Method for forming shallow-trench isolation structure

A technology of isolation structure and shallow trench, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of line width loss in the active area, achieve small loss of line width, reduce water vapor diffusion rate, and reduce oxidation Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

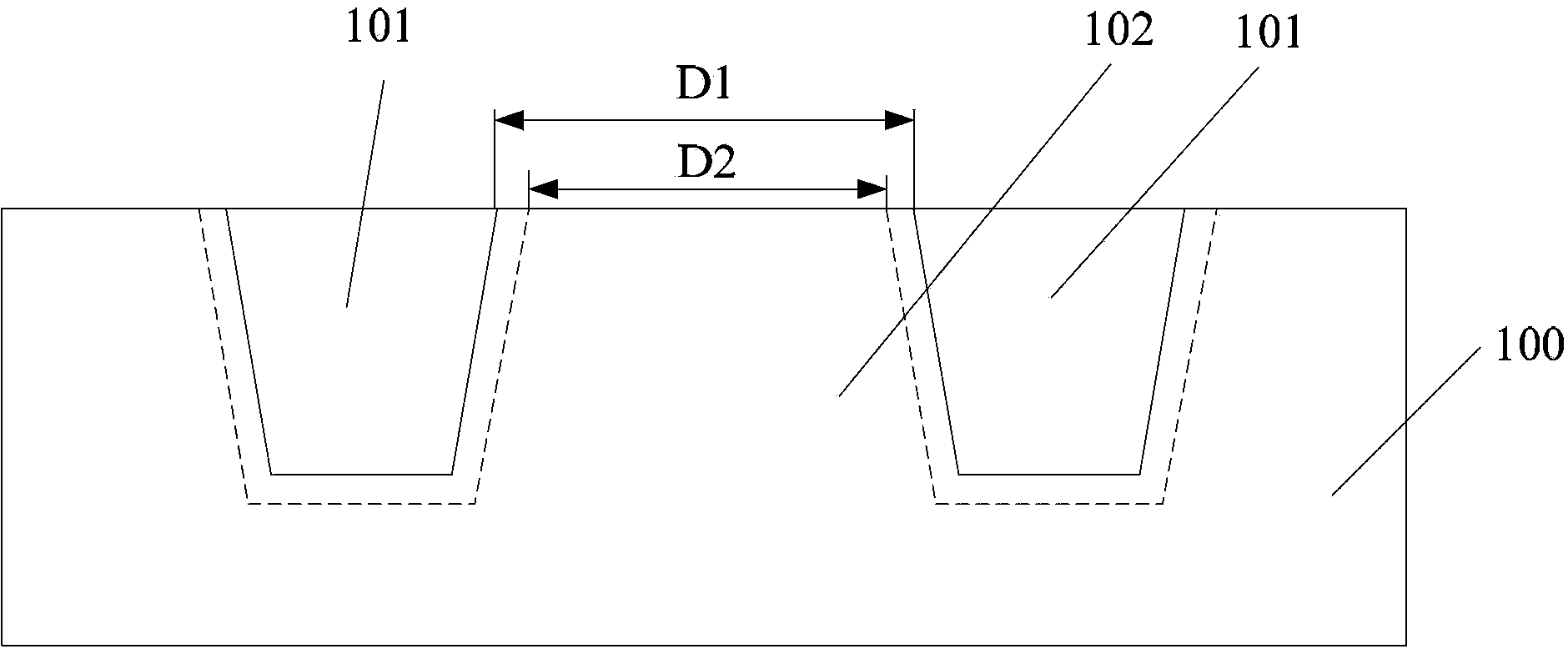

[0025] Known from the background technology, please continue to refer to figure 1 , in the prior art, after the shallow trench isolation structure 101 is treated with water vapor annealing, since water vapor can diffuse to reach Si / SiO 2 Interface, under high temperature, water vapor in Si / SiO 2 The surface will undergo an oxidation reaction with Si, resulting in the loss of the line width of the active region 102 , and the line width of the active region 102 is reduced from D1 before annealing to D2 after annealing, which affects the subsequent fabrication of devices in the active region 102 .

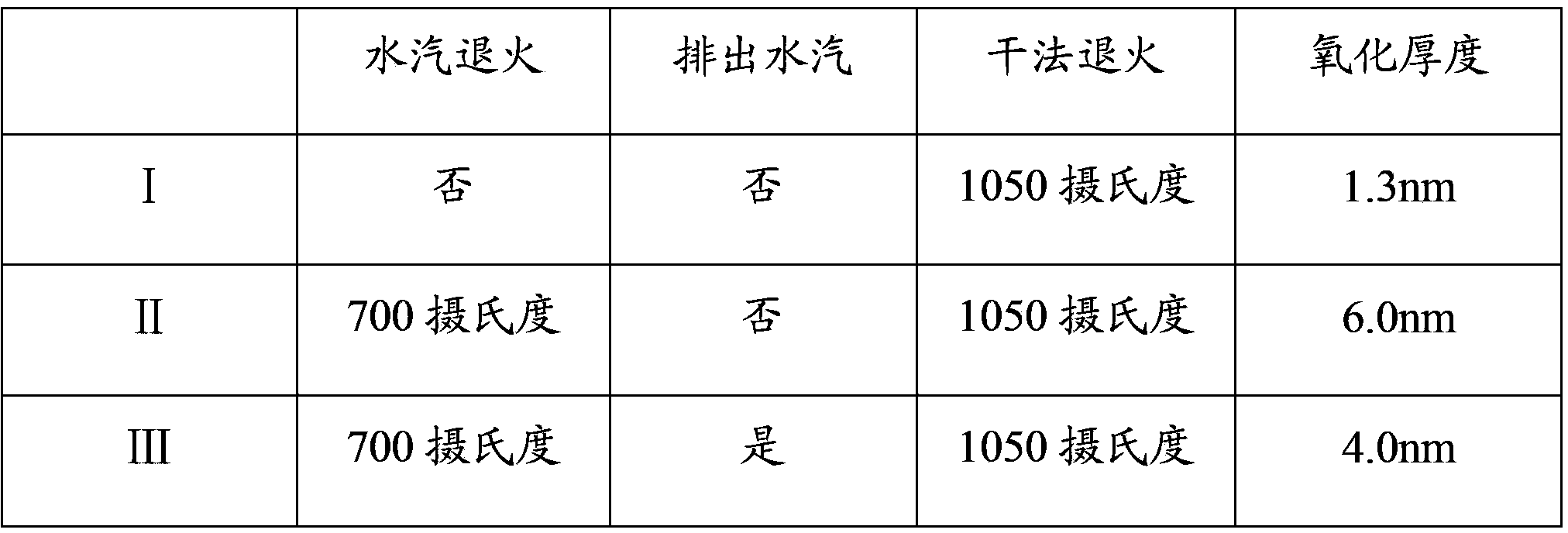

[0026] The inventors of the present invention designed three groups of comparative experiments to study the oxidation thickness of silicon material by annealing process under different annealing process conditions in the same annealing device. Please refer to figure 2 , Experiment Ⅰ used only dry annealing; Experiment Ⅱ used water vapor annealing first and then dry annealing; Exper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com