Making method of concave and convex surface of water sports skateboard

A production method and water sports technology, applied to motor vehicles, transportation and packaging, special-purpose ships, etc., can solve problems such as complex processes and insufficient firmness of surfboards, and achieve simple processes, excellent waterproof performance, and good use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

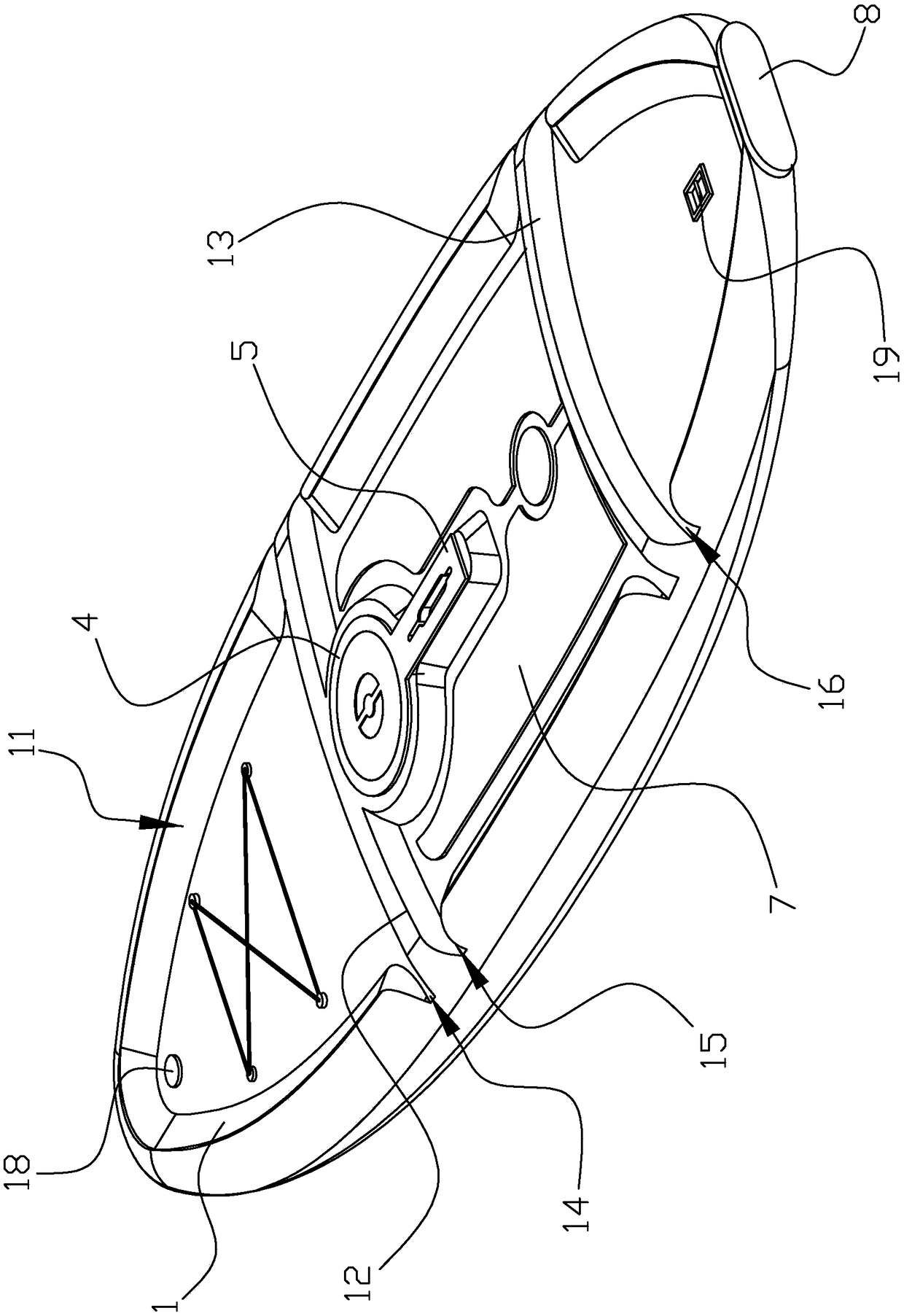

