Ripple type automobile thermal shield with efficient heat dissipation

A heat shield, corrugated technology, applied in the field of auto parts, can solve the problems of poor heat dissipation effect of heat shield, influence heat insulation effect, heat dissipation of heat shield, etc., to improve heat dissipation effect, not easy to deform, avoid The effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

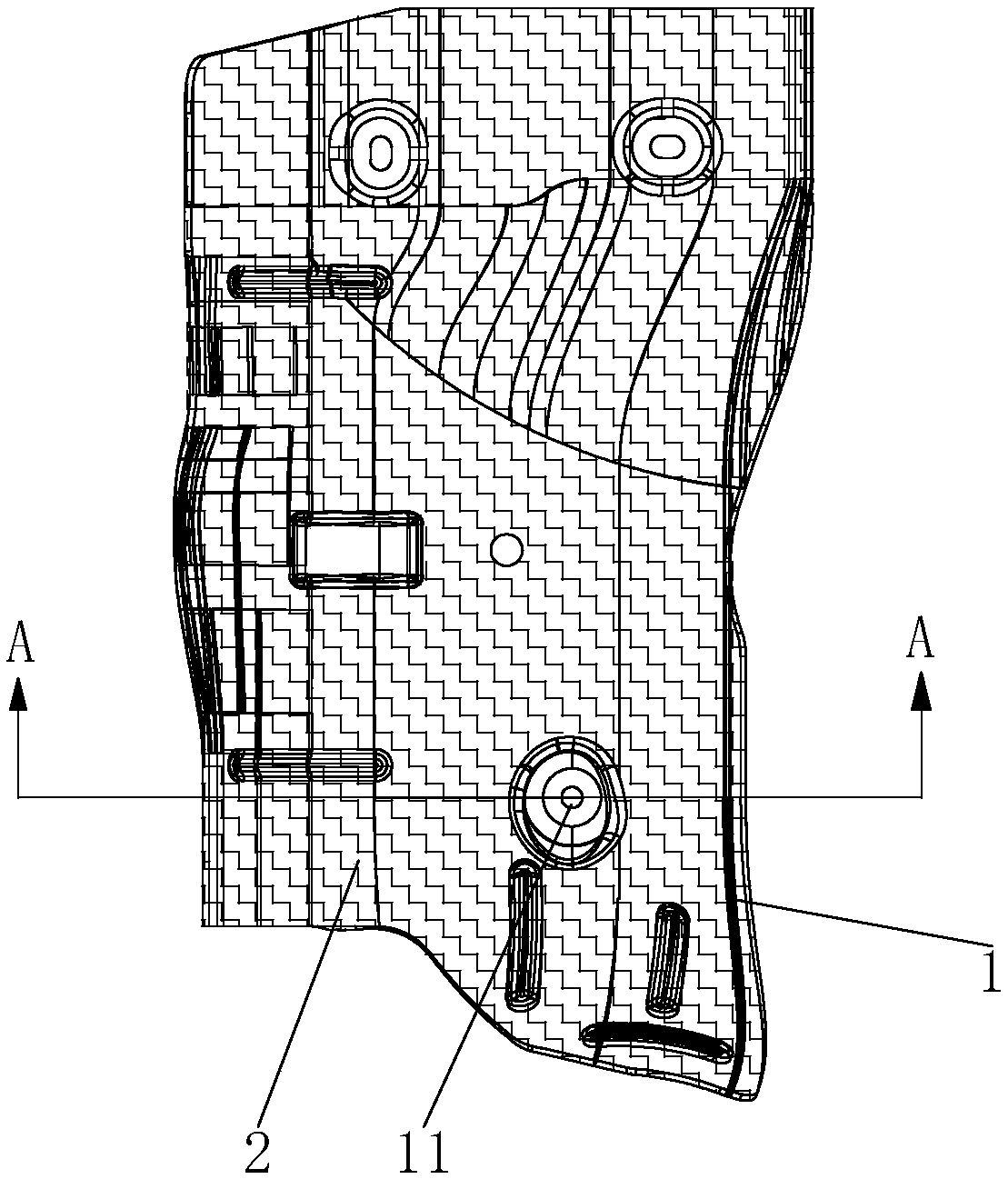

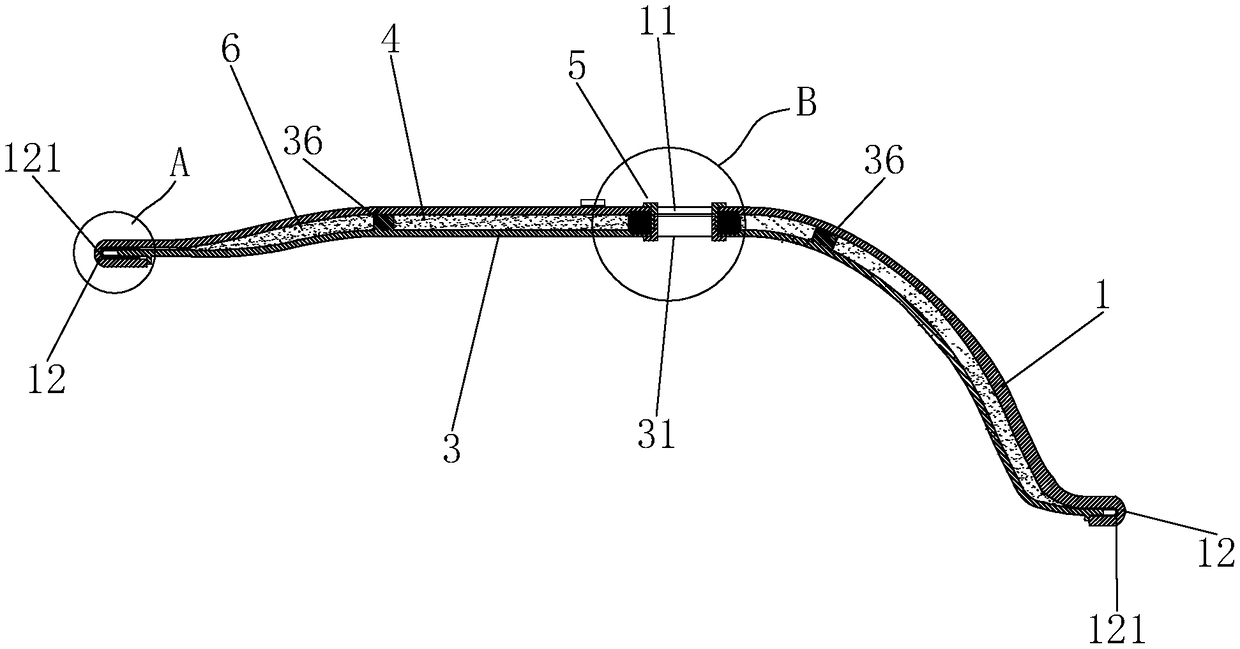

[0031] Embodiment 1: A corrugated automobile heat shield with high efficiency heat dissipation, such as figure 1 and figure 2 As shown, the first heat insulation cover body 1 is included, the first heat insulation cover body 1 is provided with a first connection hole 11, and the outer surface of the first heat insulation cover body 1 is formed with a Concave corrugated surface 2, the edge of the first heat insulation cover 1 is provided with a hemming part 12 not covered by the corrugated surface 2, and the hemming part 12 is bent downward and forms a "U"-shaped embedded groove 121.

