Impregnated PDC bit

A drill bit and impregnated technology, which is applied in the direction of drill bit, drilling equipment, earthwork drilling, etc., can solve the problem of low ROP of impregnated diamond drill bit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the figures.

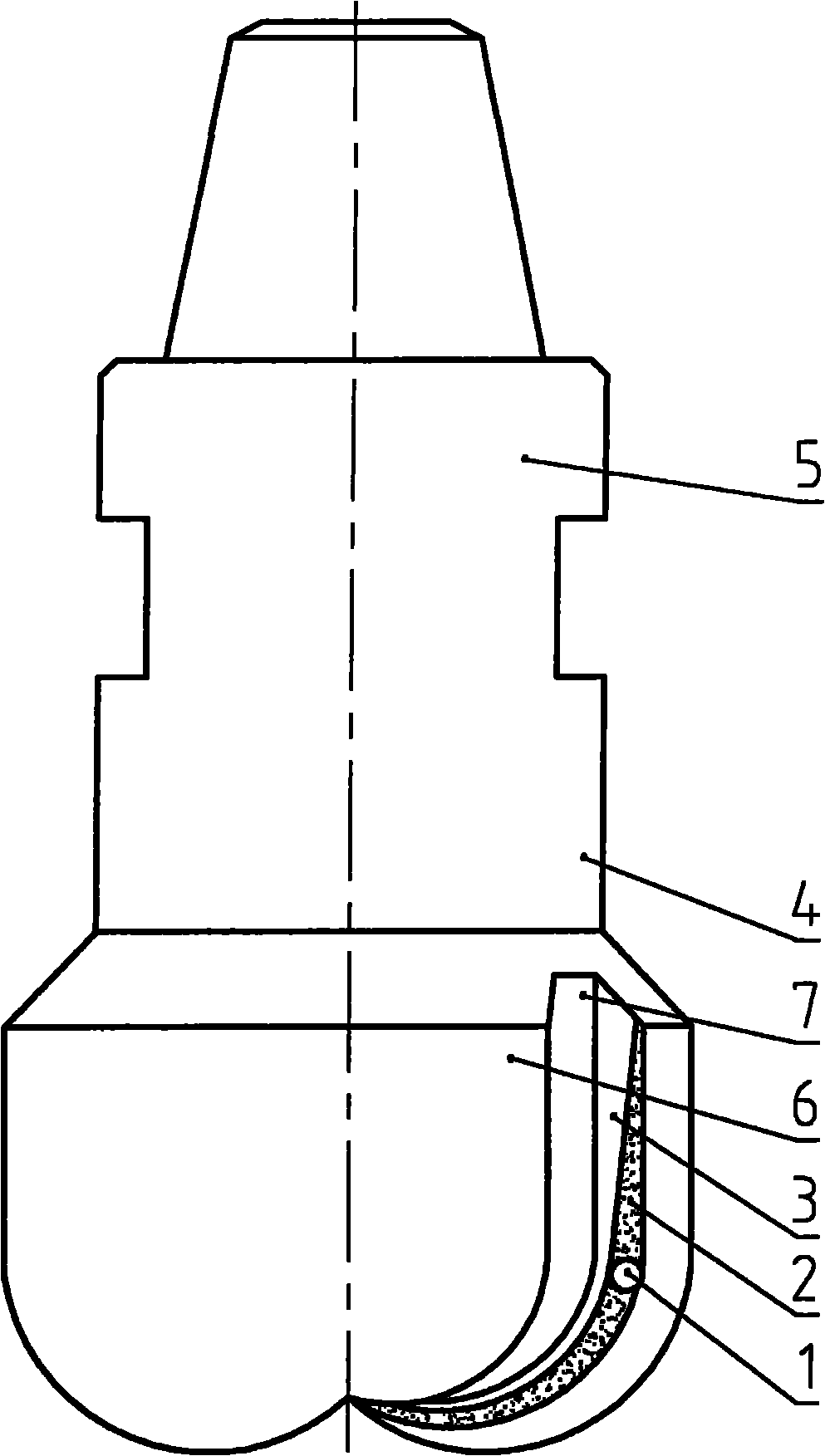

[0009] figure 1 The impregnated PDC bit is composed of a PDC composite sheet 1, a diamond-impregnated layer 2, a matrix 3, a steel core 4 and a joint 5, and the diamond-impregnated layer 2, the matrix 3 and the steel core 4 are sintered into a bit body 6, A flow channel 7 is arranged on the impregnated diamond layer 2 and the matrix 3 of the bit body 6. The PDC composite sheet 1 is impregnated in the impregnated diamond layer 2, and the diameter of the exposed 0 ~ PDC composite sheet / 3 is in the impregnated surface. State, and cover the crown contour line of the drill bit, the drill bit body 6 is connected with the joint 5 .

