Patents

Literature

43 results about "Interbedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geology, interbedding occurs when beds (layers or rock) of a particular lithology lie between or alternate with beds of a different lithology. For example, sedimentary rocks may be interbedded if there were sea level variations in their sedimentary depositional environment.

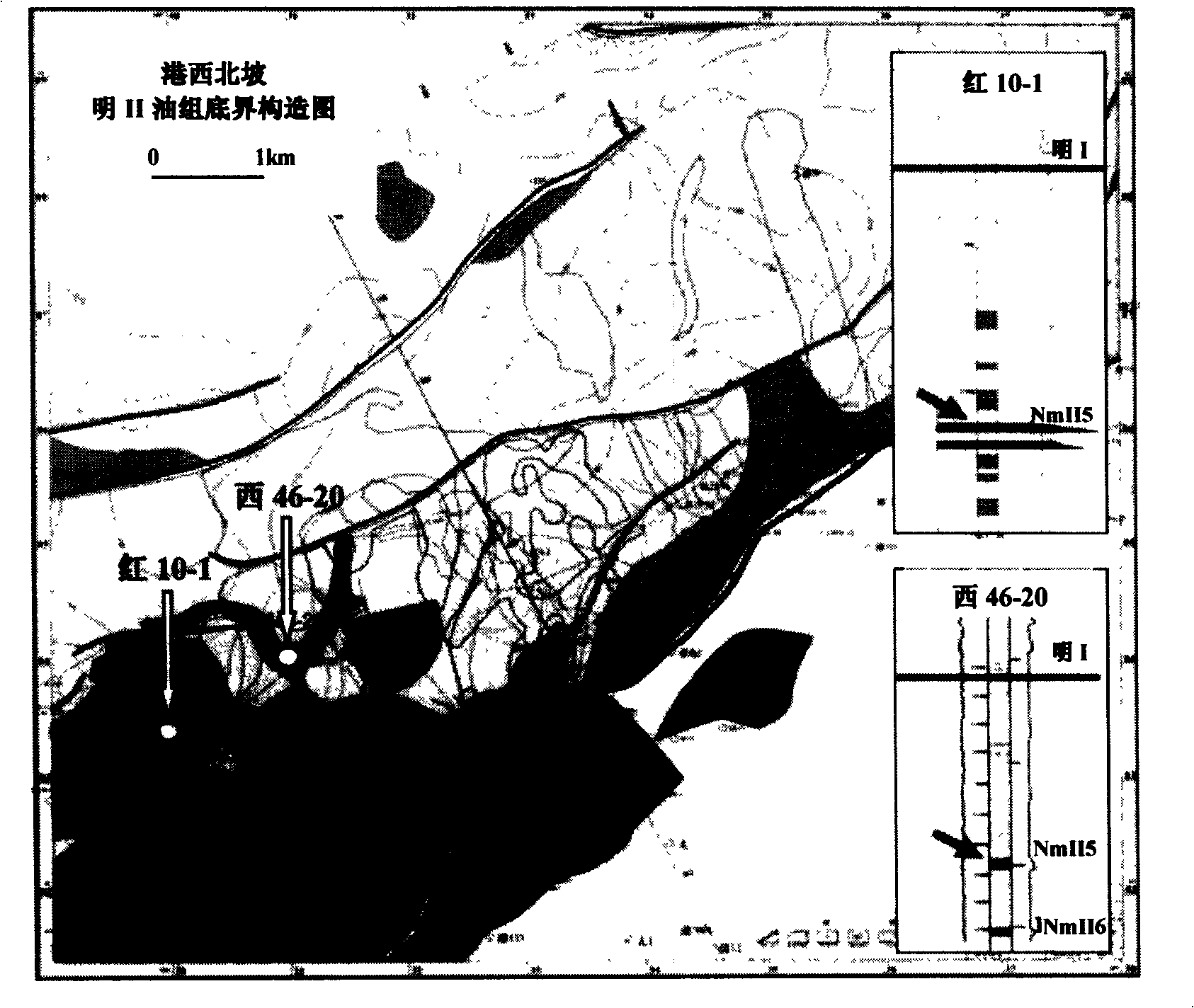

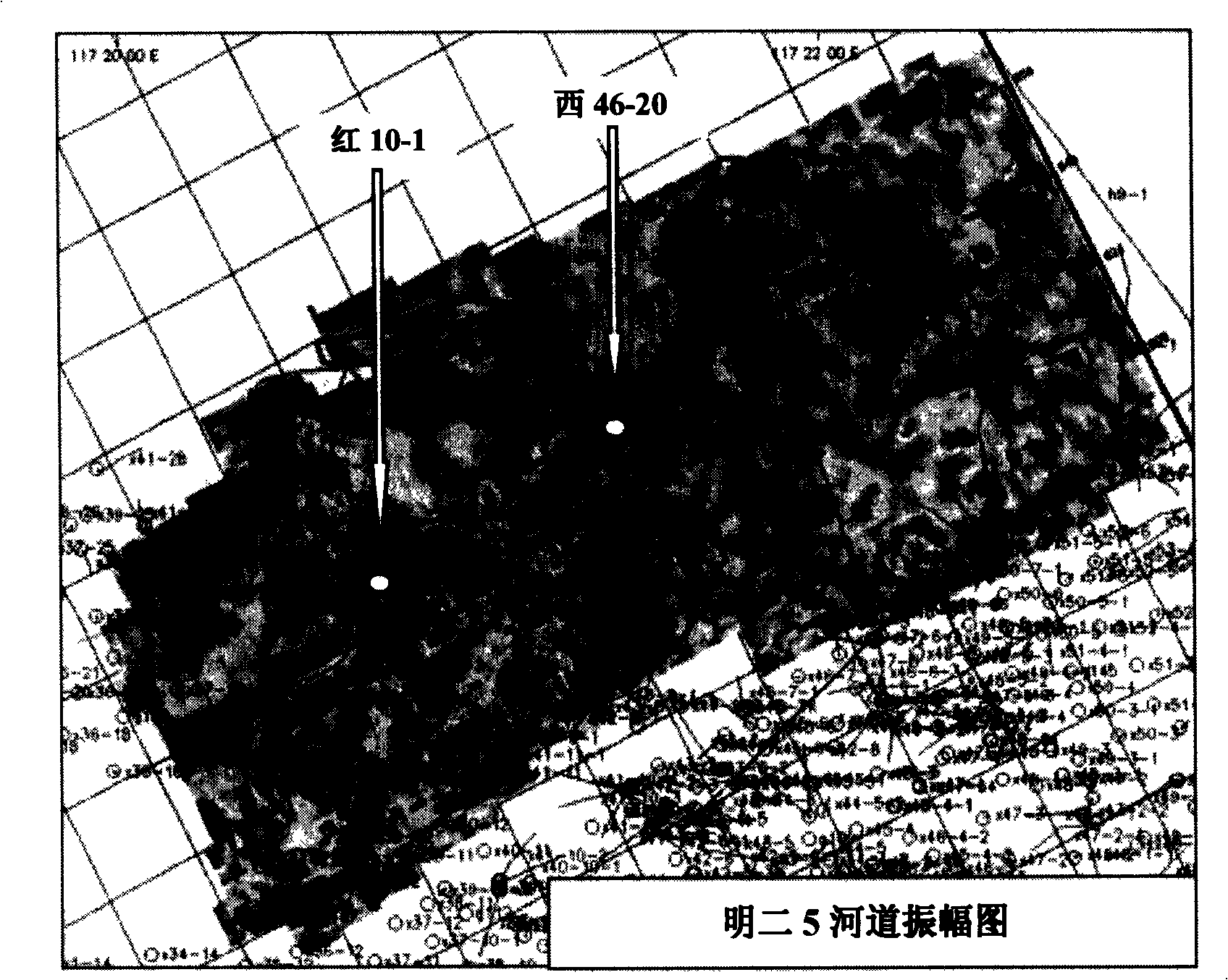

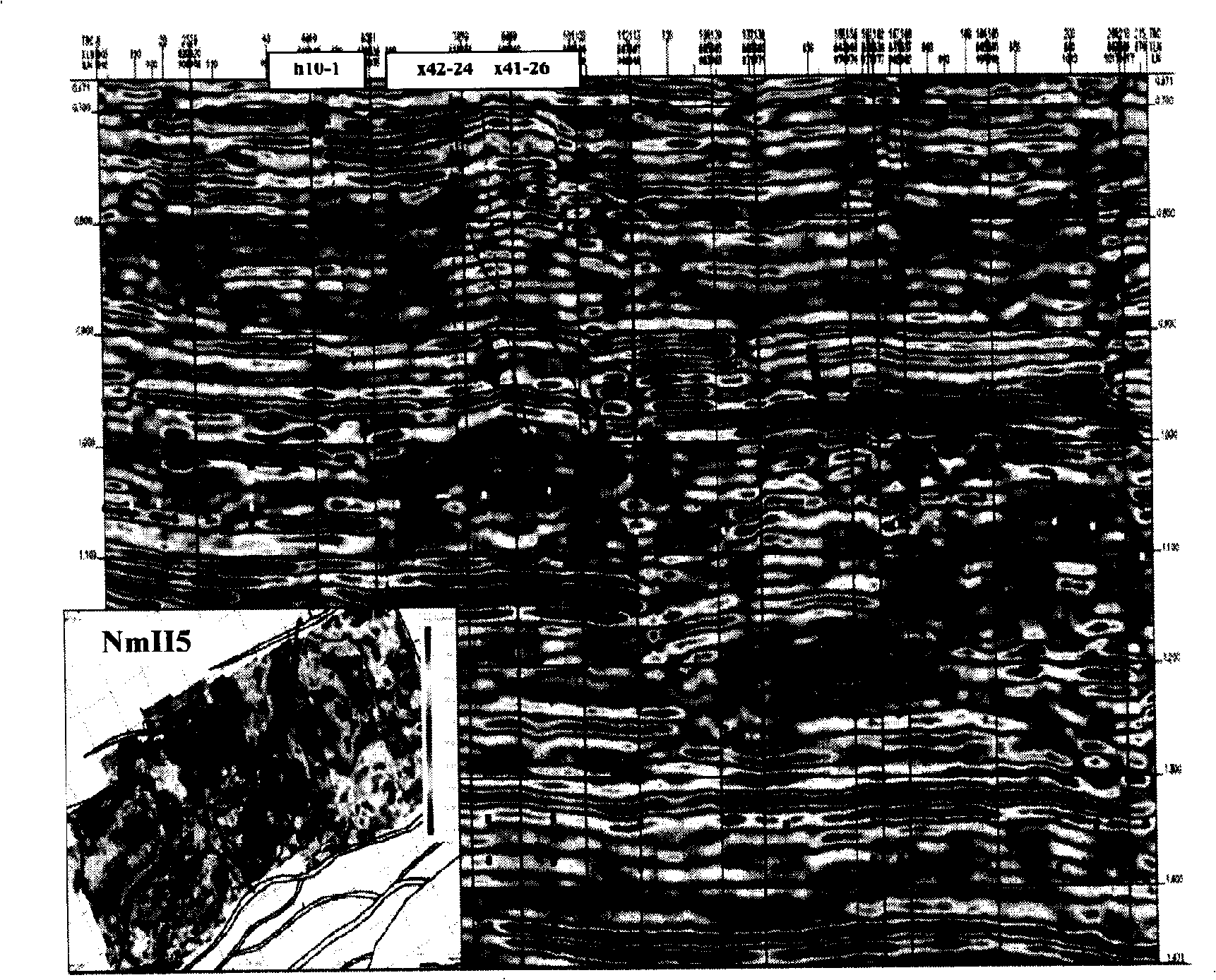

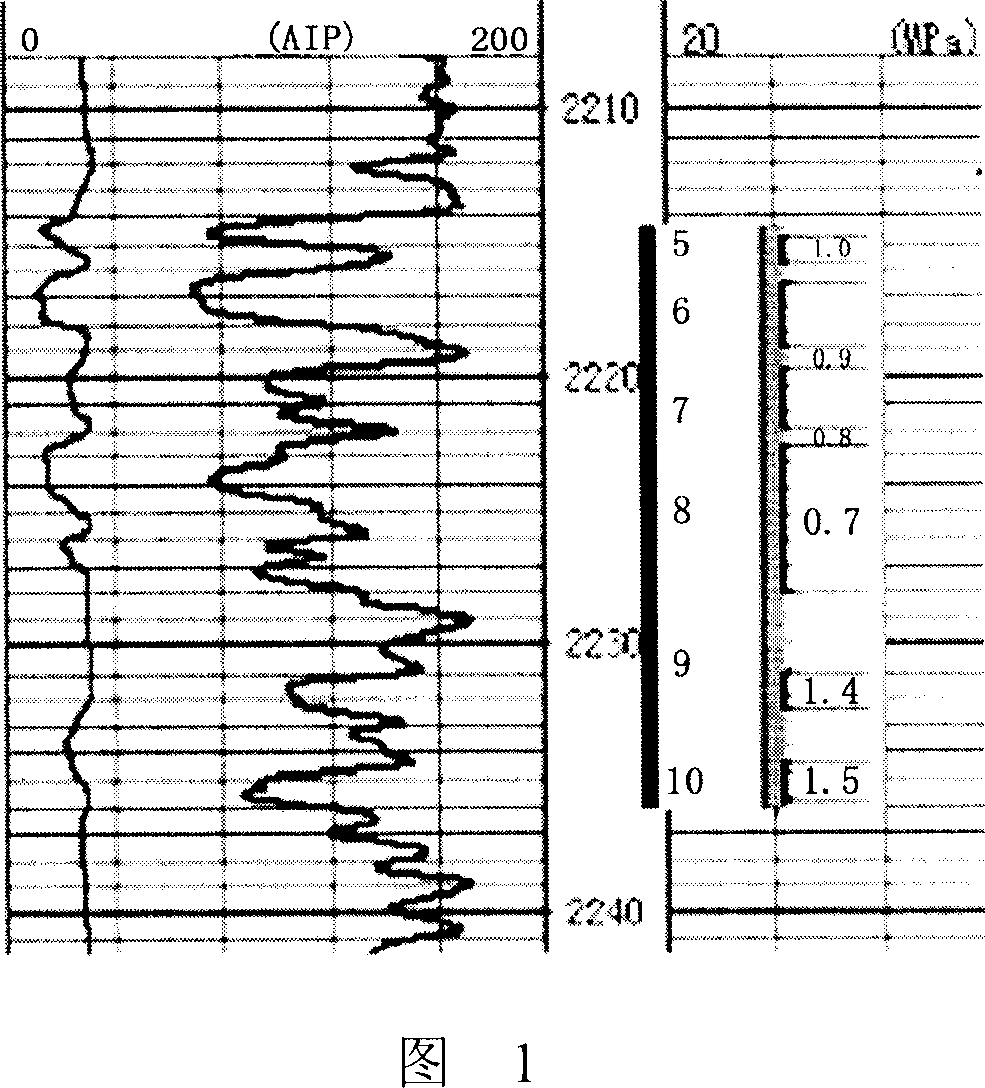

Forecasting and evaluating technologies of three-dimensional earthquake optimum time window river course sand body storage layer

InactiveCN101408624AHigh-resolutionImprove frequency division inversionSeismic signal processingDepth conversionRoot mean square

The invention discloses a prediction and evaluation technology of 3D seismic optimum time window river channel sand body reservoirs, belongs to the technical field of the prediction and evaluation of the 3D seismic reservoirs, and aims at solving technical problem that the river channel predictive resolution of the traditional methods is not enough. The technical proposal is as follows: the 3D visualization scanning is performed on each reservoir at the interval of 1-2ms, the optimum time window is determined according to the scope shown by the target river channel, the corresponding subfield is cut out, clairvoyance and scanning are carried out on the time window properties, such as root-mean-square amplitude, wave impedance and the like, auto-tracing is performed, top surface and bottom surface are picked up, a time isopach map is calculated and converted into a sand body isopach map, a top surface structure diagram is formed by time-depth conversion, and the reservoir physical properties are evaluated by curve reconstruction, thus realizing the prediction and evaluation of the plane morphology, longitudinal thickness and the reservoir physical properties of the river channel sand body. The method adopts the optimum time window to effectively inhibit interference, is applicable to various data volumes, and can effectively predict and evaluate a thin river channel sand body with the thickness far less than 1 / 4 of a wavelength under the condition of frequent interbedding of sand and mudstone, the thin river channel sand body comprises the river channel sand body which is not corresponding to wave crest or wave trough, and the method has good application effect in petroleum exploration and development.

Owner:陶庆学 +2

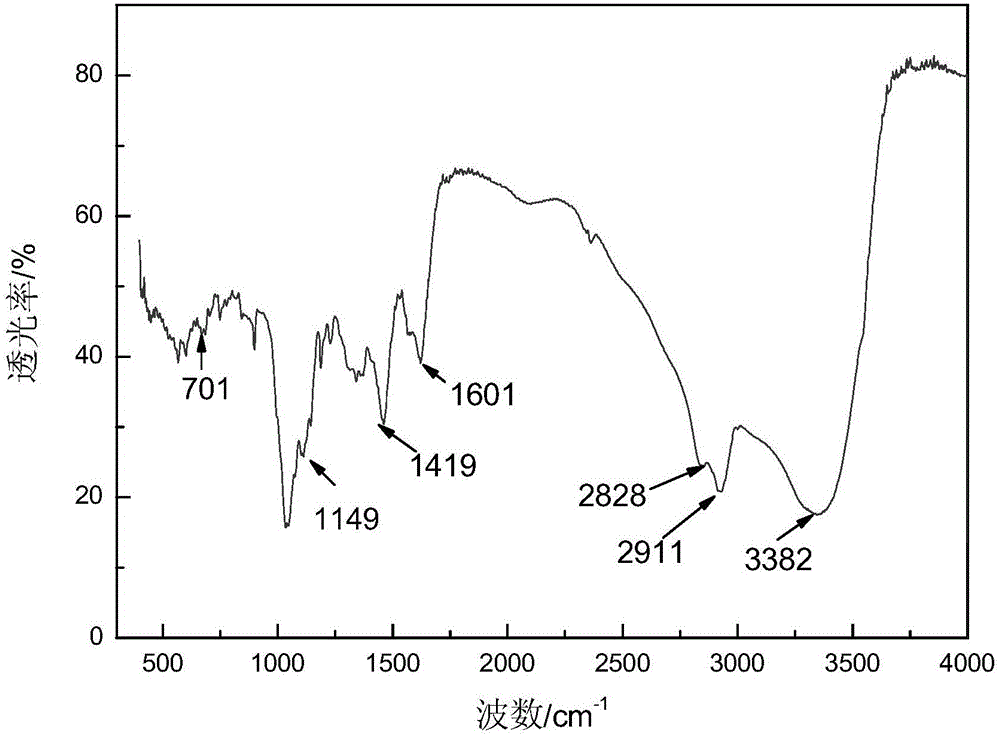

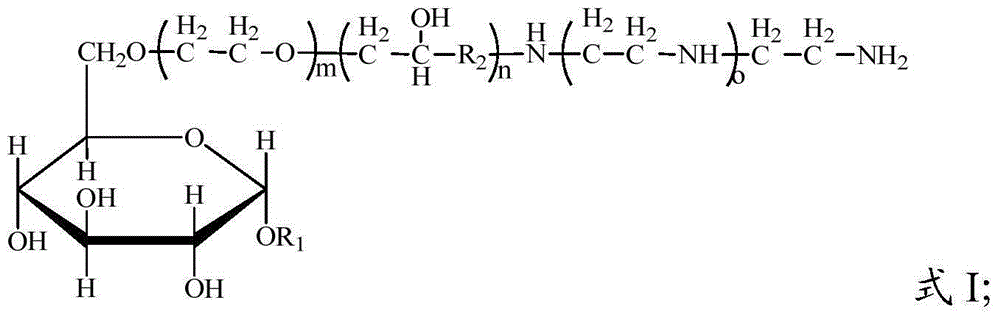

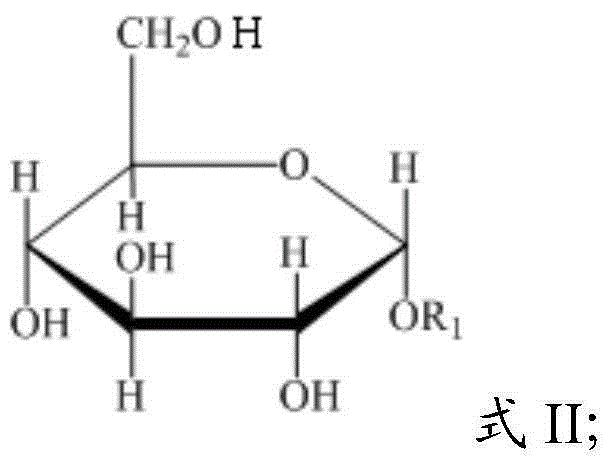

Polyether amine alkyl glycoside and preparation method and application thereof

ActiveCN106432375AEnhanced inhibitory effectImprove the lubrication effectSugar derivativesDrilling compositionMethyl groupLubrication

The invention provides polyether amine alkyl glycoside with the structure as shown in the formula I; in the formula I, m is 1 to 16, n is 1 to 3, R1 is alkyl of which the carbon atomic number is 1 to 10 and R2 is methyl or ethyl. The invention provides a preparation method of polyether amine alkyl glycoside adopting the technical solution; the method comprises the following steps: reacting chlorinated epoxides, dihydric alcohol compounds, water and acid catalysts to obtain a reaction product; reacting the reaction product with organic amine to obtain an intermediate product; reacting the intermediate product with alkyl glycoside to obtain polyether amine alkyl glycoside. The polyether amine alkyl glycoside provided by the invention is good in inhibition performances and lubrication performances and can be applied to drilling fluid. Polyether amine alkyl glycoside is added in the drilling fluid, so that the problems of easy sloughing formation of strong water-sensitive shale, sandstone-mudstone interbedding and basalt-mudstone interbedding and the like can be solved by the drilling fluid. The polyether amine alkyl glycoside is suitable for well drilling construction of a shale gas horizontal well.

