Vertical prestress steel pipe supporting structure for large-section subsurface tunnel and construction process

A technology of vertical prestressing and steel pipe support, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as poor safety, achieve high safety, shorten costs, and reduce the impact of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

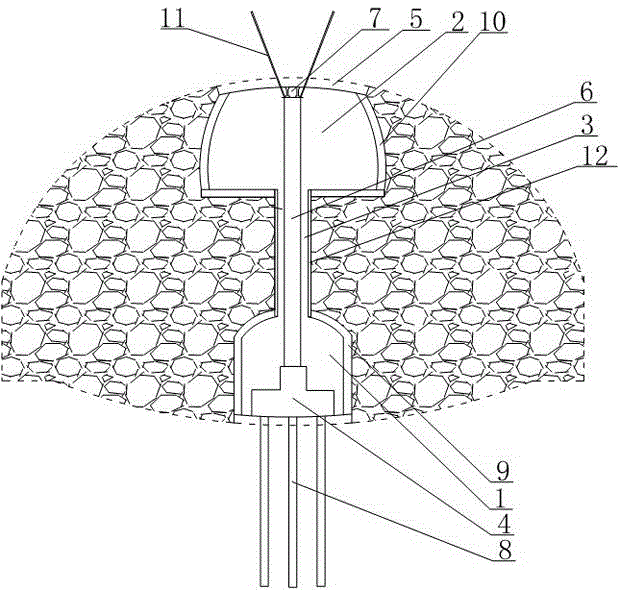

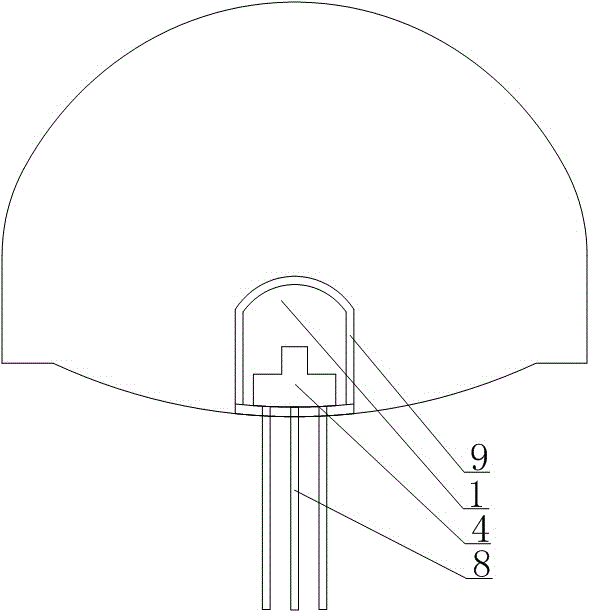

Method used

Image

Examples

Embodiment

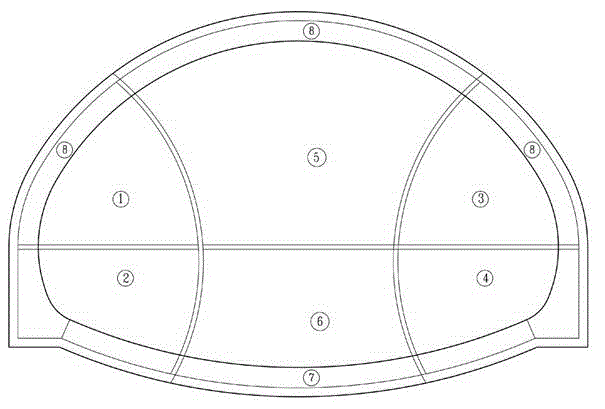

[0043] Taking the parking line tunnel project of a certain section of the Xi’an Metro as an example, the length of the project is 222.3 meters, the height of the cross section is 10.4 meters, the width is 13.5 meters, and the vault is covered with 8.4 meters of soil. The soil layer of the vault is saturated soft loess. Sewage pipes, rainwater pipes and gas pipelines have high requirements for settlement control. For example, according to the construction technology in the prior art, such as figure 1 The double side wall pilot pit method shown in the construction,

[0044] Step 1, Excavation of the left upper pilot pit ①, initial support;

[0045] Step 2, Excavation of the left lower pilot pit ②, initial support;

[0046] Step 3, Excavation of the upper pilot pit on the right side ③, initial support;

[0047] Step 4, Excavation of the right lower pilot pit ④, initial support;

[0048] Step 5, Excavation of pilot pit ⑤ in the upper part of the middle, initial support;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com