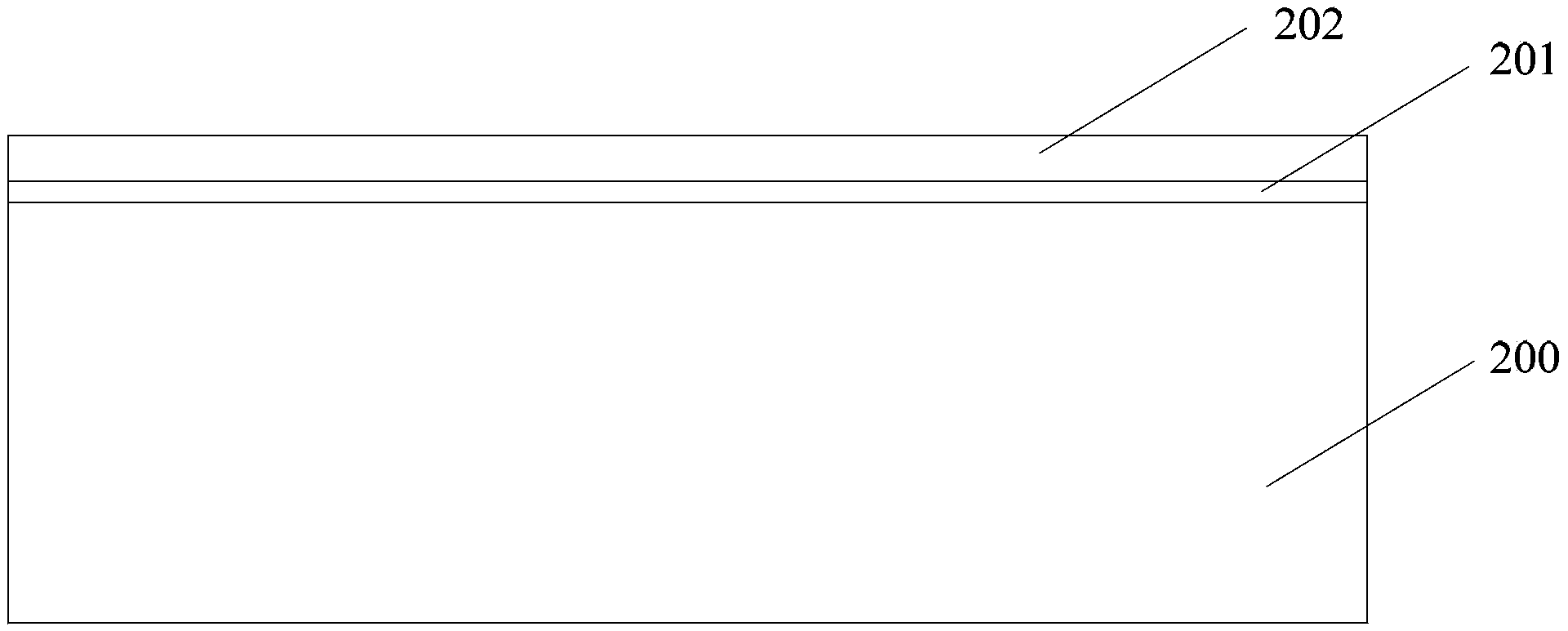

Method for forming shallow-trench isolation structure

InactiveCN103681311ANot easy to gapSmall shrinkageSemiconductor/solid-state device manufacturingLine widthWater vapor

The invention relates to a method for forming a shallow-trench isolation structure. The method comprises the following steps: providing a semiconductor substrate, and forming a trench in the semiconductor substrate; forming a liner layer in the trench, wherein the liner layer covers the side wall and the bottom of the trench; filling the whole trench, in which f the liner layer is formed, with oxides; sequentially conducting water vapor annealing, low-pressure annealing and dry annealing on the oxides; conducting planarization processing on the oxides. According to the method for forming the shallow-trench isolation structure, the line width loss of an active region is small.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Glass ceramic and preparation method thereof

