Radial shaft seal for separating two media

A sealing device and radial shaft technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the need for front and rear sequential connections, cannot provide axial structural length, and seal ring assembly cannot be carried out separately in succession, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

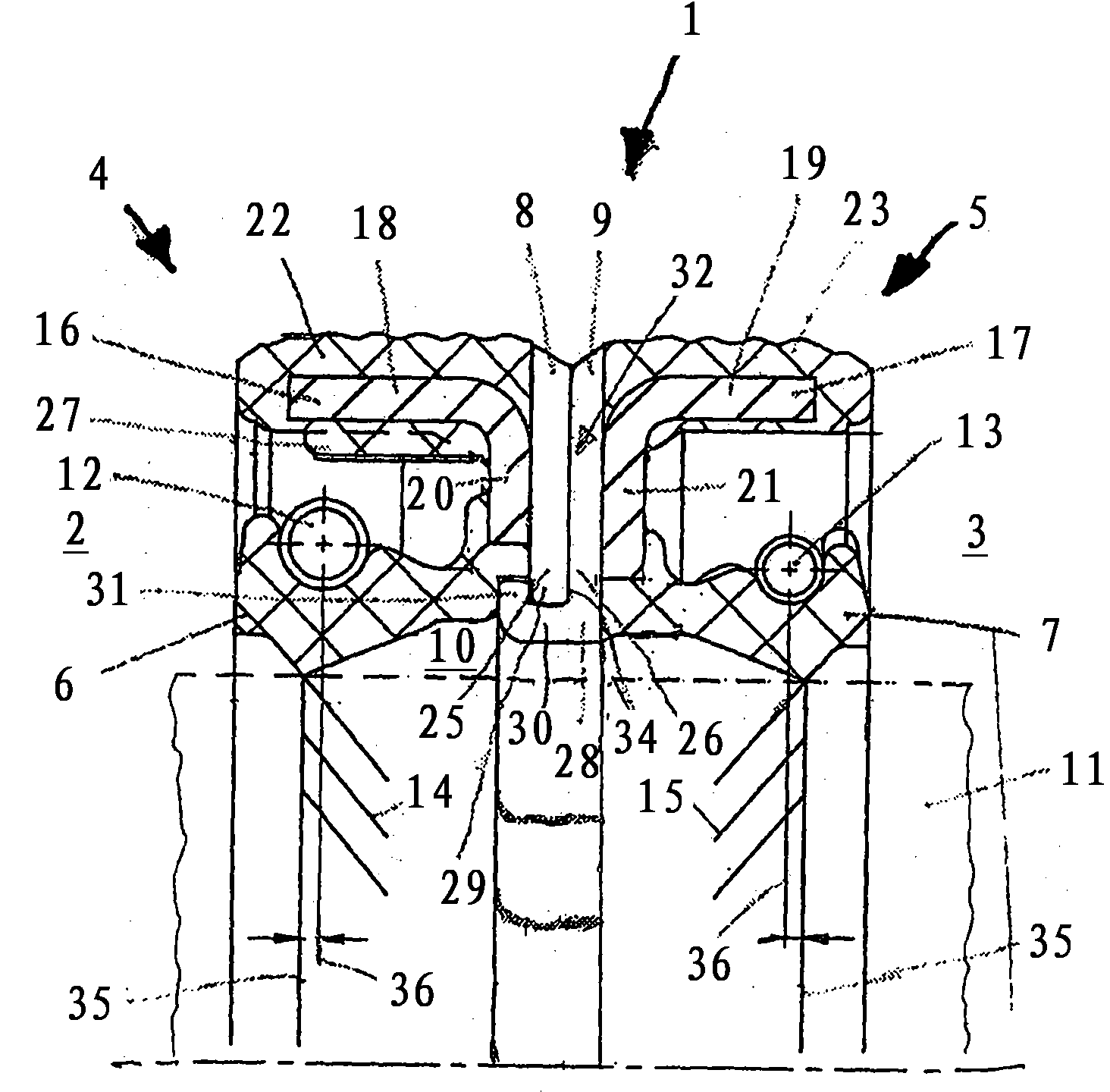

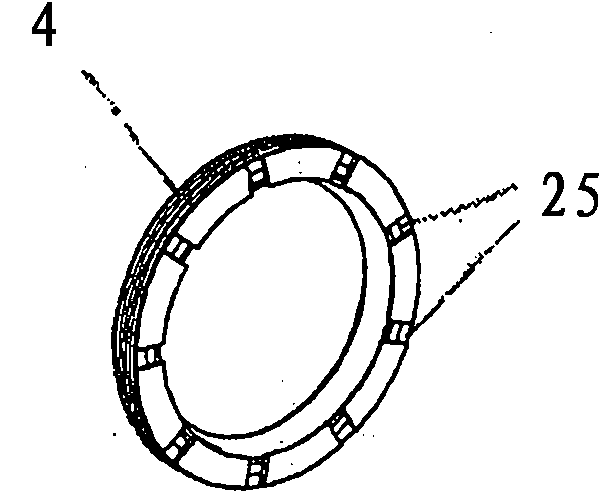

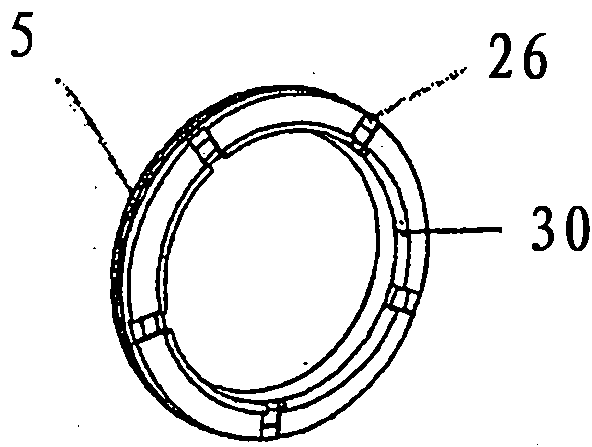

[0014] exist figure 1 The embodiment of a radial shaft seal 1 shown in for separating two media in spaces 2 and 3 not shown in detail basically comprises radial shaft seal rings 4 and 5 which The seals are connected to each other in a ring-locking manner. The sealing lips 6 and 7 are oriented axially opposite. Their bases 8 and 9 bear against each other in the assembled state. The space 10 formed between the sealing lips 6 and 7 is provided with an outward ventilation 32 . The shaft 11 surrounded by the seal is shown in dashed lines. The sealing lip 6 visible in the figure is larger than the sealing lip 7 . In this embodiment, the coil springs 12 and 13 used have different dimensions and are matched accordingly. Also possible are embodiments in which the two lips are of the same size. The sealing lips 6 and 7 are each provided with return grooves 14 and 15 , which bring about a return of leakage fluid in the corresponding direction of rotation of the shaft. In this case...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com