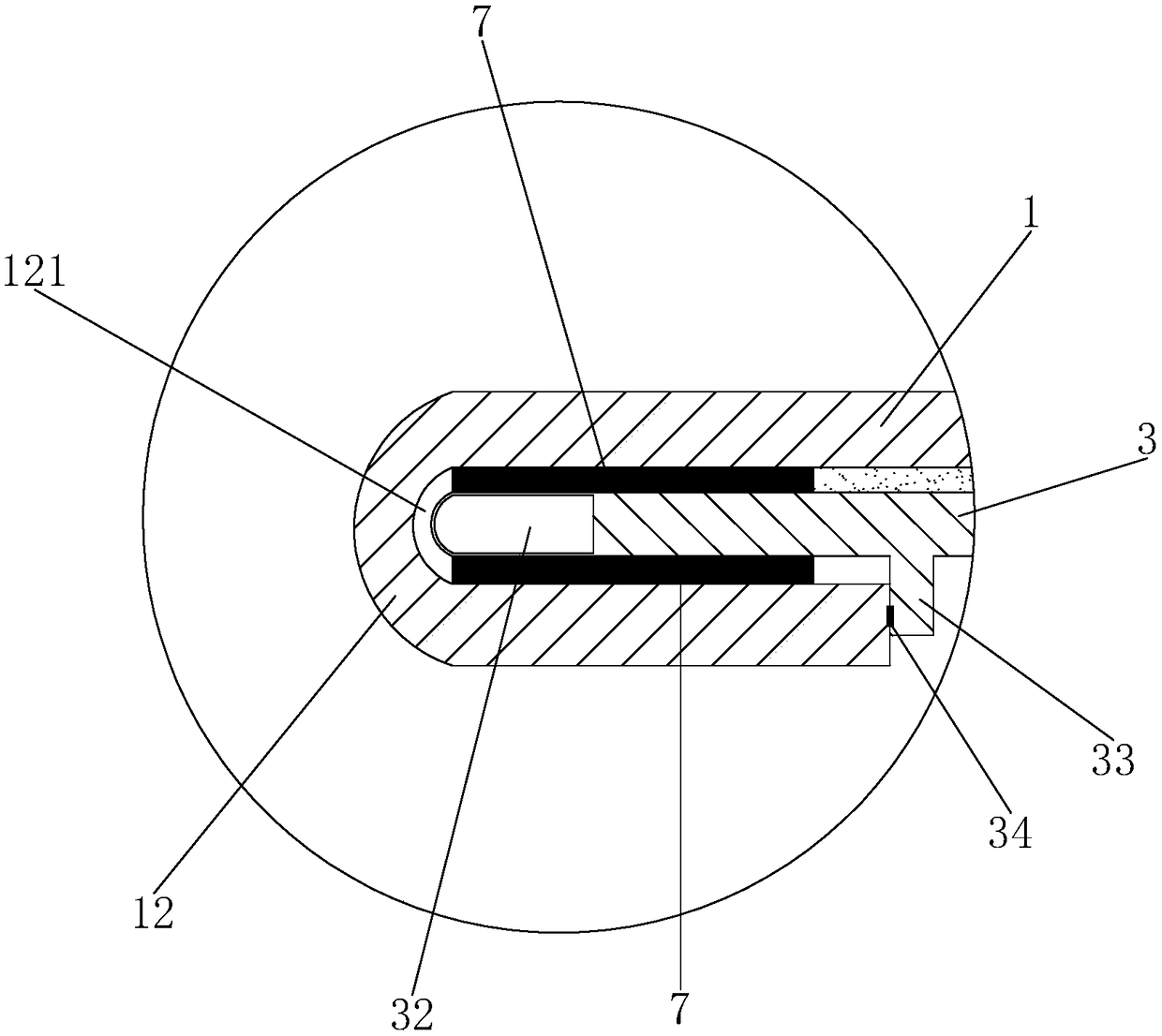

[0032] Such as Figure 2 to Figure 4 As shown, it also includes a second heat insulation cover 3 spaced from the lower surface of the first heat insulation cover 1 , and a second connection hole 31 corresponding to the first connection hole 11 is opened on the second heat insulation cover 3 . The edge of the second heat-insulating cover 3 is connected to the hem portion 12 of the first heat-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com