The invention relates to a glass ceramic and a preparation method thereof, comprising the following raw materials by weight parts: 75-100 weight parts of quartz sands, 10-30 weight parts of lithium feldspar, 30-60 weight parts of feldspar, 25-45 weight parts of sodium carbonate, 2-8 weight parts of sodium nitrate, 2-6 weight parts of barium carbonate, 5-15 weight parts of fluorite powders, 5-10 weight parts of borax, 10-30 weight parts of sodium fluosilicate and 10-20 weight parts of calcite; the method comprises the following steps of: mixing the raw materials and sending the mixture in a glass furnace; melting the mixture as glass melt at the temperature of 1400-1600 DEG C; sending the glass melt into a material supply machine by a material supply passage; sending the glass melt into a forming machine for forming by the material supply machine; sending the formed product into an annealing furnace for annealing; subsequently inspecting the quality of the annealed product; returning the unqualified product to the raw material; and conducting the operations of applique, enamel firing and steeling to the qualified product so as to prepare the finished products. Compared with the prior art, the method has the advantages of low expansion heat-resistance performance, high hardness, being not easy to be scraped or cracked, environmental protection and the like.

Owner:JINGDEZHEN COKING IND GRP CO LTD

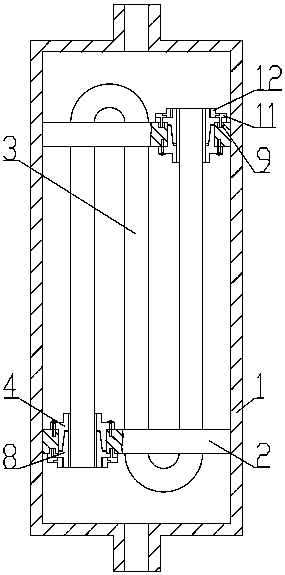

Electromagnetic induction heating boiler heat conductor

An electromagnetic induction heating boiler heat conductor comprises a heat conductor shell, separation plates, a water delivery pipe, a positioning flange, a fastening flange, a limiting ring, a limiting flange and a positioning sleeve. The interior of the heat conductor shell is connected with the separation plates, the separation plates are arranged on the two sides of the heat conductor shell,an oil storage chamber is formed between the separation plates, water storage chambers are formed between the outer sides of the separation plates and the heat conductor shell, the two sides of the water delivery pipe are connected with the separation plates, the middle of the water delivery pipe is arranged in the oil storage chamber, the water delivery pipe is wavy, water delivery openings arearranged in the two ends of the water delivery pipe and penetrate through the separation plates, the outer sides of the water delivery openings are sequentially connected with the positioning flange and the fastening flange through threads, the positioning flange is connected with the inner sides of the separation plates, the fastening flange is connected with the outer sides of the separation plates, and the positioning flange and the fastening flange are clamped on the separation plates.

