Feeding and positioning component of spring coiling machine

A technology of positioning assembly and spring coiling machine, applied in the field of feeding positioning assembly, can solve the problems of high manufacturing cost, affecting the feeding accuracy of spring forming accuracy, axial movement of the feeding wheel, etc., saving material costs and processing costs, and facilitating frequent shifting , The effect of stable and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

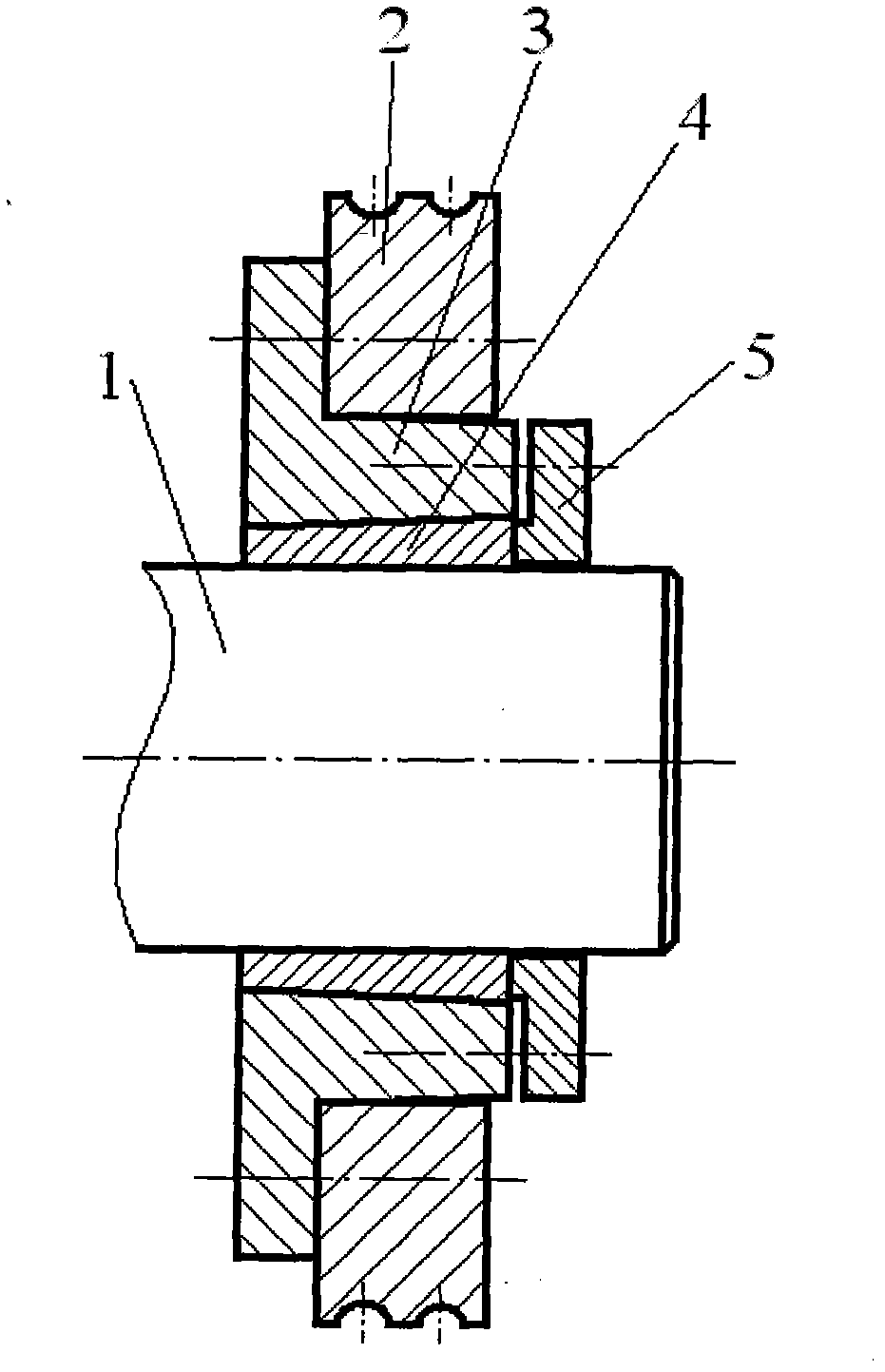

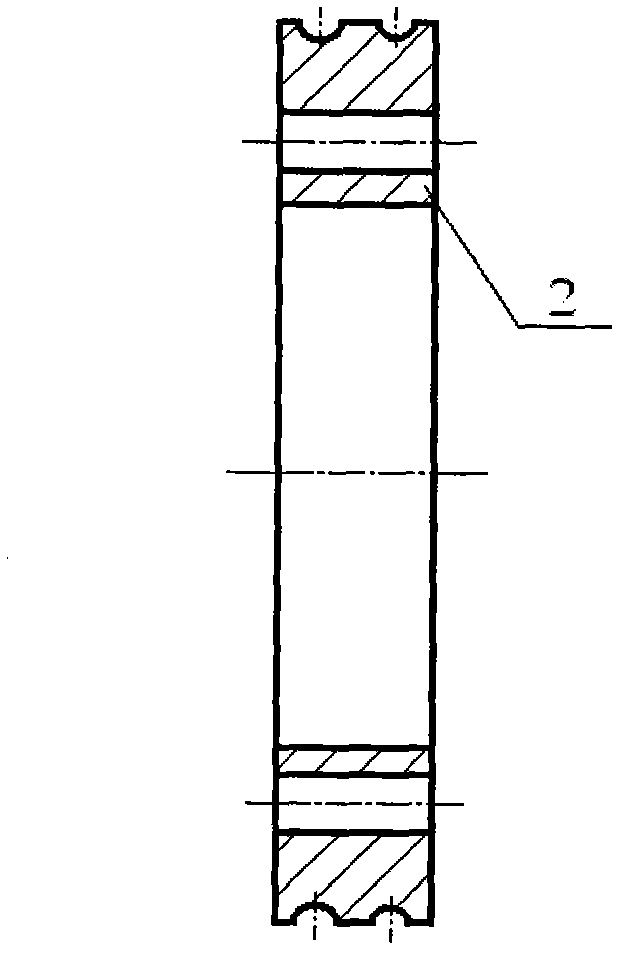

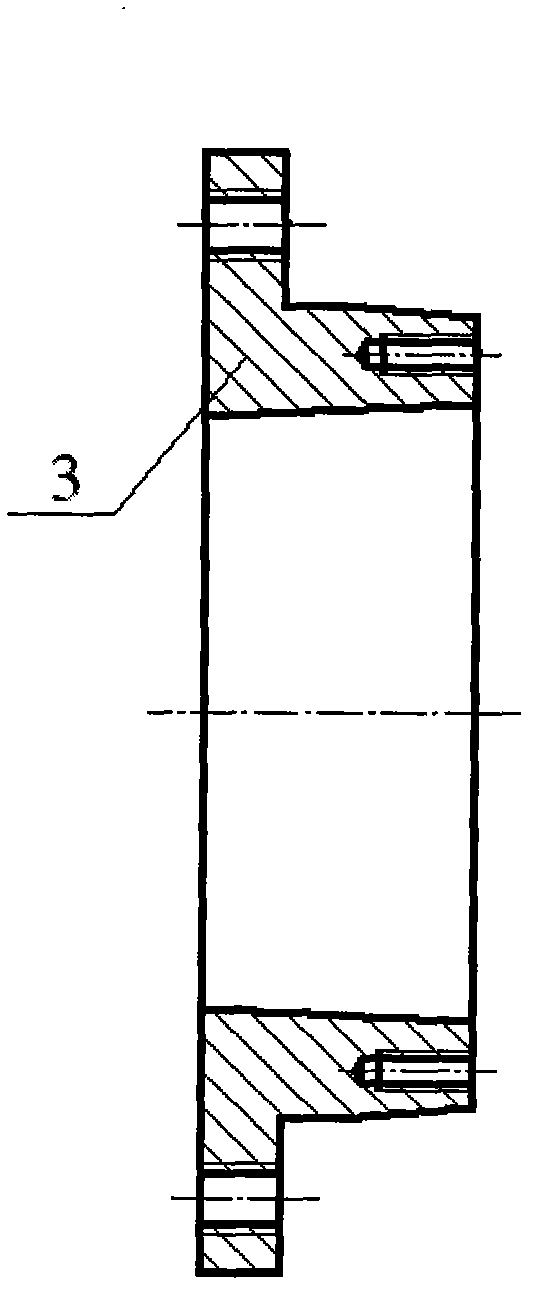

[0022] A coil spring machine feed positioning assembly, sleeved on the feed shaft 1 of the coil spring machine, its structure is as follows figure 1 As shown, including feeding wheel 2, positioning bushing 3, expansion taper sleeve 4 and pressure ring 5, the structure of feeding wheel 2 is as follows figure 2 As shown, two arc grooves are provided on the outer side, and the grooves are equidistant from the end face of the feed wheel 2, so that the thickness of the feed wheel 2 is greatly reduced, and 6 screws for installation and clamping are also provided on the end face of the feed wheel 2. hole. The positioning bushing 3, the expansion taper sleeve 4 and the pressure ring 5 constitute the positioning device, and the structures of the positioning shaft sleeve 3, the expansion taper sleeve 4 and the pressure ring 5 are respectively as follows image 3 , Figure 4 , Figure 5 As shown, the positioning sleeve 3 has a flange edge, the inner surface has a taper, and the oute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com