Power distribution switchgear with high safety performance

A technology of safety performance and power distribution switch, which is applied in substation/switch layout details, cooling/ventilation of substation/switchgear, substation/power distribution device shell, etc. Problems such as heat dissipation of bundled wires and cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

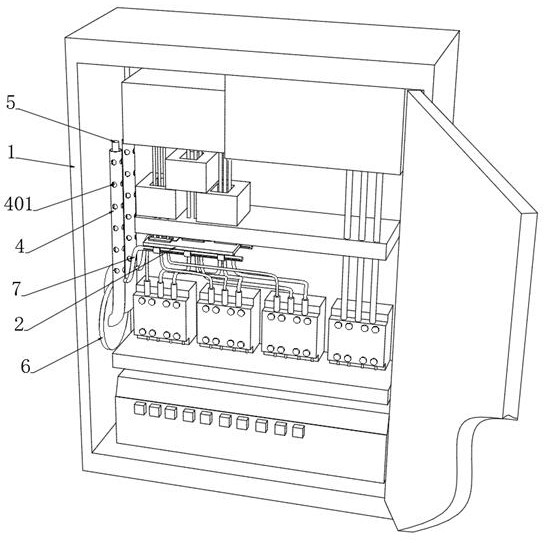

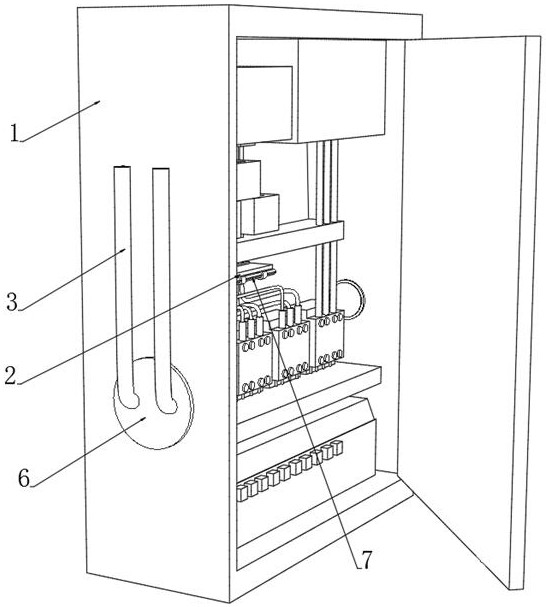

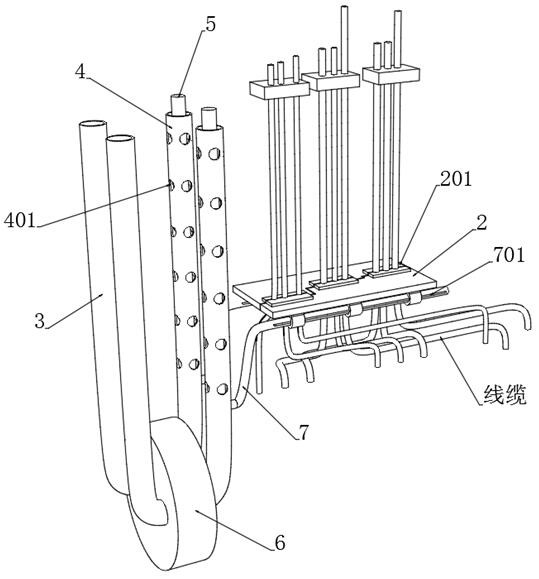

[0045] see Figure 1-4 , a power distribution switch cabinet with high safety performance, including a cabinet body 1, a switch assembly is installed in the cabinet body 1, the switch assembly and other electrical components are connected by cables, and a pair of switches are embedded on the inner wall of the cabinet body 1 The cable cladding plate 2 for positioning the component cables, the cable cladding plate 2 is provided with multiple sets of sheaths 201, and the sheath 201 is provided with a plurality of sleeve holes 2011, and the cable cladding plate 2 is separated in half along the horizontal direction of the sheath 201. There are two butt joints at the front and back, and an adhesive layer is provided at the junction of the two butt joints, which is easy to install and position multiple bundles of cables, and plays a role in combing the cables, which is conducive to the circulation of airflow and improves heat dissipation. Two butt joints that are separated front and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com