Installing structure of independent suspension system

A technology of installation structure and independent suspension, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of poor stress state of installation structure, affecting work efficiency, large impact force, etc., and achieve good guiding and positioning functions , Low strength and precision requirements, and the effect of improving strength and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

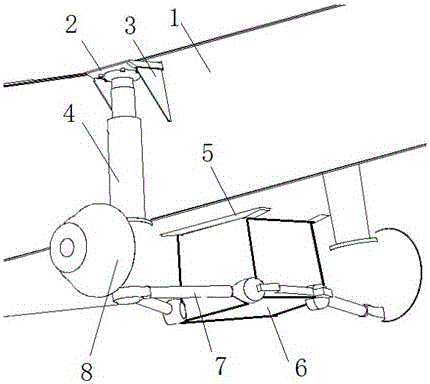

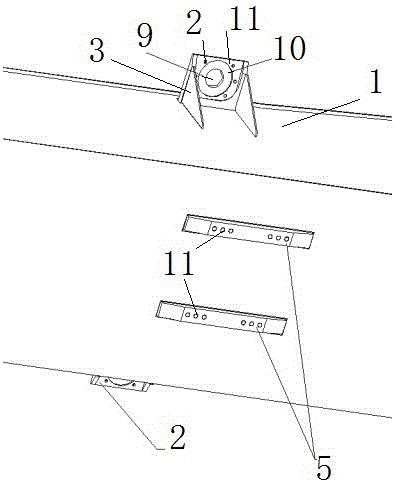

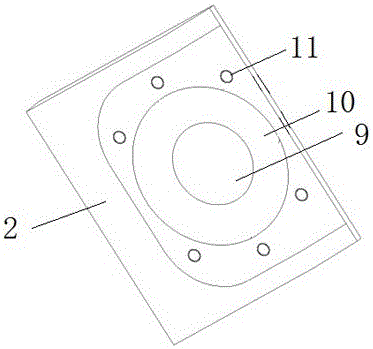

[0029] An installation structure of an independent suspension system, a thick plate 5 is welded on the lower bottom surface of the frame 1 in a butt manner, and the thick plate 5 and the lower bottom surface of the frame 1 have a certain height difference. The hole 11 is used to fix the base 6 .

[0030] The protruding surface of the thick plate 5 can be finished after the overall welding of the frame 1 is completed, which not only facilitates the structural tailoring of the frame 1, but also improves the flatness of the mounting surface of the thick plate 5 and the thickness of the thick plate 5 and the frame. 1 The accuracy of the height difference of the base plate.

[0031] Two sides of the frame 1 are welded with a support 2 and a reinforcing plate 3 , and a stepped plane and a mounting screw hole 11 are processed on the support 2 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com