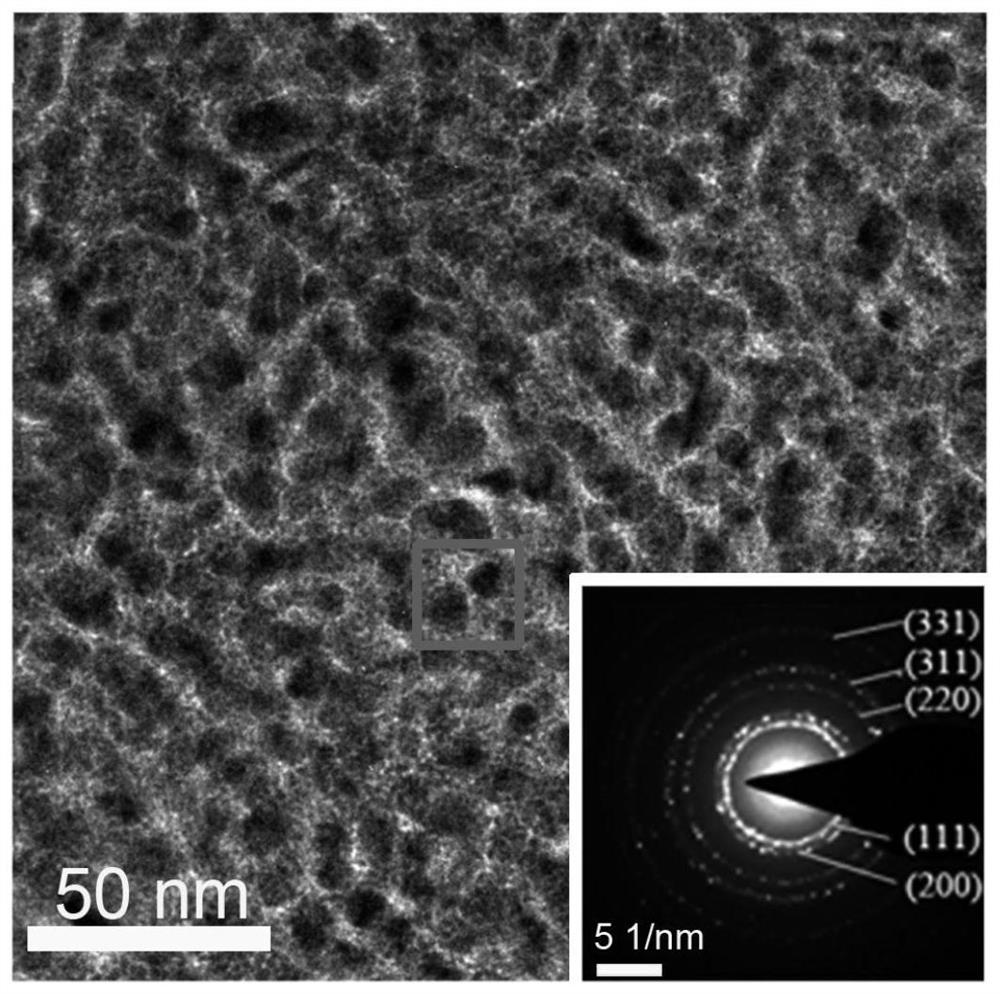

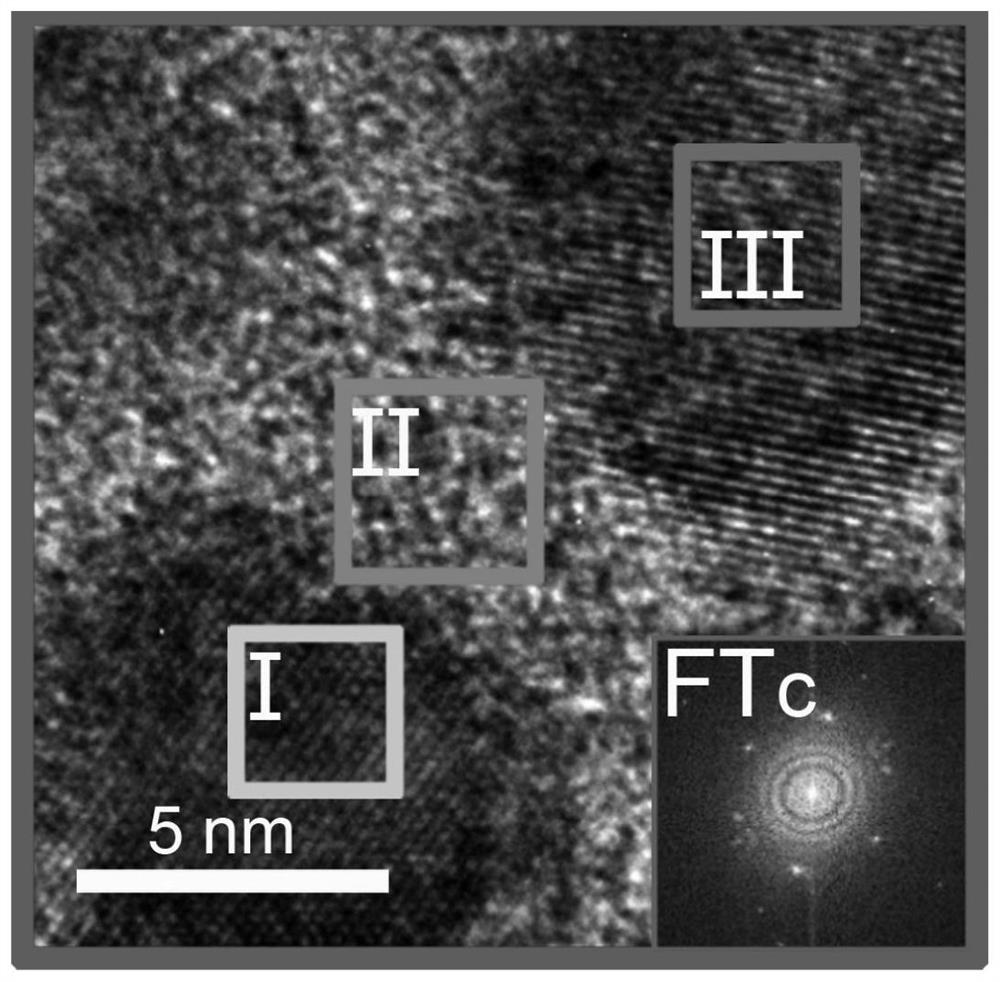

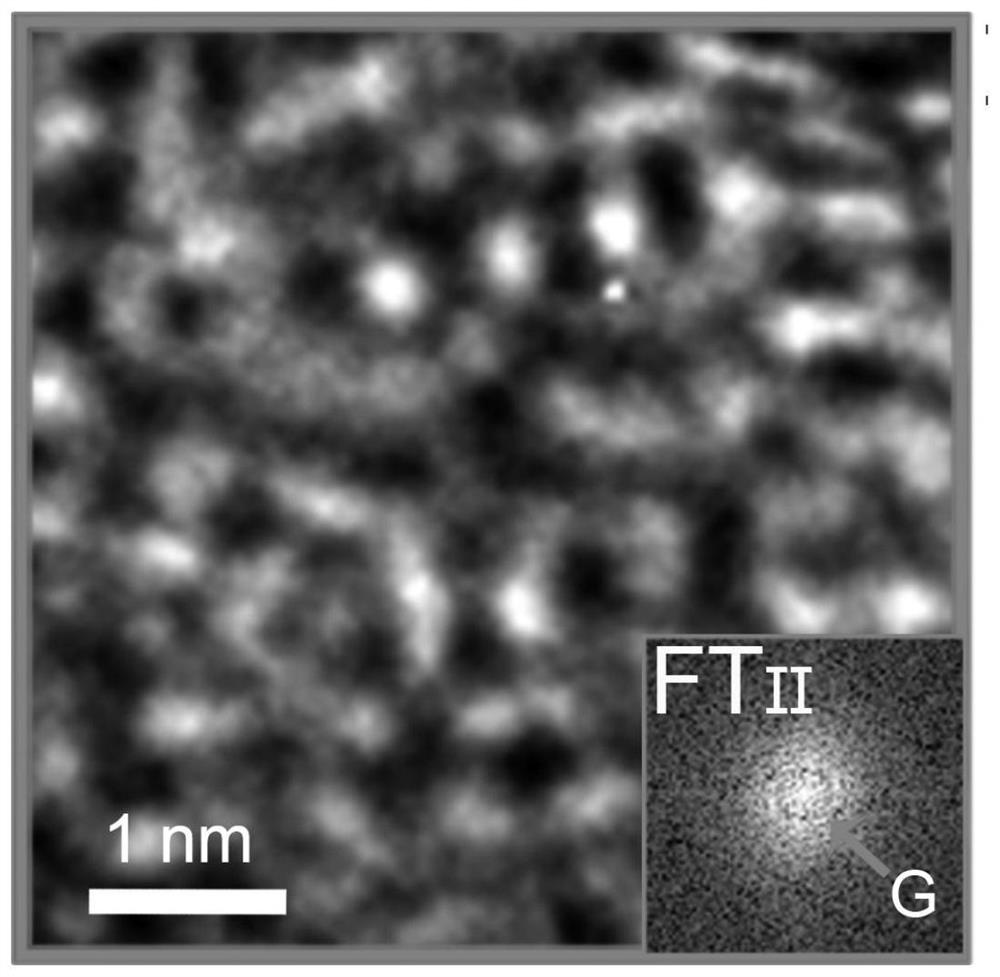

Method for converting graphite phase in nano-diamond film into diamond phase under low pressure

A nano-diamond and graphite phase technology, which is applied in metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of high preparation cost, harsh experimental conditions, and high difficulty in preparing large single crystals, and achieve phase transition The effect of low temperature and increased diamond content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] One end of 6 annealed tantalum wires with a diameter of 0.7 mm and a purity of 99.99% is fixed on the electrode column, and the other end is fixed on the spring sheet. This operation can ensure that the tantalum wire does not bend during the carbonization process. The carbonization chamber pressure was 5.3kPa, the carbon source was acetone in an ice-water bath, the bubbling gas was hydrogen, the ratio of the bubbling flow and the straight-through hydrogen flow was 80:100sccm, the carbonization voltage was 7V, and the holding time was 10min. The carbonization voltage was increased to 12V, and the holding time was 10min, the carbonization voltage was increased to 15V, and the holding time was 5min.

[0035] Prepare 0.05g / ml diamond suspension in glycerol, the particle size of diamond powder is about 1 micron, drop the prepared suspension on the surface of the polishing fleece, and polish the monocrystalline silicon substrate on the polishing fleece for 0.5h; A 0.01g / ml di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com