Owner:TIANJIN SAIJIN ENERGY SAVING SCI & TECH CO LTD

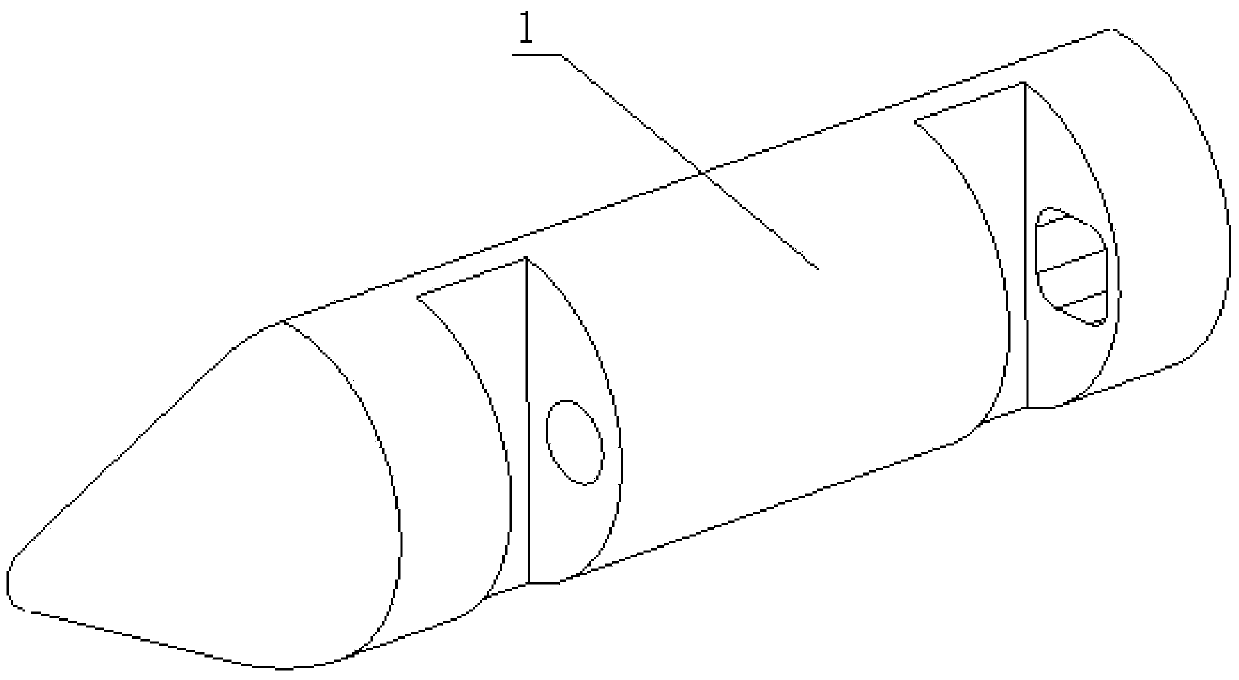

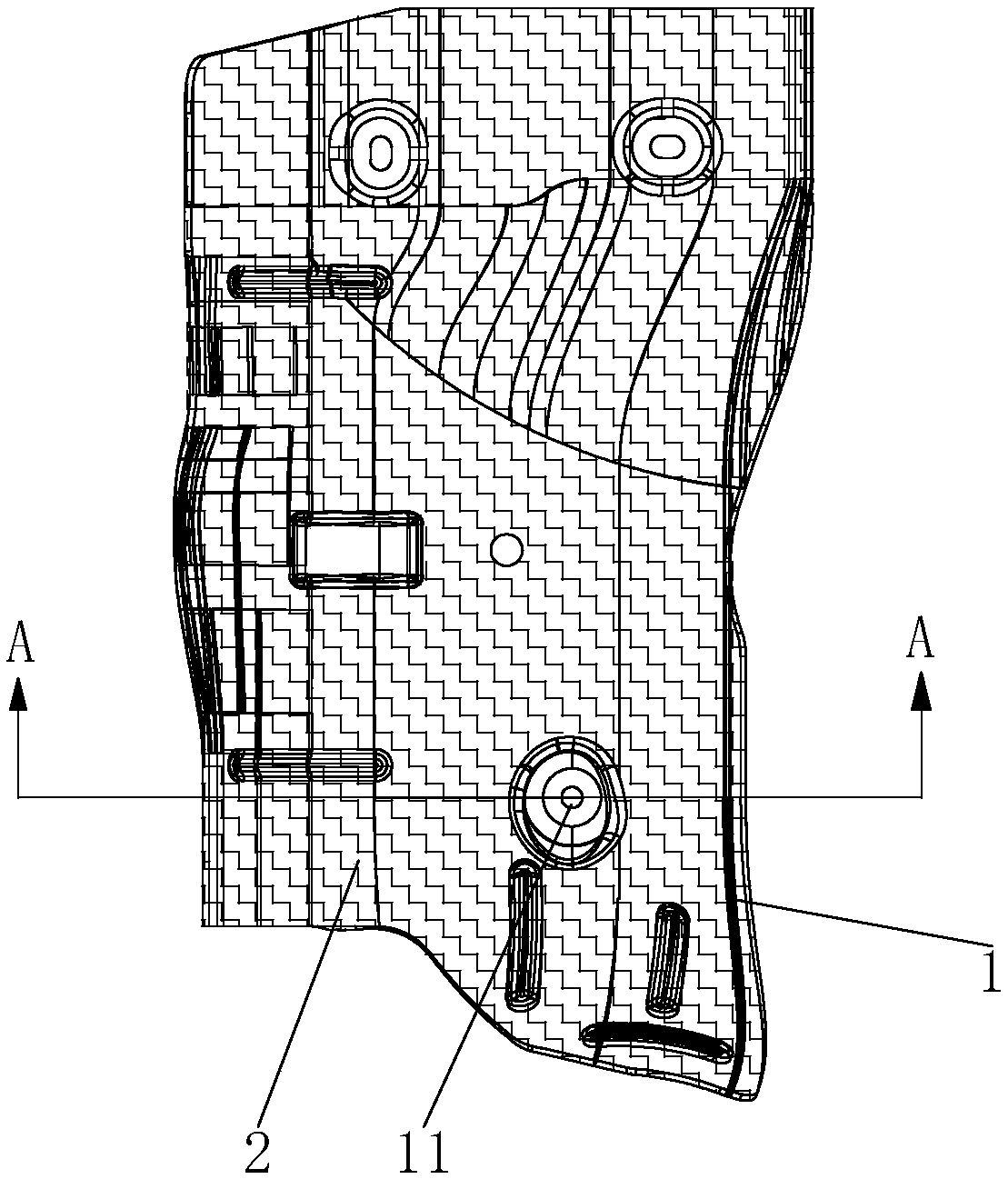

Winglet connecting device for aviation aircraft

InactiveCN109606627ASmall footprintReduce weightWing adjustmentsHeat reducing structuresAviationFlight vehicle

The invention discloses a winglet connecting device for an aviation aircraft. The device comprises a wingtip support and wingtip connecting units, wherein each wingtip connecting unit comprises an embedded block, a connecting rod and a holddown spring; the wingtip support adopts a half-cylinder body; the wingtip support is fixed on a wing end through a plane of a side part on one side of the half-cylinder body; a plurality of grooves used for mounting the wingtip connecting units are formed in a cylindrical surface on the other side of the half-cylinder body; a non-circular embedded block groove is formed in one side wall surface in a groove; a blind hole is formed in the other side wall surface in the