Waterproof slide fastener

A waterproof and zipper technology, applied in the direction of sliding fastener components, applications, fasteners, etc., can solve the problems of infiltration, increase the manufacturing cost, reduce the softness of the waterproof belt 82, etc., to prevent water infiltration and simplify the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

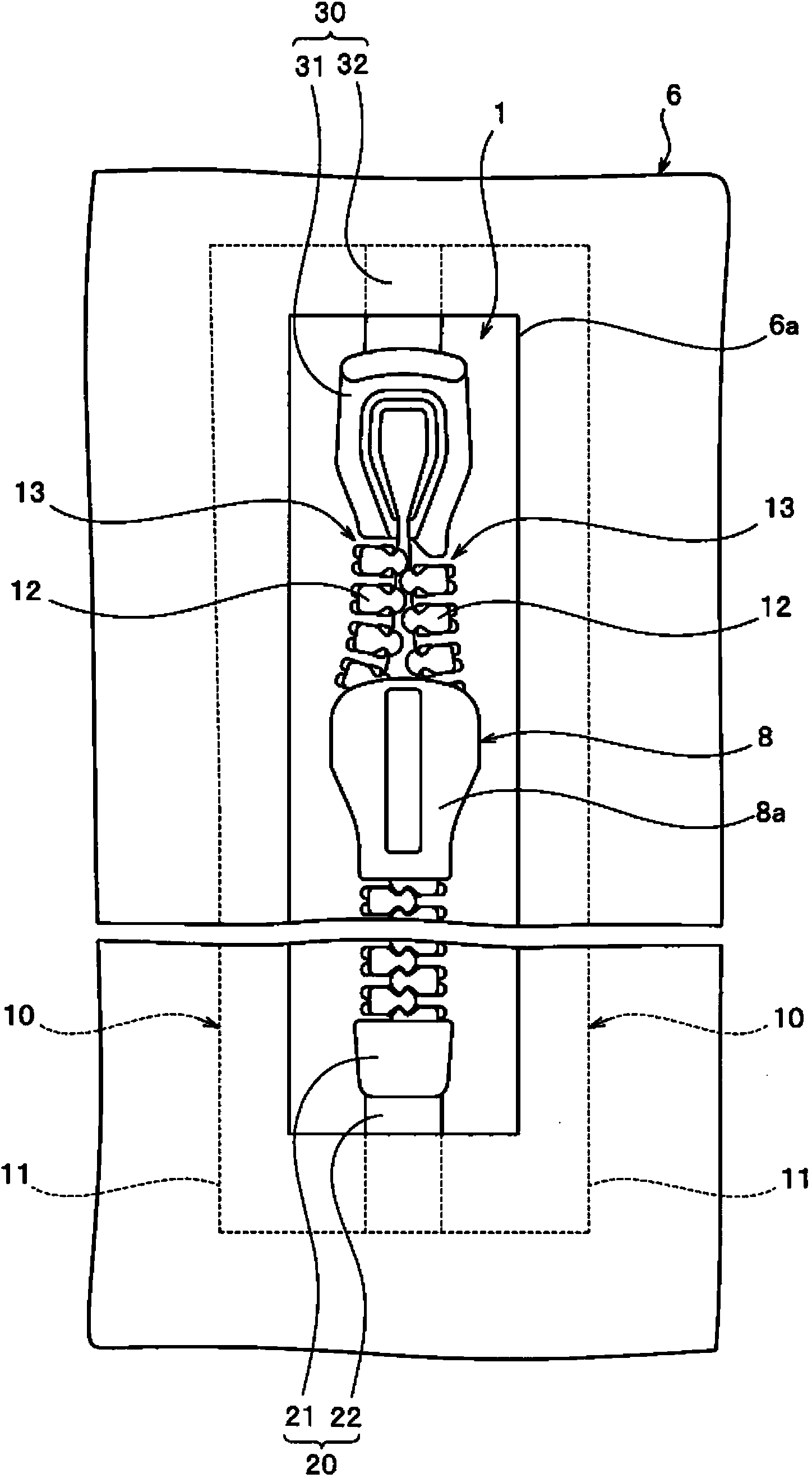

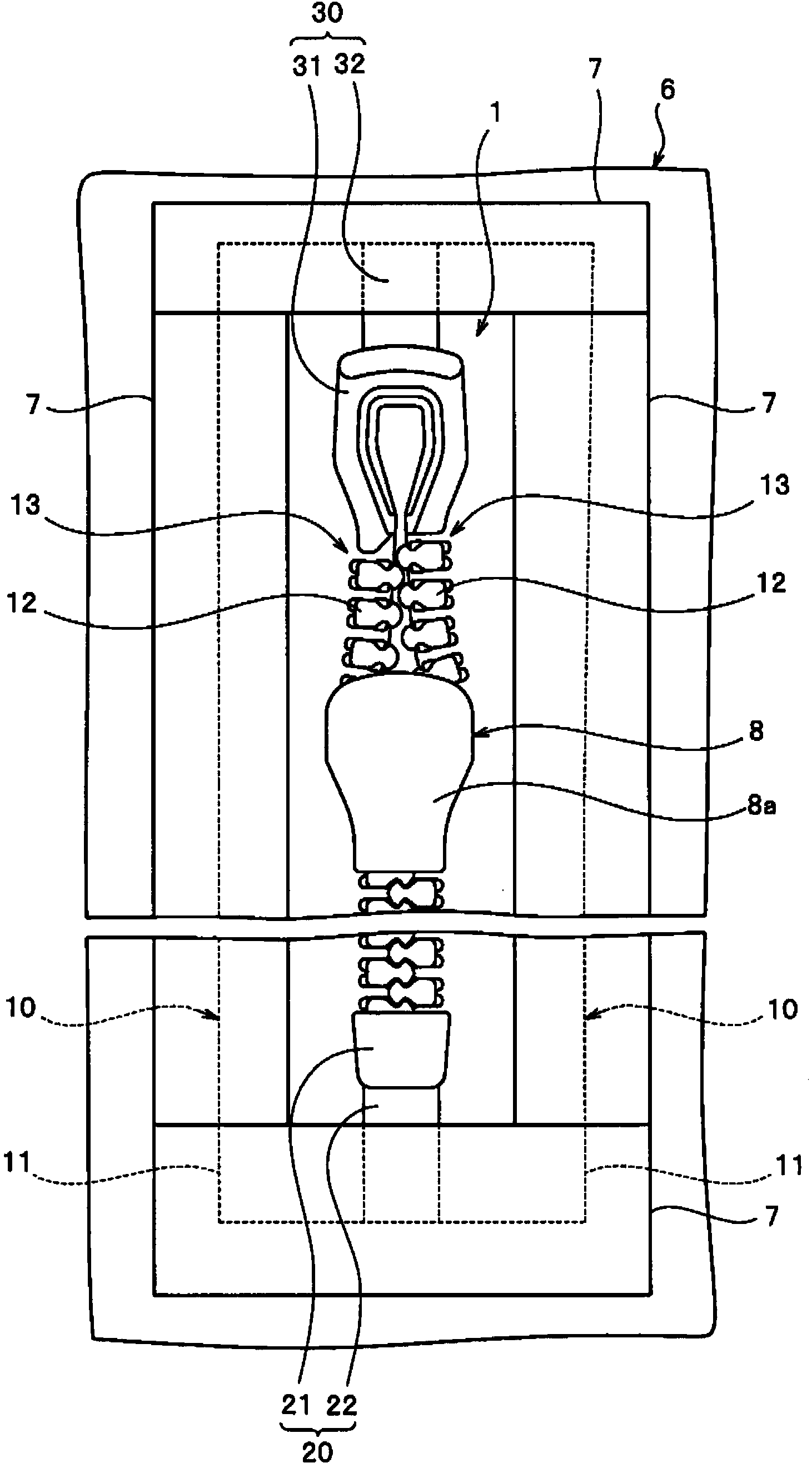

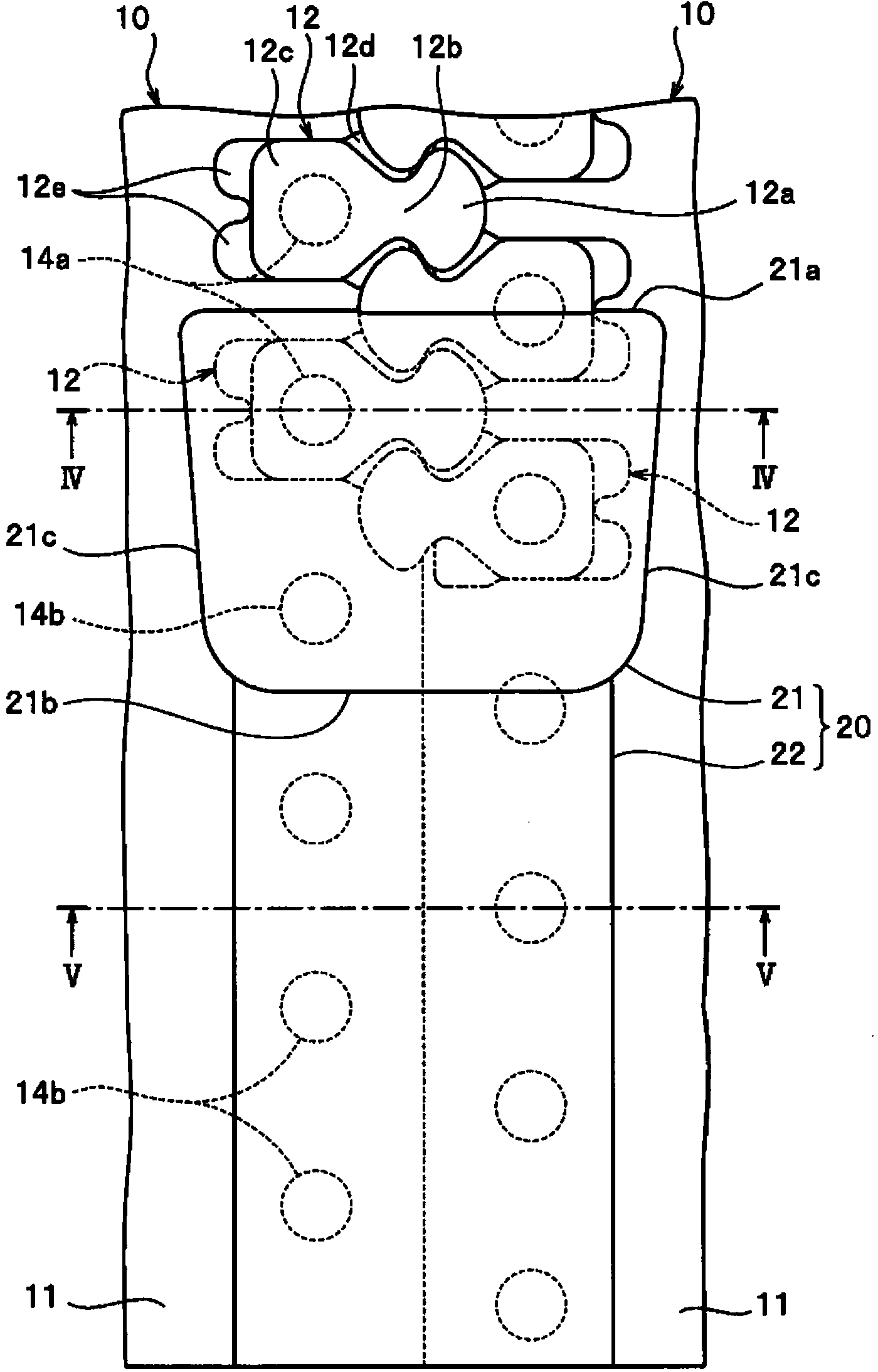

[0077] figure 1 It is the front view which shows the waterproof slide fastener of this Example 1, figure 2 yes figure 1 Rear view of waterproof zipper. also, image 3 yes means figure 1 An enlarged view of the main part of the first stopper of the waterproof zipper, Figure 6 yes means figure 1 An enlarged view of the main part of the second stopper of the waterproof zipper.

[0078] Such as figure 1 As shown, the waterproof slide fastener 1 of this Example 1 is attached to the opening and closing part or the opening part 6a of the slide fastener attachment product 6, such as a diving suit. This waterproof slide fastener 1 has such waterproofness that liquid such as