Preparation method of PVDF membrane with catalytic self-cleaning function

A self-cleaning and functional technology, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of reducing the modification effect and failing to achieve it, and achieve the improvement of hydrophilicity, pollution resistance, and permeability. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1. Add the PVDF powder without modifier into the casting film solvent, stir at 60°C until completely dissolved, and keep stirring at 60°C for 12 hours, then defoam under negative pressure for 6 hours, and use an automatic film scraping machine The casting solution is evenly coated on the polyester non-woven fabric, and the scraped film is left to stand in the air for 30 seconds, and then put into deionized water at a temperature of 35°C to obtain a PVDF original film.

Embodiment 2

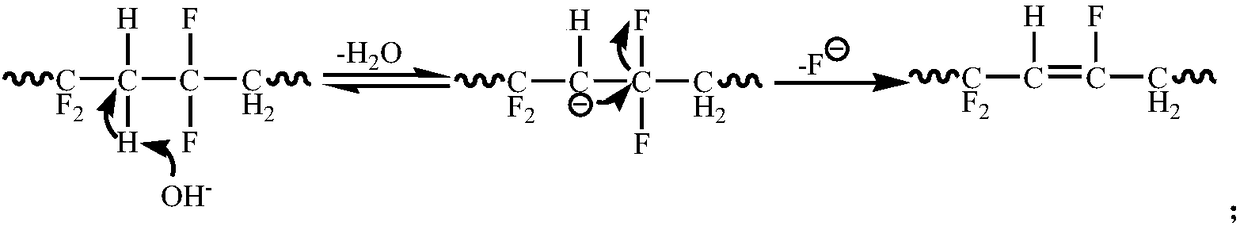

[0031] Step 1. Disperse 6g of PVDF powder into 300mL of 10wt% potassium hydroxide aqueous solution, add 30mL of 95% ethanol during the dispersion process, and stir while adding until the powder is completely wet; then stir at 70°C for 30min, filter and wash Several times, vacuum drying at 60°C to obtain light yellow alkalized PVDF powder;

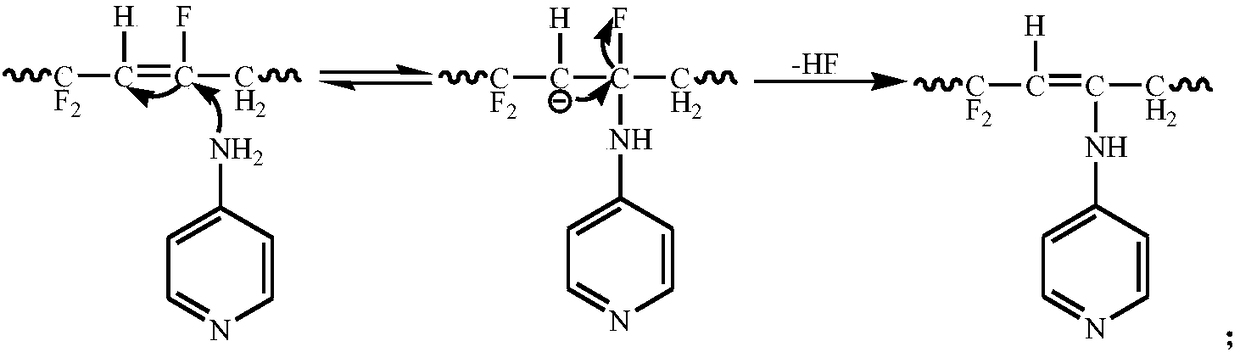

[0032] Step 2. Disperse 5g of the PVDF powder obtained in step 1 into an aqueous solution of 1wt% sodium bicarbonate, and then add a certain amount of 3g of 4-aminopyridine dropwise during vigorous stirring at 120°C; Stirring was continued for 4 hours, and vacuum drying was carried out at 60° C. to obtain reddish-brown PVDF powder grafted with 4-aminopyridine;

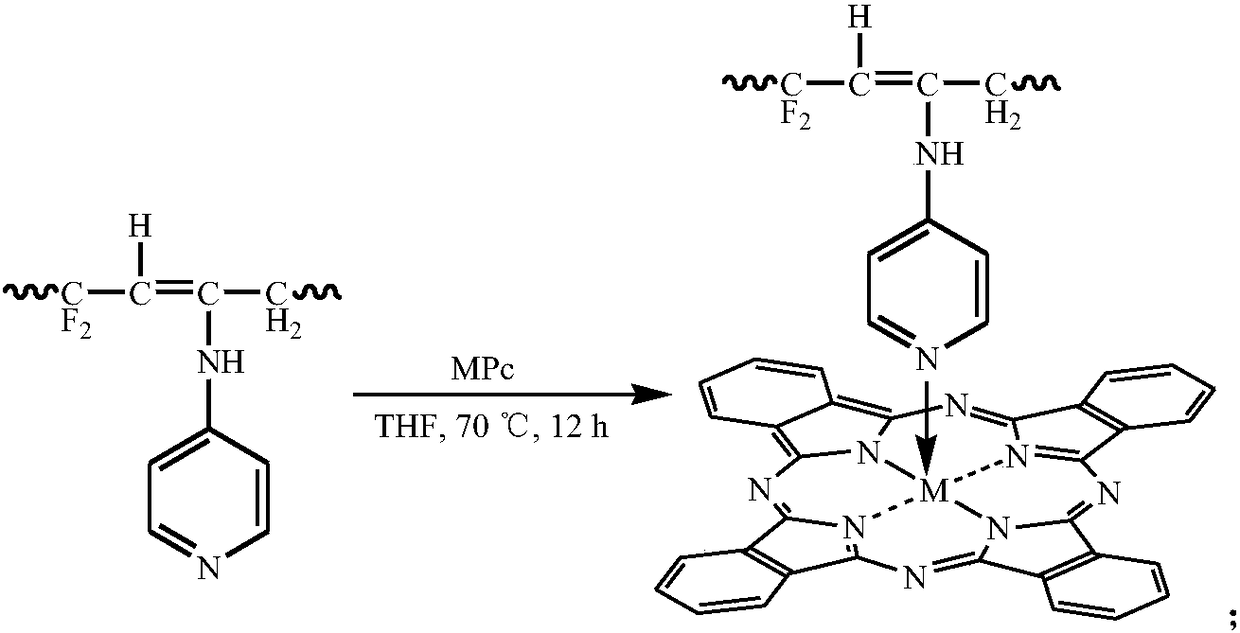

[0033] Step 3. Disperse 3 g of the PVDF powder obtained in step 2 into tetrahydrofuran, then add dropwise the tetrahydrofuran solution in which metal phthalocyanine is dissolved (dissolve 0.3 g of iron phthalocyanine in 50 ml of tetrahydrofuran), after the dropwise addition is compl...

Embodiment 3

[0037] 2wt% modifier was doped into PVDF powder to prepare PVDF composite membrane, and the anti-fouling and catalytic self-cleaning properties of the membrane were investigated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com