groove; the embedded block can be clamped in the embedded block groove in a matching manner; a plurality of dividing plug sockets uniformly distributed along a circumference are formed in the outer end surface of the embedded block; one end of the connecting rod is used for being connected with a winglet; one side surface of the other end part of the connecting rod forms a plane; a plug is arranged on the other side surface of the other end part of the connecting rod; one end of thehold-down spring is positioned in the blind hole; the other end of the hold-down spring is propped against the plane on one side of the connecting rod. The device is small in occupied space and low inweight and has more adjustable angles.

Owner:CAIHONG DRONE TECH CO LTD

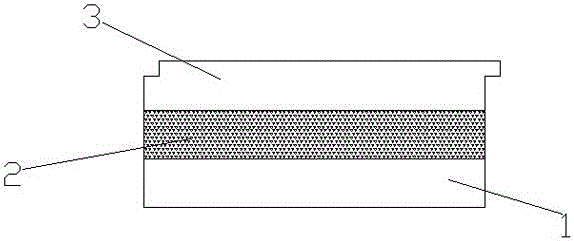

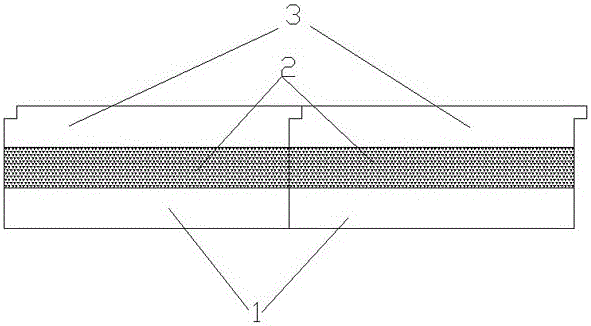

Lightweight formwork for building

InactiveCN106320694AReduce overall weightLow production costSynthetic resin layered productsConstructions elementsEngineeringSewage

