Sickle production and processing method

A processing method and technology of sickle, applied in the field of processing sickle, can solve the problems of short service life, low strength, difficult grinding, etc., and achieve the effects of stable and reliable quality, long service life and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

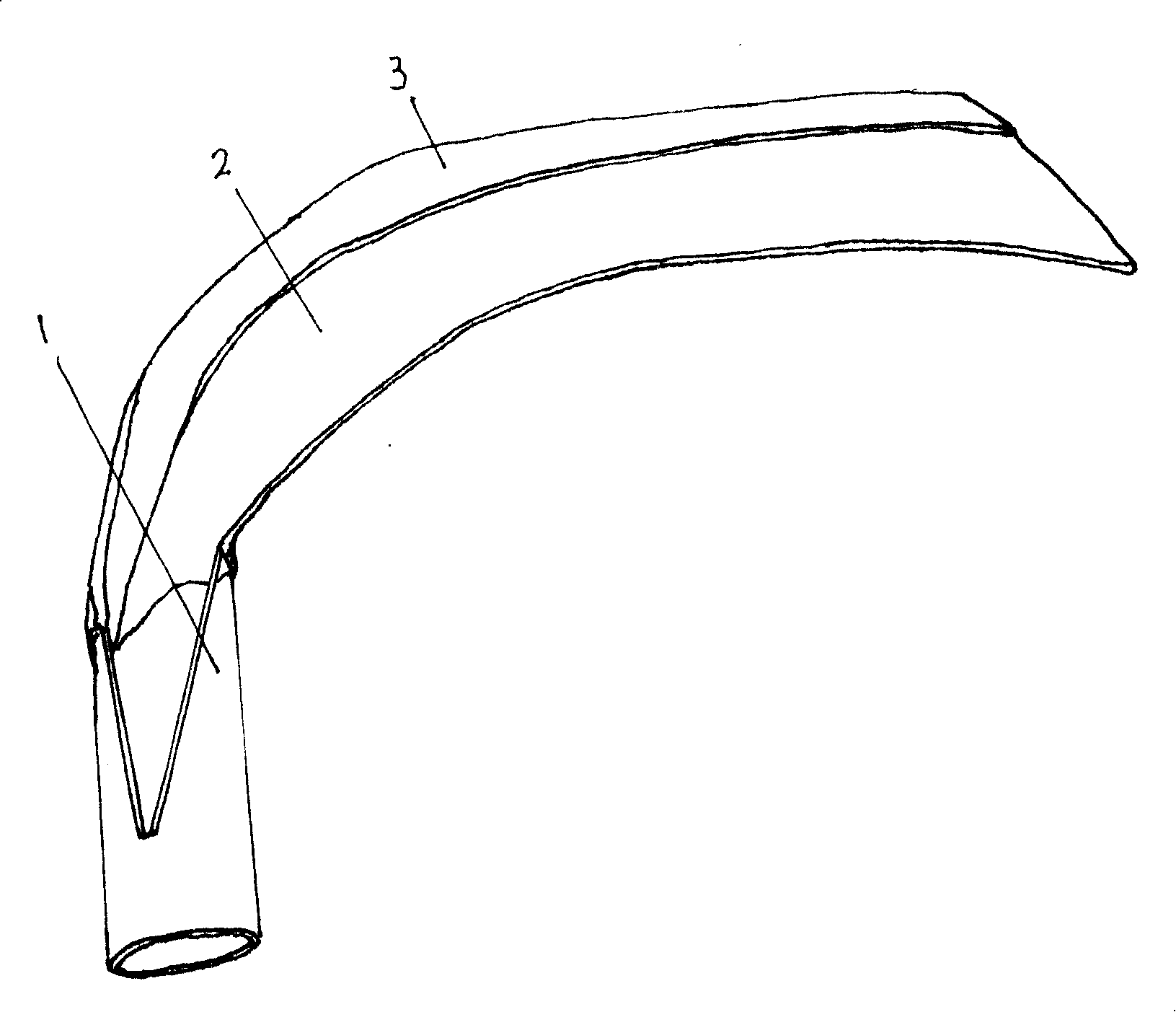

[0013] The following steps of the present invention are as follows: the metal sheet is blanked into the shape of a knife plate, the back of the knife plate is folded, the folded joint is welded, one side of the knife plate is coated with an anti-carburizing paint, and then chemically treated, the knife plate and the trousers are welded together, The trousers are stamped and formed, ground, quenched, tempered, straightened, coarsely ground, and finely ground into products.

[0014] With reference to the accompanying drawings, the present invention first blanks the metal sheet into a knife plate shape, folds a small part of the back of the knife plate, and then welds the folded joints, and the knife plate 2, the folding head 3 and the knife trousers 1 are welded together. Because a small part of the back of the knife board is folded, the folded seam gradually becomes thinner from the root to the head, which increases the overall strength of the knife board, especially the root, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com