Steering transmission shaft with telescopic pre-limiting structure

A steering transmission shaft, axial sliding technology, applied in the direction of steering control, steering column, connecting components installed on the vehicle, etc., can solve the problem of free expansion and contraction of the column transmission shaft, irregular automatic extension or shortening, heavy weight, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be specifically described below in conjunction with the accompanying drawings.

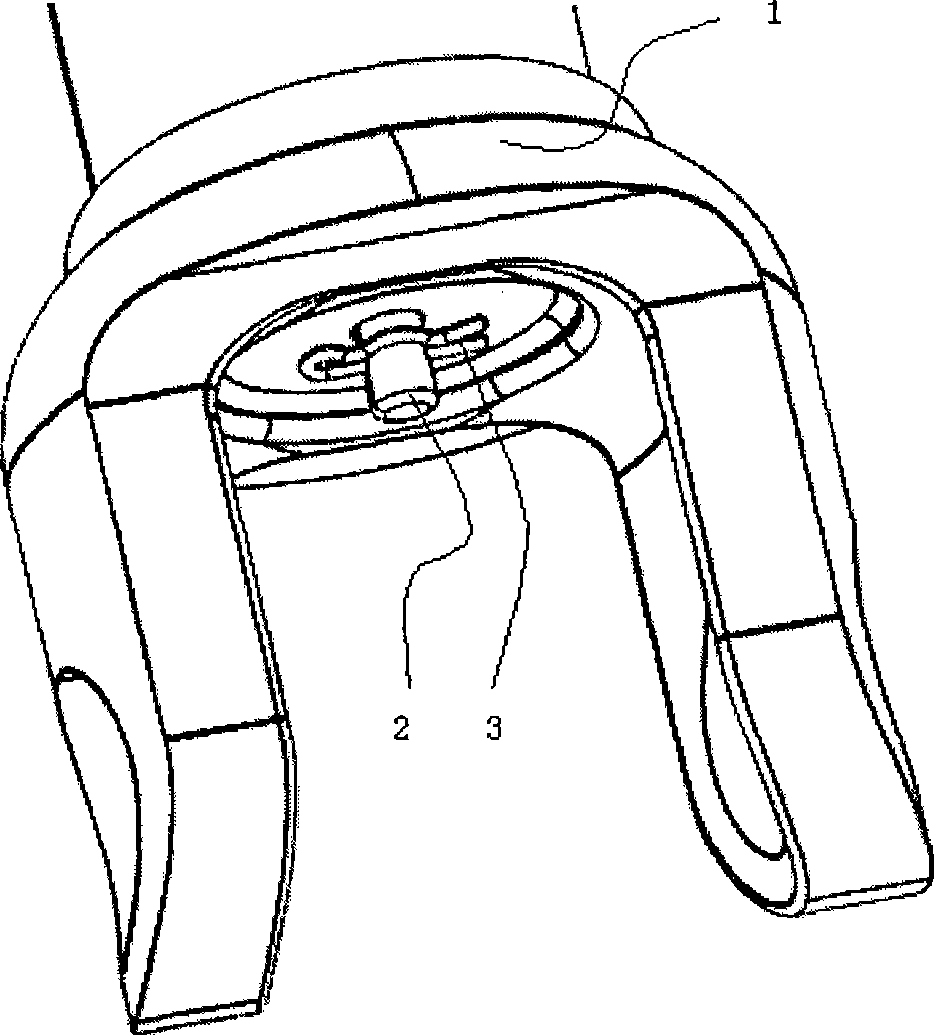

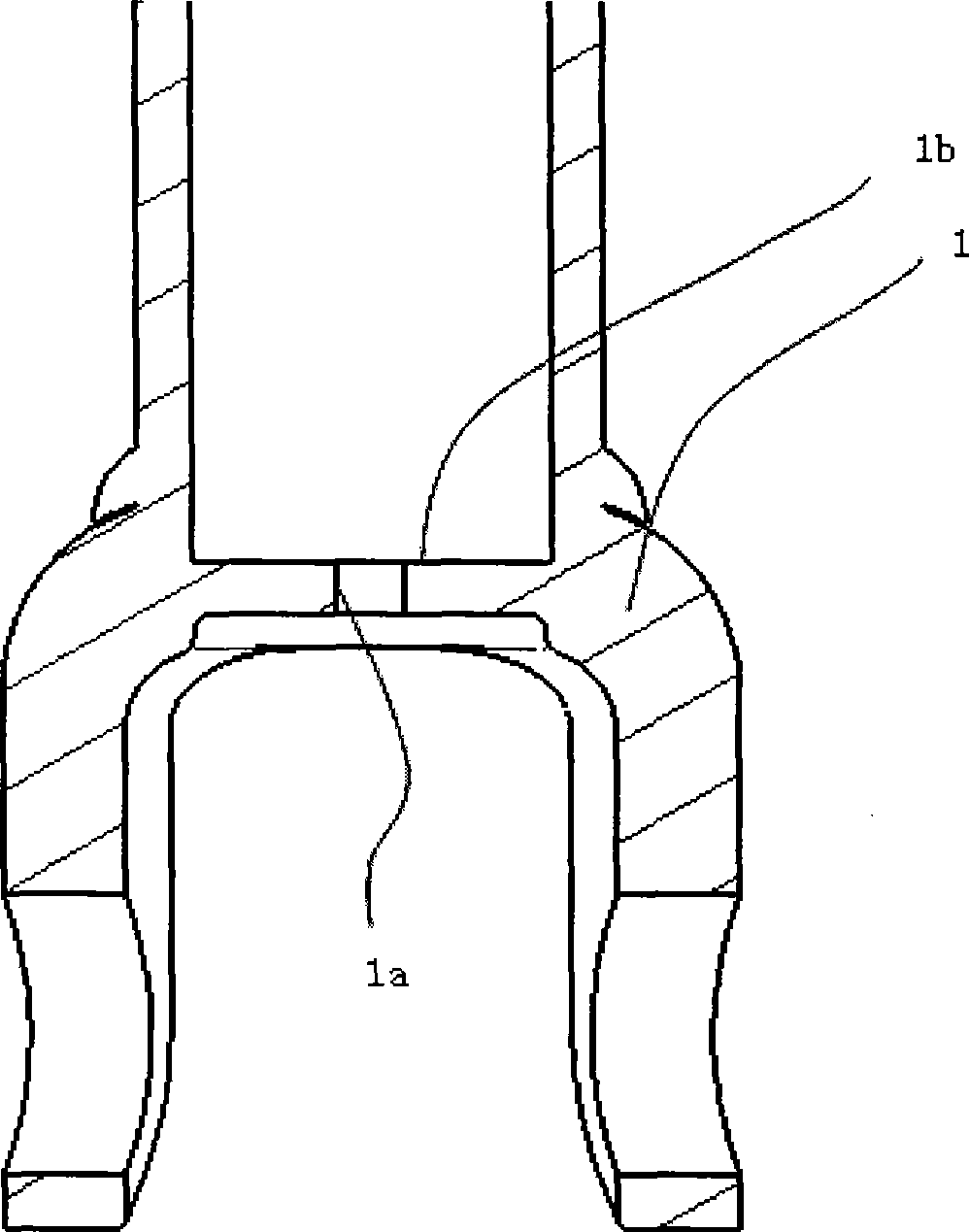

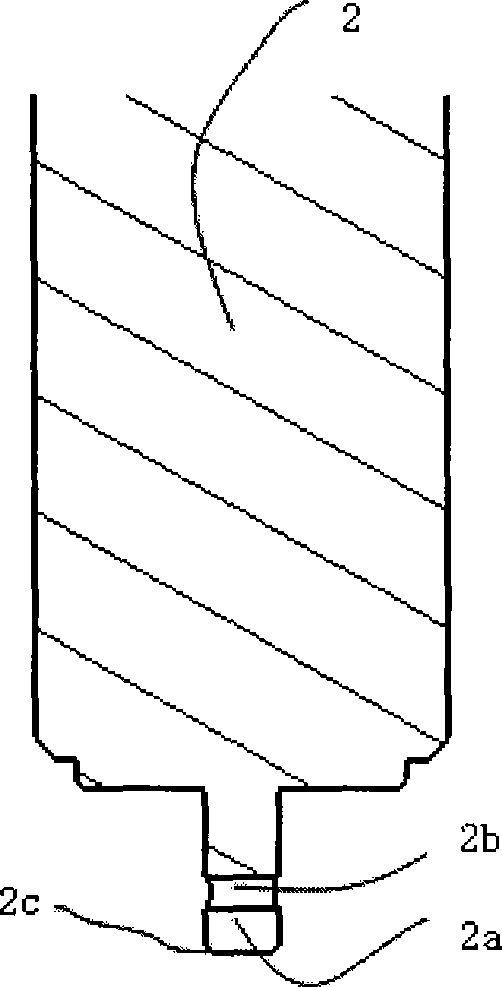

[0019] Such as figure 1 As shown, the telescopic steering transmission shaft includes an outer shaft 1 with an inner hole and an inner shaft 2 matched with the inner hole of the outer shaft 1, and an elastic clip 3 installed on the inner shaft 2, wherein the outer shaft and The inner shafts can slide axially but cannot rotate, and the axial sliding between the two shafts can be limited by the elastic clip 3 installed on the inner shaft. When the elastic clip is taken out, it can slide axially again .

[0020] Such as figure 1 As shown, the inner shaft 2 is assembled in the outer shaft 1 after the steering transmission shaft is completely assembled, and the inner and outer shafts can slide axially after the elastic clip 3 is removed. There are many mature structures for this sliding method, including multi-spline sliding fit Mode, triangular and multi-angle cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com