A construction method for underground excavation of large-section tunnels in soft rock formations

A tunnel construction and large-section technology, which is applied in tunnels, tunnel linings, underground chambers, etc., can solve the problems of difficult ground deformation and arch settlement control, difficult blasting vibration speed control, and risk of sliding at the bottom of the wall. Achieve the effects of reducing construction risks, avoiding collapse accidents, and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

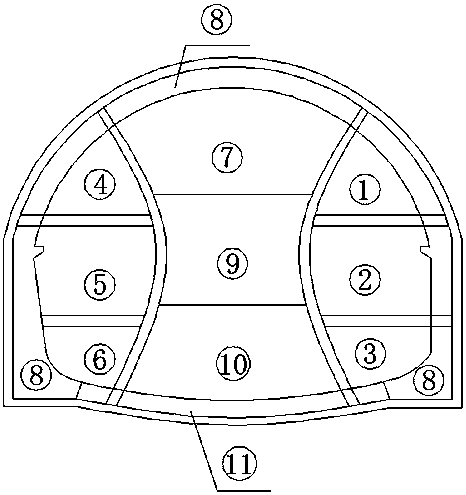

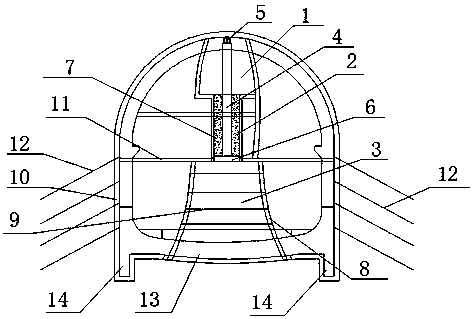

[0066] A construction method for underground excavation of large-section tunnels in soft rock formations, comprising the following steps:

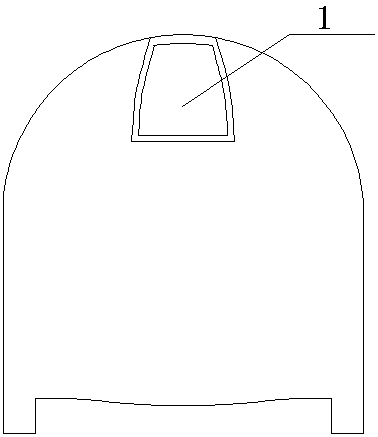

[0067] Step 1: If image 3 As shown, a small pilot tunnel 1 in the arch is excavated at the upper part of the center of the arch, and the small pilot tunnel 1 in the arch is initially supported;

[0068] Step 2: If Figure 4 As shown, in the small pilot tunnel 1 of the arch, manual excavation piles 2 are used for construction to the top of the core rock wall 3;

[0069] Step 3: If Figure 5 As shown, the steel pipe support 4 is lowered in the artificial excavation pile 2, the steel pipe support 4 runs through the artificial excavation pile 2 and the small pilot hole 1 in the arch, the longitudinal distance between the steel pipe support 4 is 3m-6m, and the top of the steel pipe support 4 passes through the shaped steel longitudinal beam 5 Supporting the vault, the bottom of the steel pipe support 4 is located on the independent foundati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com