Casting-grade chrome ore dressing device and technology

A kind of high-grade chromium ore and chrome ore technology, which is applied in the direction of filter screen, grid, wet separation, etc., can solve the problems of insufficient competitiveness such as fluid resistance, affecting the production efficiency of the production process, and the decline of the recovery rate of magnetic components. To achieve the effect of smooth operation of equipment, simple structure and stable output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

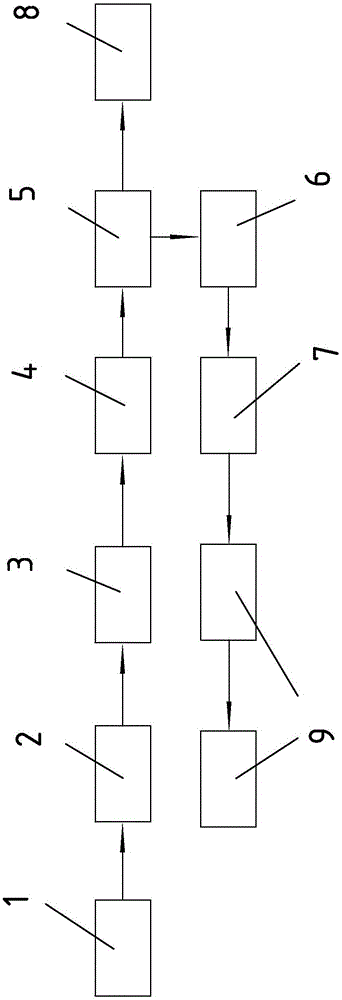

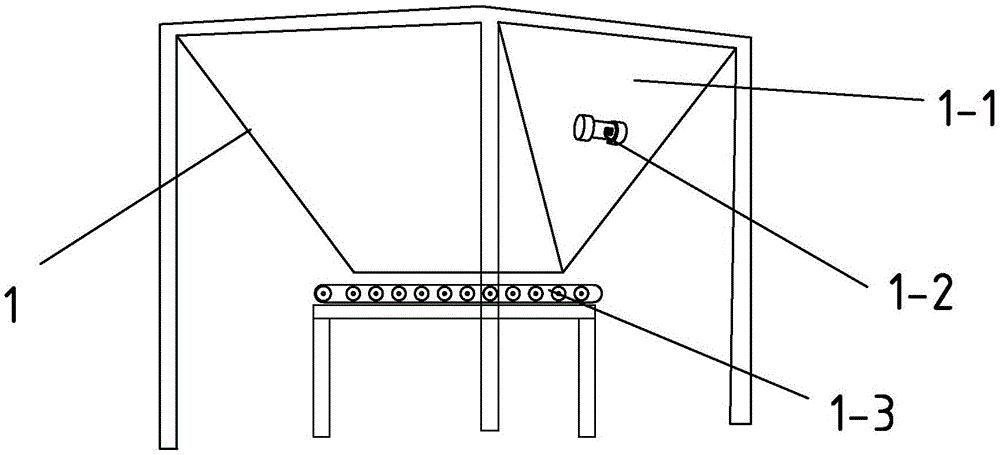

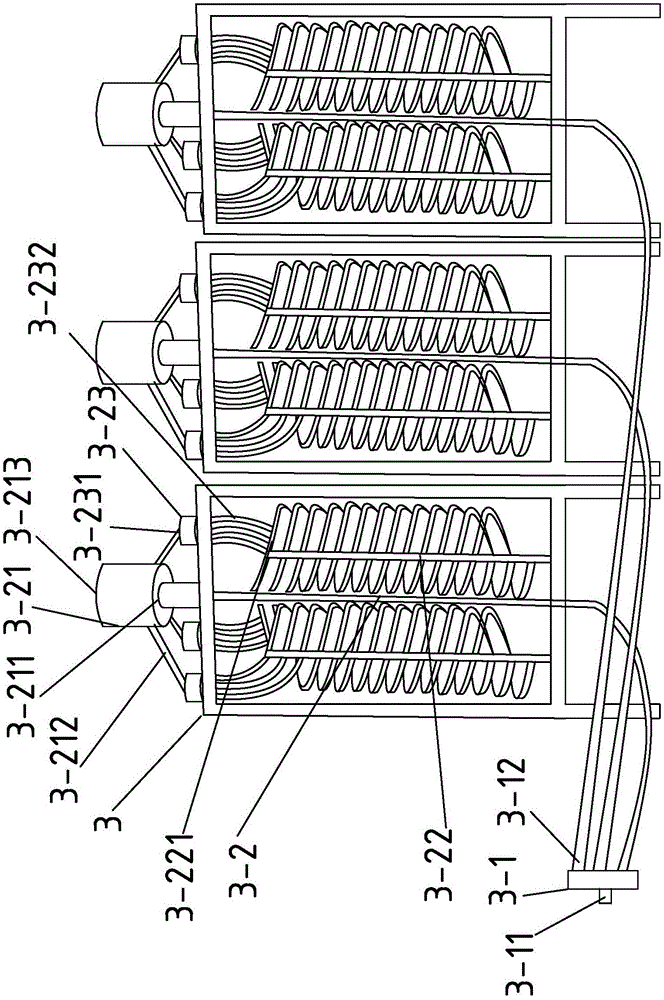

[0056] Such as Figure 1-Figure 31 As shown, a casting grade chrome ore beneficiation device includes a feeding device 1 for feeding metallurgical grade chrome ore, a trommel 2 for screening metallurgical grade chrome ore, and the refined chromium ore obtained through the trommel 2 A spiral launder system 3 for removing silicon from ore, a dehydration device 4 for dehydrating the concentrate obtained through the spiral launder system 3, and a drying device for drying the dehydrated concentrate obtained through the dehydration device 4 Drying device 5, a cooling system 6 for cooling the dried concentrate obtained by the drying device 5, a rocker screen 7 for screening the cooled concentrate obtained by the cooling system 6 and A dry magnetic separation device for magnetically separating the oversize ore obtained through the rocker screen 7 . The feeding device 1 has a feeding hopper 1-1, at least one vibrating motor 1-2 is provided on the outer wall of the feeding hopper 1-1, ...

Embodiment 2

[0058]A process of using the cast-grade chrome ore beneficiation device described in Example 1 to carry out cast-grade chrome ore beneficiation has the following steps: S1, transporting the metallurgical-grade chrome ore in the feeding device 1 to the trommel 2 Screening and washing are carried out on the sieve, the trommel 2 is a double-deck trommel, the screens of the double-deck trommel are 30 mesh screen and 100 mesh screen, the metallurgical grade chromium on the 30 mesh sieve and under the 100 mesh sieve The ore is processed as tailings; S2, concentrates between 30-100 mesh are transported to the spiral launder system 3 for silicon removal, and the concentrate obtained through the spiral launder system 3 is processed by the dehydration device 4 Dehydration, the tailings obtained by the spiral launder system 3 are treated as waste ore; S3, the dehydrated concentrate obtained by the dehydration device 4 is dried by the drying device 5; S4, the The dried concentrate obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com