Owner:CHINA PETROCHEMICAL CORP +2

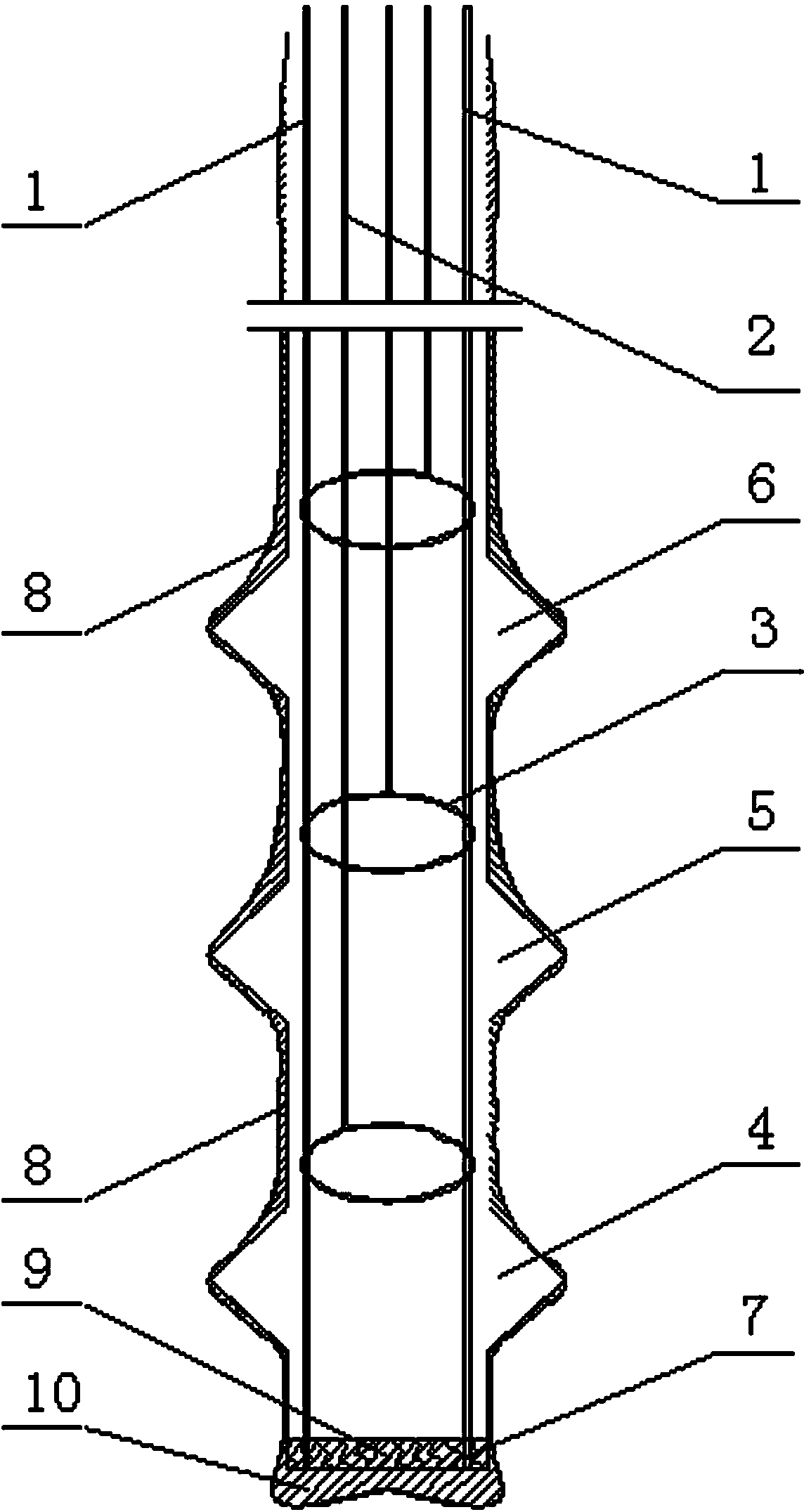

Construction method of post-grouting squeezing and expanding combination cast-in-place bored pile

InactiveCN103452100AImprove bearing capacityEliminate and reduce impactBulkheads/pilesEngineeringRebar

The invention discloses a construction method of a post-grouting squeezing and expanding combination cast-in-place bored pile, which is suitable for being adopted under a geological condition of soft and hard interbedding. The construction method comprises the following steps of (1) drilling construction; (2) squeezing and expanding bearing disk construction; (3) borehole cleaning; (4) arrangement of a post-grouting device and downward arrangement of a reinforcing case; (5) concrete spouting; (6) post-grouting construction at the pile end and the pile side. According to the construction method disclosed by the invention, a pile foundation post-grouting technology and a pile squeezing and expanding construction technology are organically combined, and the problems of increasing the single-pile bearing capacity and reducing post-construction settlement and differential settlement of a foundation pile under the geological condition of soft and hard interbedding are solved; the construction method is suitable for being used in the situation that high single-pile bearing capacity, low post-construction settlement and low differential settlement are required under the geological condition of soft and hard interbedding, and the construction cost can be reduced.

Owner:HEBEI CONSTR & INVESTIGATION RES INST

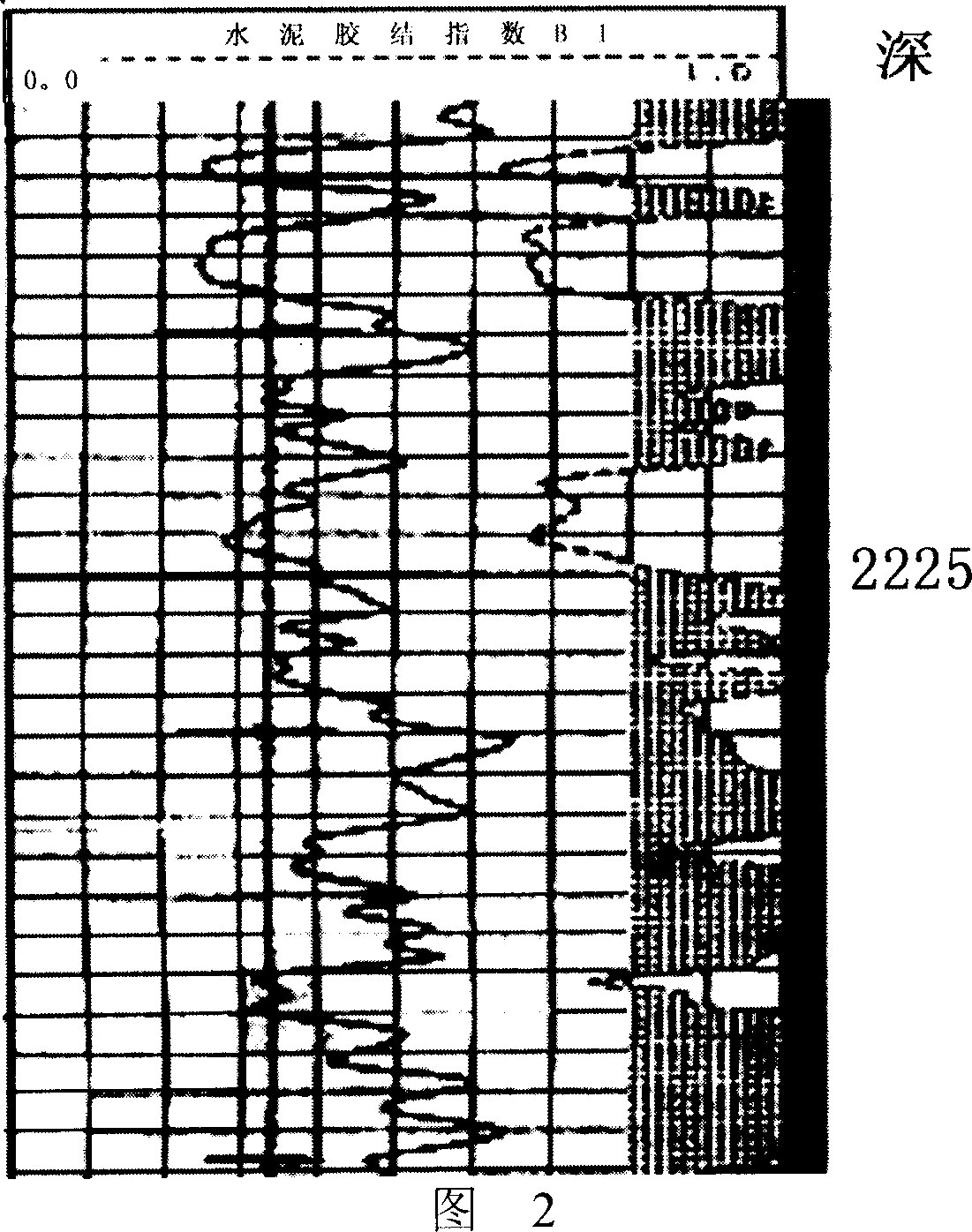

Zonation method of thin interbed in low infiltration of fracturing layer segment

InactiveCN1959062AImprove the degree of transformationImprove the blocking effectFluid removalComputer scienceLine segment

The present invention relates to a low permeable thin-interbedding fractured interval layering method. Said method includes the following steps: (1) defining effective barrier bed; (2) making restraining barrier protection, adopting low-displacement variable-displacement and low thickener concentration fracture treatment; and (3) making separate layer fracturing treatment. Said method can utilize interbed property, interbed thickness and core intersection to make division of fractured interval and can make the layer whose restraining barrier and oil layer earth stress difference value is greater than 4 MPa and restraining barrier thickness is greater than 2 m implement separate layer fracturing treatment.

Owner:DAQING OILFIELD CO LTD

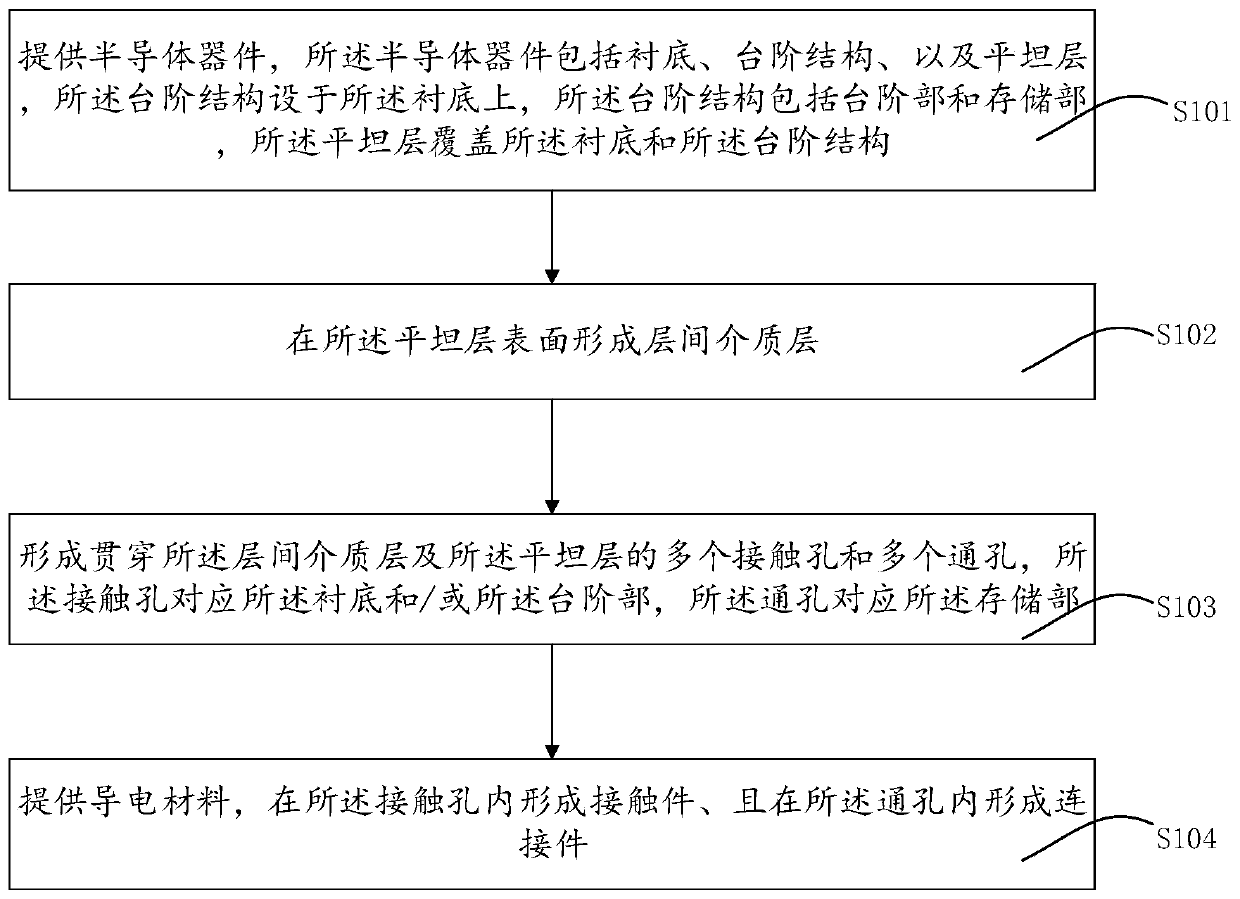

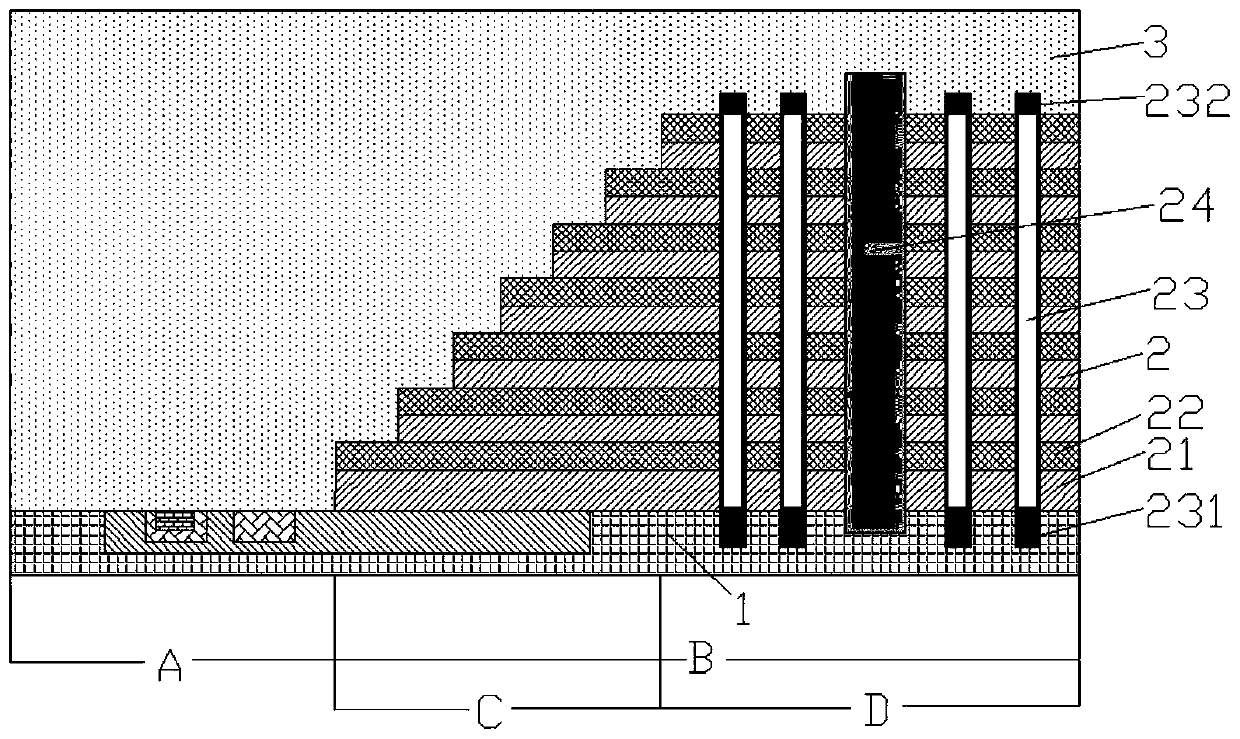

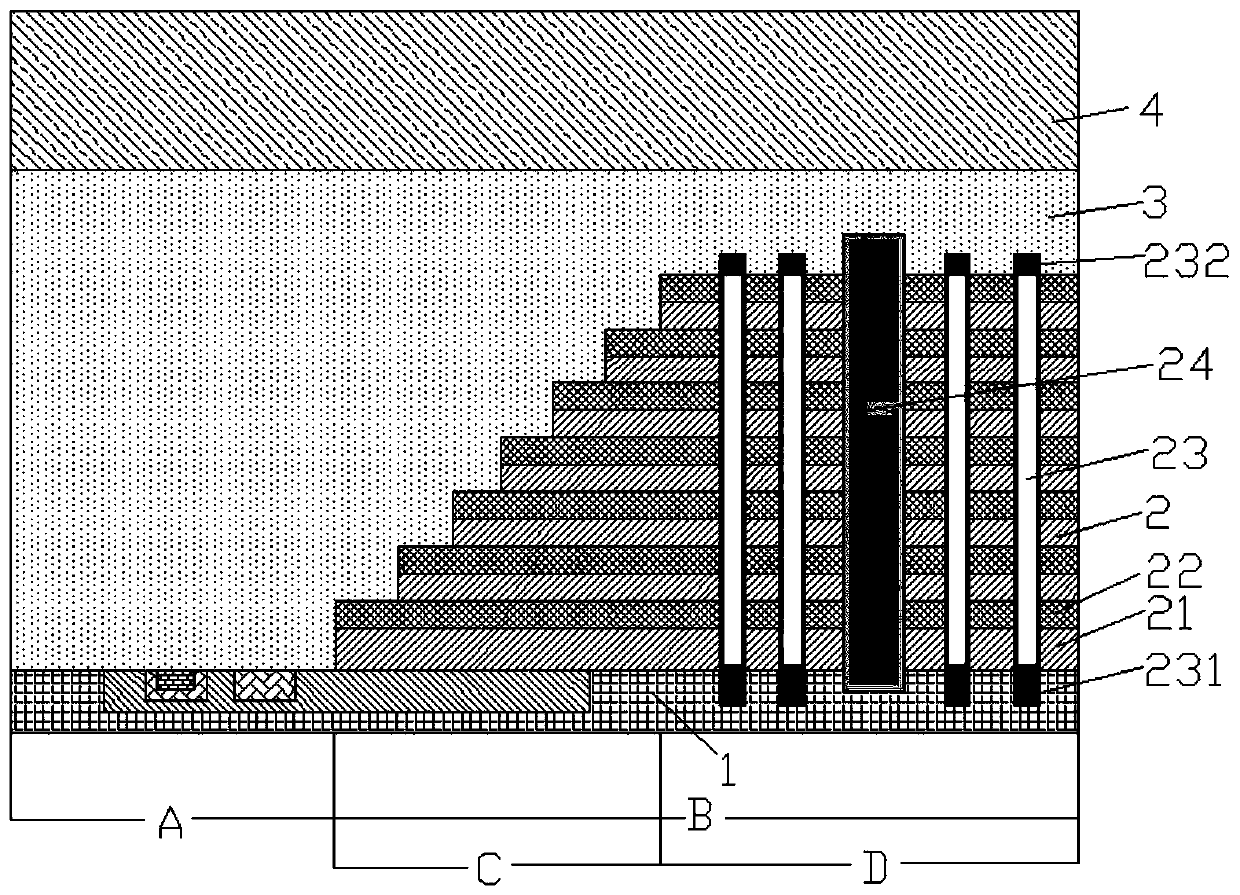

Three-dimensional memory preparation method, three-dimensional memory and electronic device

InactiveCN110047838AReduce manufacturing costShorten the timeSolid-state devicesSemiconductor devicesConductive materialsDielectric layer

Owner:YANGTZE MEMORY TECH CO LTD

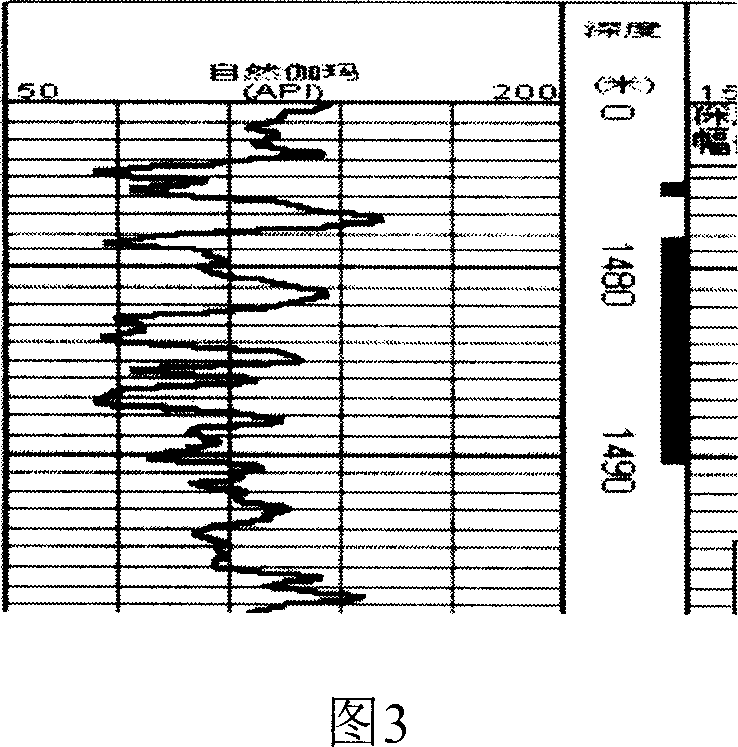

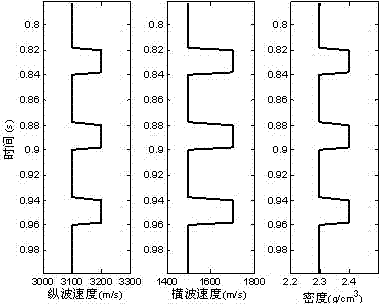

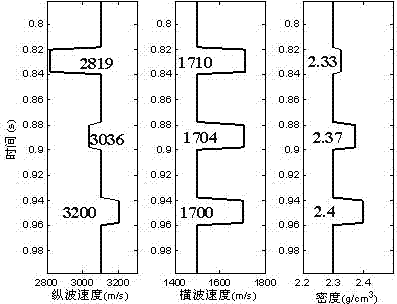

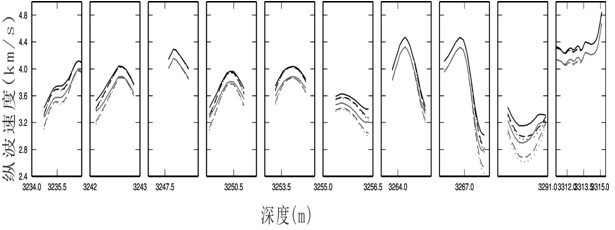

Method for analyzing fluid factor sensibility

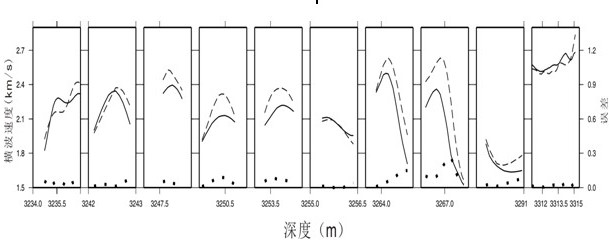

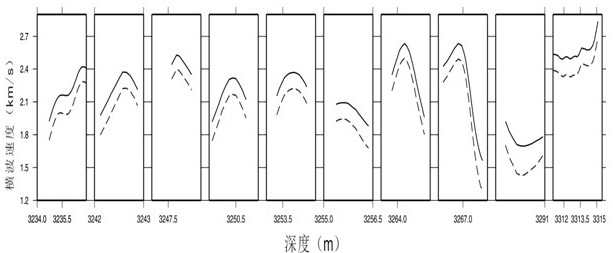

The invention provides a method for analyzing fluid factor sensibility. The method for analyzing the fluid factor sensibility comprises the steps that first, a sand shale interbedding model is constructed; second, fluid substitution is carried out; third, a plurality of fluid factors are selected; fourth, quantitative analysis of the fluid factor sensibility is conducted. According to the method for analyzing the fluid factor sensibility, the fluid factor sensibility is studied, the fluid substitution based on a Gassmann equation is achieved, and the compressional and shear velocity and density change of fluid saturated rocks after the fluid substitution can be analyzed in a quantitative mode; on this basis, the different fluid factors are selected, and the sensibility of the different fluid factors can be analyzed in a quantitative mode by calculating the sensitivity coefficient of the fluid factors.

