High-speed and high-precision magnetic induction absolute value encoder for machine tool spindle and measurement gear of absolute value encoder

An absolute value encoder and machine tool spindle technology, applied in the encoder field, can solve the problems of low control accuracy and reliability of the encoder, and achieve the effects of improving anti-interference and high-speed requirements, high-reliability detection, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

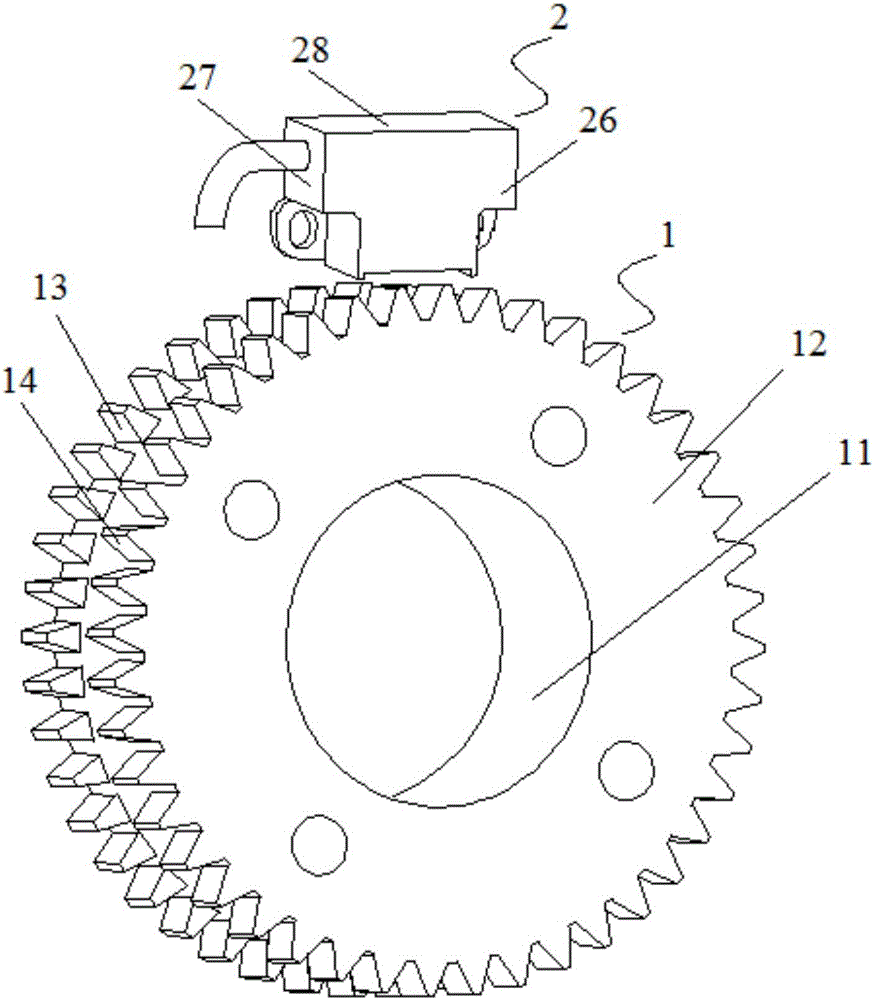

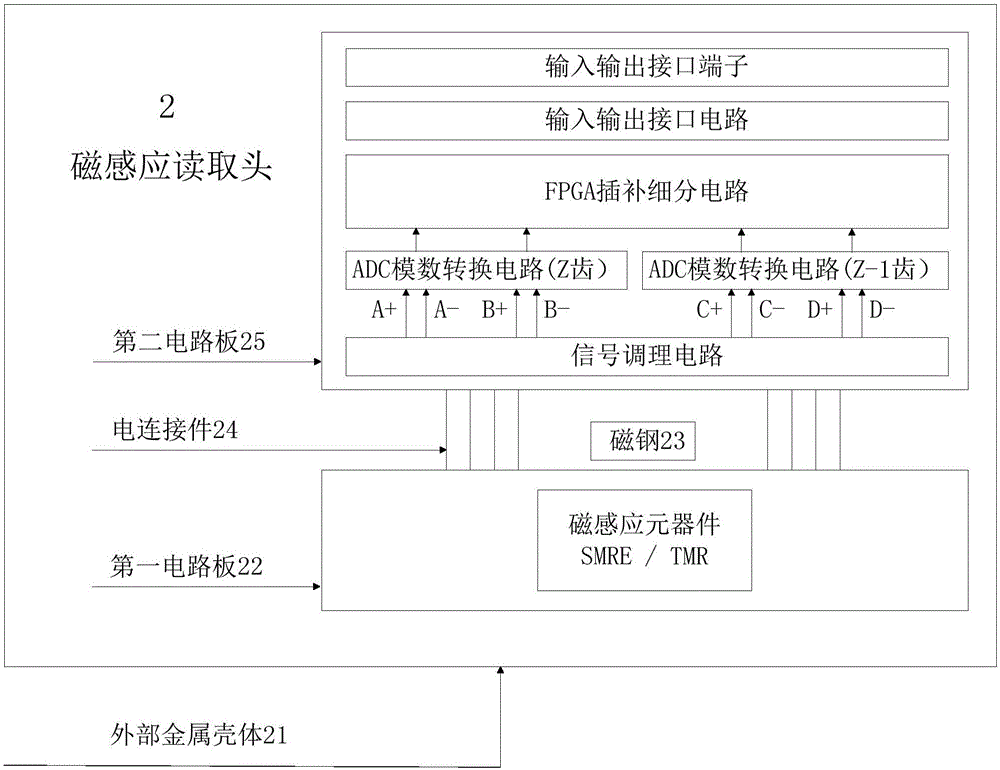

[0032] Such as figure 1 , the high-speed and high-precision machine tool spindle magnetic induction absolute value encoder of the present invention includes a ferromagnetic measuring gear 1 which is set on the machine tool spindle and the electric spindle and