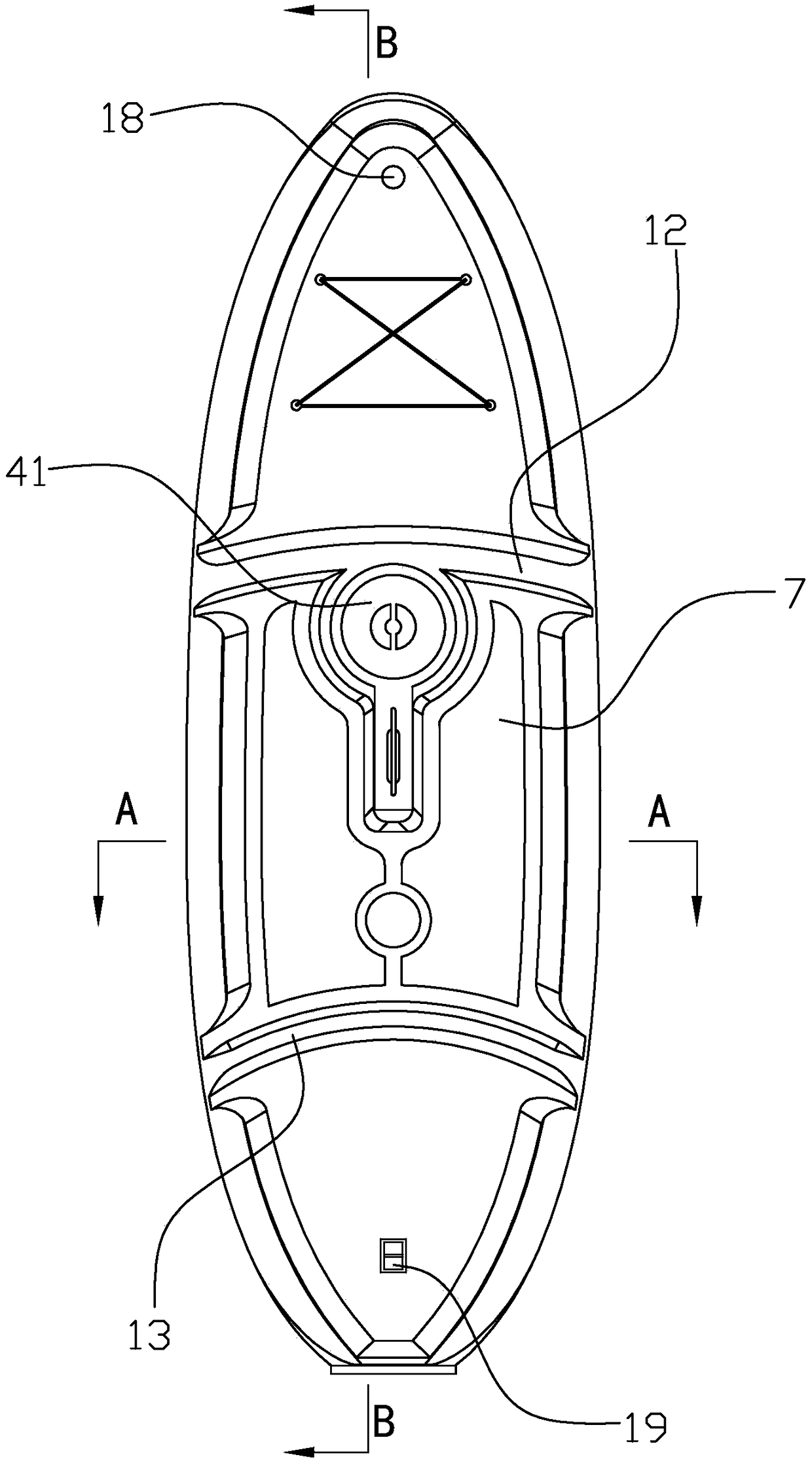

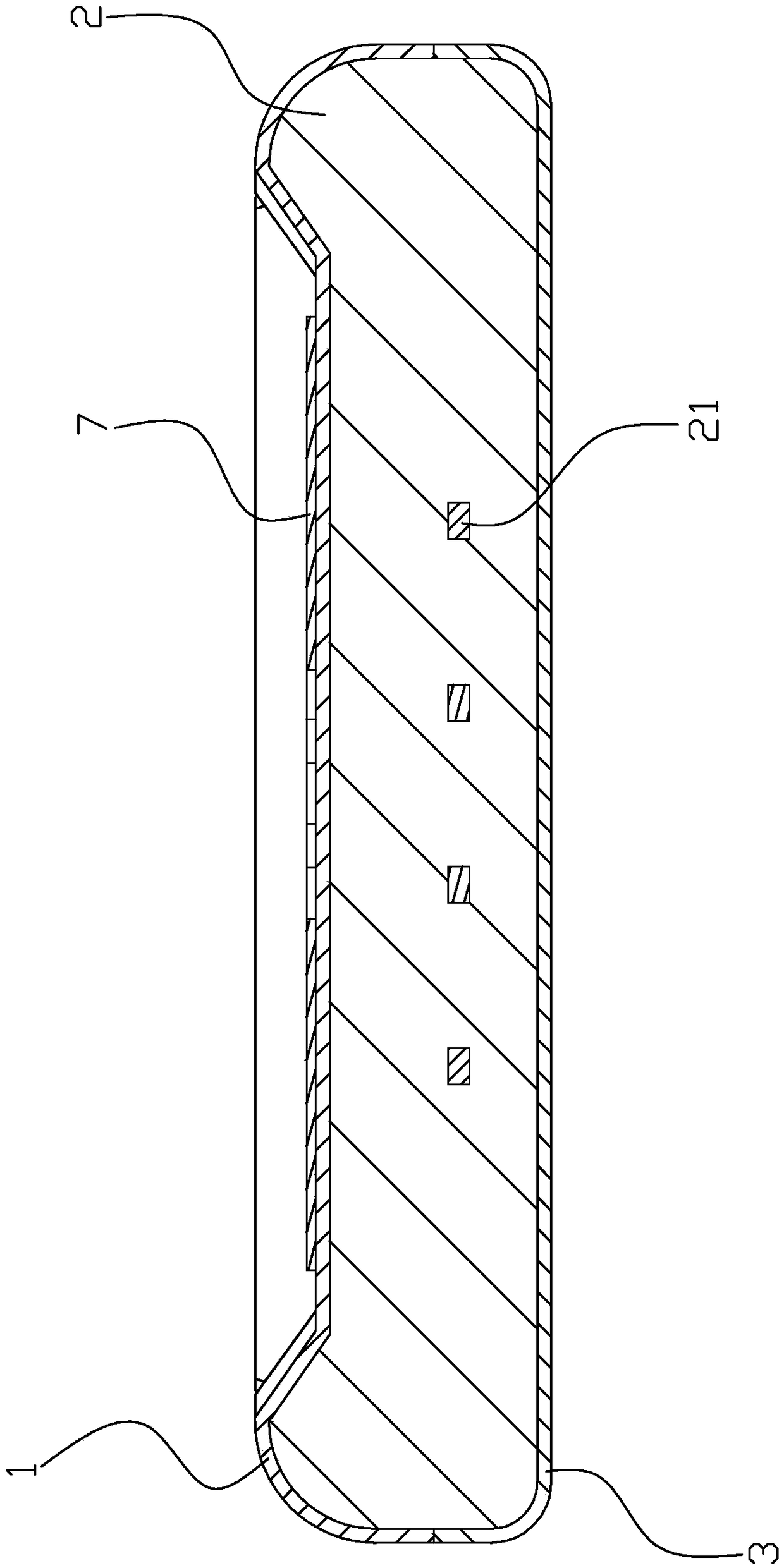

[0030] Such as Figure 1 to Figure 8 As shown, the manufacturing method of the water sports skateboard of the present embodiment includes the following steps:

[0031] 1. Panel manufacturing steps, core board manufacturing steps, and base plate manufacturing steps;

[0032] Wherein, the manufacturing step of the core board is: put the polystyrene particles for foaming into the foaming mold, the foaming temperature in the foaming mold is 95-110°C, and the foaming time is 3-5 minutes After cooling, the foam core board 2 with the concave-convex surface 11 at the top is taken out according to the design requirements, and a drainage gap is formed on the top of the foam core board 2 with the concave-convex surface 11, and the foam core board 2 is heated at a temperature of 50-60°C Intermediate drying for 24 to 36 hours, trimming the dried foam cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com