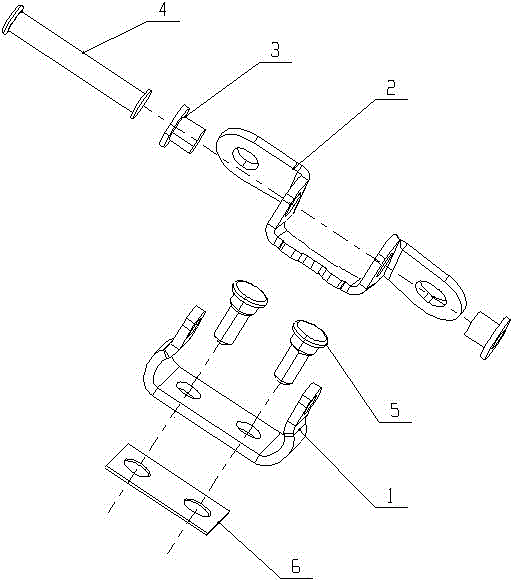

rear door hinge assembly

A back door and hinge technology, applied in door/window fittings, hinged panels, buildings, etc., can solve problems such as increasing the workload of assembly workers for debugging, uneven clearance between the back door and the side wall, and affecting the normal use of the back door. Good strength, good anti-rotation torque, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings:

[0009] The rear door hinge assembly includes a rear door hinge fixing seat 1 and a rear door hinge press-fit bolt 5, characterized in that: the rear door hinge press-fit bolt 5 passes through the upper surface of the rear door hinge fixing seat 1 and is pressed into the rear door hinge fixing seat 1 ; The rear door hinge press-fit bolt 5 passes through the rear door hinge gasket 6, and the rear door hinge gasket 6 is pasted on the lower surface of the rear door hinge fixing seat 1; The inclined surface of the rear door hinge swing arm 2 is set on the upper surface of the rear door hinge fixing seat 1, and the rear door The rear door hinge wear-reducing bushings 3 are respectively provided on both sides of the hinge fixing seat 1, and the rear door hinge connecting shaft 4 passes through the rear door hinge wear-reducing bushings 3, the rear door hinge fixing seat 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com