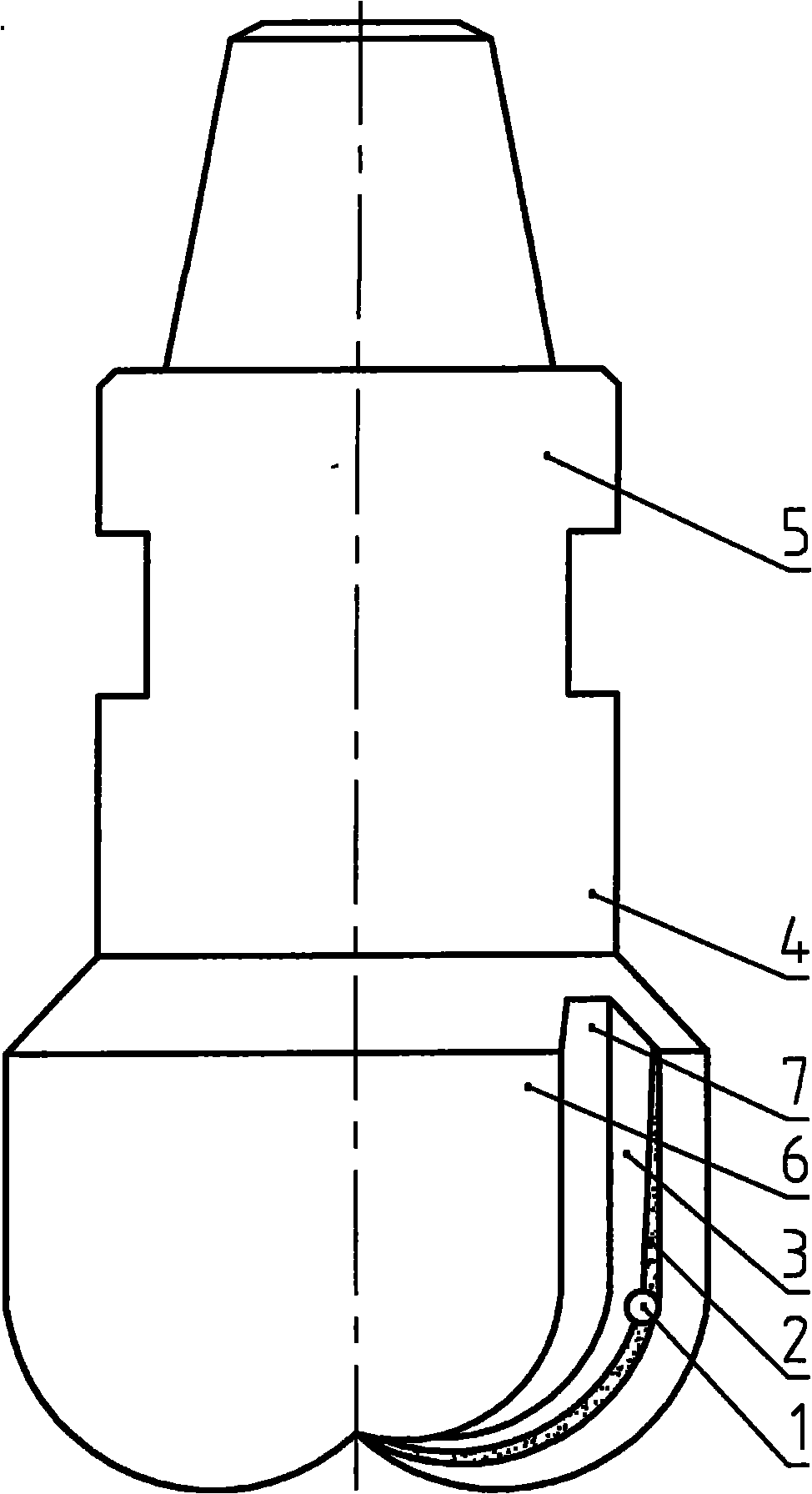

[0010] figure 2 Shown are impregnated PDC bits with figure 1 The impregnated PDC bit shown is similar, the difference is that the PDC composite sheet 1 is impregnated in the impregnated diamond layer 2 and the matrix 3, and the exposed 0 ~ PDC co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com