A kind of preparation method of crushed stone clay core wall material

A manufacturing method and clay core wall technology, which is applied in sea area engineering, construction, dams, etc., can solve the problems of poor uniformity of admixture, large amount of civil engineering, high construction cost, etc., and achieve small amount of civil engineering, high output and high quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Mixing crushed stone clay core wall material with 25% crushed stone content:

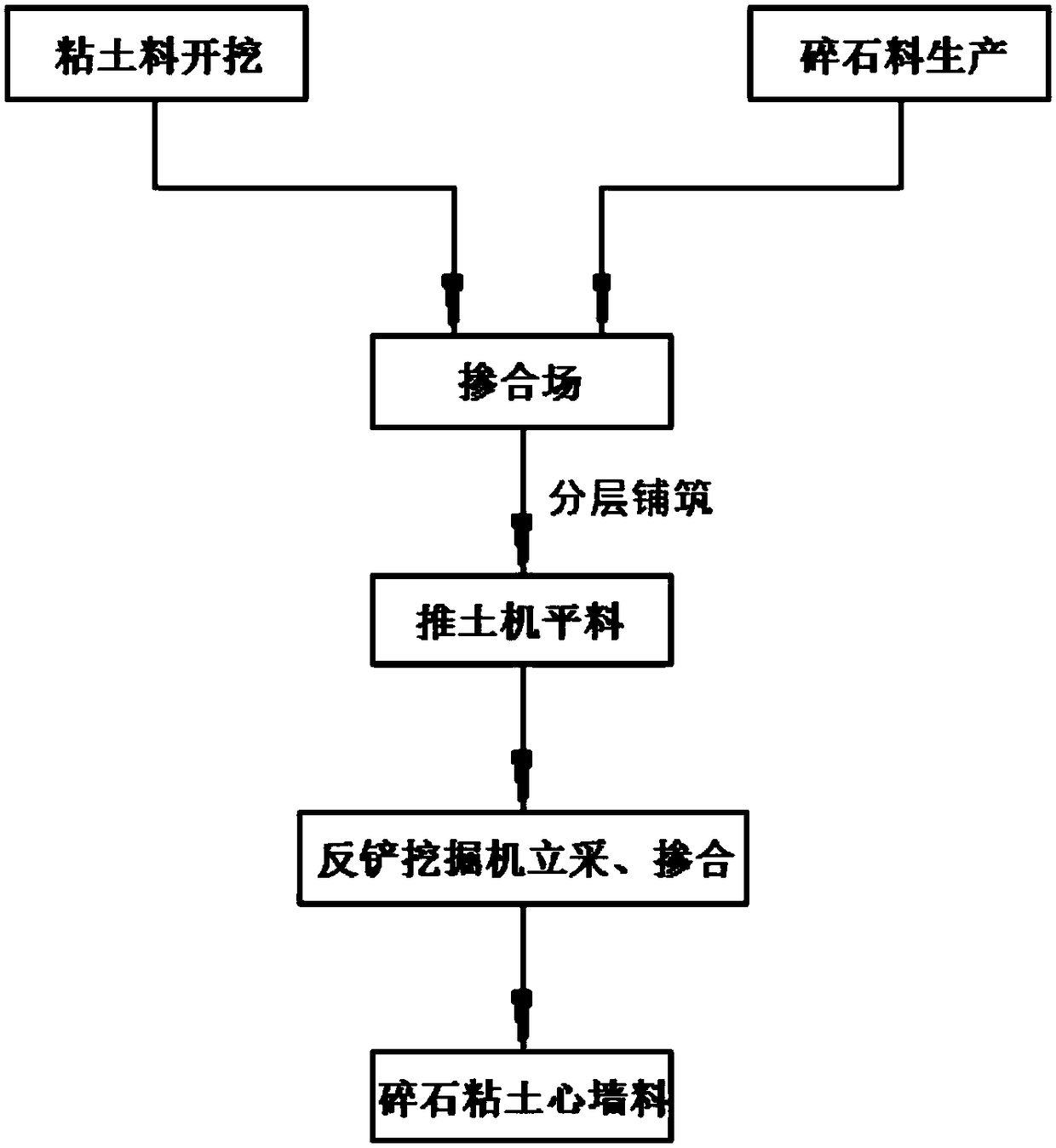

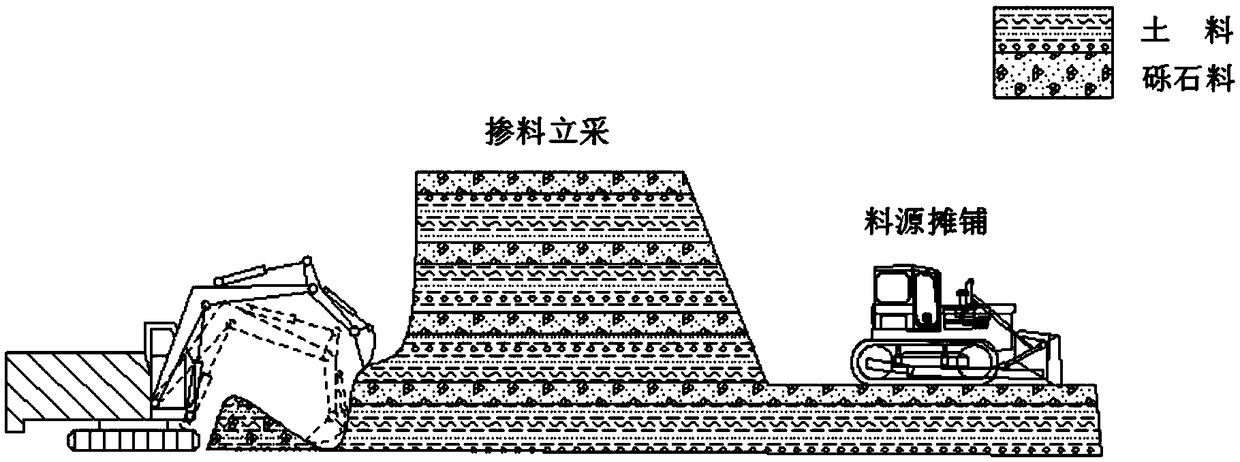

[0036] The production flow chart of crushed stone clay core wall material is as follows figure 1 As shown, the elevation mining backhoe mixing process diagram is as follows figure 2 shown.

[0037] Blending field specification: 8m×15m;

[0038] The single layer thickness of clay material paving is 75cm, and the single layer thickness of gravel material paving is 25cm, alternate horizontal paving, clay material is paved for the first time, a total of 6 layers;

[0039] After the paving is completed, use a backhoe excavator to excavate the facade with a thickness of 40cm, and mix it 4 times with a backhoe excavator;

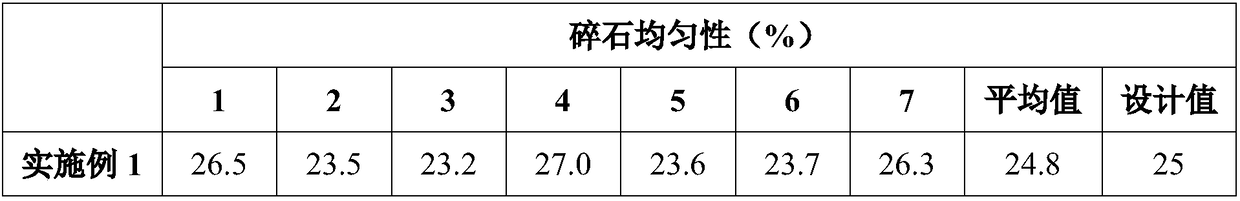

[0040] The quality inspection adopts the method of measuring the mass content and uniformity of gravel in the admixture. The content of gravel in the admixture is controlled within ±5% of the design content. Seven positions were sampled to detect the crushed stone content. Th...

Embodiment 2

[0042] Mixing crushed stone clay core wall material with 30% crushed stone content:

[0043] The production flow chart of crushed stone clay core wall material is as follows figure 1 As shown, the elevation mining backhoe mixing process diagram is as follows figure 2 shown.