The invention discloses a lightweight formwork for a building. The lightweight formwork comprises a middle layer, a lower layer and an upper layer. A plastic layer serves as the lower layer, a plastic layer serves as the upper layer, and a composite layer serves as the middle layer. The middle layer and the upper layer are glued and pressed together. The middle layer and the lower layer are glued and pressed together. A stepped groove is formed in one end of the upper layer. A protrusion table matched with the stepped groove is arranged on the other end of the upper layer. The lightweight formwork is composed of the plastic layers and the composite layer, so that the overall weight is low; through the design of the stepped groove and the matched protrusion table, the building formwork can be used in a spliced mode, the assembling efficiency is improved, gaps between formworks are not prone to occur, the defect that sewage such as mud is prone to being injected when the formwork is used is overcome, the overall intensity of the formwork is increased, and the service life of the formwork is prolonged.

Owner:张振堂

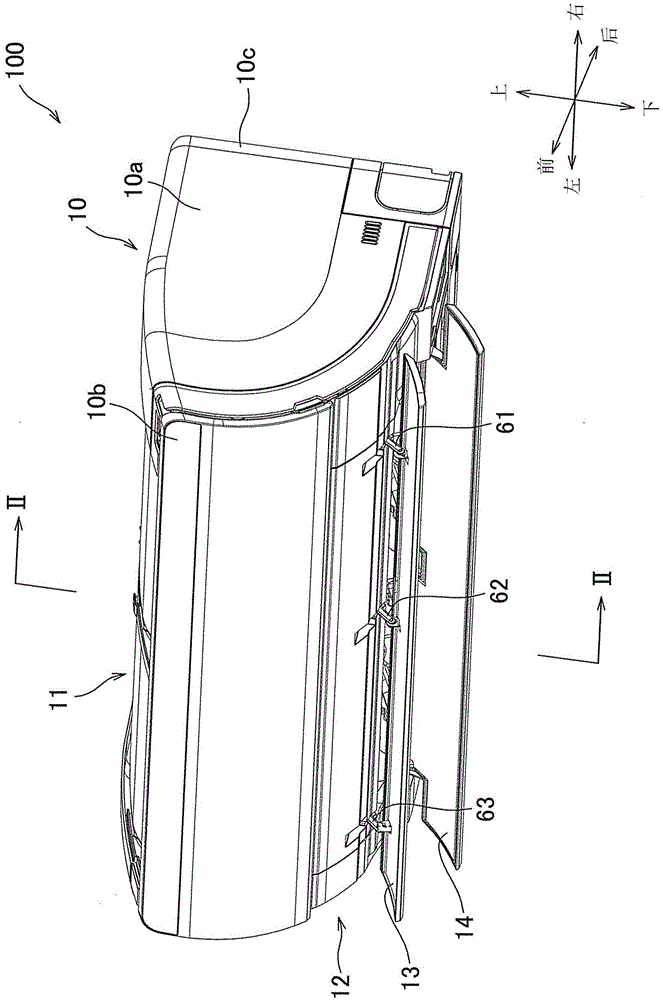

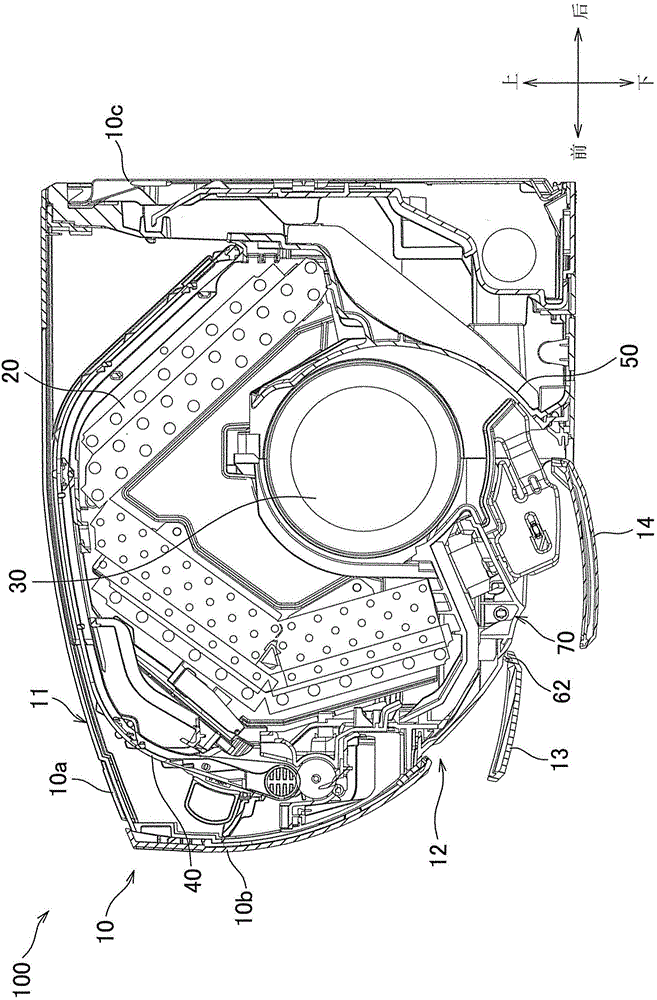

air conditioner indoor unit

Owner:DAIKIN IND LTD

rear door hinge assembly

A novel back door hinge assembly comprises a back door hinge press-fitting bolt, wherein the back door hinge press-fitting bolt penetrates in the upper surface of a back door hinge fixing seat, and is pressed in the back door hinge fixing seat; the head of the back door hinge press-fitting bolt is fixed with the upper surface of the back door hinge fixing seat in a spot welding manner; the back door hinge press-fitting bolt penetrates in a back door hinge gasket; the back door hinge gasket is adhered to the lower surface of the back door hinge fixing seat; an inclined surface of a back door hinge swinging arm is arranged on the upper surface of the back door hinge fixing seat; back door hinge anti-attrition bushes are respectively arranged on two sides of the back door hinge fixing seat; a back door hinge connecting shaft sequentially penetrates in the back door hinge anti-attrition bushes with the symmetric structures, the back door hinge fixing seat and the back door hinge