Press-mounting tool and press-mounting method for axle-box pull rod

A technology of axle box tie rods and press-fitting tooling, which is applied in metal processing, manufacturing tools, transportation and packaging, etc., can solve the problems that the metal ball joint cannot be guaranteed, and the accuracy needs to be improved, so as to prevent axial deviation and guide reliability High, improve the effect of press-fitting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

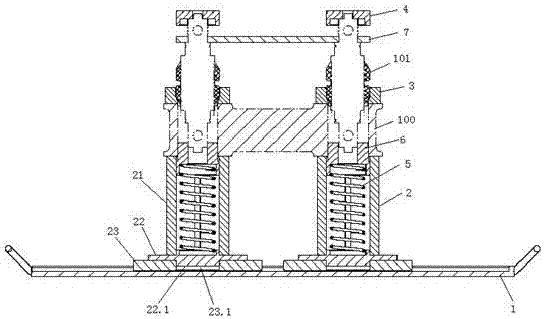

[0042] Attached below Figures 3 to 9 Embodiments of the present invention are described in detail.

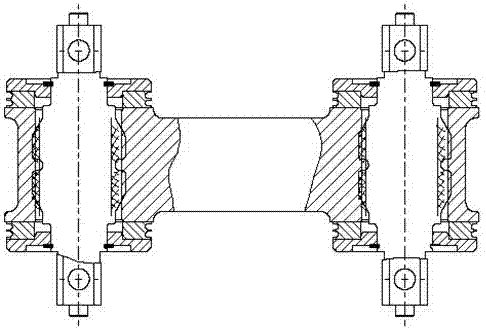

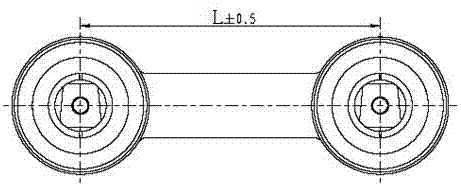

[0043] The press-fitting tooling of the axle box pull rod includes a base 1, a support cylinder assembly 2 placed on the base 1 and vertically arranged, a guide cylinder assembly 3 and a pressure head 4, and the feature is that the number of the support cylinder assemblies 2 is Two, and the two support cylinder assemblies 2 are aligned, the rod body 100 of the axle box pull rod is placed horizontally on the support cylinder assembly 2, the guide cylinder assembly 3 is positioned on the rod body 100, and the guide cylinder assembly 3, the rod body 100 The press-fit hole and the support cylinder assembly 2 are coaxially aligned from top to bottom, and the vertically arranged tie rod ball hinge 101 passes through the guide cylinder assembly 3, and the lower end extends into the press-fit hole of the rod body 100, and the upper end is covered by the pressure block 4 live.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com