Lightweight formwork for building

A constructional, lightweight technology, applied in building elements, synthetic resin layered products, layered products, etc., can solve problems such as environmental pollution, waste of resources, etc., and achieve the effects of reducing production costs, saving construction periods, and quick installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail below by embodiment, and embodiment is only used for illustrating the present invention, does not limit the scope of the present invention.

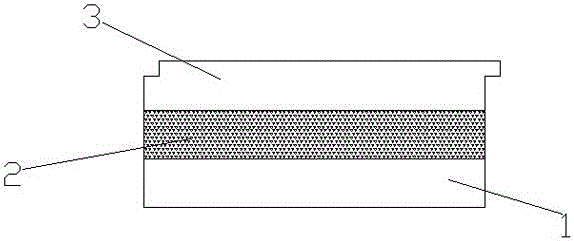

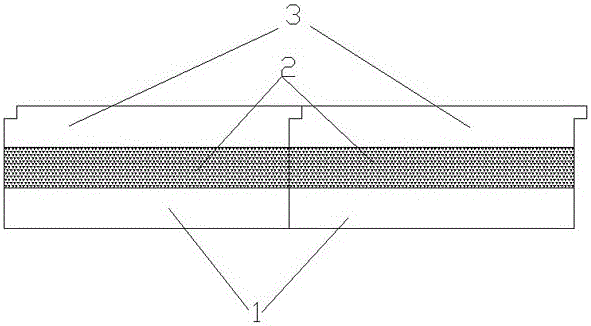

[0013] Such as figure 1 , 2 A light formwork for construction is shown, comprising a middle layer 2, a lower layer 1 and an upper layer 3, the lower layer 1 is a plastic layer, the upper layer 3 is a plastic layer, the middle layer 2 is a composite layer, the middle layer 2 and the upper layer 3 are pressed on the Together, the middle layer 2 and the lower layer 1 are pressed together by gluing, one end of the upper layer 3 is provided with a stepped groove 4 , and the other end of the upper layer 3 is provided with a raised platform 5 matching the stepped groove 4 .

[0014] The lower 1 plastic layer is made of PP or PE, and the upper 3 plastic layers are made of PP or PE.

[0015] The composite layer of the middle layer 2 is formed by pressing rice husk or crop straw powder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com