Bottle stopper

A technology of bottle stopper and stopper body, applied in the field of bottle stopper, can solve the problems of flow out of content, difficult to hold and apply force, and bottle body toppling, etc., and achieve the effects of good tightness, convenient storage and arrangement, and convenient holding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

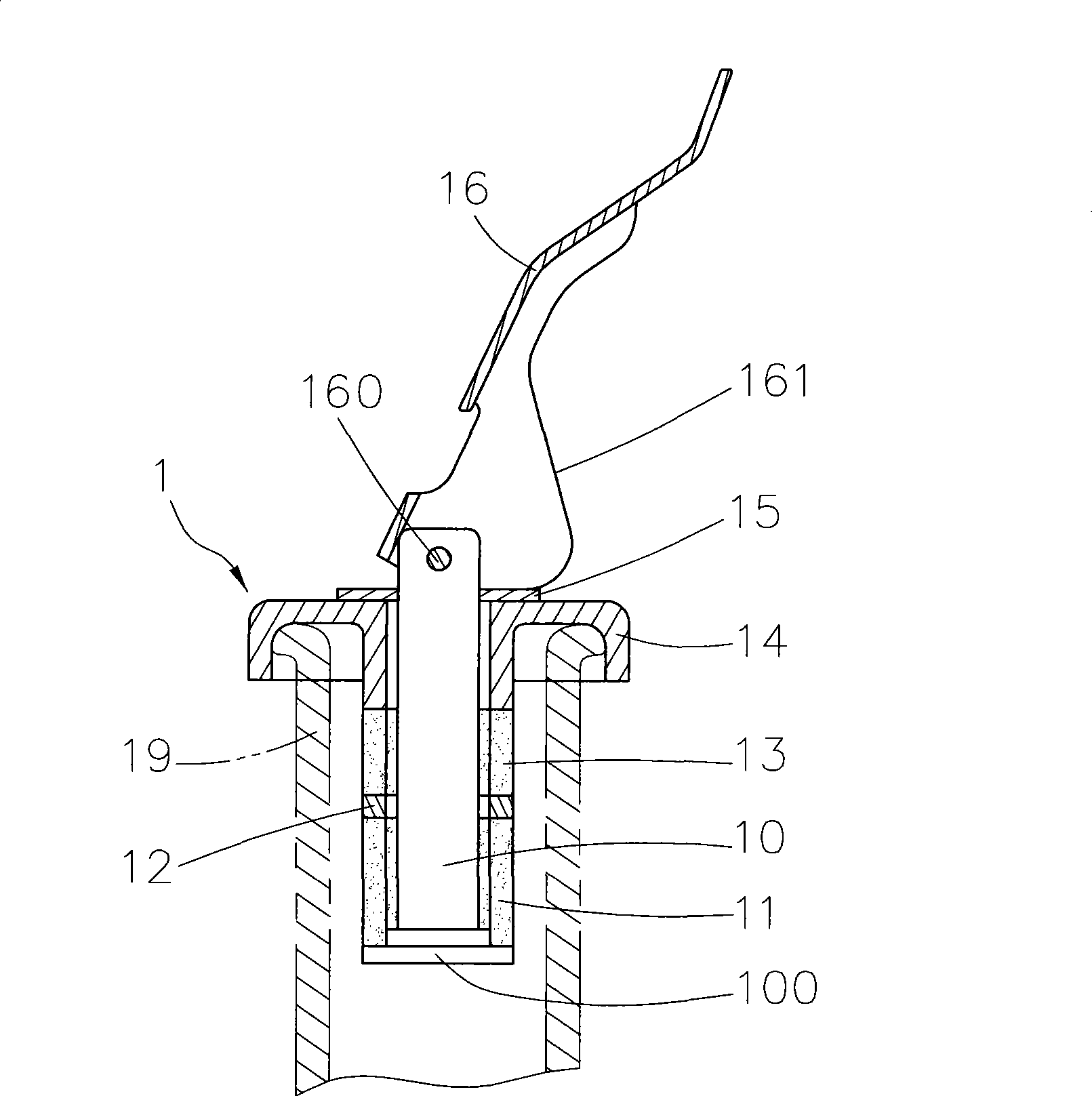

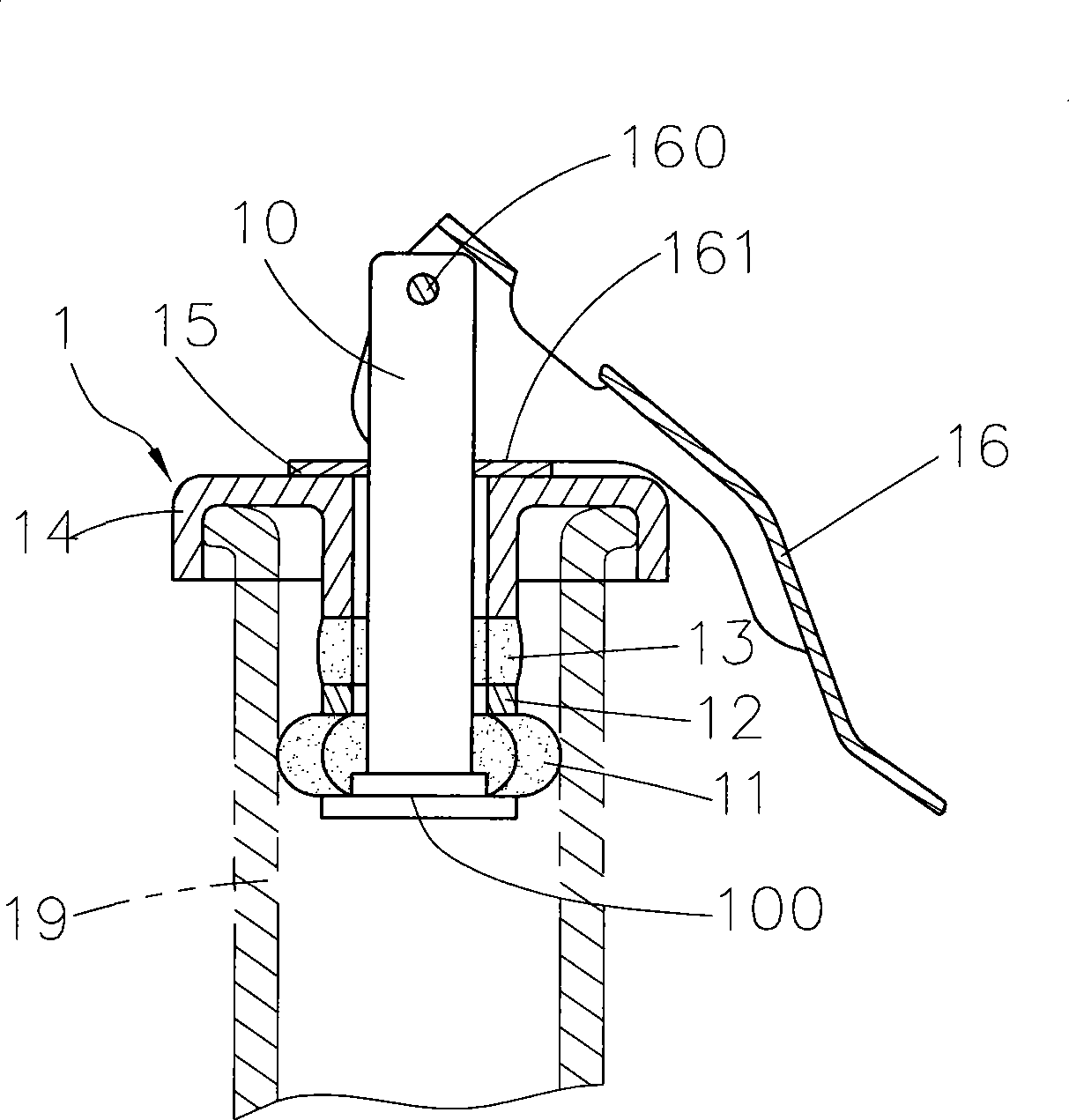

[0015] Relevant present invention is for reaching above-mentioned purpose of use and effect, the technical means that adopts, presents preferred feasible embodiment hereby, and cooperates as shown in the drawing, is described in detail as follows:

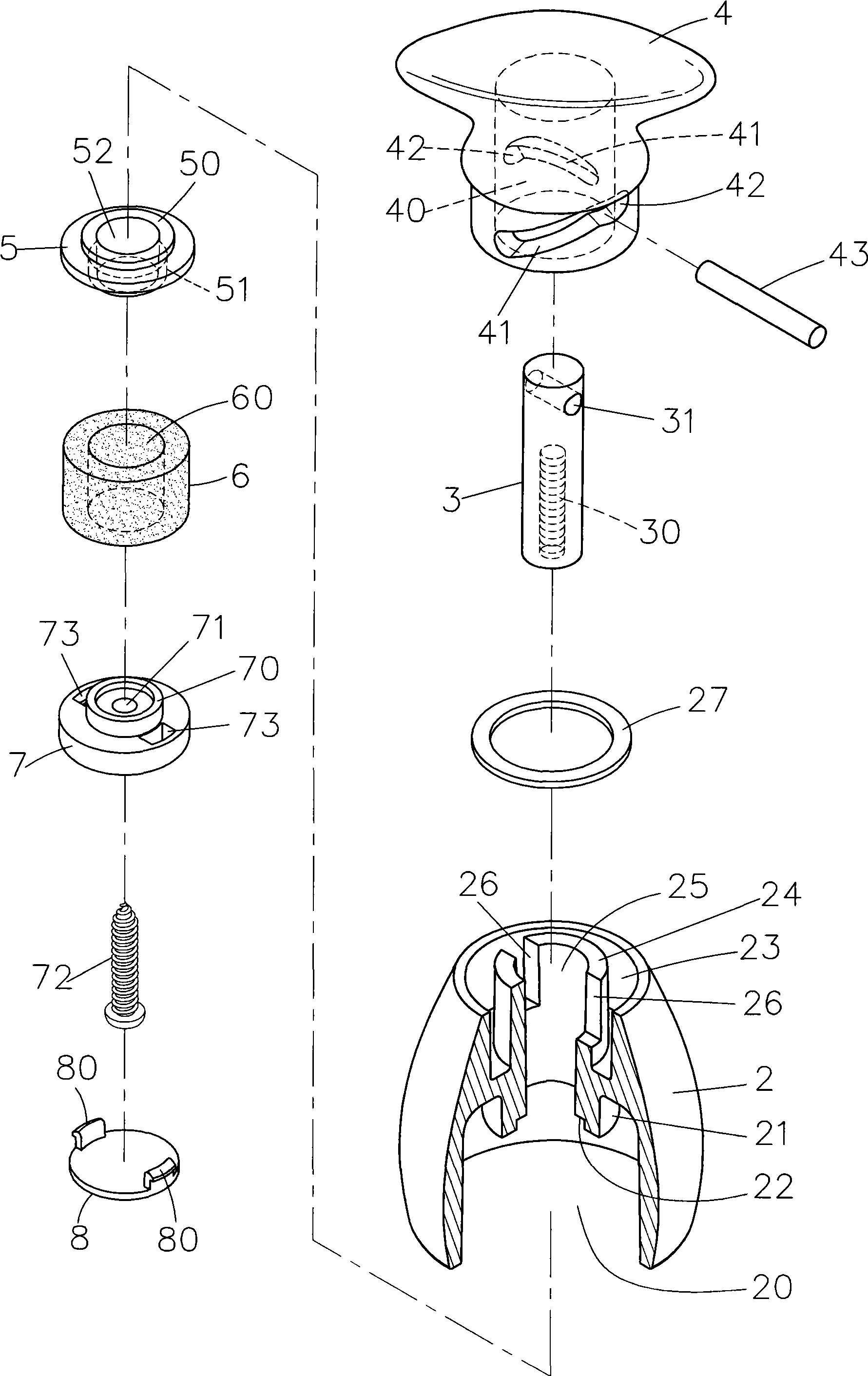

[0016] For an example of the invention, see Figure 3 ~ Figure 5 As shown, it is mainly provided with a cover body 2, the bottom of the cover body 2 is provided with an alcove 20, and a protruding post 21 is arranged in the alcove 20, and a groove 22 is provided on the bottom surface of the protruding post 21. The top surface of the body 2 is provided with an annular groove 23, and a convex seat 24 is provided in the annular groove 23, and a shaft hole 25 is provided in the convex post 21 to penetrate to the top surface of the convex seat 24, and the convex seat 24 A guide groove 26 is oppositely provided on the wall surface, and a gasket 27 is arranged in the ring groove 23; a shaft rod 3 is penetrated in the shaft hole 25 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com