Owner:CHINA PETROLEUM & CHEM CORP +1

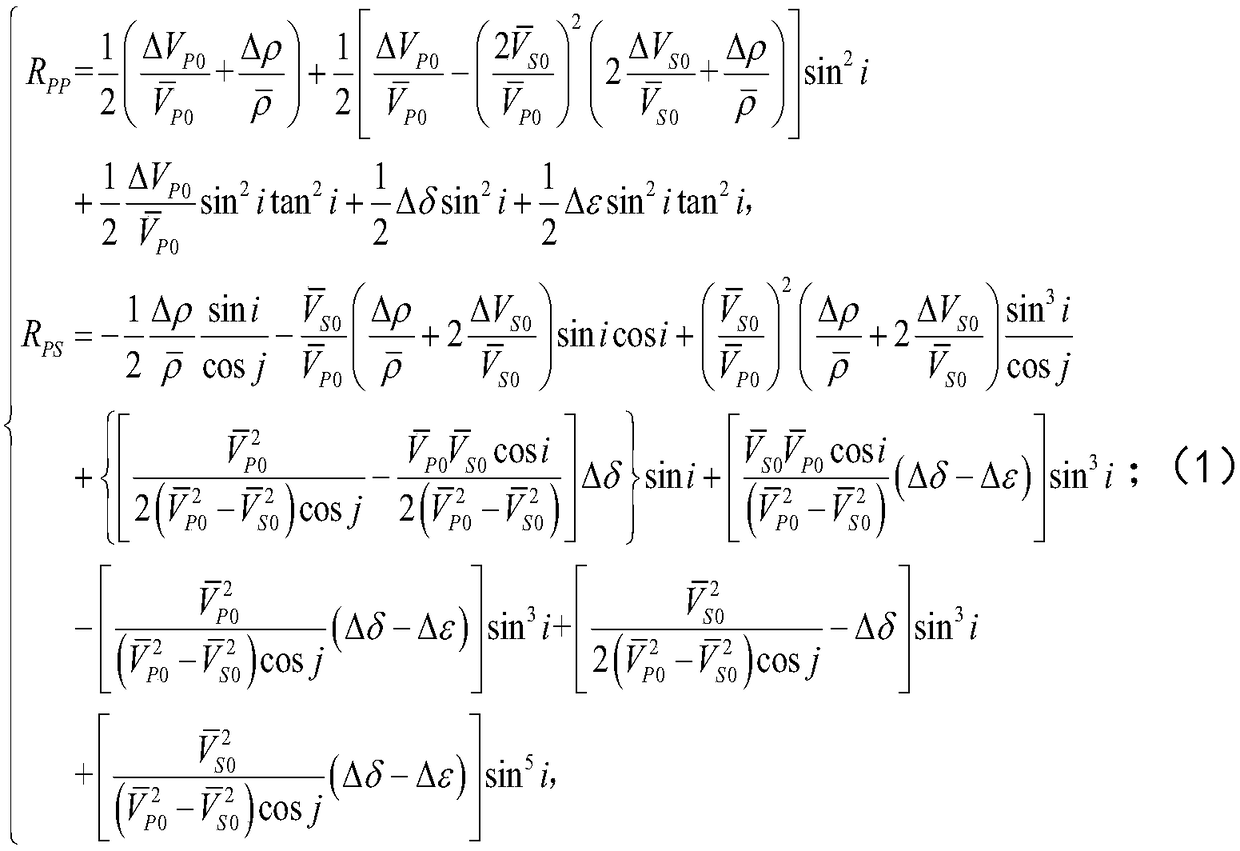

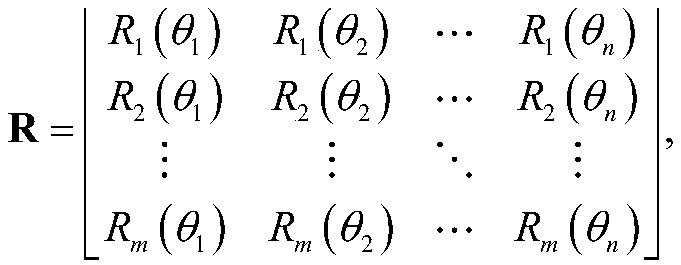

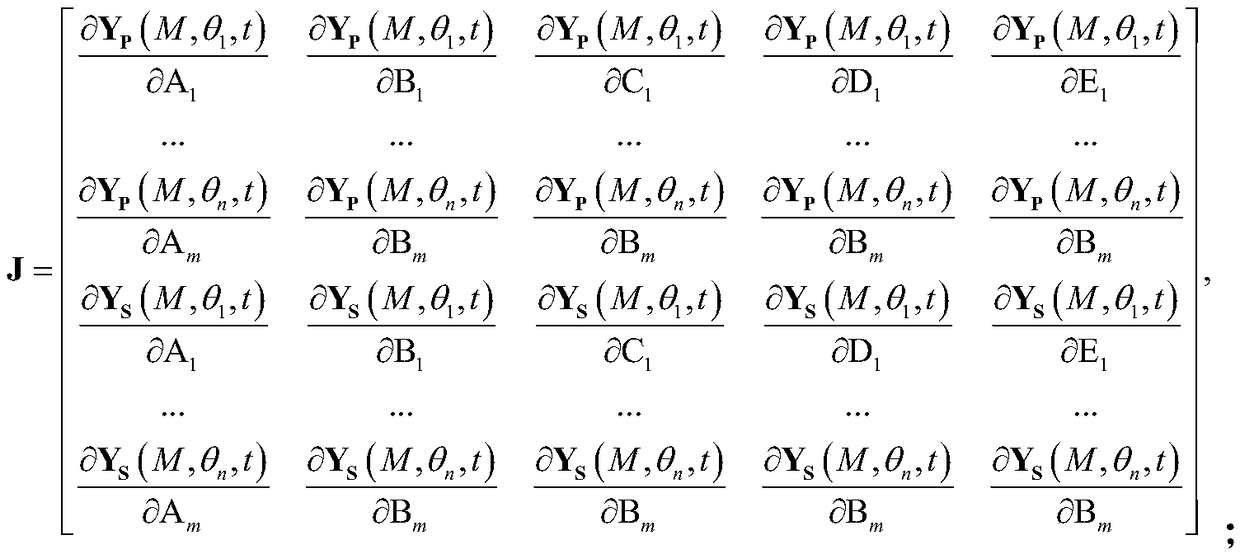

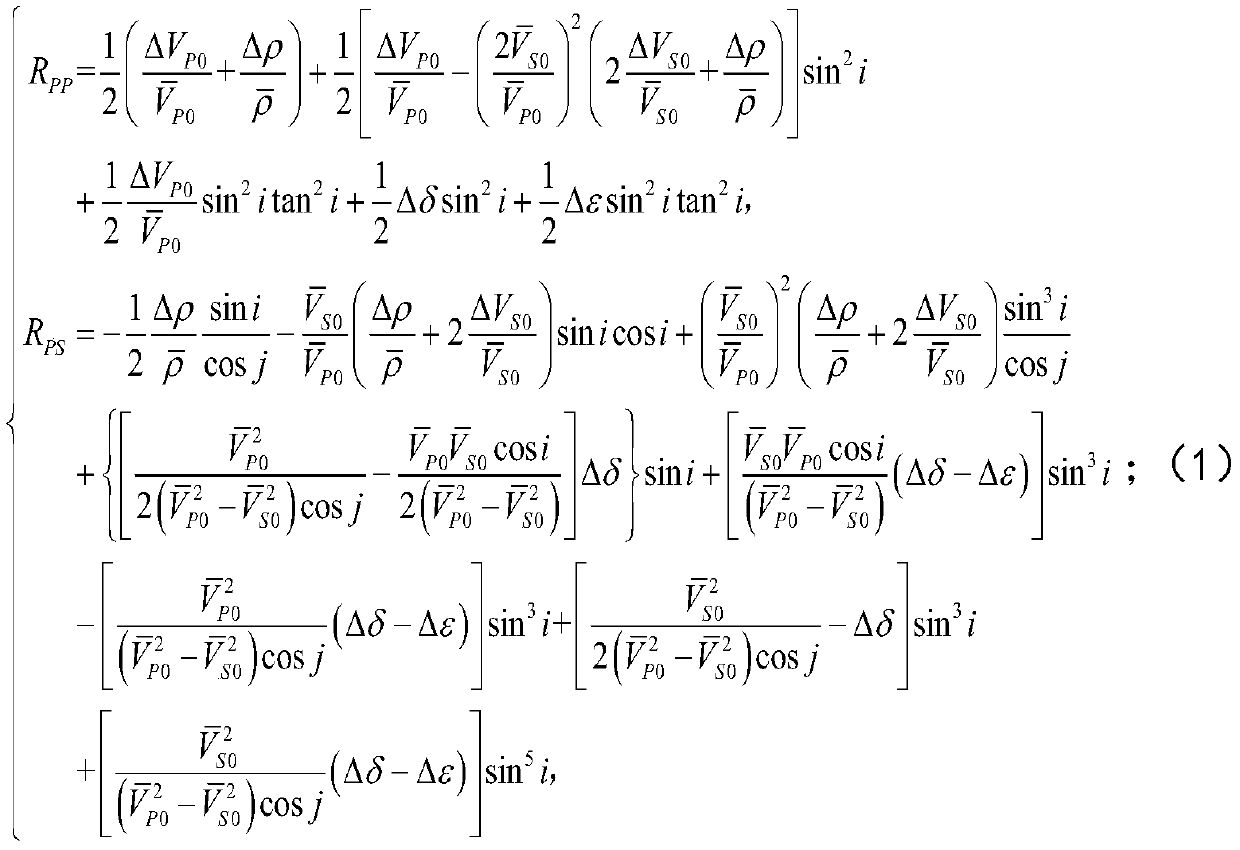

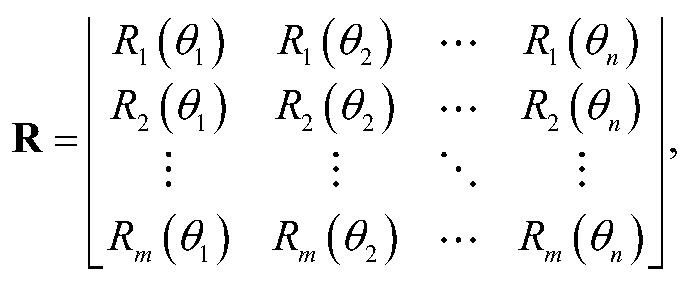

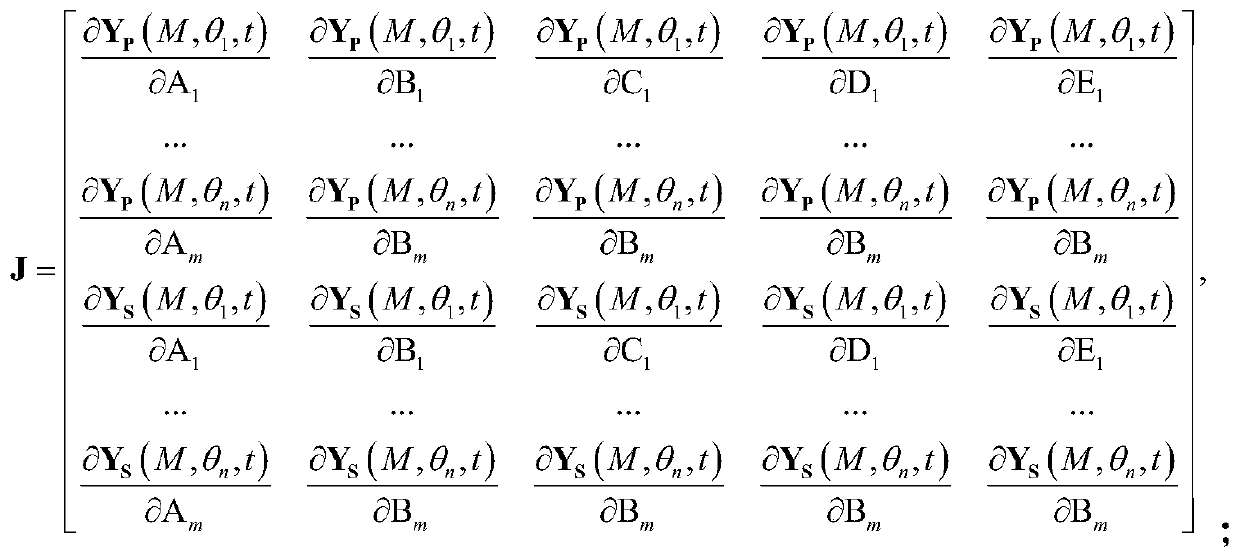

Multi-wave AVO joint inversion method for sand-shale thin interbed medium

ActiveCN109188511AThe effect is satisfactorySeismic signal processingComputer scienceInversion methods

The invention discloses a multi-wave AVO joint inversion method for a sand-shale thin interbed medium. The method comprises the following steps: for a complex thin interbed medium, adopting a VTI medium reflection coefficient equation proposed by Ruger, firstly using the pre-stack AVA corner gather to invert five parameters of an equivalent VTI medium, and then using the parameters of the VTI media and a relationship between its internal single-layer parameters and N / G to reverse the parameters of sandstone and mudstone in the thin interbed and the interbed structure N / G, wherein the result shows that the inversion can always achieve satisfactory effect for whether the VTI medium or the internal parameters of the thin interbed.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Construction method for ultra-deep vibroflotation gravel pile of complicated stratum

ActiveCN103628463ASolve the problem that the hole making speed is slow or even impossible to make holesImprove construction progressSoil preservationEngineeringFault rate

The invention discloses a construction method for an ultra-deep vibroflotation gravel pile of a complicated stratum. The method comprises the following steps: (1) doing construction preparation work; (2) carrying out pore-forming; (3) cleaning pores; (4) filling; (5) forming a pile: repeating the step (4) until materials are densely filled to a pile block. According to the construction method for the ultra-deep vibroflotation gravel pile of the complicated stratum, the construction problems of a large-power vibroflotation device, including hole embracing, slow construction speed, hole stringing and the like in the construction process of the complicated stratum of a medium-coarse sand powder-containing fine sand interlayer (an interbedding) and a round gravel powder-containing fine sand interlayer (the interbedding) with the size which is more than 15m, even more than 20m can be solved. Compared with a traditional construction method, the construction progress can be accelerated effectively, the construction efficiency is improved, the fault rate of equipment is reduced, and the cost is reduced.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

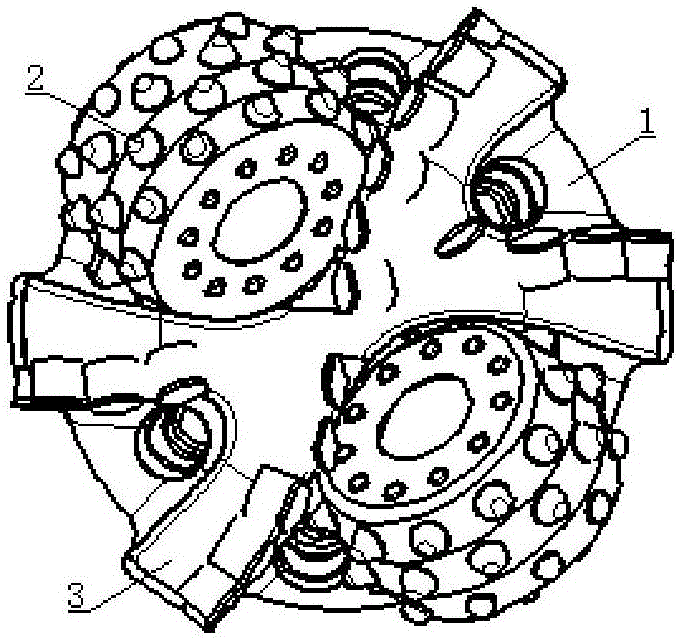

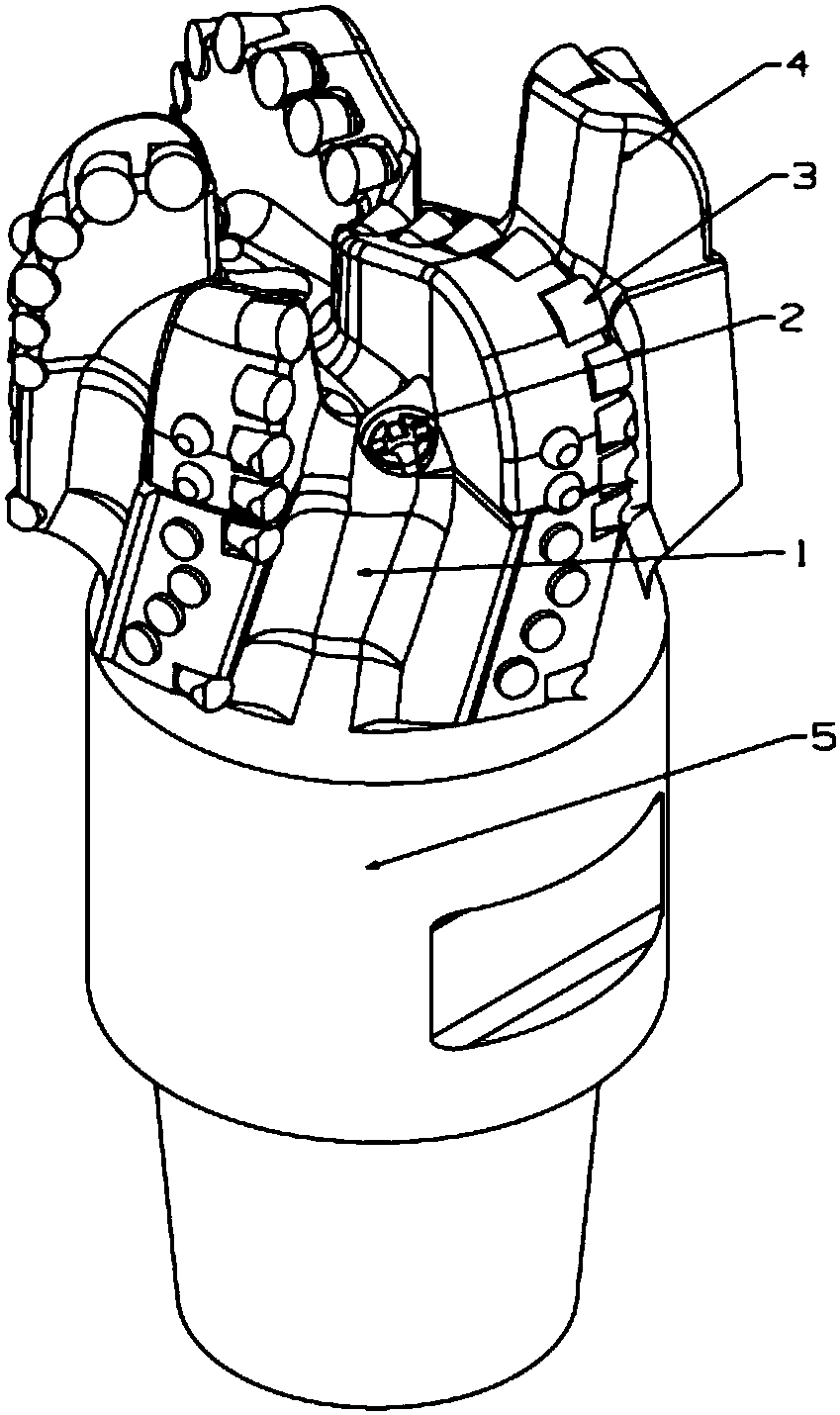

Composite drill bit

InactiveCN106121541AWide operating parameter spaceEasy to controlDrill bitsConstructionsTorsional vibrationIgneous rock

The invention relates to the technical field of petroleum drilling and well cementation, in particular to a composite drill bit which comprises a PDC drill bit body and roller cones. The roller cones are installed on the PDC drill bit body. The roller cone and PDC composite drill bit is composed of the roller cones and PDC, the advantages of roller cone drill bits and PDC drill bits are combined, the aggressivity is high, the cutting efficiency is high, the mechanical drilling speed of the composite drill bit is 2-4 times higher than the roller cone drill bits when the composite drill bit operates on poor-drillability stratums (such as igneous rock and mud and sand interbeddings containing gravels), and the mechanical drilling speed and the rotation speed are in direct proportion. When a motor is adopted by the roller cone and PDC composite drill bit for drilling, the mechanical drilling speed is increased remarkably. Another advantage is reflected in the influences of the roller cones on drill bit dynamics, compared with the conventional PDC drill bits, the torque fluctuation degree can be reduced by as much as 50%, the torsional vibration degree is lowered under the low rotation speed condition, and the whirling vibration degree is lowered under the high rotation speed condition.

