Eccentric oscillating reduction gear and stabilizer shaft rotating device using eccentric oscillating reduction gear

An eccentric swing and reducer technology, applied in transmission, gear transmission, transportation and packaging, etc., can solve the problem of high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

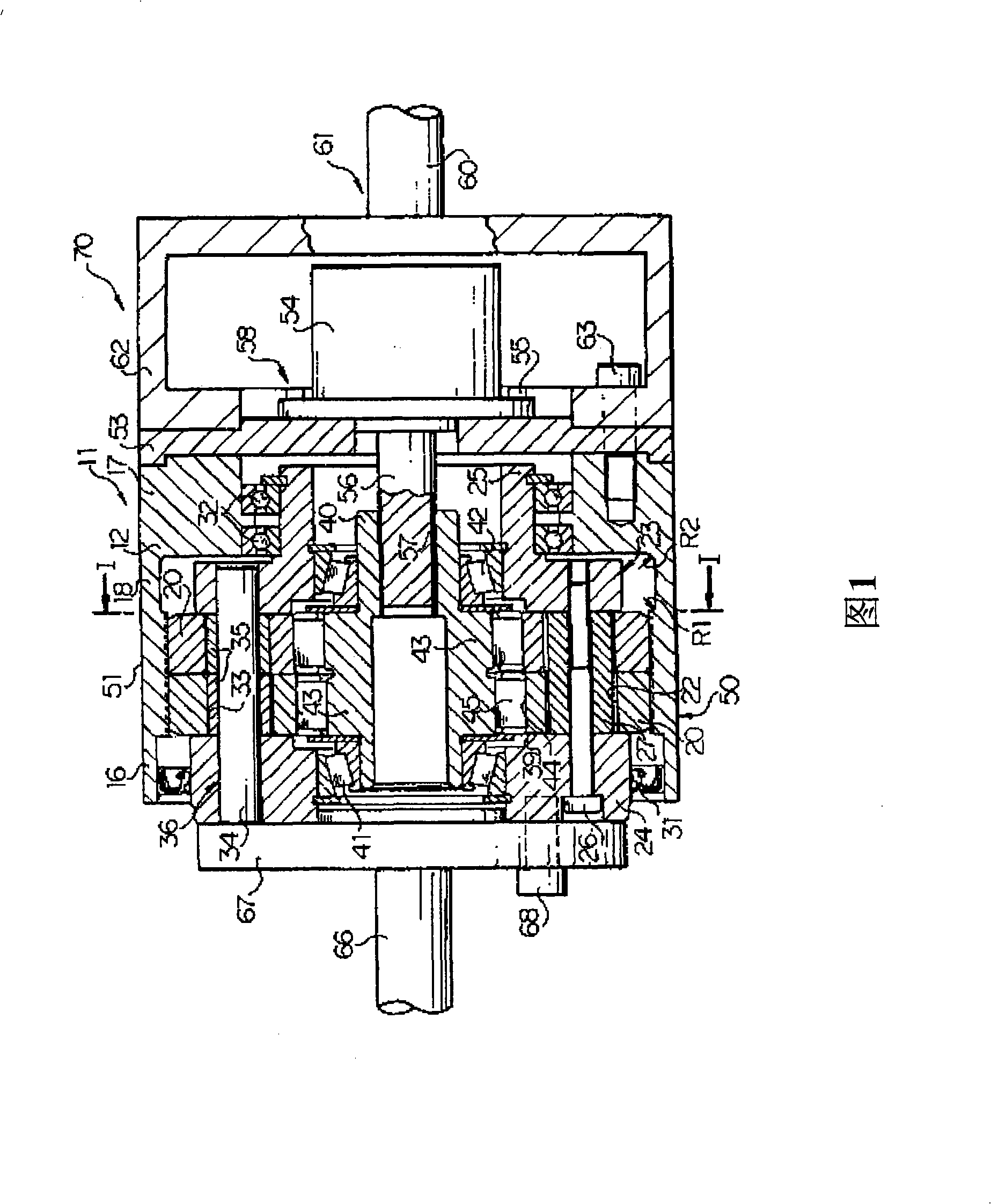

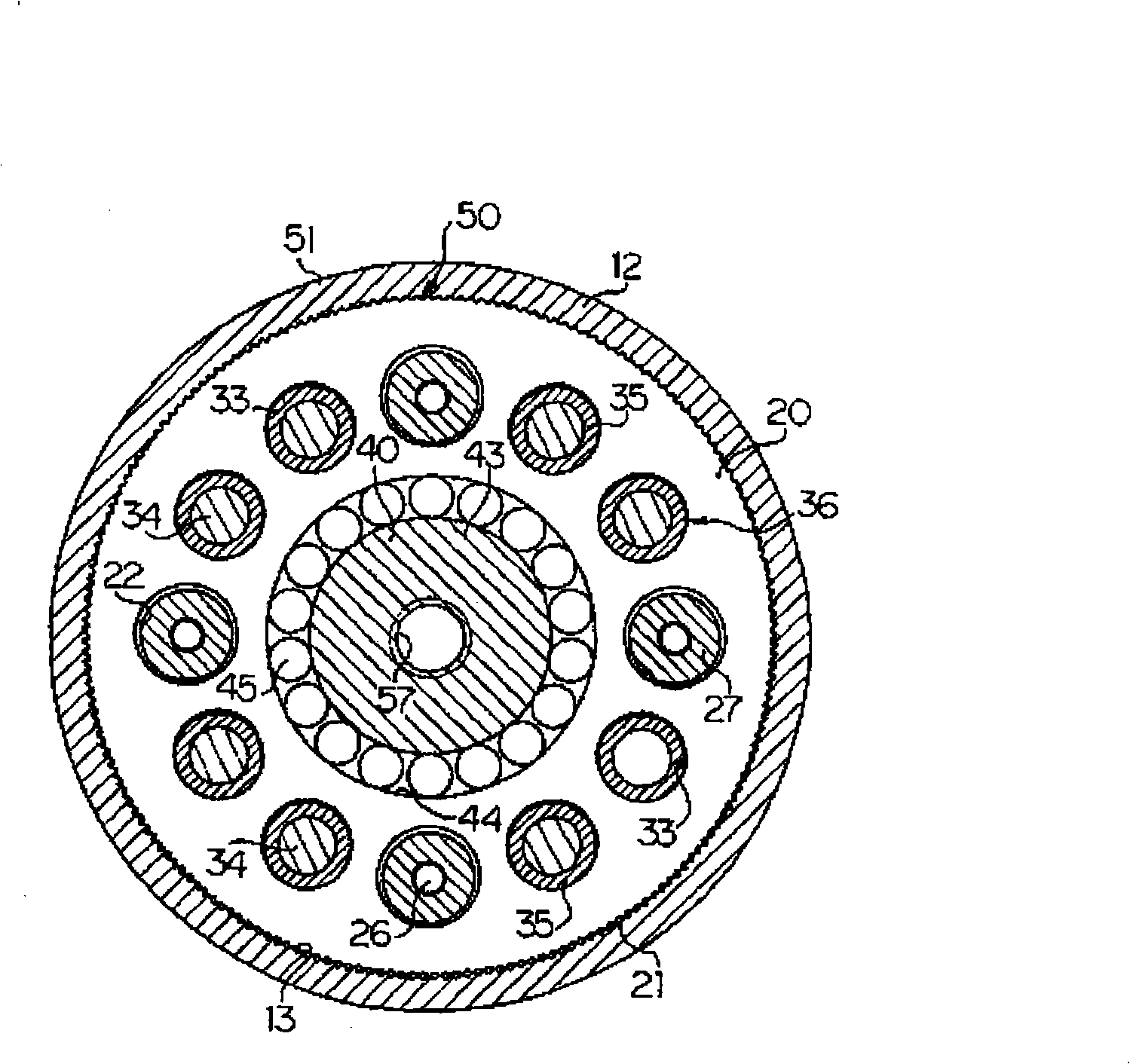

[0020] Hereinafter, Embodiment 1 of the present invention is described with reference to the drawings.

[0021] exist figure 1 , 2 In and 3, reference numeral 11 denotes an eccentric oscillating type speed reducer that reduces the input rotation speed and outputs the reduced rotation speed. The eccentric oscillating speed reducer 11 has a cylindrical housing 12 . Many internal teeth 13 whose inter-tooth curves extend in the axial direction are integrally formed, for example, by cutting using a hob or a shaper cutter, or by precision casting.

