Construction method for ultra-deep vibroflotation gravel pile of complicated stratum

A technology of vibrating gravel piles and complex strata, which is applied in the fields of soil protection, infrastructure engineering, construction, etc. It can solve the problems of slow construction speed, achieve the effects of improving construction efficiency, speeding up construction progress, and reducing damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

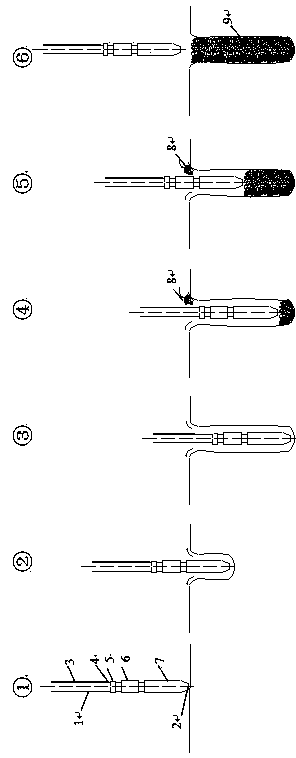

[0031] As a preferred embodiment of the present invention, comprise the following steps:

[0032] (1) Construction preparations;

[0033] (2) Hole making;

[0034] (3) clear hole;

[0035] (4) filler;

[0036] (5) Pile formation: Repeat step (4) until the filler is densified to the top of the pile.

[0037] In the above-mentioned step (2), it is aimed at complex formations with a depth exceeding 15-20m of medium-coarse sand with silt-fine sand interlayer (interbed) and round gravel with silt-fine sand interlayer (interbed).

[0038] The power of the vibrator used in the step (2) is 130kW~180kW.

[0039] The volume of the air compressor used in the gas cooperation method in the step (2) is 7-12m3, and the air pressure at the jet orifice is 0.2-0.8Mpa.

[0040] In the step (2), the pore-forming current of the vibratory impactor is 110-190A, and the pore-forming water pressure is 0.2-0.8Mpa.

[0041] In the case of collapsed holes in the above step (2), clay mud slurry can ...

Embodiment 2

[0056] As a specific application example of the present invention, its implementation mode is: the Ruili sub-transportation compressor station project of the China-Myanmar natural gas pipeline project (domestic section) includes three 5×104m3 storage tanks with a diameter of 60m. According to the survey report, the main soil layers from top to bottom are: ①clay, plastic, layer thickness 0.50-4.10m; ②medium-coarse sand, loose, interbedded with silt and gravel, layer thickness 1.50-8.70m; ③round gravel , medium-dense, layer thickness 0.50-4.30m; ④ medium-coarse sand, medium-dense, thin layer with silt and gravel sand, exposed layer thickness 0.50-9.50m; ⑤ medium-coarse sand, dense, local pebbles, gravel, Silt interlayer, exposed layer thickness 1.00-35.10m. The buried depth of the stable groundwater level of the site is 0.50-1.40m. The peak ground acceleration value of the proposed site is 0.20g (corresponding to an earthquake with a basic intensity of 8 degrees), and ②medium-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com