Method for adjusting center of magnetic field of high-voltage motor

A magnetic field center and adjustment method technology, which is applied in the direction of centering/balancing the rotor, etc., can solve the problems of motor axial movement, unfavorable high-voltage motor operation, and axial movement of the motor shaft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

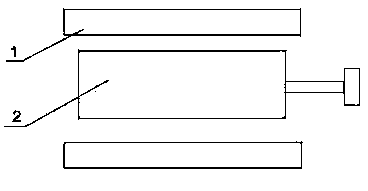

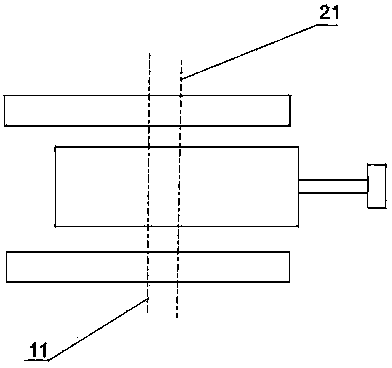

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is further described.

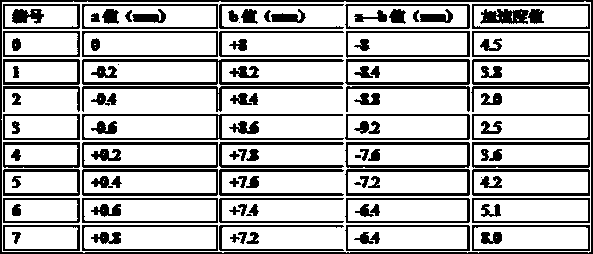

[0024] The high-voltage motor of this embodiment is the main motor of the coal mill of the pulverized coal supply system of the 1000t / d rotary kiln production line produced in 1993, the model is YRKK450--8 280KW 6KV, the end cover type bearing housing, the motor tail bearing is NU224ECM, and the front bearing is For NU228EM and 6228, in February 2010, the motor bearings suffered serious abnormal wear. The amount of wear on both sides of the raceway of the front bearing 6228 was obviously asymmetrical, and the worn parts were abnormal. There is no wear, while the axial wear length of the raceway on the side of the coupling is about 4.5mm, and the tail bearing NU224ECM and the front bearing NU228EM have almost no wear. After analysis, it is known that the reason for this phenomenon is that the centers of the motor magnetic fields do not coincide. Adjust with the high-voltage motor magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com