Owner:TIANJIN LILIN BIT

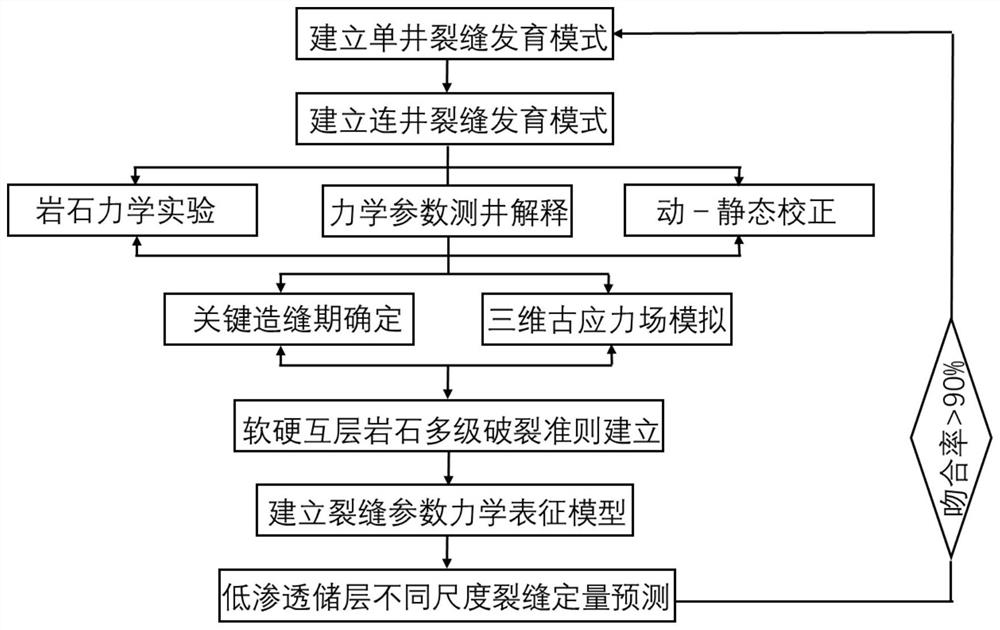

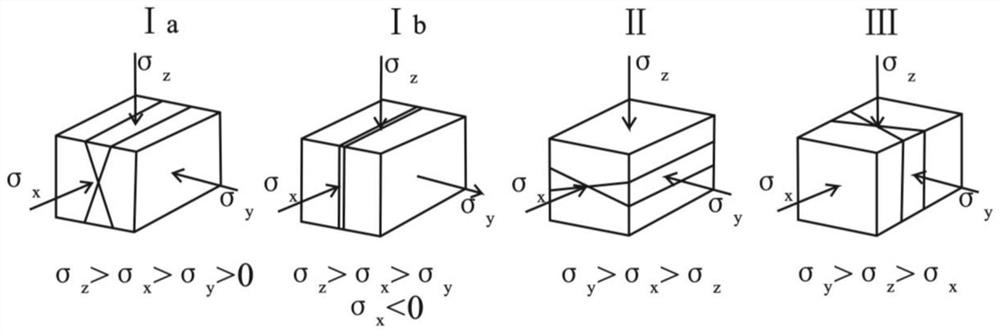

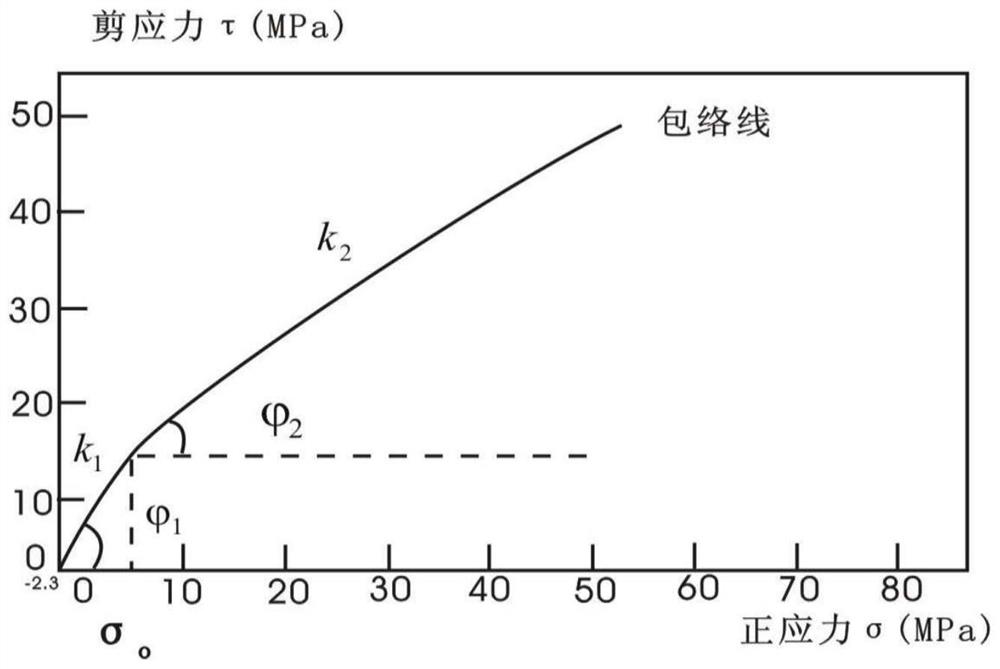

Quantitative prediction method for different-scale fractures of low-permeability reservoir under constraint of rock mechanical layer

ActiveCN113534291AEfficient prediction of spatial distribution characteristicsEffective prediction of fracture densityGeological measurementsWell loggingClassical mechanics

The invention belongs to the field of oil exploration, and particularly relates to a quantitative prediction method for different-scale fractures of a low-permeability reservoir under constraint of a rock mechanics layer, which comprises the following steps: establishing a single-well fracture development mode, establishing a well-connected fracture development mode, dividing fracture scales, performing a rock mechanics experiment, performing mechanical parameter logging interpretation and dynamic-static correction, dividing various levels of rock mechanical layer structures, establishing a three-dimensional geomechanical model, determining a key fracture forming period, performing three-dimensional ancient stress field simulation, deducing and establishing a soft and hard interbed rock multi-stage fracture criterion and a fracture parameter mechanical characterization model, and performing quantitative prediction on fractures of different scales of a low-permeability reservoir, and finally verifying the reliability of a crack quantitative prediction result through well point actual measurement data. According to the method, the multi-scale fracture parameters of the sand-mudstone interbed type low-permeability reservoir can be accurately obtained and quantitatively represented, the method is suitable for fracture quantitative prediction work of any stratified structure reservoir, and the risk and cost of exploration and development are reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

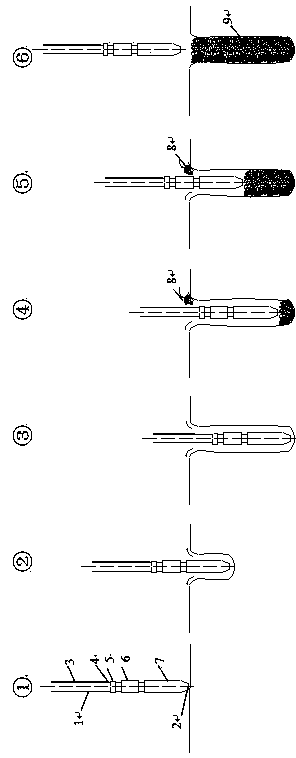

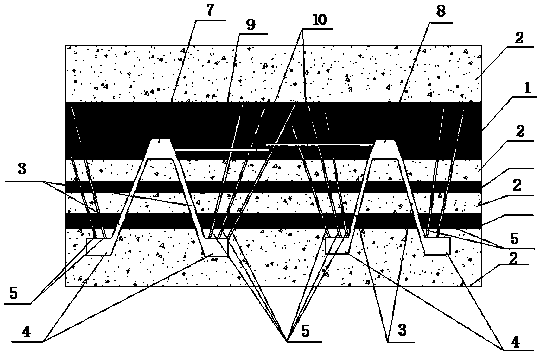

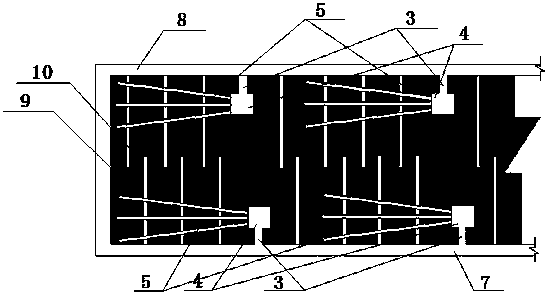

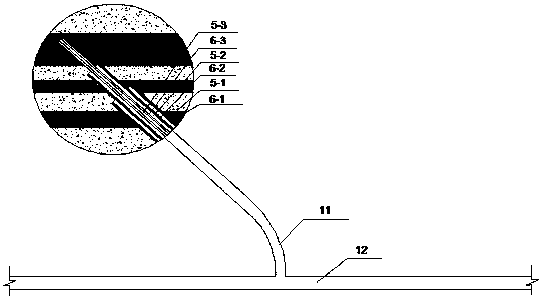

Low-level multi-step crossing hole gas extraction method for coal interbedding coal seams

ActiveCN109899105AEliminate outstanding hazardsGuaranteed sampling complianceGas removalCoalExtraction methods

The invention relates to a low-level multi-step crossing hole gas extraction method for coal interbedding coal seams. The low-level multi-step crossing hole gas extraction method is characterized in that transporting crossheadings (or air return crossheadings) are dug in the mined coal seams (1), a 0.3-1 m of inclined dip (3) penetrating into bottommost rock strata (2) of all coal interbeddings isconstructed obliquely downwards along the left (right) side of a roadway, a low-level drilling field (4) is dug, wherein the product of the length, the width and the height of the low-level drillingfield (4) is equal to 3.0 m*2.5 m*2 m, a plurality of low-level multi-step crossing holes (5) penetrating through the multiple coal seams to a mined bed are constructed in the low-level drilling fieldin the roadway tunneling direction obliquely upwards, multi-step sleeves (6-1), (6-2) and (6-3) are inserted into the low-level multi-step crossing holes (5), the sleeve (6-1) is connected with a multi-way part through a phi 120 mm of rubber hose (11), and the sleeve (6-1) is connected with a gas extraction pipeline (12) in the roadway to converge for low-level multi-step crossing hole (5) networking gas extraction operation. Gas at coal seam bottom plates is effectively extracted, the safe and efficient effects are achieved, and the low-level multi-step crossing hole gas extraction method can be used for implementation of outburst prevention measures of a working surface.

Owner:EASTERN GANSU UNIVERSITY

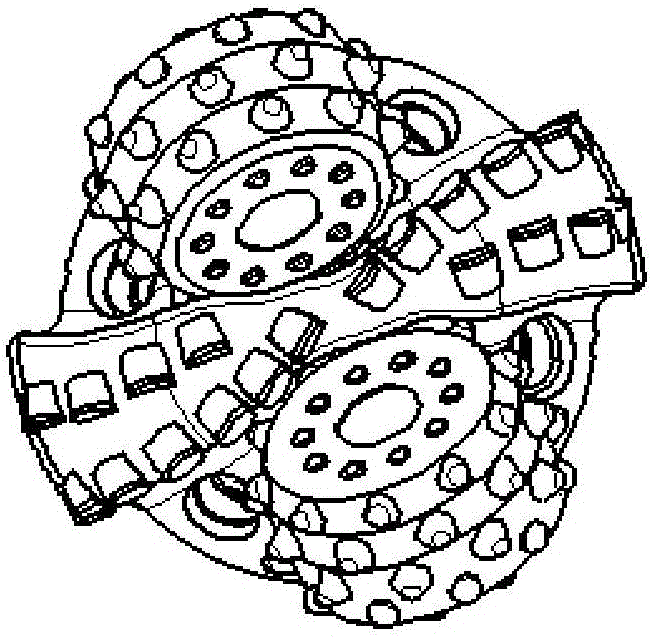

Novel diamond bit

InactiveCN104295240AReduce abnormal wear and tearHelps rule out abnormal wearDrill bitsConstructionsEngineeringSpiral line

The invention discloses a novel diamond bit which comprises a bit body, a plurality of sector blocks and water gaps. The sector blocks are arranged on the bit body in a surrounding mode, and the water gaps are formed between every two sector blocks. The novel diamond bit further comprises through holes and pressure head type detachable cutting tools, the through holes are formed in the sector blocks, and the pressure head type detachable cutting tools are detachably installed in the through holes. Each sector block is provided with the multiple through holes, and all the through holes are distributed in a spiral line shape. The through holes in the sector blocks are distributed in a central symmetrical mode around the bit body. Rock powder is accumulated in the through holes, provides abrasives for working lip faces and is beneficial to eliminating matrix polishing. The part, probably being abraded abnormally, at the hole bottom of the diamond bit can be enhanced through the through holes and the pressure head type detachable cutting tools installed in the through holes, the efficiency for smashing rock is improved, the service life of the bit is effectively prolonged, the drilling speed is effectively increased, and the novel diamond bit can be applied to drilling in hard rock or soft and hard interbedding stratums and is wider in drillable stratum range.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

