Full radial protection PDC bit

A drill bit and bit body technology, which is applied to drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of shortened service life, fragmentation and breakage of composite sheets, and achieves improved footage and ROP, simple manufacturing process, and extended The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

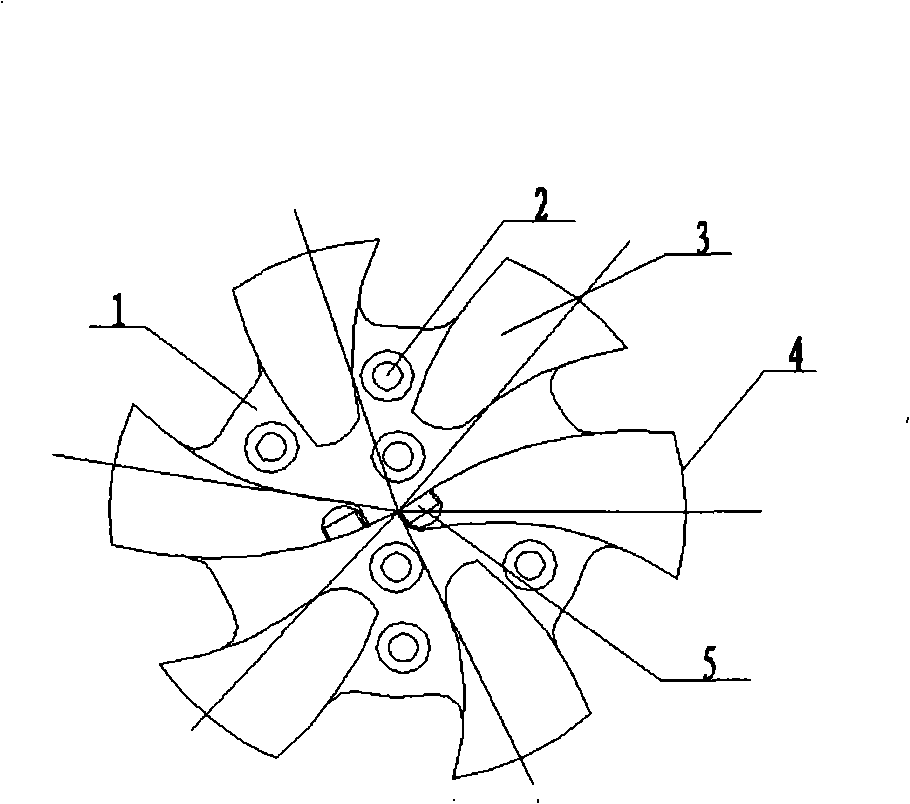

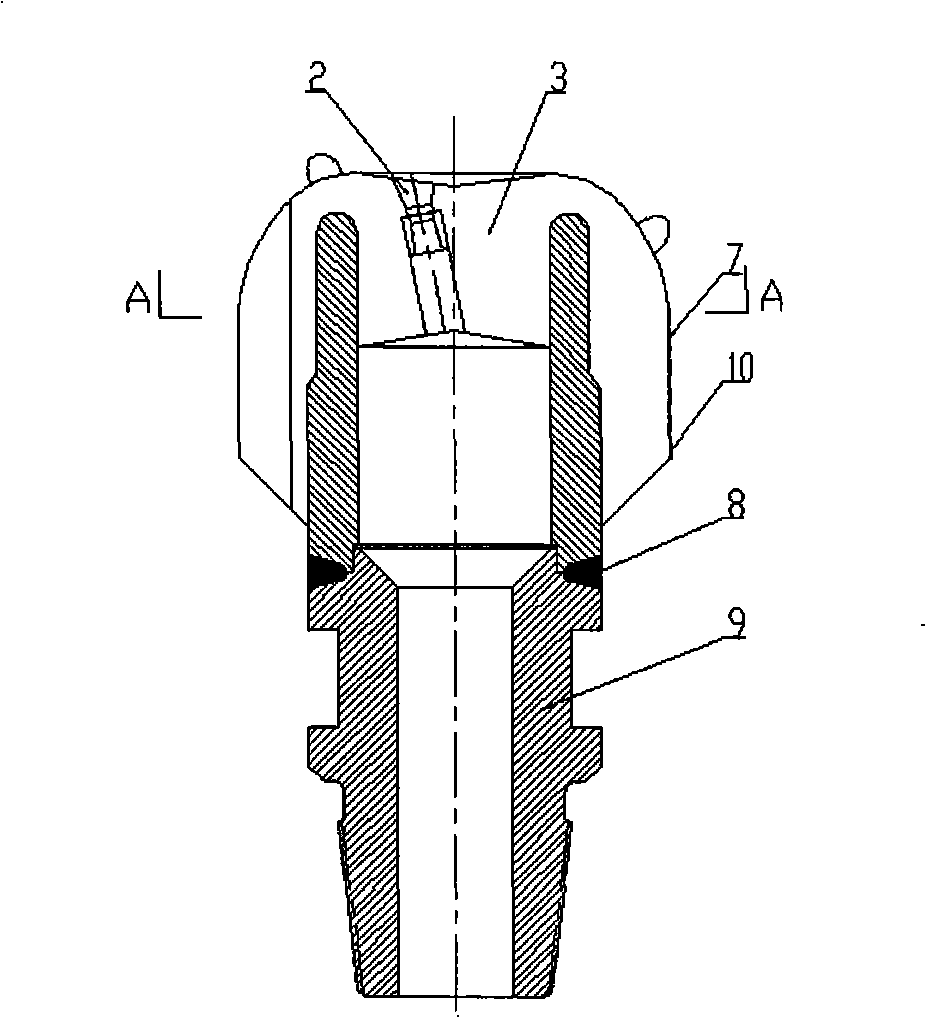

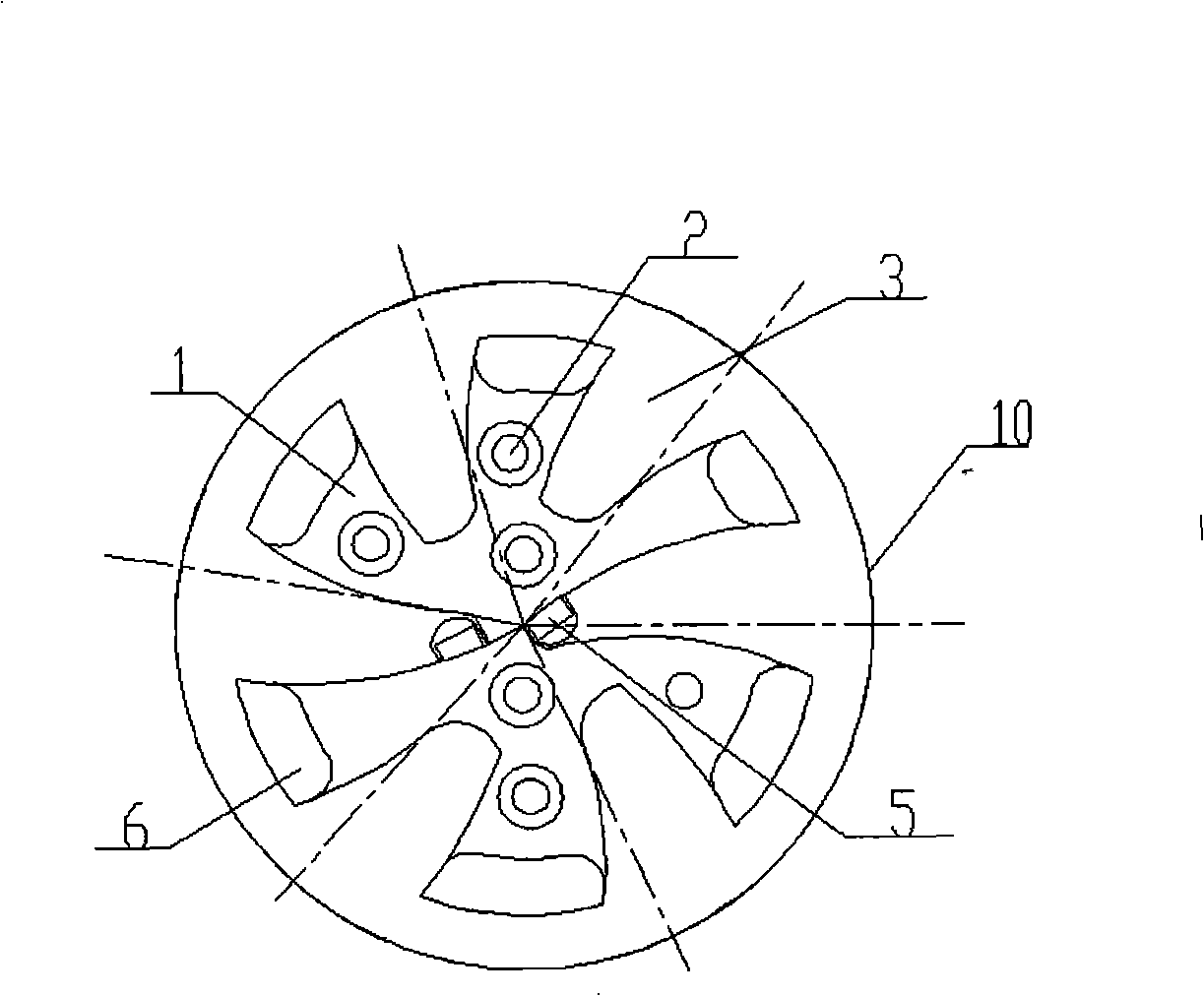

[0011] Such as Figure 1-4 As shown, the PDC drill bit is composed of a fluid flow channel 1, a nozzle 2, a drill body 3, a gauge diameter gauge 4 and a composite sheet 5, and the gauge gauge gauge gauge 4 is fixed on the protruding periphery of the drill bit body 3, and the fluid flow channel 1 is arranged on Between the gauge diameter and the gauge diameter 4, the nozzle 2 is arranged in the middle part of the drill body 3, and the composite sheet 5 is fixed on the top of the drill bit. A layer of casting is added on the periphery of the fluid flow channel 1 to fix it on the fluid flow channel 1 , and the casting makes the outer diameter of the gauge diameter gauge 4 connected into a smooth whole to form a gauge gauge full gauge gauge 10 . During production, on the basis of not changing the basic design principles and methods of ordinary PDC bits, based on the principles of rock elastic-plastic mechanics, hydrodynamics and kinematics, the pressureless impregnation method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com