water does not leak from the outside of the slide fastener installation product 6 to the inside of the slide fastener installation product 6 (or from the inside to the outside) from the outside of the slide fastener installation product 6 when the waterproof slide fastener 1 is closed. .

[0079] In ...

Embodiment 2

[0130] Figure 7 It is an enlarged view of main parts showing main parts of the waterproof slide fastener of the present Example 2.

[0131] In addition, in this embodiment 2 and the embodiment 3 and embodiment 4 described later, the form of the first stopper is different from the above-mentioned embodiment 1, and the form of the waterproof slide fastener is different from that of the first stopper. The external structure is the same as that of the aforementioned embodiment 1.

[0132] The first stopper 40 of the waterproof slide fastener 2 according to the second embodiment has a first stopper main body 41 and a bottom protruding from the first stopper main body 41 so as to straddle the left and right waterproof tapes 11 . The first extension part 42 . In addition, the first stopper body part 41 and the first extension part 42 each have a first half part arranged on the front side of the belt and a second half part arranged on the back side of the belt, and these first half...

Embodiment 3

[0138] Figure 8 It is a front view showing a part of the waterproof slide fastener of the present Example 3, Figure 9 It is an enlarged view of the main part of this waterproof zipper.

[0139] The first stopper 50 of the waterproof slide fastener 3 according to the third embodiment has a first stopper main body 51 and a bottom protruding from the first stopper main body 51 so as to straddle the left and right waterproof belts 11 . The first extension part 52 . In this case, a concave portion 56 is formed that is recessed from the upper bottom portion 51a of the first half and the second half of the first stopper body portion 51 toward the direction (downward) in which the first extension portion 52 protrudes. . The concave portion 56 of the first stopper main body 51 is formed by a protruding portion protruding from the cavity surface side of the mold to prevent leakage of the molding material during injection molding of the first stopper 50 .

[0140] Specifically, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com