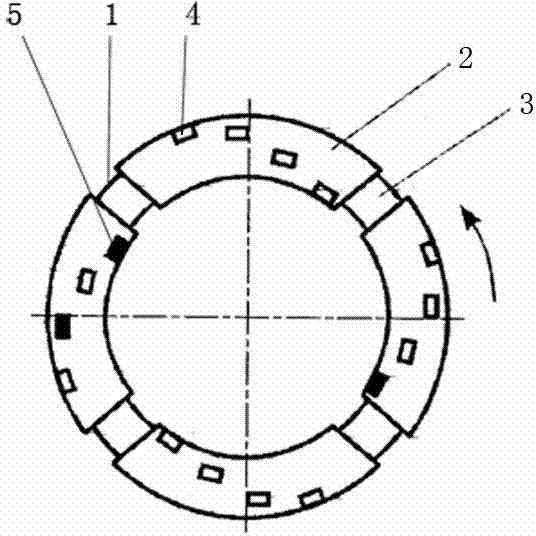

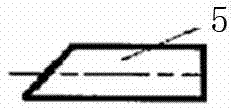

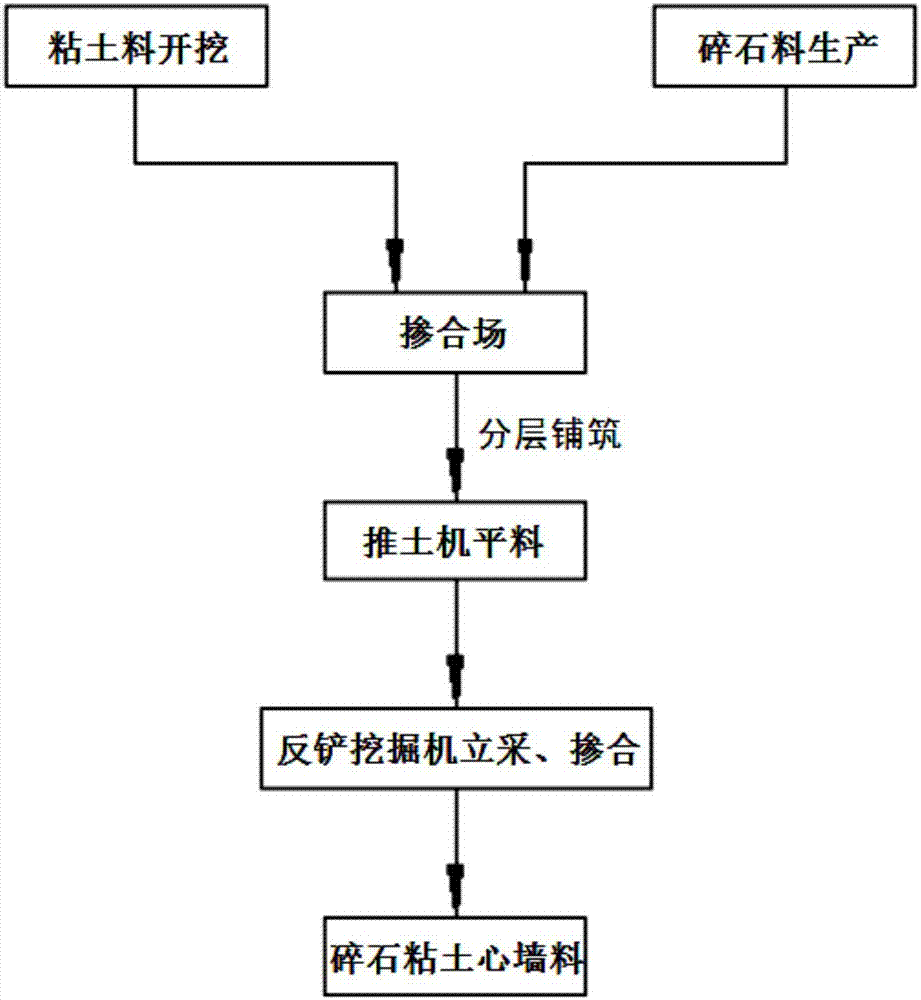

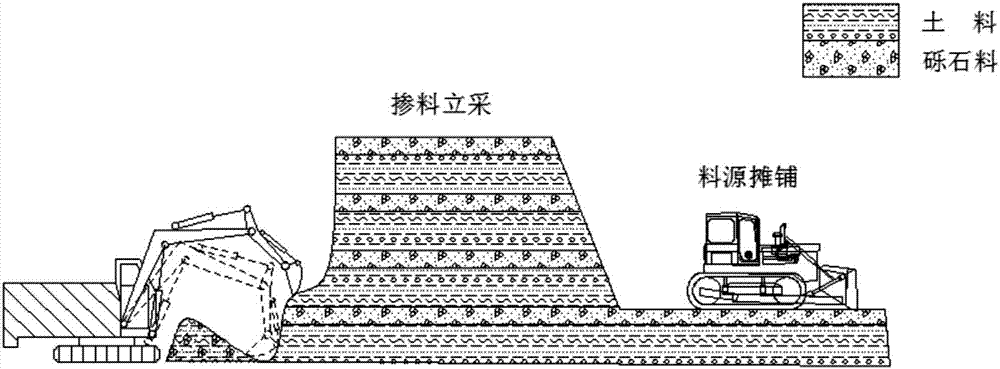

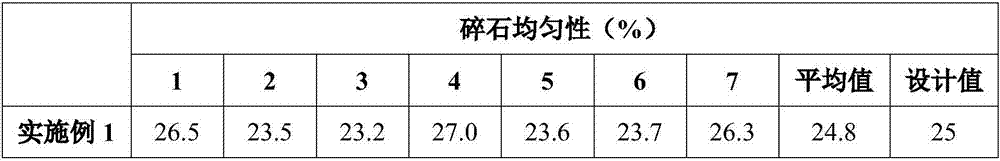

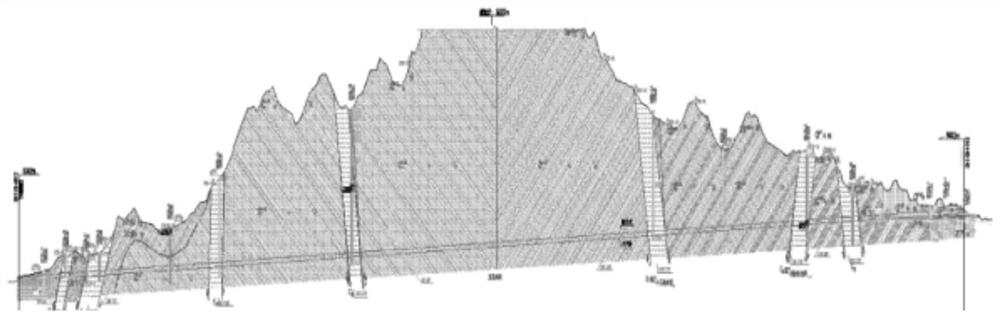

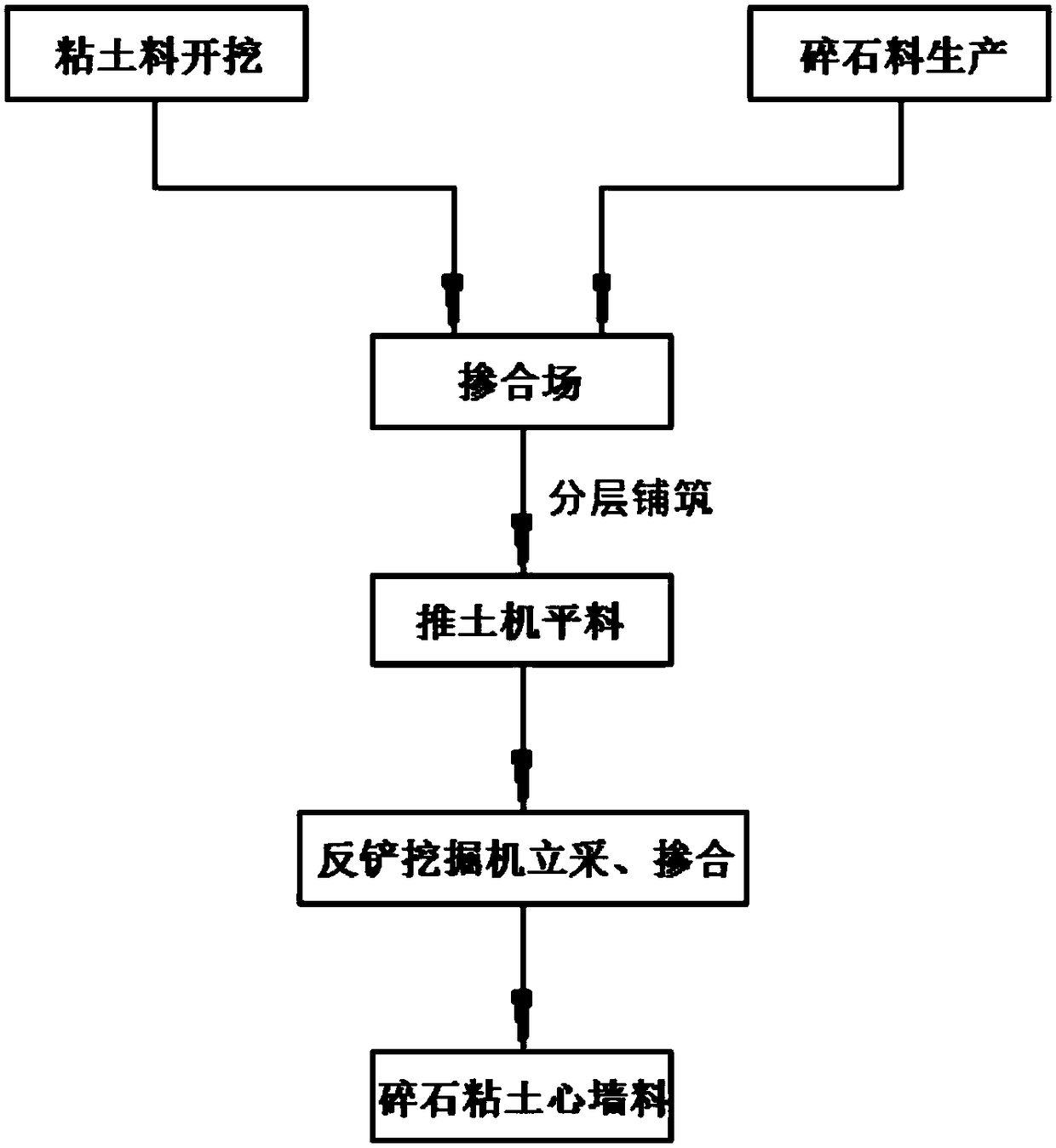

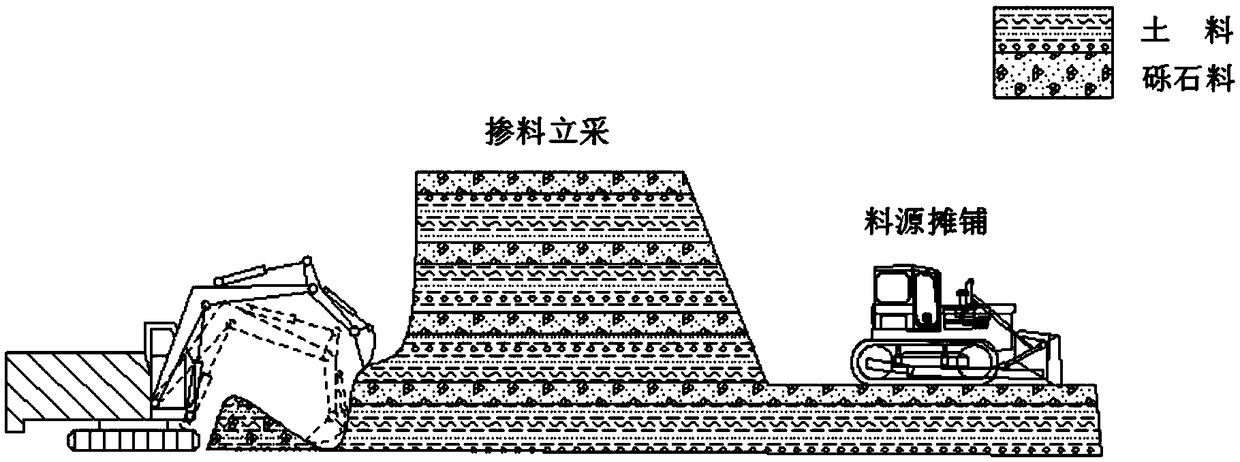

Manufacturing method of breakstone clay core wall material

ActiveCN106996095AIncrease productionReduce the amount of civil worksEarth-fill damsRock-fill damsMaterials preparationVertical plane

The invention discloses a manufacturing method of breakstone clay core wall material. The manufacturing method comprises the following steps: (1) arranging a blending site for excavating an upper dam and a blending site for material preparation; (2) determining the size grading and moisture content of breakstone and clay, and then calculating to determine the mass ratio of the breakstone to the clay; (3) determining the paving thickness of each layer, the interbedding number and the material pile design pile height of the breakstone and the clay; (4) carrying out a small-scale blending test; (5) correcting the paving parameters according to the result of the small-scale blending test, and then carrying out large-scale paving and blending; (6) after paving, adopting a backdigger to cut out leftover material to form an excavation vertical face; and (7) adopting the backdigger to carry out excavation on the vertical face and repeated blending to obtain the breakstone clay core wall material. According to the manufacturing method, the blending method that the clay and the breakstone are alternately paved layer by layer and the backdigger excavates on the vertical plane is adopted, the civil engineering quantity is smaller, the blending technology is simple, economic and high in quality, and the breakstone clay core wall material is high in yield.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

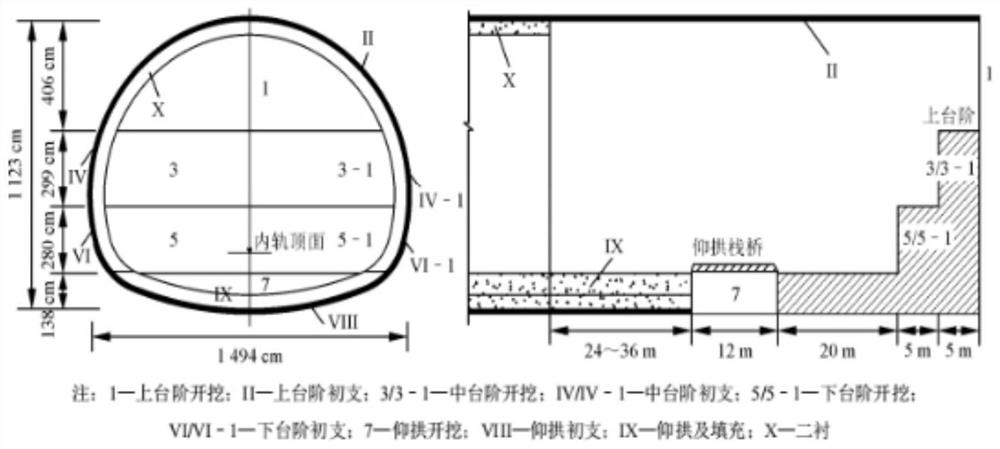

High ground stress interbed soft rock tunnel failure mechanism and construction control research method

PendingCN113094778AIncrease shear deformationSurrounding rock range is smallGeometric CADDesign optimisation/simulationRock tunnelNumerical models

The invention discloses a high ground stress interbed soft rock tunnel failure mechanism and construction control research method. The method comprises the following steps: 1, establishing a numerical model; 2, analyzing the stability of the surrounding rock of the apex mountain tunnel; 3, analyzing the stability of the initial support of the apex mountain tunnel; 4, analyzing a failure mechanism of the high-ground-stress interbed soft rock tunnel; 5, implementing an apex mountain tunnel monitoring and measuring scheme; 6, analyzing a field monitoring and measuring result, wherein the deformation of the surrounding rock generally presents a rule that the horizontal convergence is greater than the vault settlement, the horizontal convergence value and the rate are greater than the vault settlement amount and the settlement rate, and the vault settlement amount tends to be stable earlier than the horizontal convergence value and is consistent with the numerical simulation surrounding rock deformation rule; the overall rules are consistent, so that certain reasonability is achieved, and meanwhile it is verified that the supporting mode of section optimization, advanced reinforcement and variable-section spray layer has a good effect on supporting of the high ground stress interbed soft rock tunnel.

Owner:中国铁路兰州局集团有限公司兰州工程建设指挥部 +2

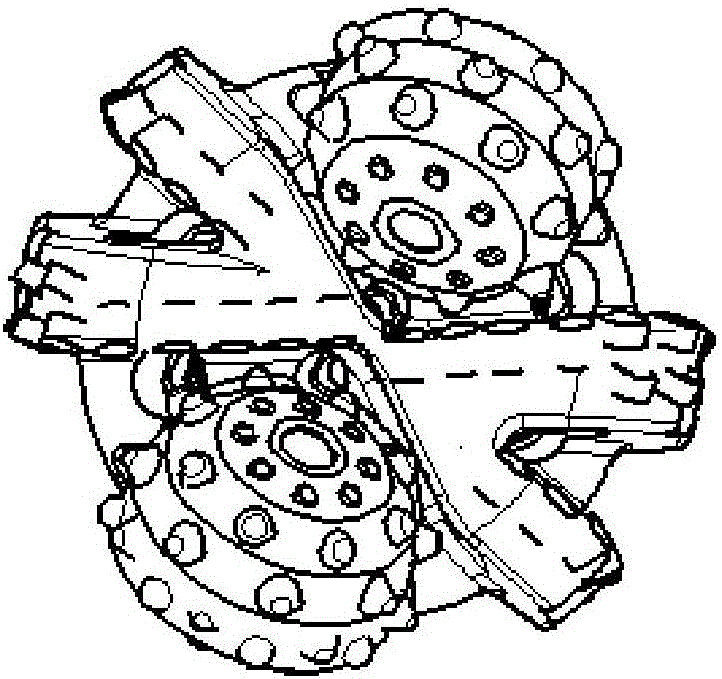

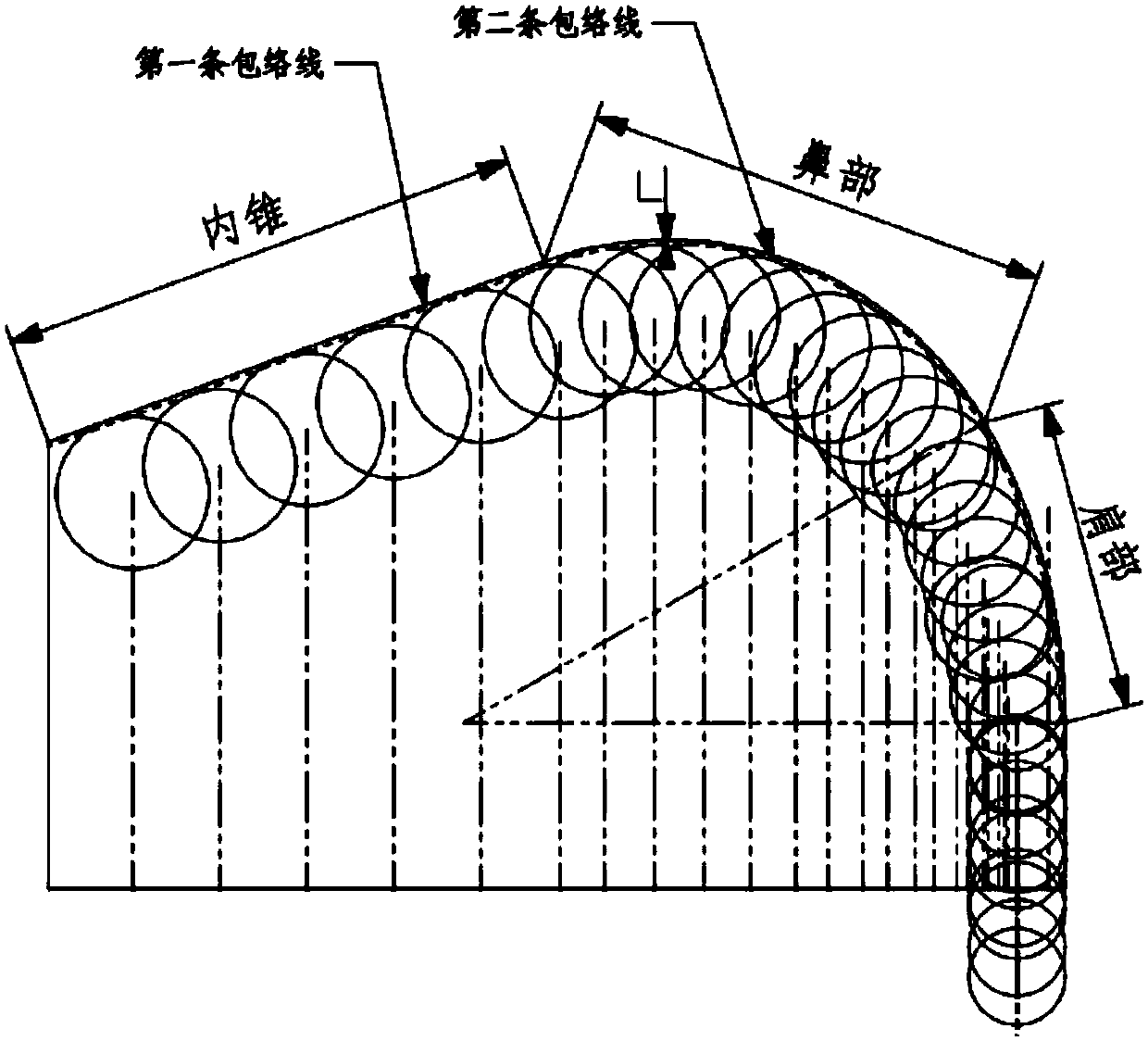

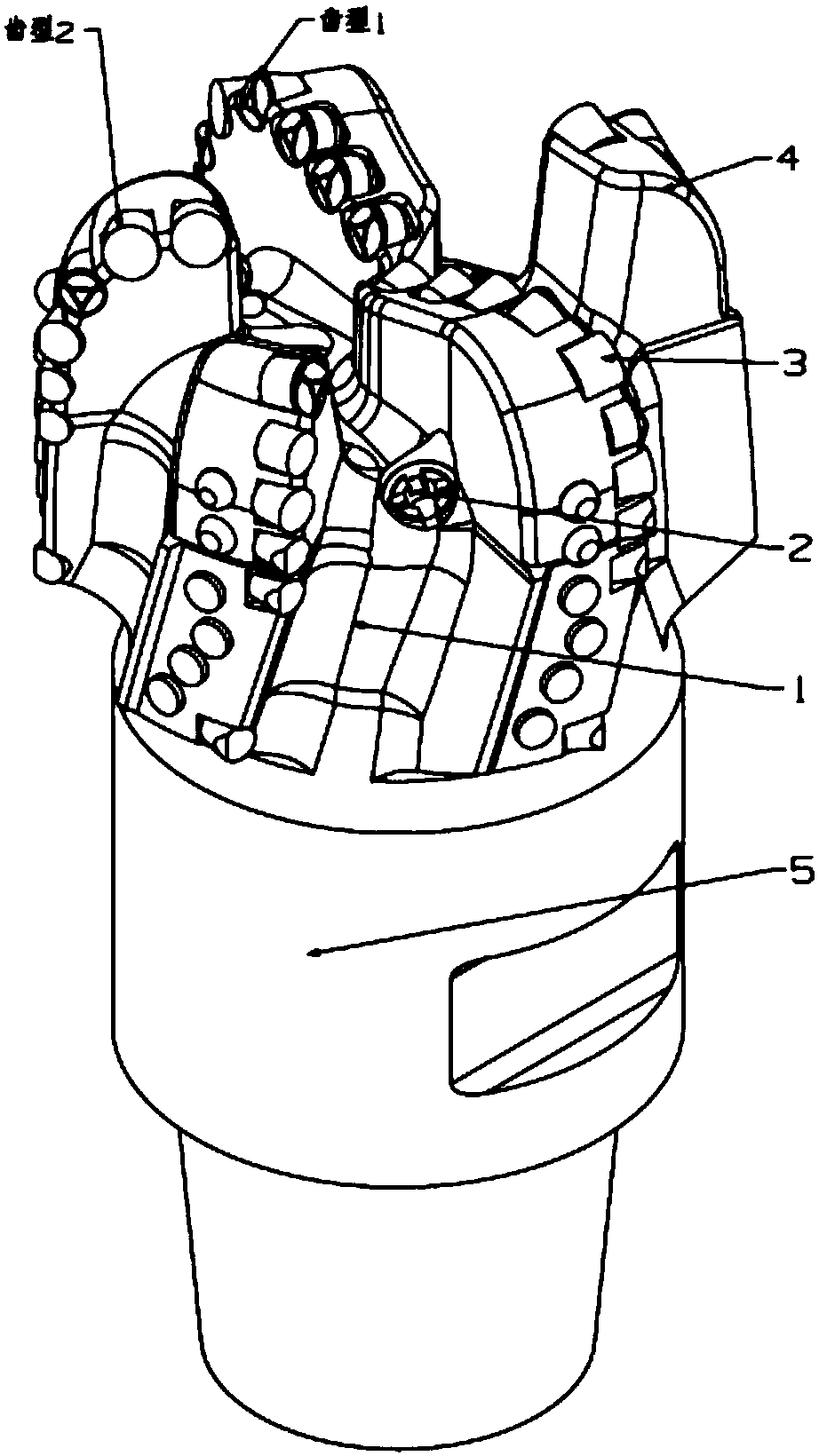

Two-stage cutting PDC bit

InactiveCN107859489ASufficient wear resistanceIncrease ROPDrill bitsEngineeringMechanical engineering

The invention relates to a two-stage cutting PDC bit. The two-stage cutting PDC bit comprises a bit body, and cutting blades are arranged on the bit body in the circumferential direction at intervals;fixed cutting teeth are mounted and arranged on the cutting blades along inner cones, nasal parts, shoulder parts and gauge-protection segments; and the fixed cutting teeth of the inner cones, the nasal parts and the shoulder parts on the cutting blades are arranged from inside to outside in an arrayed mode and cover the whole shaft bottom, so that cutting profile envelope curves of the fixed cutting teeth are formed. The two-stage cutting PDC bit is characterized in that all the fixed cutting teeth of the inner cones, the nasal parts and the shoulder parts on the cutting blades correspondingly form two groups of corresponding fixed cutting teeth, and two spaced cutting profile envelope curves are formed and are high in one and low in another. The two-stage cutting PDC bit can adapt to the drilling of interbedding of sandstone and dense mudstone, and not only can the mechanical drilling speed be ensured, but also the service life of the bit can be maintained.

Owner:KINGDREAM PLC CO +1

Diamond bit with wedge-shaped matrix crown contours

InactiveCN104131783AEliminates the effects of dynamic loads (vibration)Reduce energy consumptionDrill bitsEnergy consumptionMaterials science

The invention provides a diamond bit with wedge-shaped matrix crown contours. The diamond bit with wedge-shaped matrix crown contours comprises a drill bit body, the matrix crown contours and water ways. The matrix crown contours are arranged on the drill bit body in a surrounding mode. The water ways are arranged between the matrix crown contours. Each matrix crown contour is composed of a fan-shaped block, a matrix wedge surface, a hole wall forming portion and a core forming portion, wherein the whole matrix crown contour is in a wedge shape, the matrix wedge surface, the hole wall forming portion and the core forming portion both incline relative to the fan-shaped block, and the inclination angle of the matrix wedge surface relative to the upper surface of the fan-shaped block, the inclination angle of the hole wall forming portion relative to the outer surface of the fan-shaped block and the inclination angle of the core forming portion relative to the inner surface of the fan-shaped block all range from 15 degrees to 40 degrees. According to the diamond bit, the wedge-shaped matrix crown contours are adopted, an effective pre-breaking area and a breaking area are generated during drilling, the influence of a dynamic load is eliminated, the energy consumption is reduced during rock breaking, and the drill bit is suitable for breaking hard rock and quite hard rock under a complicated crack condition and drilling a rock stratum of a stratum with interbedding of soft and hard rocks and increases the drilling rate and the footage per bit.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

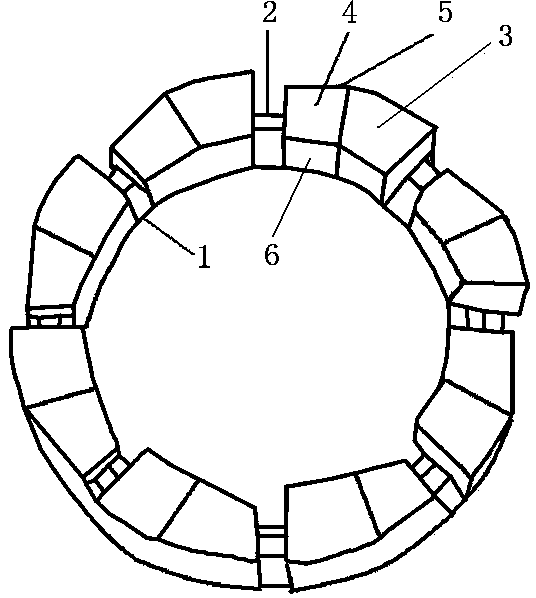

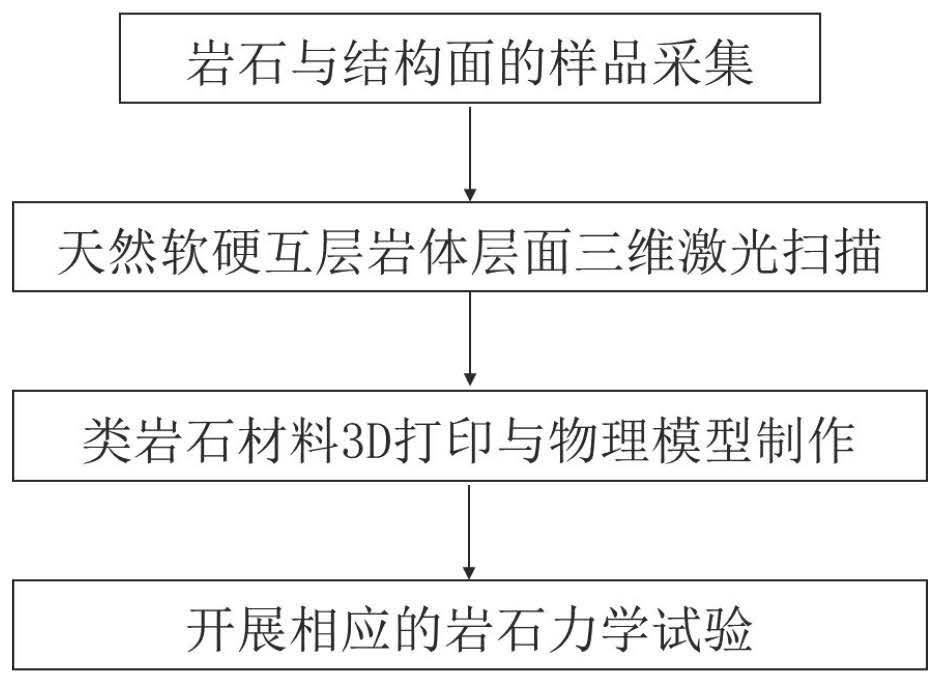

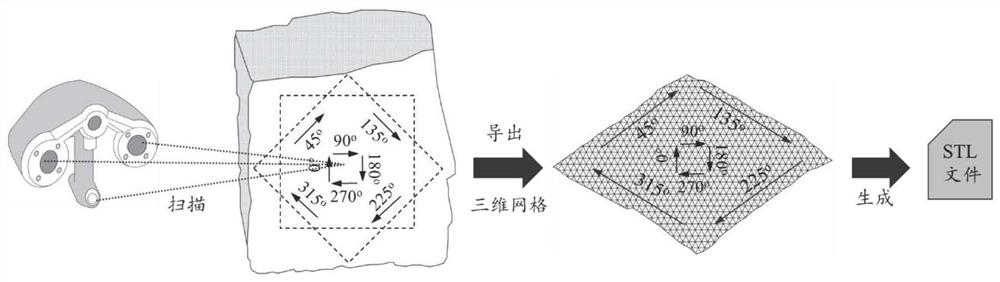

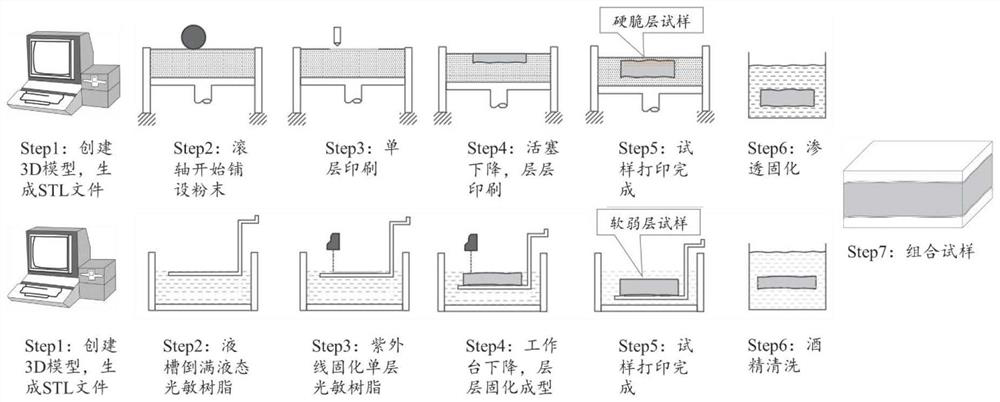

Method for researching mechanical behaviors of soft and hard interbedded rock mass based on 3D printing technology

PendingCN114235519ATrue reflection of interface conditionsPreparing sample for investigationMaterial strength using tensile/compressive forcesLaser scanningPhysical model

The invention discloses a method for researching mechanical behaviors of soft and hard interbedded rock mass based on a 3D printing technology. The method comprises the following steps: 1, collecting samples of rock and a structural surface; 2, performing three-dimensional laser scanning on a natural soft and hard interbedded rock mass layer; 3, 3D printing of the rock-like material and manufacturing of a physical model; 4, carrying out a corresponding rock mechanical test; compared with a conventional sample preparation method, the method has the following advantages: the internal material of the 3D printing model is approximately homogeneous, so that the evolution rule of the damage of the 3D printing model is easier to observe during a test; soft and hard interbed rock mass models with different strengths are realized by controlling the glue concentration and the glue saturation in the 3D process; through scanning and extraction of a natural rock structural surface, 3D printing is adopted to reconstruct the natural structural surface, and the interface conditions of the soft and hard interbed rock mass can be reflected more truly.

