A composite vc radiator containing copper/diamond composite configuration liquid-absorbing core and its preparation method

A diamond, absorbent core technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating renovation, etc., can solve the problems of low thermal expansion, small diamond content, limited improvement in thermal conductivity, etc. The effect of small resistance, improved wettability, and improved overall heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

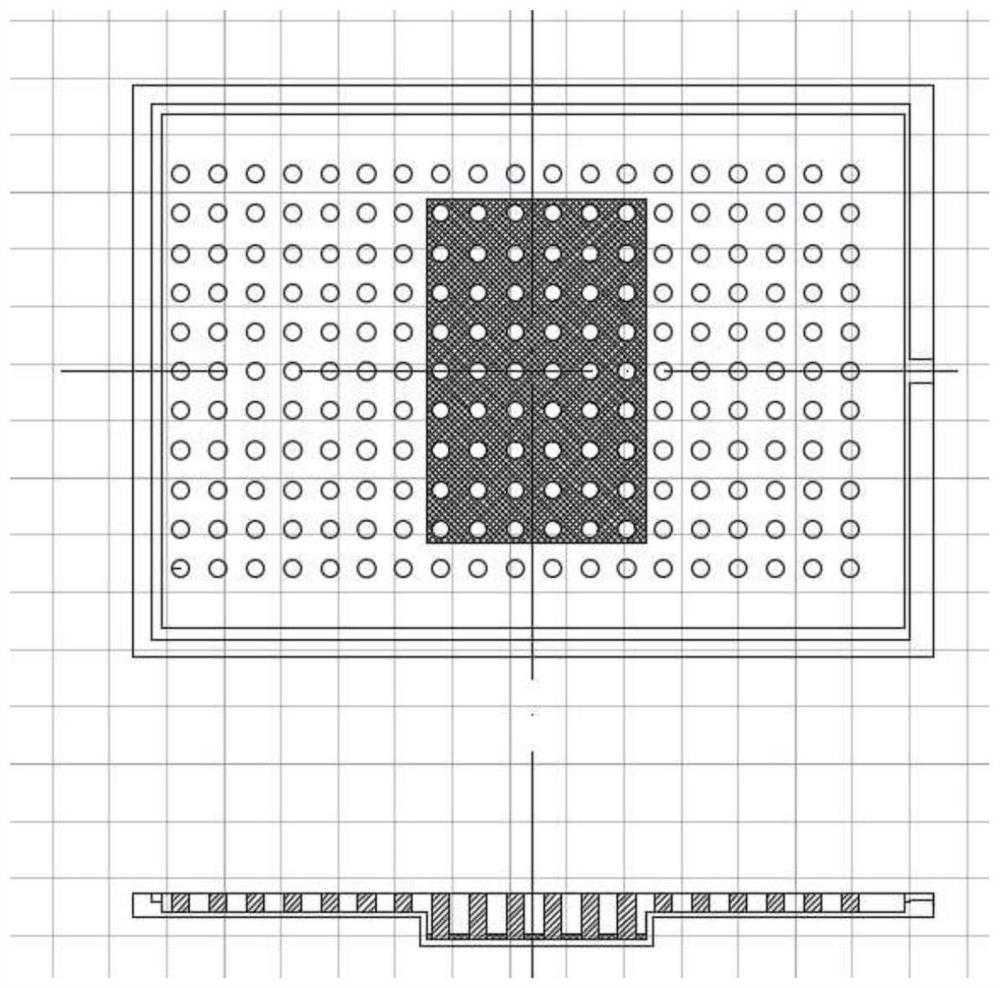

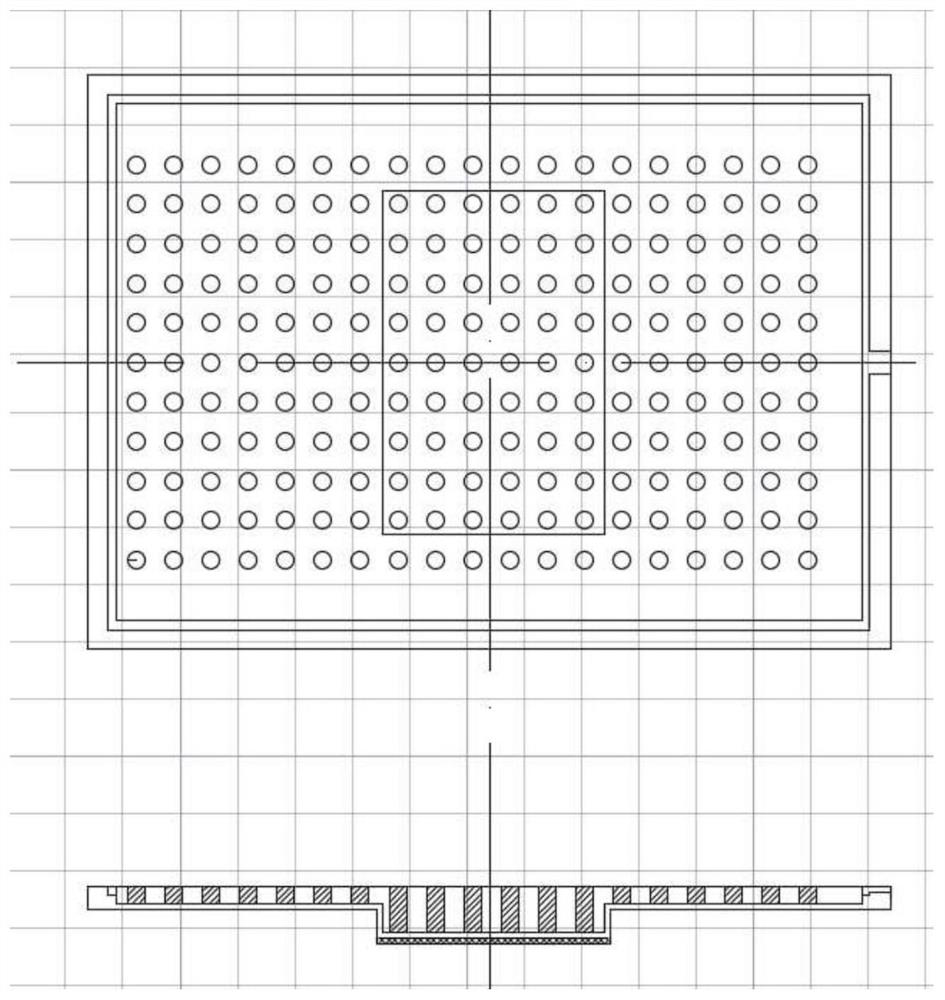

Image

Examples

Embodiment 1

[0059] Preparation of copper / diamond sintered framework:

[0060] Take diamond particles with a particle size of 150 μm (100 mesh) to deposit a Cr transition layer, the magnetron sputtering power is 200w, and the deposition time is 20 minutes to obtain diamond particles with a thickness of 2 μm containing a Cr transition layer, and then on the diamond particles containing Cr overcoating. The surface is copper-plated. The specific copper-plating process is as follows: magnetron sputtering power is 200w to obtain a copper cladding layer with a thickness of 2 μm, and then the diamond particles containing the copper cladding layer and the copper powder with a particle size of 150 μm are in a mass ratio of 40: 60 mixed to obtain mixed powder, loosely packed in a graphite mold, and sintered in a hydrogen atmosphere. During sintering, the temperature was first heated to 750°C at a rate of 5°C / min, and then heated to 900°C at a rate of 3.3°C / h. , holding time for 60min, and then air-c...

Embodiment 2

[0071] Preparation of copper / diamond sintered body:

[0072] Take diamond particles with a particle size of 250 μm (60 mesh) to deposit a Cr transition layer, the magnetron sputtering power is 200 W, and the deposition time is 90 min to obtain diamond particles with a thickness of 9 μm containing a Cr transition layer, and then the diamond particles containing Cr overcoating are obtained. The surface is copper-plated, and the specific copper-plating process is: magnetron sputtering power 200W, deposition time 90min to obtain a copper cladding layer with a thickness of 9μm, and then the diamond particles containing the copper cladding layer and the particle size of 150μm copper powder according to the quality Mixed at a ratio of 50:50 to obtain mixed powder, loosely packed in a graphite mold, and sintered in a hydrogen atmosphere. During sintering, the temperature was first heated to 750°C at a rate of 300°C / h (5°C / min), and then sintered at 200°C. The temperature was raised to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com