Pressure yielding internally-grouted anchor cable

A technology of grouting anchor cables and grouting, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., which can solve the problems of high support cost and complicated construction process, so as to simplify the construction process, improve production efficiency and economy Benefit, the effect of increasing the spread range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

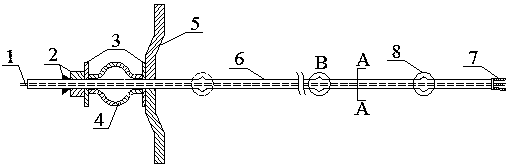

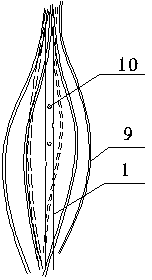

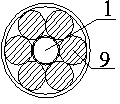

[0015] Such as figure 1 As shown, the anchor cable of the present invention is mainly composed of a hollow inner grouting cable body 6, an anchor cable tray 5, an anchor cable sling 2 and a pressure yielding pipe 4, and the hollow inner grouting cable body 6 It is composed of a hollow rubber grouting core tube 1 and a multi-strand steel strand 9 wound on the hollow rubber grouting core tube 1. The hollow rubber grouting core tube 1 is drilled with multiple sets of grouting holes intersecting at 90°. Holes 10, the distance between the multiple groups of pulp outlet holes 10 is 300-400mm. The hole pitch of every group of slurry holes 10 is 50mm, and the multi-strand steel strands 9 at the position of each group of slurry holes 10 protrude in a honeycomb-shaped slurry section 8, such as image 3 As shown; the tail of the hollow inner grouting cable body 6 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com