Owner:CHANGAN UNIV

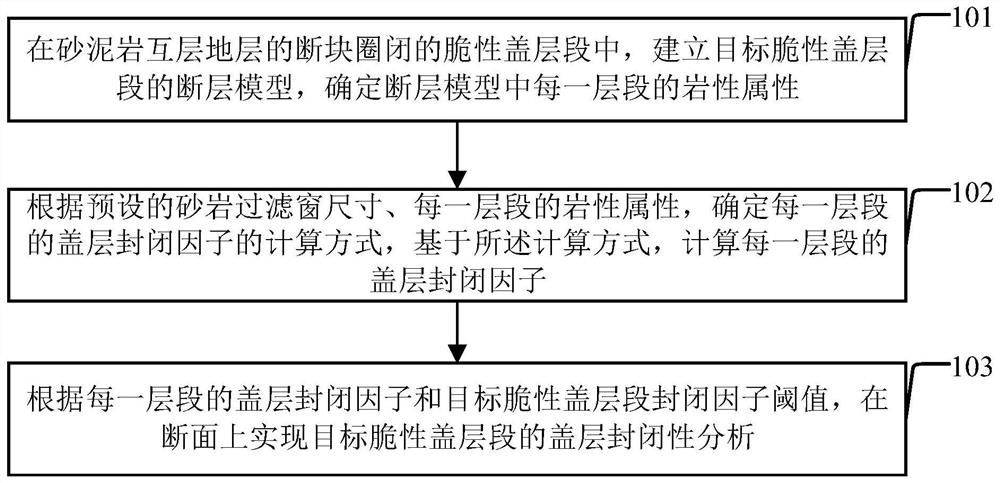

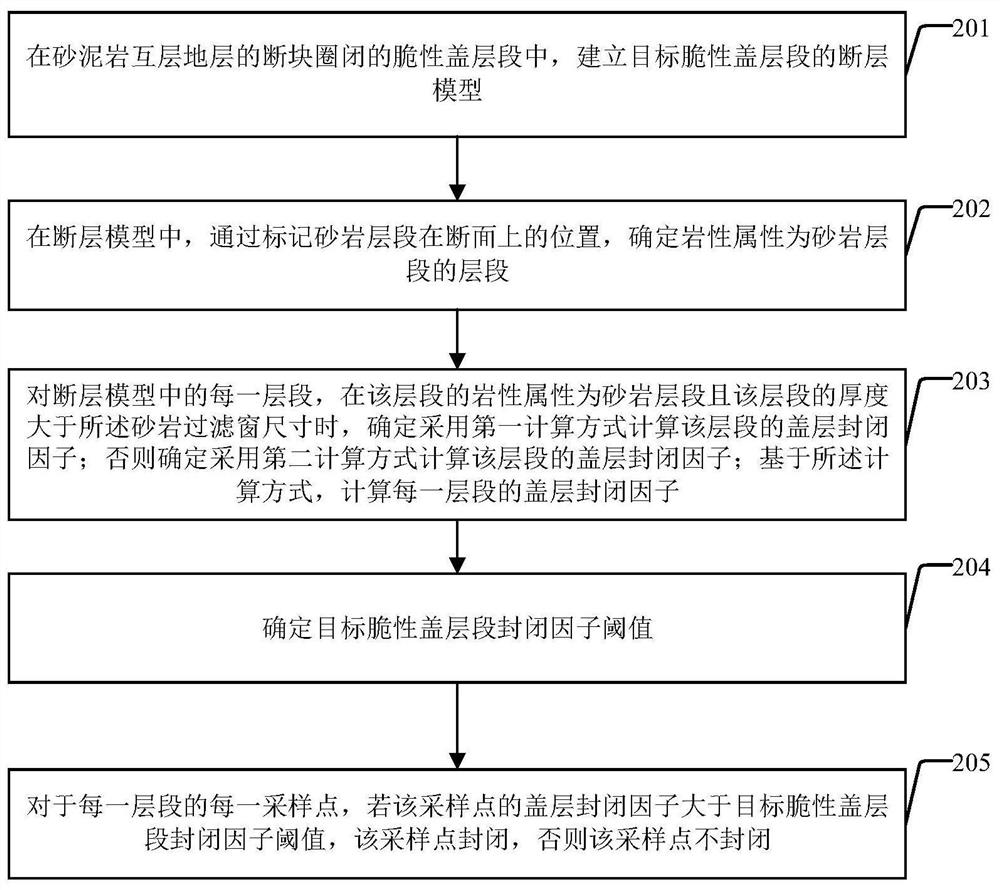

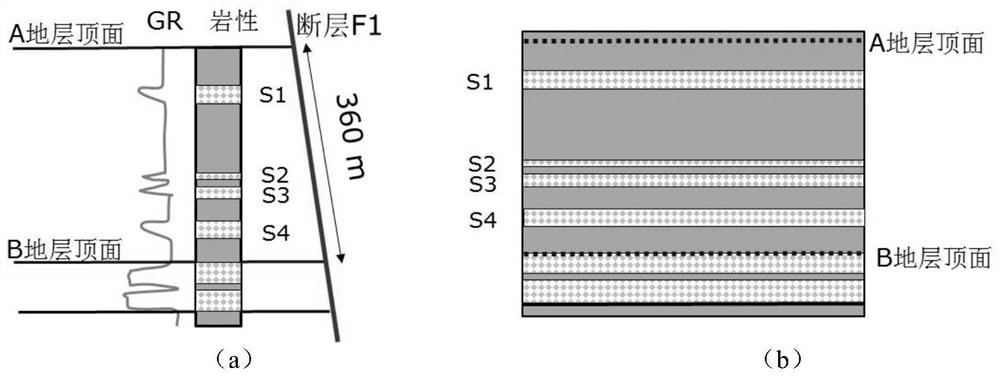

Method and device for analyzing brittle cover layer closeness of fault block entrapment

ActiveCN111680386AAccurate closureDesign optimisation/simulationComplex mathematical operationsLithologyMudrock

The invention provides a method and device for analyzing the brittle cover layer closeness of a fault block entrapment, and the method comprises the steps: building a fault model of a target brittle cover layer section in a brittle cover layer section of a fault block entrapment of a sand-mudstone interbed stratum, and determining the lithological attributes of each layer section in the fault model; according to a preset sandstone filtering window size and the lithology attribute of each layer section, determining a calculation mode of a cover layer sealing factor of each layer section, and based on the calculation mode, calculating the cover layer sealing factor of each layer section; and according to the capping layer sealing factor of each layer section and the target brittle capping layer section sealing factor threshold value, achieving capping layer sealing performance analysis of the target brittle capping layer section on the section. The method and device can analyze the sealing performance of the brittle cover layer on the section, and are high in accuracy.

Owner:PETROCHINA CO LTD

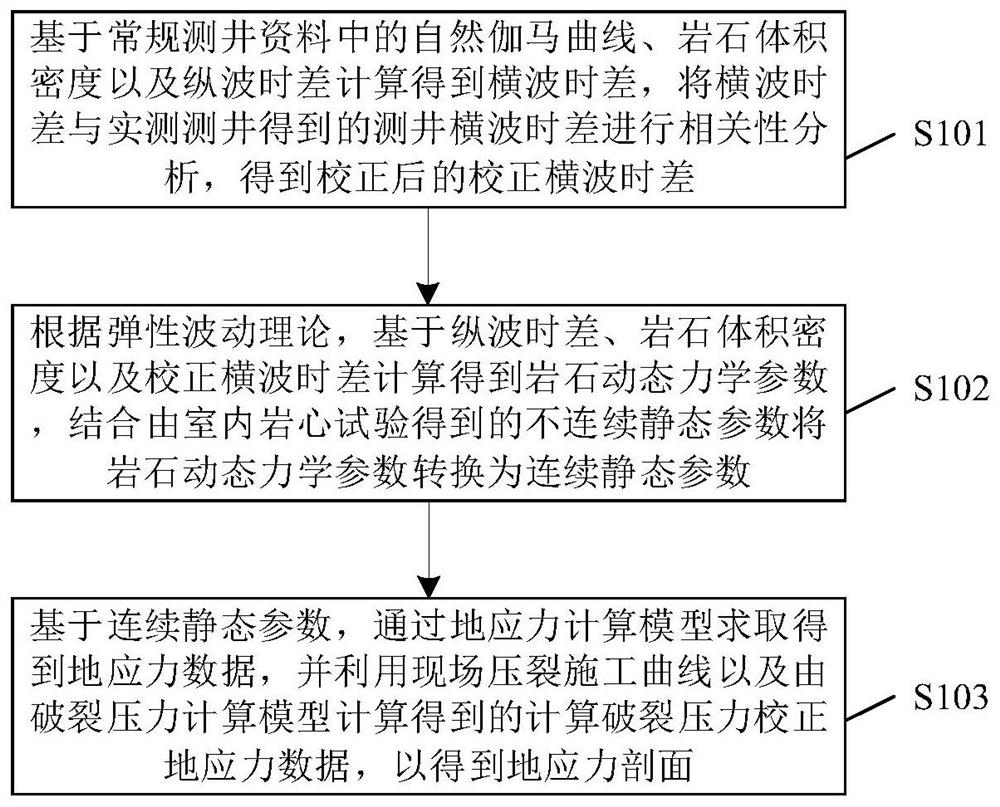

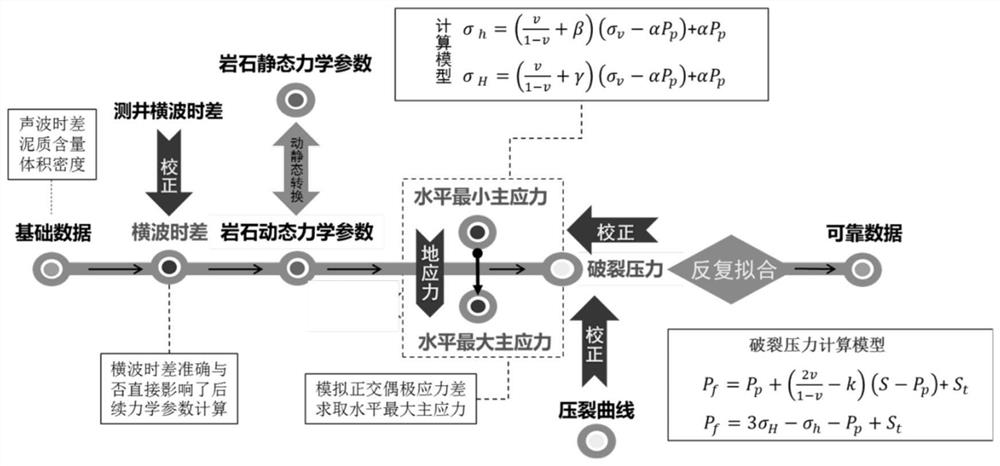

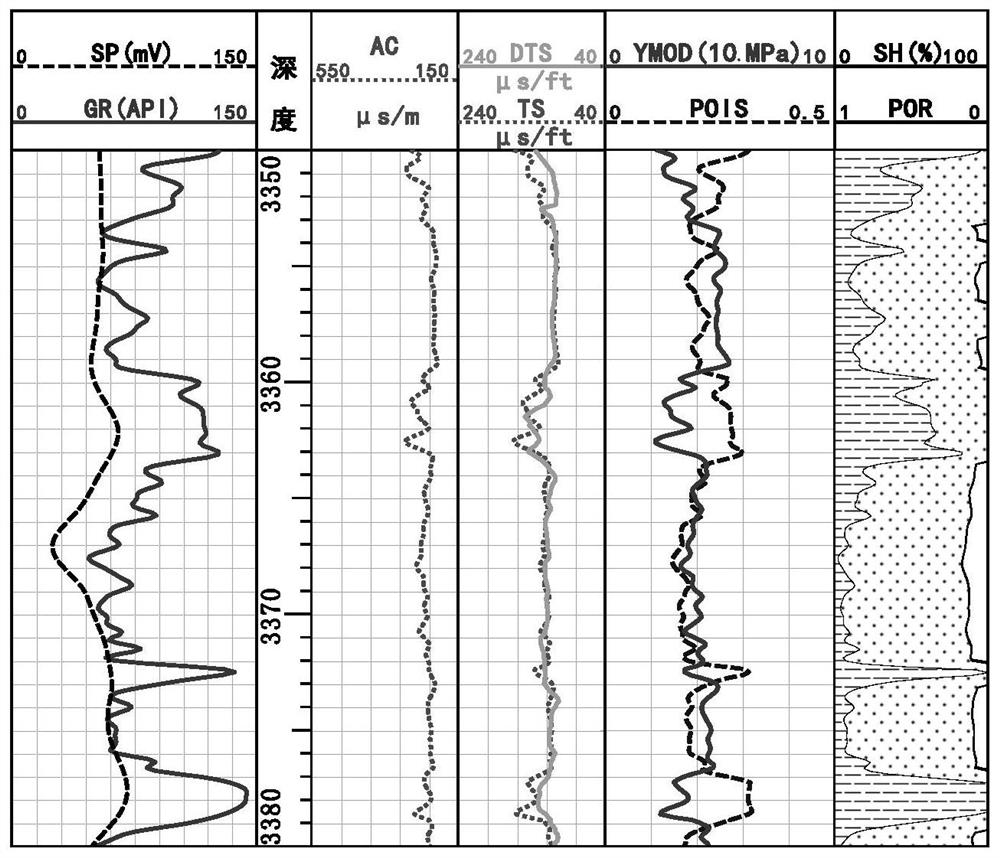

Crustal stress calculation method and device for sand shale interbed tight gas reservoir

PendingCN113777668AReliable portrayalReflect the law of changeGeomodellingGeological measurementsRock coreWell logging

The invention provides a crustal stress calculation method for a sand shale interbed tight gas reservoir. The method comprises the following steps of: calculating to obtain a shear wave time difference, and carrying out correlation analysis on the shear wave time difference and a logging shear wave time difference obtained by actual measurement logging to obtain a corrected shear wave time difference after correction; calculating to obtain rock dynamic mechanical parameters, and converting the rock dynamic mechanical parameters into continuous static parameters in combination with discontinuous static parameters obtained by an indoor rock core test; and acquiring crustal stress data through a crustal stress calculation model on the basis of the continuous static parameters, and correcting the crustal stress data by using a field fracturing construction curve and calculated fracture pressure obtained by the fracture pressure calculation model to obtain a crustal stress profile. According to the crustal stress calculation method, reliable rock dynamic mechanical parameters are obtained through calculation and correction of the shear wave time difference, continuous static parameters are obtained through related conversion of the rock dynamic mechanical parameters and the rock static mechanical parameters, and a reliable data foundation is laid for subsequent crustal stress calculation.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of crushed stone clay core wall material

ActiveCN106996095BIncrease productionReduce the amount of civil worksEarth-fill damsRock-fill damsMaterials preparationVertical plane

The invention discloses a manufacturing method of breakstone clay core wall material. The manufacturing method comprises the following steps: (1) arranging a blending site for excavating an upper dam and a blending site for material preparation; (2) determining the size grading and moisture content of breakstone and clay, and then calculating to determine the mass ratio of the breakstone to the clay; (3) determining the paving thickness of each layer, the interbedding number and the material pile design pile height of the breakstone and the clay; (4) carrying out a small-scale blending test; (5) correcting the paving parameters according to the result of the small-scale blending test, and then carrying out large-scale paving and blending; (6) after paving, adopting a backdigger to cut out leftover material to form an excavation vertical face; and (7) adopting the backdigger to carry out excavation on the vertical face and repeated blending to obtain the breakstone clay core wall material. According to the manufacturing method, the blending method that the clay and the breakstone are alternately paved layer by layer and the backdigger excavates on the vertical plane is adopted, the civil engineering quantity is smaller, the blending technology is simple, economic and high in quality, and the breakstone clay core wall material is high in yield.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD +1

A multi-wave avo joint inversion method for sand-shale thin interbedded media

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Preparation method of microbial agent-containing red-layer sandstone and mudstone interbedding side slope wound surface artificial soil

ActiveCN102173920BImprove physical and chemical propertiesPromote circulationOrganic fertilisersSoil conditioning compositionsRevegetationMicrobial agent

The invention provides a preparation method of microbial agent-containing red-layer sandstone and mudstone interbedding side slope wound surface artificial soil. The microbial agent-containing red-layer sandstone and mudstone interbedding side slope wound surface artificial soil is prepared by effectively mixing the raw material ingredients of the microbial agent, red-layer sandstone or / and red-layer mudstone, farmland soil or / and natural soil, straw, livestock and poultry excrement, high-water-absorbility resin, cement, attapulgite powder and fertilizer under a certain condition. The preparation method has obvious effects of accelerating circulation of soil nutrient elements, increasing supply of soil available nutrients, improving soil physical and chemical characteristics and contributing to recovery of vegetation.