rotates synchronously with the machine spindle and the electric spindle, and a magnetic induction reading gear used in conjunction with the measuring gear 1 head 2. The magnetic induction reading head 2 is located above the outer side of the measuring gear 1, the installation side 26 of the magnetic induction reading head is in the same plane as the side surface 12 of the measuring gear, and the gap between the magnetic induction reading head and the measuring gear is 0.1mm to 0.3mm.

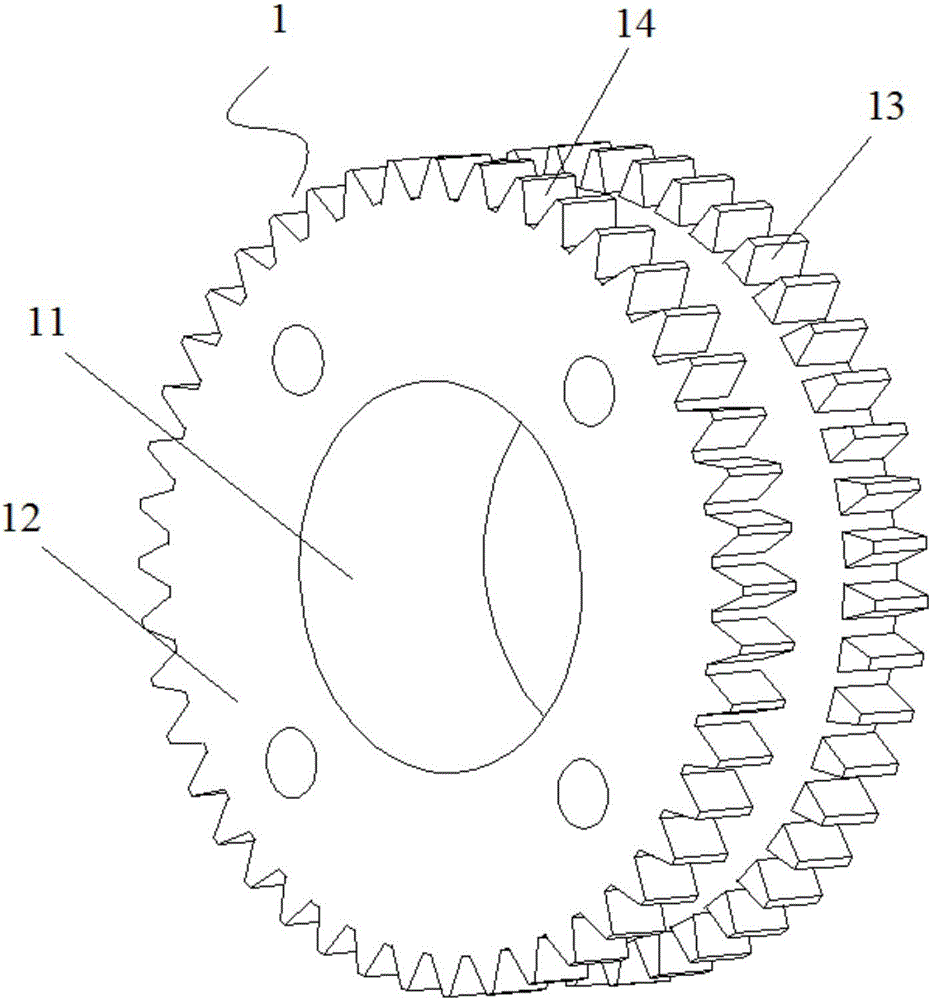

[0033] Such as figure 2 , the measuring gear 1 is a double-track measuring gear with a central hole 11 mounted on the rotating spindle, the number of teeth on the main track 14 of the inner ring is Z, and the number of teeth on the verni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com