[0044] Blending field specification: 8m×15m;

[0045] The single layer thickness of clay material paving is 70cm, and the single layer thickness of gravel material paving is 30cm, alternate horizontal paving, clay material paving for the first time, a total of 6 layers;

[0046] After the paving is completed, use a backhoe excavator to excavate the facade with a thickness of 40cm, and mix it 4 times with a backhoe excavator;

[0047] The quality inspection adopts the method of measuring the mass content and uniformity of gravel in the admixture. The content of gravel in the admixture is controlled within ±5% of the design content. Seven positions were sampled to detect the crushed stone content. The ...

Embodiment 3

[0049] Mixing crushed stone clay core wall material with 35% crushed stone content:

[0050] The production flow chart of crushed stone clay core wall material is as follows figure 1 As shown, the elevation mining backhoe mixing process diagram is as follows figure 2 shown.

[0051] Blending field specification: 8m×15m;

[0052] The single layer thickness of clay material paving is 65cm, and the single layer thickness of gravel material paving is 35cm, alternate horizontal paving, clay material is paved for the first time, a total of 6 layers;

[0053] After the paving is completed, use a backhoe excavator to excavate the 50cm thick facade, and backhoe excavator to mix 3 times;

[0054] The quality inspection adopts the method of measuring the mass content and uniformity of gravel in the admixture. The content of gravel in the admixture is controlled within ±5% of the design content. Seven positions were sampled to detect the crushed stone content. The uniformity of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com