Owner:SICHUAN UNIV

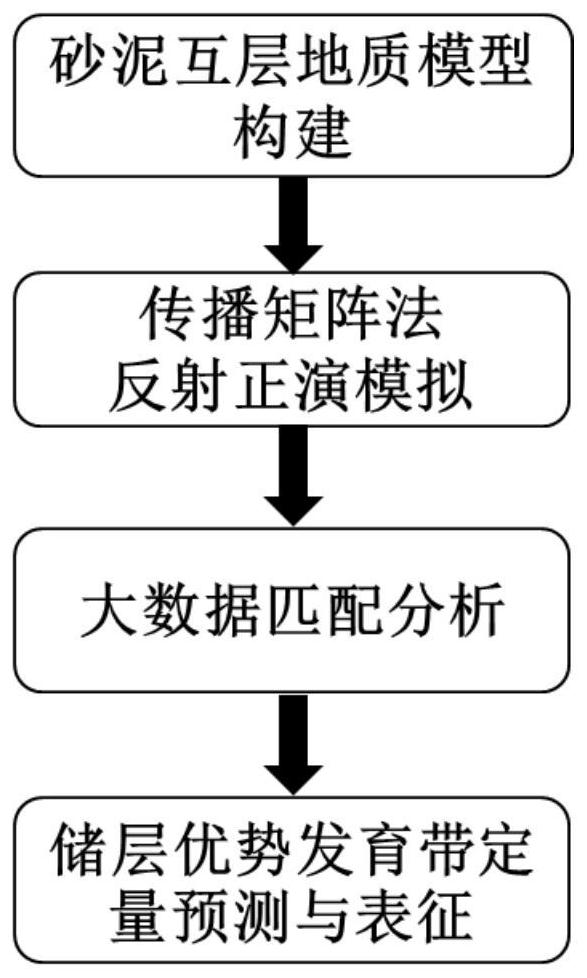

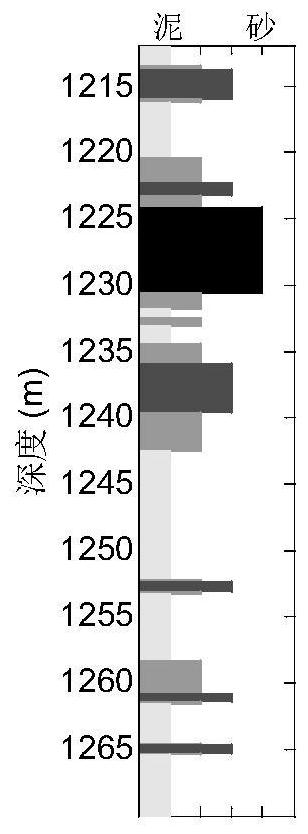

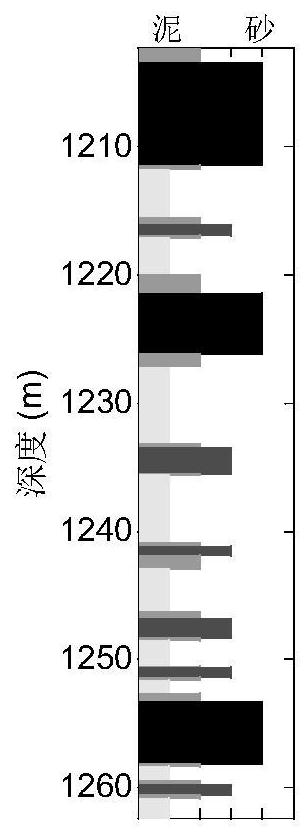

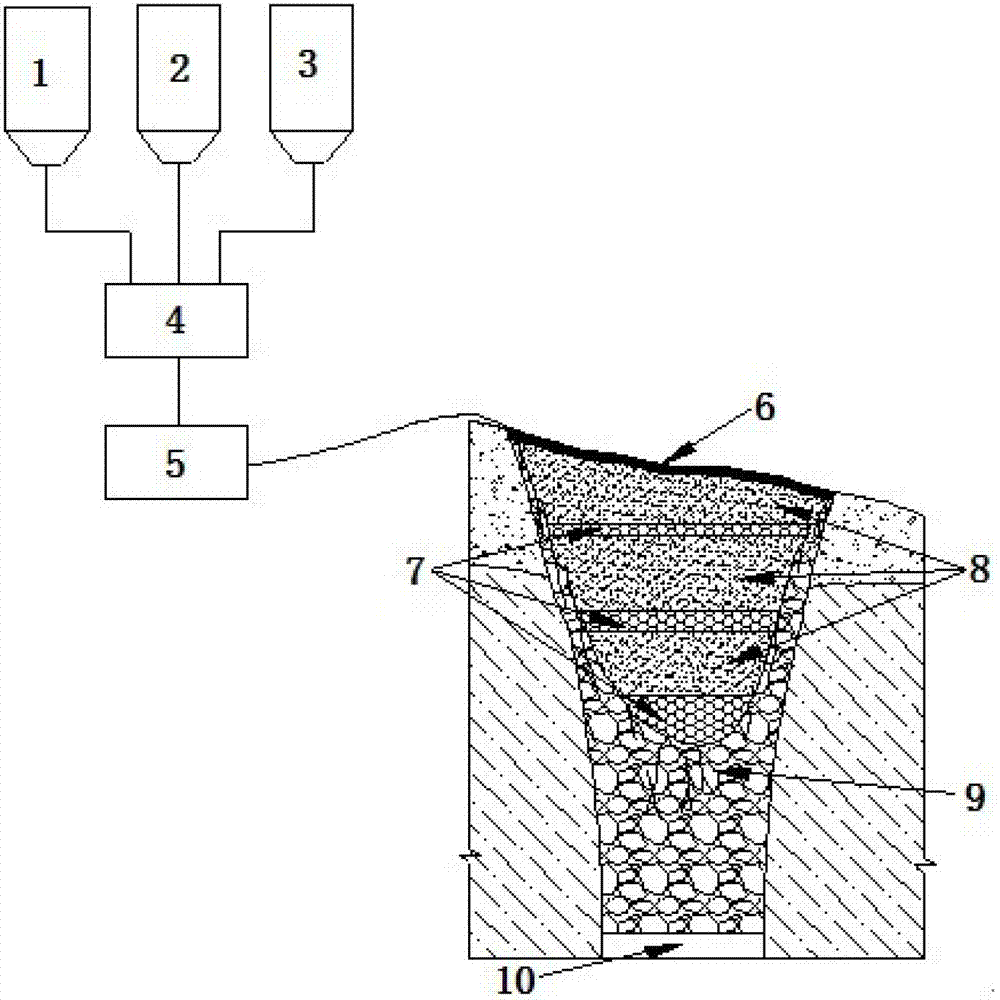

Sand-mud interbed reservoir developmental zone earthquake prediction method based on big data analysis

ActiveCN113534262AEnhancement of actual reservoir characterization capabilitiesQuantitative uncertaintySeismic signal processingSeismology for water-loggingData setEarthquake prediction

A sand-mud interbed type reservoir developmental zone earthquake prediction method based on big data analysis comprises the following steps: 1, building a mass sand-mud interbed type geologic model based on the deposition characteristics of a drilled reservoir, and obtaining a transition probability matrix; 2, constructing a 0-degree incident PP wave reflection seismic record of the model in a forward modeling algorithm and a 90-degree phase Ricker wavelet simulation model; 3, screening a model trace data set which is highly matched with the seismic record waveform of the actual stratum through a big data analysis technology, and carrying out normalization processing, and matching a record closest to the actual seismic waveform in the big data model according to a formula; and 4, obtaining quantitative prediction and characterization of the reservoir dominant developmental zone earthquake. According to the invention, seismic forward modeling is realized; moreover, the probability density distribution of the sand-to-ground ratio corresponding to the corresponding geologic model and the maximum single-layer sand body thickness is obtained through statistics, the reservoir development degree is indicated, and meanwhile, the uncertainty of interpretation is quantified.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Backfill handling method for activity subsidence area of mine

InactiveCN103216239BImprove liquiditySuitable for permeabilityUnderground miningSurface miningHigh concentrationSlurry

Owner:UNIV OF SCI & TECH BEIJING +1

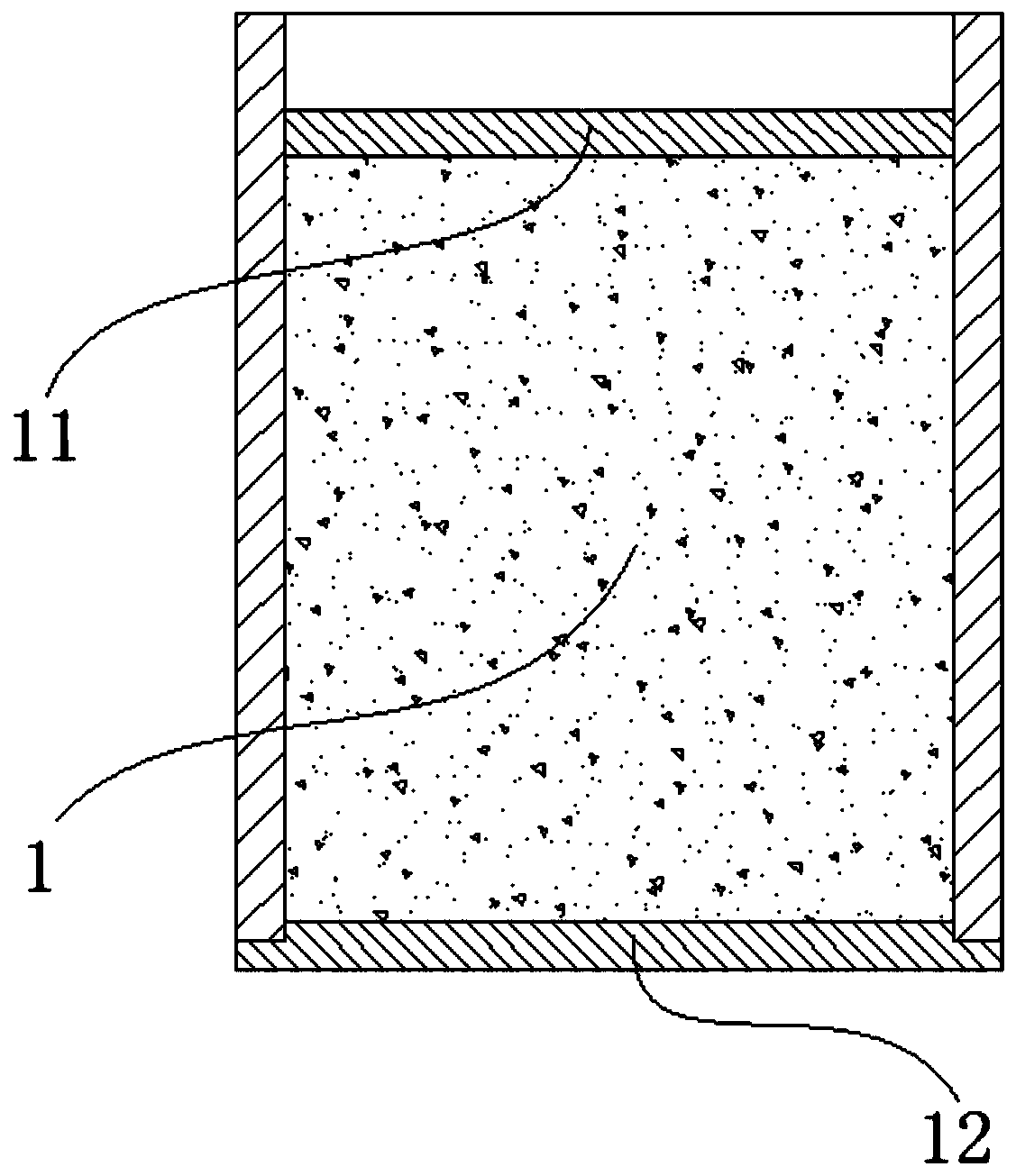

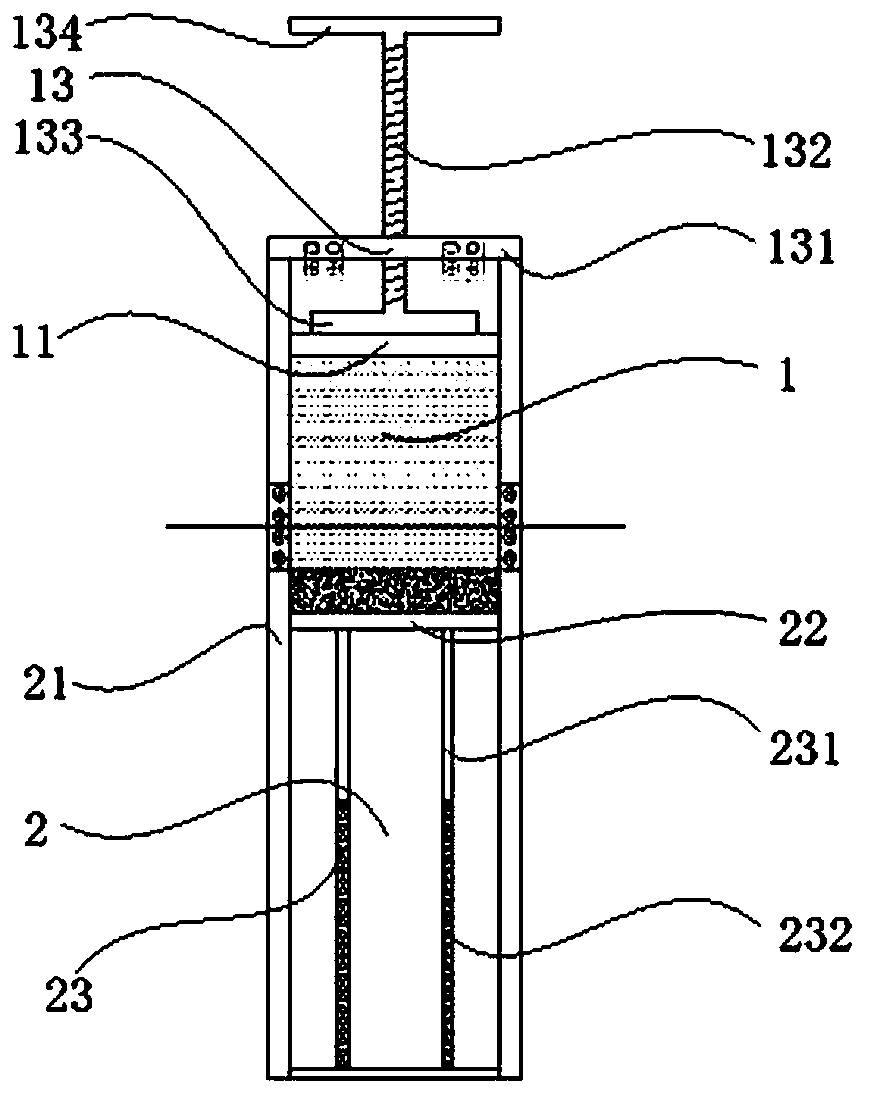

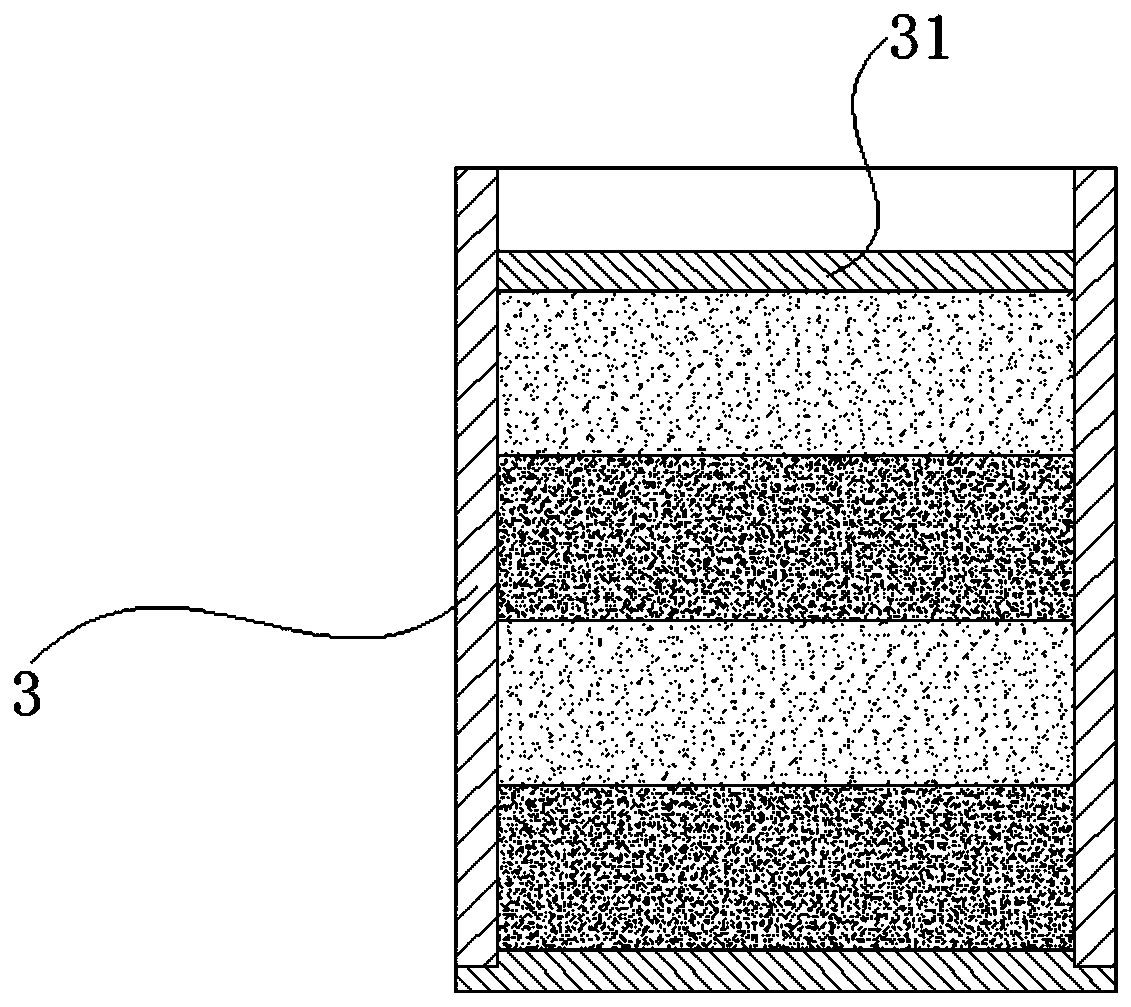

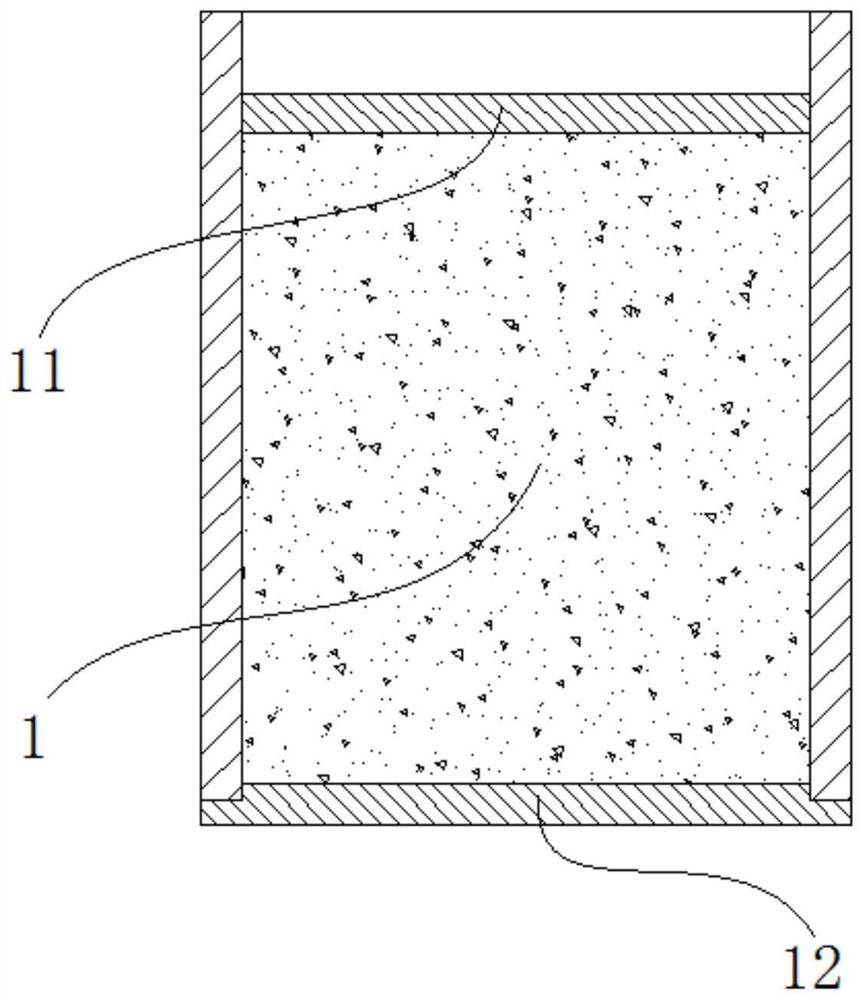

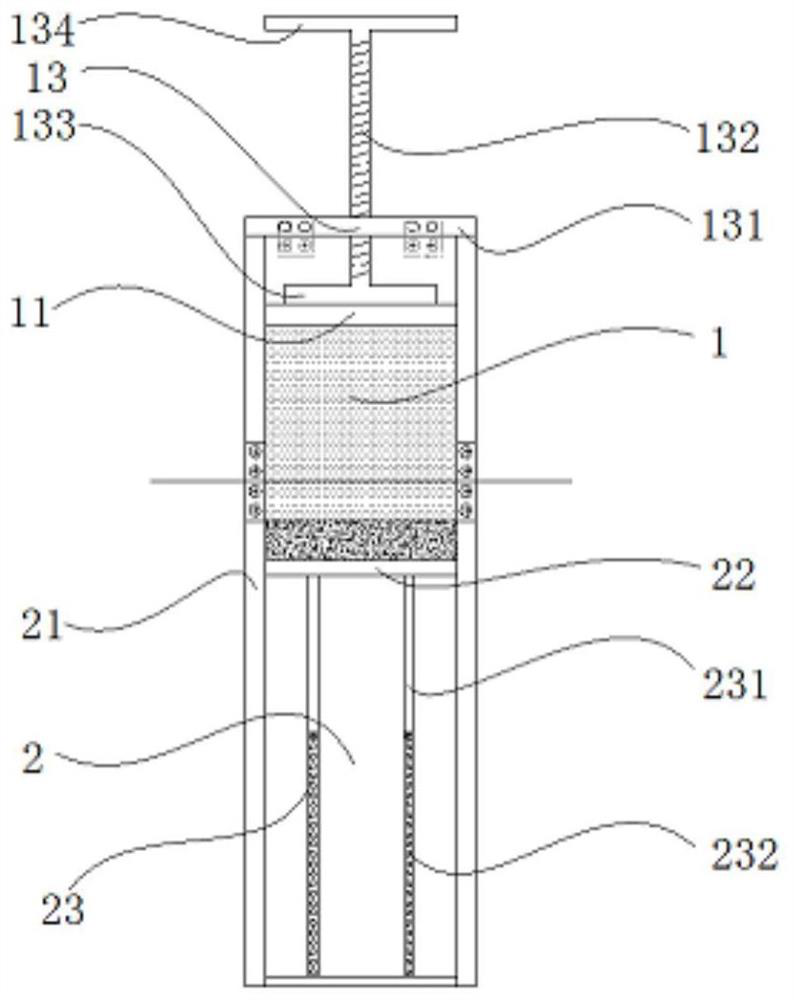

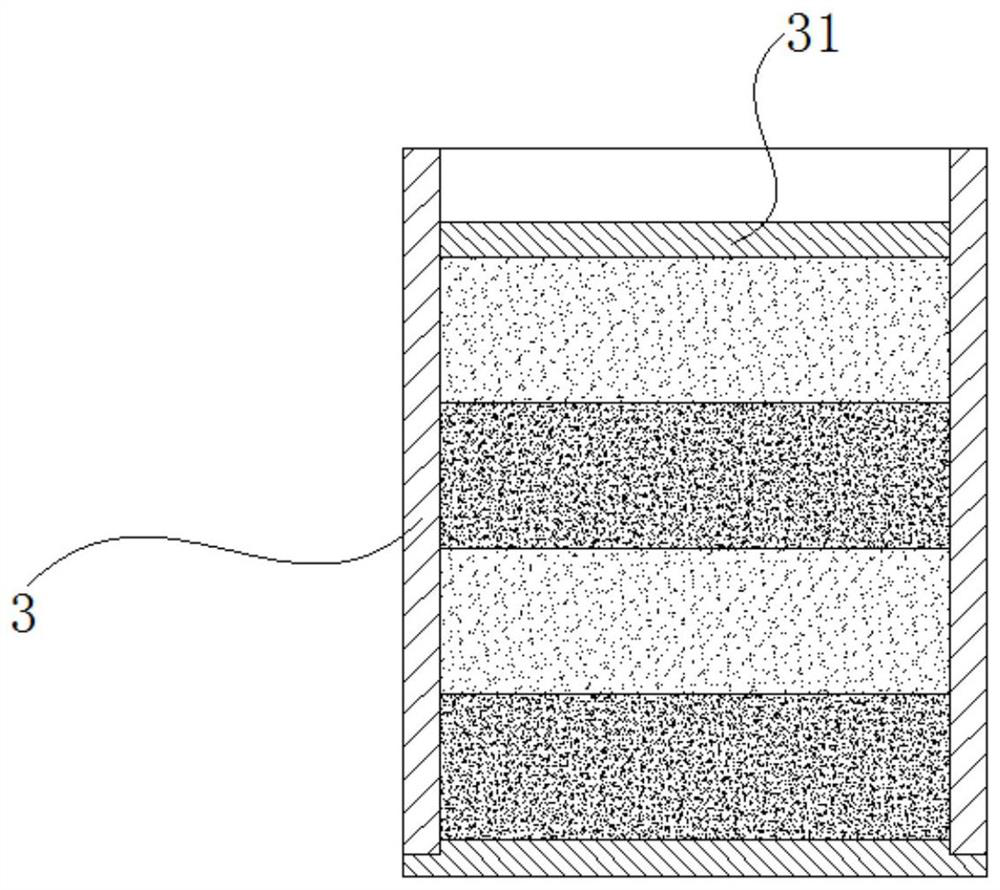

Soft and hard interbedding rock test sample manufacturing device and manufacturing method

ActiveCN110044675AControl thicknessIntegrity guaranteedPreparing sample for investigationSoft layerTest sample

The invention belongs to the field of soft and hard interbedding rock mass testing, and relates to a soft and hard interbedding rock test sample manufacturing device, comprising: a pre-pressing die, acutting and stacking unit and a pressing die. The invention further relates to a soft and hard interbedding rock test sample manufacturing method, utilizing the above method and comprising the following steps: preparing a soft layer mixed material; preparing a hard layer mixed material; preparing a soft layer material block and a hard layer material block; preparing a soft and hard interbedding material block; preparing a soft and hard interbedding compression block; and preparing a soft and hard interbedding rock test sample. By adjusting the distance between a load bearing plate and a material stacking port, the interbedding thickness of a soft and hard interbedding material can be conveniently controlled, the inclination angle of the soft and hard interbedding compression block with the horizontal plane is fixed after being solidified, a sample is extracted by using a core drilling machine, and the interbedding inclination angle can be controlled; and the manufacturing process is simple, the manufacturing efficiency is high, meanwhile, a single-layer material is carried and stacked in the manufacturing to ensure the integrity of a single-layer sample.

