Real-time on-site drilling full parameter optimization method

An optimization method and a full-parameter technology, applied to drilling equipment, automatic drilling control systems, earthwork drilling and production, etc., can solve problems such as rheological model deviation, hydraulic prediction is difficult to implement, and optimization work is difficult to be accurate, etc., to achieve results Reliable, easy to implement, and the effect of maximizing drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

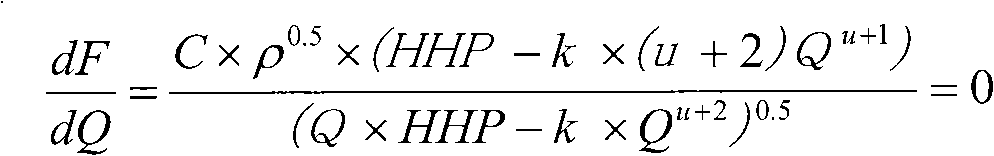

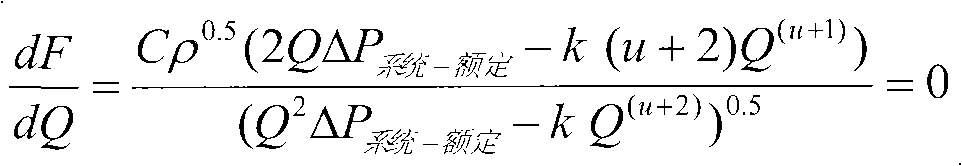

[0170] Example 1—Optimized calculation of jet impact force of drill bit nozzle

[0171] The pump displacement and pressure measurement data of an on-site hydraulic optimization are shown in Table 1, and the total flow area of the old drill bit nozzle, mud density, rated pump pressure and rated output water power of the mud pump are known at the time of pressure measurement. And it is known that the new drill bit is designed with three nozzles, and the optimization limit condition is the rated pump pressure.

[0172] Table 1. Known data for drill bit hydraulic optimization

[0173] Pump displacement 1, l / s

[0174] The constant C=1.10 is selected, u=1.658 and k=0.079 can be obtained according to formula 10, and then the optimized pump displacement, the total flow area of the drill nozzle and the optimized impact force of the drill jet can be obtained as follows through formulas 16, 17 and 18 ,As shown in table 2.

[0175] Table 2. Data calculated by drill bit hy...

example 2

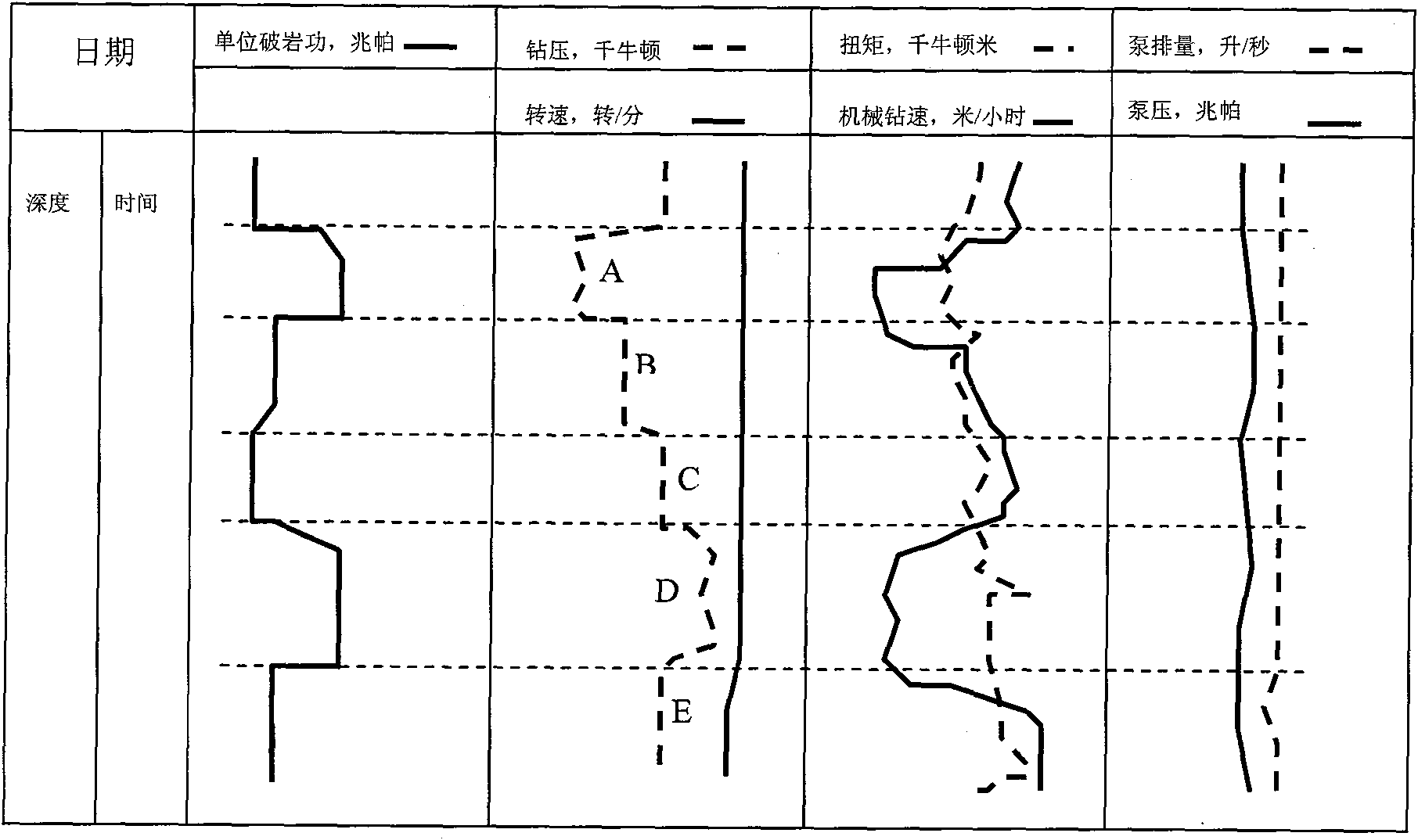

[0178] Example 2—Optimization of WOB

[0179] attached figure 1 Shown is an example of weight-on-bit optimization. It is an optimized operation that only changes the weight on bit while controlling the hydraulic power (pump displacement, pump pressure) and rotational speed of the constant drill bit. It can be seen that when the WOB changes from small to large, it goes through the A-B-C-D time period. In this time period, it can be seen that the unit rock breaking work in the lower WOB section A is larger. With the increase of the WOB, from B to B The unit rock-breaking work of section C is small, and when the WOB increases to D section, the unit rock-breaking work increases to a larger value, indicating that in the WOB section B and C, the cutting efficiency of the drill bit is very high, while In sections A and D, the cutting efficiency of the drill bit is very low due to too small and too large bit pressure. Although the ROP lags behind, it can be seen that the ROP is low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com