Ceramic bearing fluoroplastic magnetic drive pump

A technology of ceramic bearings and magnetic pumps, which is applied in the direction of pumps, pump components, pump devices, etc., can solve the problems of affecting the use effect of magnetic pumps, increasing production costs, and large application limitations, so as to solve the problem of eccentricity and vibration and stable operation , Low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

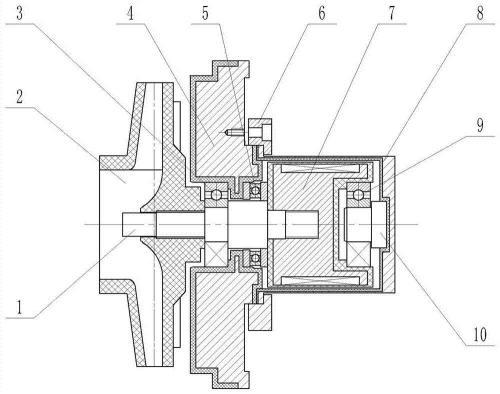

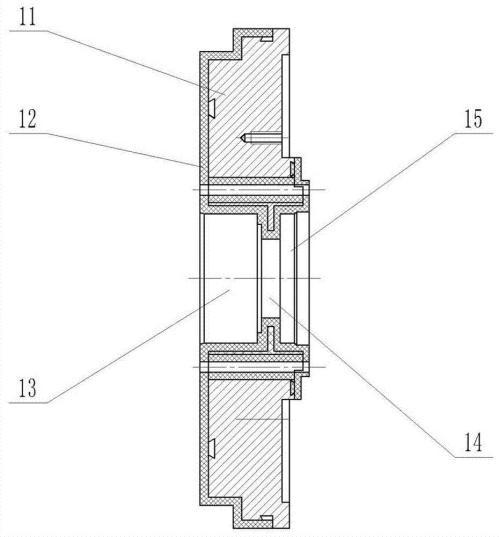

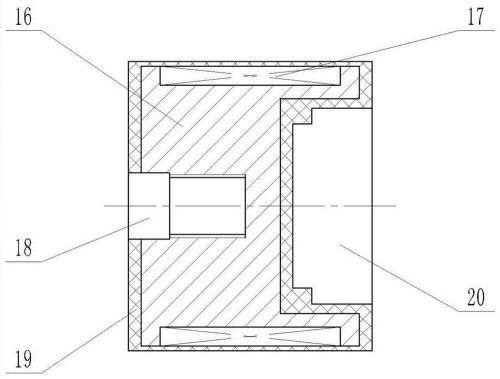

[0016] according to Figures 1 to 5 The specific structure of this invention is demonstrated in detail. The ceramic bearing fluorine plastic magnetic pump includes a main pump shaft 1 with an impeller 2 at one end; the other end of the main pump shaft 1 is provided with an inner magnetic steel 7 for cooperating with the outer magnetic assembly to rotate. Between the impeller 2 and the inner magnet 7, and outside the middle of the main pump shaft 1, a magnetic pump cover 4 is provided. The magnetic pump cover 4 is composed of a pump cover main body 11. The main shaft through hole 14 passing through; the pump cover main body 11 is provided with through holes and grooves for the fixing of the fluorine lining layer, and the main shaft through hole 14 is also provided with a rib for increasing the structural strength. The main shaft through hole 14 of the pump cover main body 11 is close to one end of the impeller 2, and is provided with a ball bearing installation groove I13 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com