Owner:CHONGQING JIAOTONG UNIVERSITY

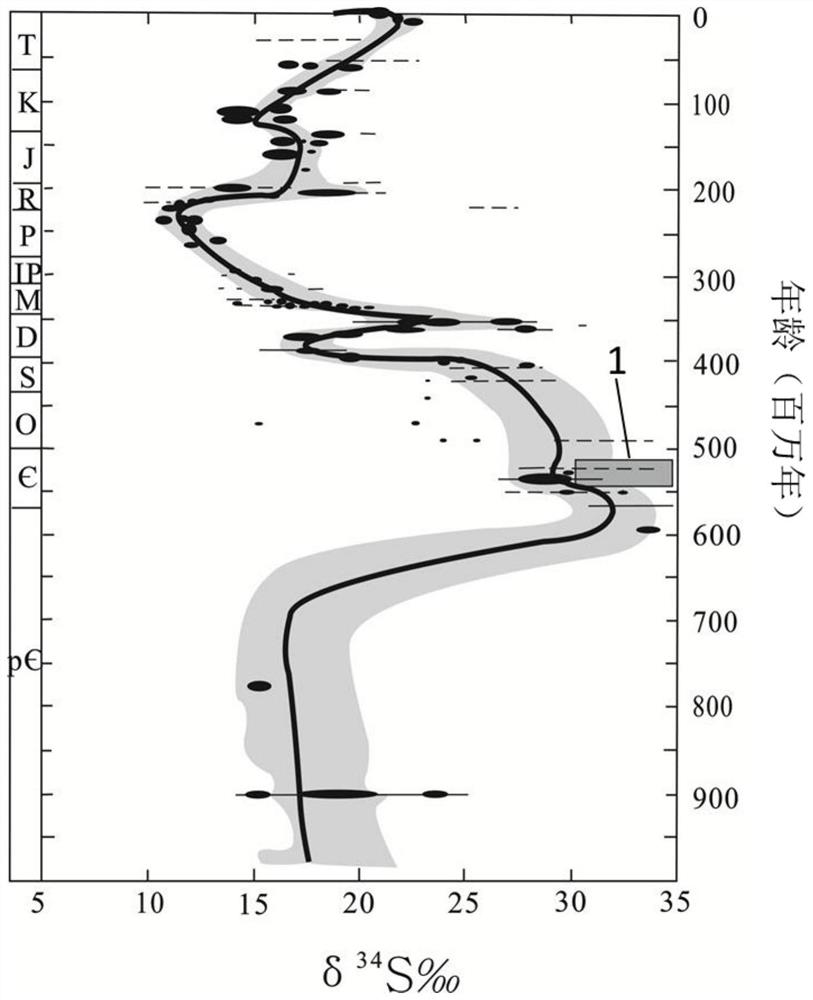

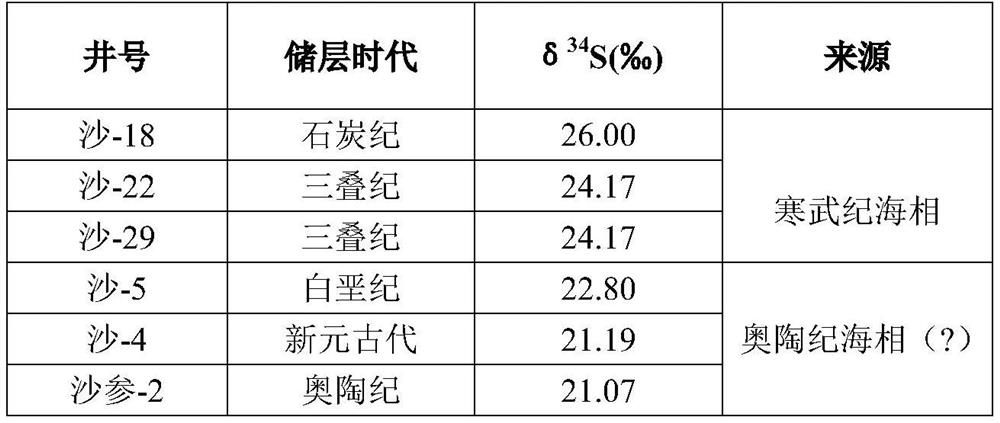

Method for judging the age of petroleum source rocks by comparing evaporites with petroleum sulfur isotopes

The invention discloses a method for judging the age of petroleum source rocks by comparing evaporite and petroleum sulfur isotopes, comprising the following steps: S101, collecting sulfate samples in evaporite strata and performing sulfur isotope analysis to obtain the sulfur isotope of evaporite strata Data; S102. Collect carbon isotope samples in carbonate strata interbedded with evaporite strata and conduct carbon and oxygen isotope analysis, and then conduct carbon isotope stratigraphic studies to determine the geological age of evaporites; S103. Based on evaporation Sulfur isotope data of rock formations and the geological age of evaporite rocks to improve the international sulfur isotope curve; S104. Analyze sulfur isotope in oil and obtain sulfur isotope data of oil; S105. Combine sulfur isotope data of oil with sulfur isotope data of evaporite formations For comparison, and combined with the international sulfur isotope curve to determine the geological age of petroleum source rocks.

Owner:CHINA PETROLEUM & CHEM CORP +1

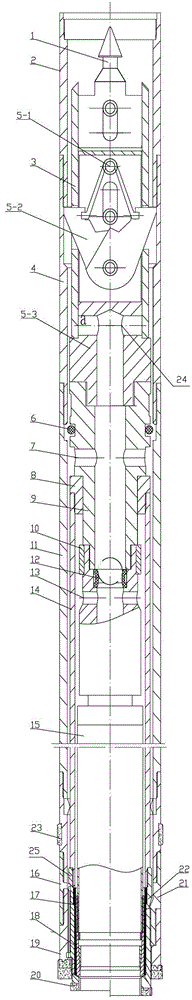

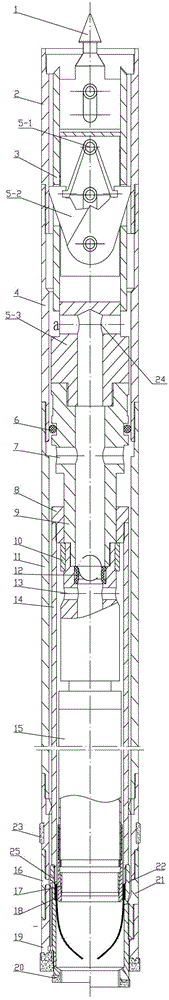

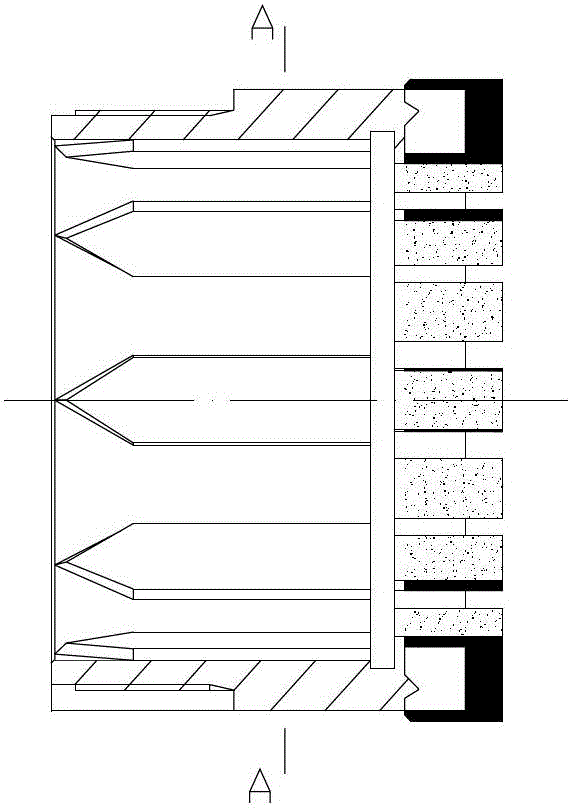

A rope coring drill

The invention discloses a rope core taking drill which comprises an outer pipe assembly and an inner pipe assembly. A reamer (23) is arranged in the outer wall assembly, and an inner pipe (14) and a third layer core pipe (15) are arranged in the inner pipe assembly. The rope core taking drill is characterized in that the lower end of the reamer (23) in the outer pipe assembly is connected with an external connector (16), and the lower end of the external connector (16) is connected with an external drill head (19). The lower end of the inner pipe (14) of the inner pipe assembly is connected with an inner drill head (20), and the inner drill head (20) protrudes forwards relative to the external drill head (19). The inner drill head is inserted into the outer drill head in a spline mode, and the inner drill head can be fished out together with the inner pipe, a clamping spring seat (18) and a clamping spring are arranged at the lower portion of the inner side of the third layer core pipe (15), and a blocking spring (17) is arranged on the outer side of the third layer core pipe (15). Regarding complex formation of fracture development, hard brittle fracture, soft and hard interbedding and the like, the drill has the advantages of prolonging the service life to the largest extent, increasing drill lifting intervals, improving the core recovery rate and the like.

Owner:李国民 +1

A kind of soft-hard interbedded rock sample production device and production method

ActiveCN110044675BControl thicknessIntegrity guaranteedPreparing sample for investigationClassical mechanicsEngineering

The invention belongs to the field of soft-hard interbedded rock mass testing, and relates to a soft-hard interbedded rock sample production device, including: a pre-pressing mold, a cutting and stacking unit and a pressing mold, and also relates to a soft-hard interbedded rock sample production device The method, using the above-mentioned device, includes the following steps: preparing a soft-layer mixed material; preparing a hard-layer mixed material; preparing a soft-layer material block and a hard-layer material block; preparing a soft-hard interlayer material block; preparing a soft-hard interlayer compressed block; Prepare soft and hard interbedded rock samples. By adjusting the distance between the load-bearing plate and the stacking port, the interlayer thickness of soft and hard interlayer materials can be easily controlled. After the soft and hard interlayer compressed blocks are solidified, they are fixed at an inclination angle to the horizontal plane, and the interlayer can be controlled by sampling with a coring machine. Inclined angle: The production process is simple and the production efficiency is high. At the same time, the single-layer material block is transported and stacked in the pre-pressing mold to ensure the integrity of the single-layer sample.

Owner:CHONGQING JIAOTONG UNIVERSITY

Time-lapse seismic forward modeling method for CO2 geological storage in sand-mud interbed without shear wave velocity logging

ActiveCN106842326BEffective forward modelingSeismic signal processingSeismology for water-loggingFluid saturationWell logging

The invention discloses a forward simulation method for a sand-mud interbed CO2 geology sealing time-shifting earthquake without shear wave velocity logging. The method comprises the following steps: collecting data; extracting the data layer by layer; using logging information to calculate a sandstone mineral composition curve, calibrating the longitudinal and shear wave velocity under the pressure condition after the CO2 injection, and forecasting the shear wave velocity; executing the mixed fluid to replace the longitudinal and shear wave velocity curve after the injection; reserving the logging information time-depth conversion of the thin-layer information and using a Zoeppritz equation to calculate the reflection coefficient; executing the convolution with Ricker wavelet to obtain a synthetic seismogram; and using the time-shifting forward artificial synthetic seismogram of the different injection stages and different basic frequencies before and after the CO2 injection to subtract, to obtain the difference forward earthquake response. The method is capable of, in allusion to the feature of the complicated sand-mud thin interbed, solving the mixed fluid saturation replacement problem of the different reservoir features in the CO2 oil flooding and geology sealing process better and forecasting the longitudinal and shear wave velocities of the pressure change in the CO2 injection stage.

Owner:CHINA PETROLEUM & CHEM CORP +1

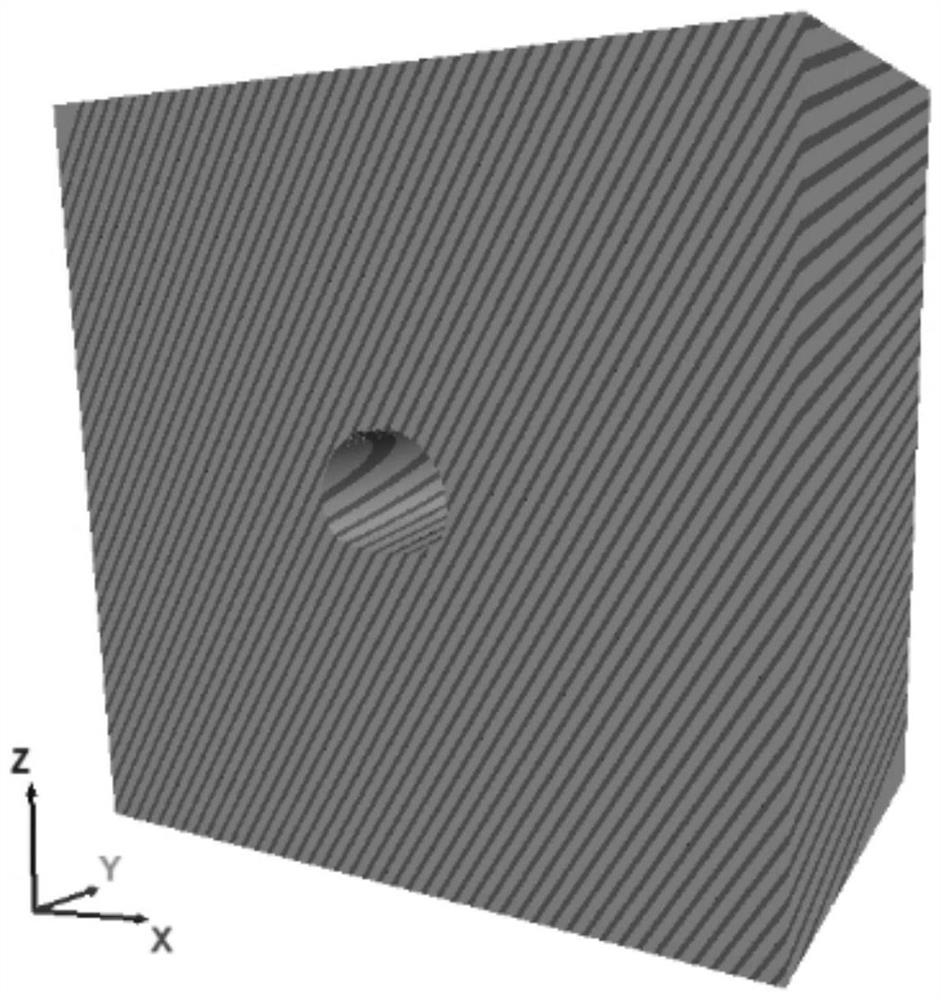

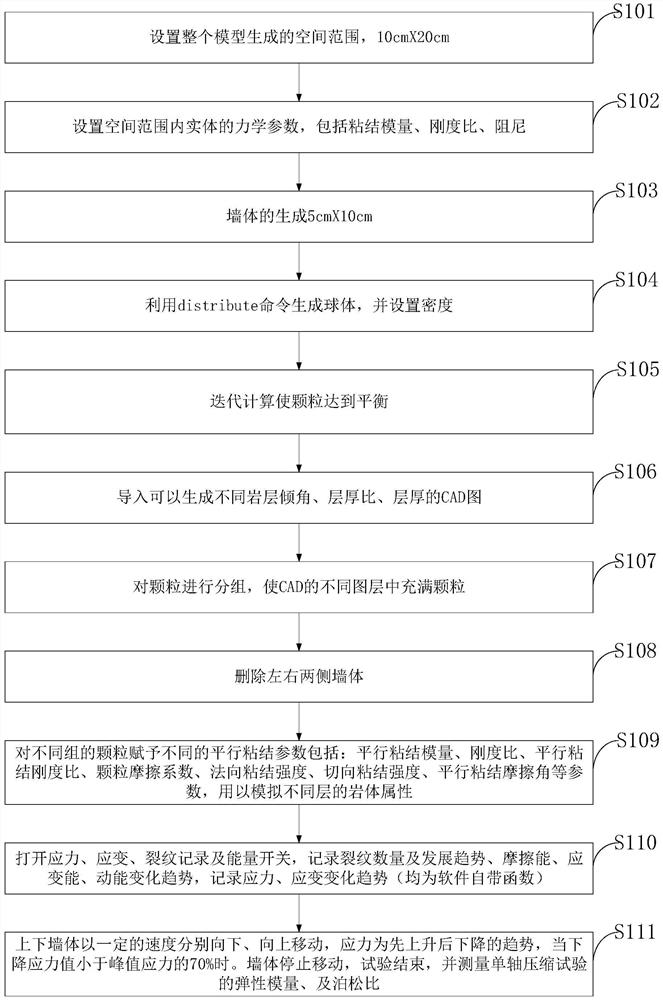

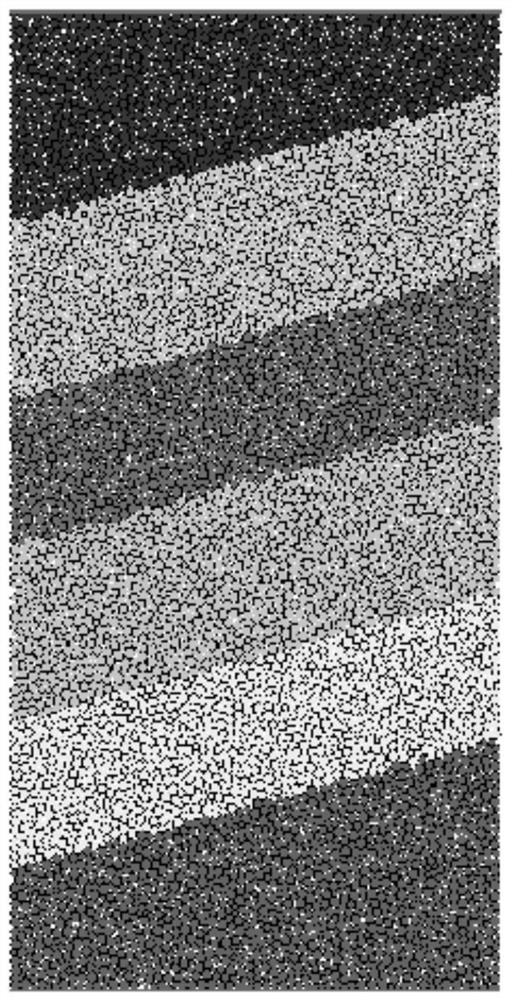

Simulation method and system for simulating numerical model of interbed rock mass and processing terminal

The invention belongs to the technical field of interbed rock mass simulation, and discloses a simulation method and system for simulating an interbed rock mass fluid-solid coupling numerical model and a processing terminal. The simulation method comprises the following steps: setting mechanical parameters of entities in a generated spatial range, and generating a wall body; generating spheres, and setting the density; balancing the particles through iterative calculation; importing CAD drawings capable of generating different rock stratum dip angles, layer thickness ratios and layer thicknesses; grouping the particles, so that different layers of the CAD are filled with the particles; deleting the left and right wall bodies; endowing different groups of particles with different parallel bonding parameters, simulating rock mass attributes of different layers, and achieving the purpose of fluid-solid coupling by performing data exchange operation with OpenFoamt. The definition and simulation method of the interbed rock mass can be realized in software. According to the method, particle flow numerical simulation is adopted to analyze interbed rock mass mechanical property response rules and mesoscopic failure characteristics under the action of factors such as a rock mass dip angle, a layer thickness ratio and layer thickness from a mesoscopic perspective.

Owner:新疆建筑科学研究院(有限责任公司)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com