Flat coil flat insulated electric wire and manufacturing method for same

A technology of an insulated wire and a manufacturing method, which is applied in the directions of insulated cables, insulated conductors, and conductor/cable insulation, etc., can solve the problems of lower insulation of the outer peripheral side of the curl and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

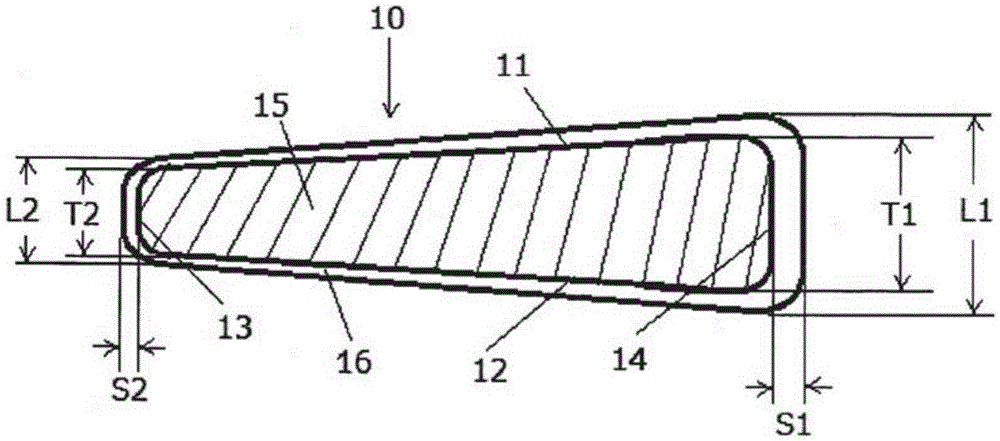

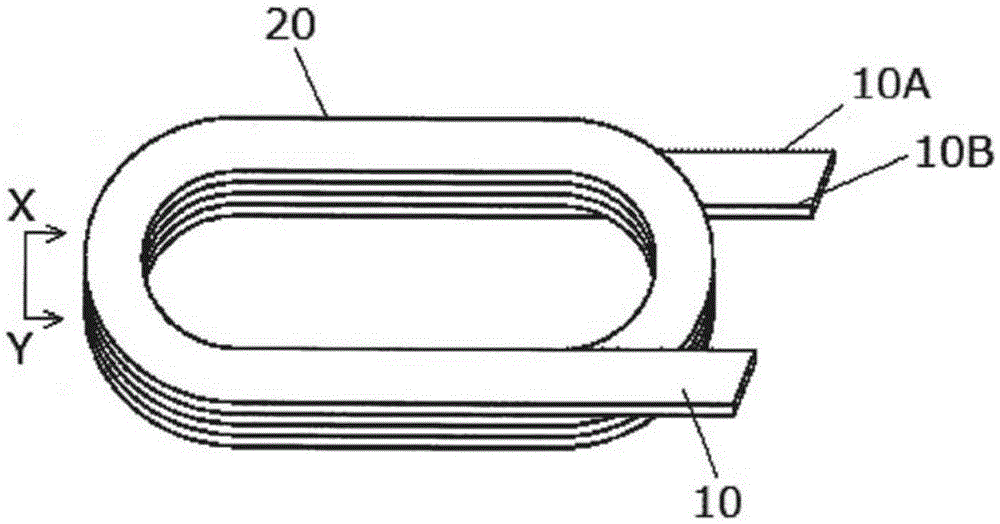

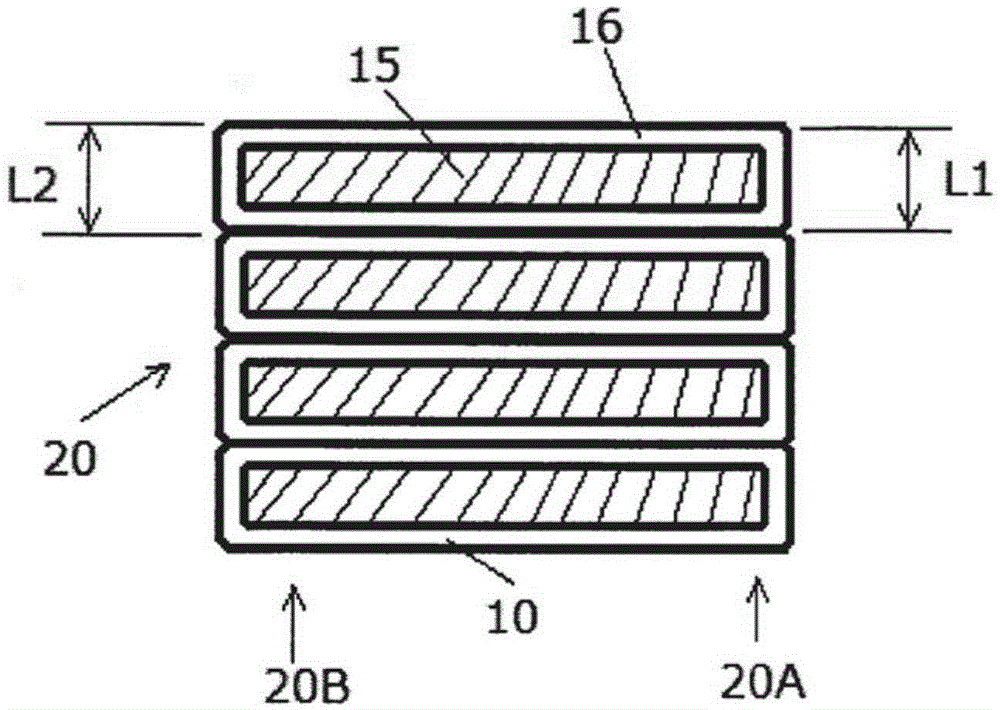

[0043] An example of the flat insulated wire 10 of this embodiment is shown in figure 1 . An example of an edgewise coil 20 using this flat insulated wire 10 is shown in figure 2 . When looking down, figure 2 The edgewise coil 20 is an example of a racetrack shape in which both ends of a pair of linear portions are connected by semicircular portions. The shape of the edgewise coil 20 using the flat insulated wire 10 of this embodiment is not limited to figure 2 shape. These are edge-to-edge coils of various curled shapes, such as a rectangular shape with four corners curled into a circular arc or a circular shape when viewed from above.

[0044] Such as figure 1 As shown, the thickness L1 of one side of the flat insulated wire 10 of this embodiment is formed thicker than the thickness L2 of the other side, as shown in FIG. figure 2 As shown, the flat insulated wire 10 is wound (curled) upright with the thicker side as a curled outer peripheral portion 10A and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com