swinging arm and then is fixed in a riveted manner; the back door hinge anti-attrition bushes are made of powder metallurgy anti-attrition materials; the wall thickness of the back door hinge anti-attrition bushes is 2mm; and the back door hinge gasket is made of an asbestos-free material. The novel back door hinge assembly is reasonable in structure, and is beneficial to adjustment on gaps of a door of a vehicle and water leakage prevention. Moreover, the novel back door hinge assembly is applicable to a minibus.

Owner:JIANGSU HAORI AUTO PARTS

Flaky inorganic filler heavy-duty anti-corrosion epoxy composite coating with multi-layer structure

InactiveCN113637390AImprove surface reactivityIncrease elasticityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceCrazing

The invention discloses a flaky inorganic filler heavy-duty anti-corrosion epoxy composite coating with a multi-layer structure, and relates to the technical field of anti-corrosion coatings. The heavy-duty anti-corrosion epoxy composite coating is prepared from a component A and a component B according to a mass ratio of 3:(1.0-1.4). The component A is prepared from the following raw materials in parts by weight: 55 to 68 parts of bisphenol A type epoxy resin E44, 23 to 29 parts of butyl glycidyl ether, 0.5 to 0.8 part of graphene, 6 to 15 parts of flaky inorganic filler, 2 to 6 parts of aerogel nano powder and 0.35 to 0.55 part of a de-foaming agent. The component B is a T31 curing agent. According to the invention, the sheet-shaped inorganic filler and the aerogel nanopowder are added into the epoxy resin, and the flaky inorganic filler and the aerogel nanopowder can coexist in the epoxy resin and can be laid layer by layer in the epoxy resin to form a compact elastic barrier, thus the external stress resistance of the epoxy composite coating is improved, and the coating does not easily generate gaps or cracks, so that the structural integrity of the coating can be maintained, and the epoxy resin has excellent corrosion resistance.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

Connector housing

ActiveUS20170162983A1Avoid damageAvoid enteringCoupling device detailsMechanical engineeringEngineering

Owner:YAZAKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com