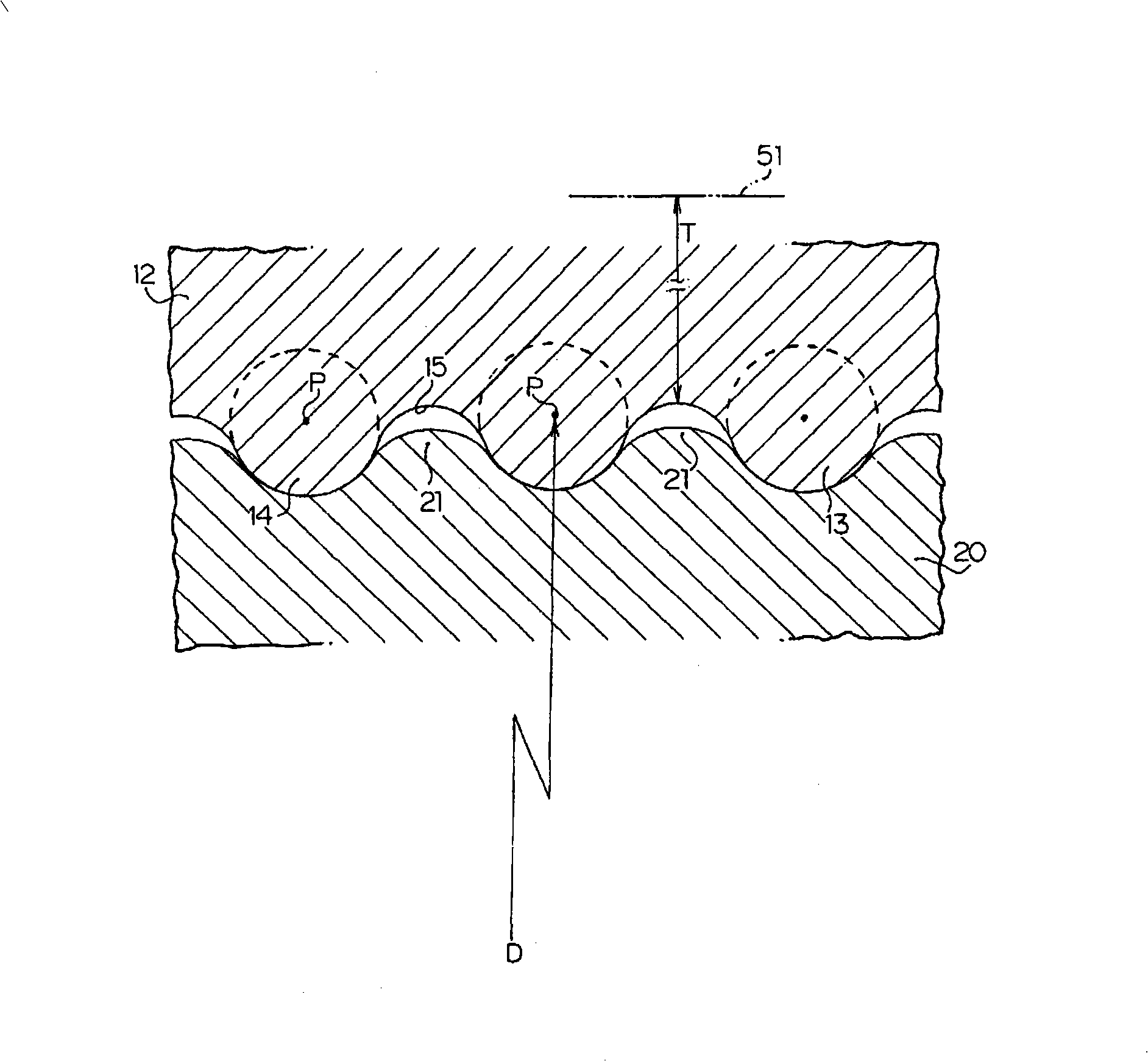

[0022] The internal teeth 13 are composed of a plurality of convex arc portions 14 and a plurality of concave arc portions 15, the convex arc portions 14 protrude radially inward and have an outer contour with a predetermined radius of curvature , each of the concave arc portions 15 is smoothly connected with the adjacent convex arc portion 14 and is radially recessed outward. Accordingly, the internal teeth 13 are formed by teeth ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com