Polyether amine alkyl glycoside and preparation method and application thereof

A polyether amino alkyl glycoside and polyether amino alkyl sugar technology, which is applied in the field of polyether amino alkyl glycoside and its preparation, can solve the problems of short reaction time, limited application and popularization, poor inhibition performance and lubricating performance etc., to achieve the effects of mild reaction conditions, simple preparation method, good inhibition performance and lubricating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention provides a kind of preparation method of polyetheramino alkyl glycoside described in above-mentioned technical scheme, comprising:

[0038] React chlorinated epoxides, glycol compounds, water and acidic catalysts to obtain reaction products; the chlorinated epoxides include epichlorohydrin or 1,2-epoxychlorobutane; the two Alcohol compounds include ethylene glycol or polyethylene glycol;

[0039] reacting the reaction product with an organic amine to obtain an intermediate product; the organic amine includes ethylenediamine, diethylenetriamine, triethylenetetramine, tetraethylenepentamine or pentaethylenehexamine;

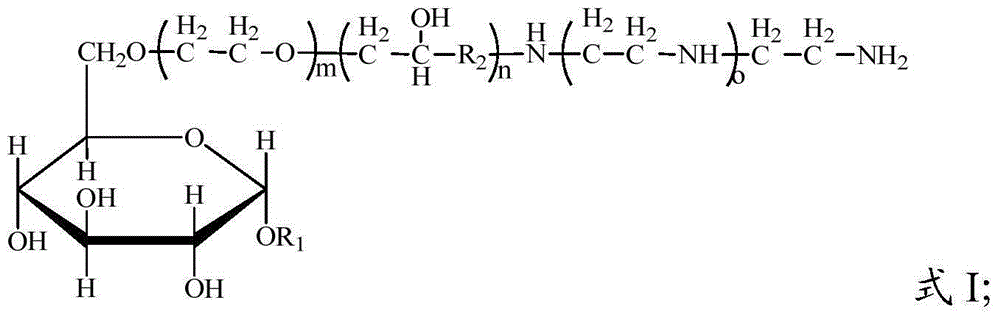

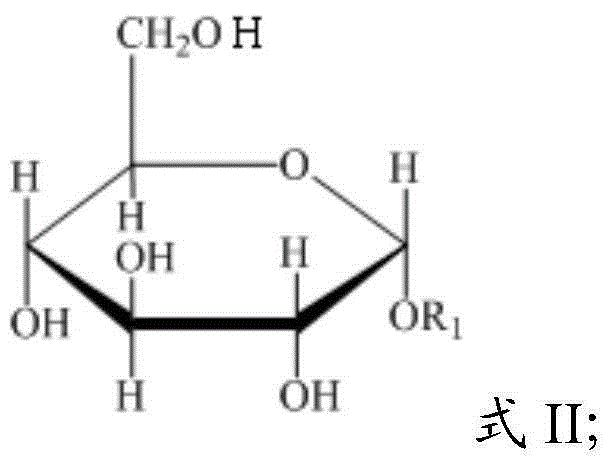

[0040] The intermediate product is reacted with an alkyl glycoside to obtain a polyetheramino alkyl glycoside; the alkyl glycoside has a structure shown in formula II:

[0041]

[0042] In formula II, R 1 selected from alkyl groups with 1 to 10 carbon atoms.

[0043] In an embodiment of the present invention, the reaction temperat...

Embodiment 1

[0071] Add 10g of epichlorohydrin, 8g of ethylene glycol, 40g of water, and 0.8g of sulfuric acid into a four-necked flask with a stirring and condensing reflux device, and react for 1.0h at normal pressure and at a temperature of 80°C to obtain reaction product;

[0072] Add 8 g of ethylenediamine to the reaction product at a dropping rate of 20 mL / min using a dropping funnel, and react for 2 h at normal pressure and at a temperature of 40° C. to obtain an intermediate product;

[0073] Add 10 g of methyl glucoside to the intermediate product, react at normal pressure and temperature of 95°C for 2.0 h, and distill the obtained reaction product to remove water under reduced pressure to obtain polyether aminomethyl glucoside with a yield of 94.87% .

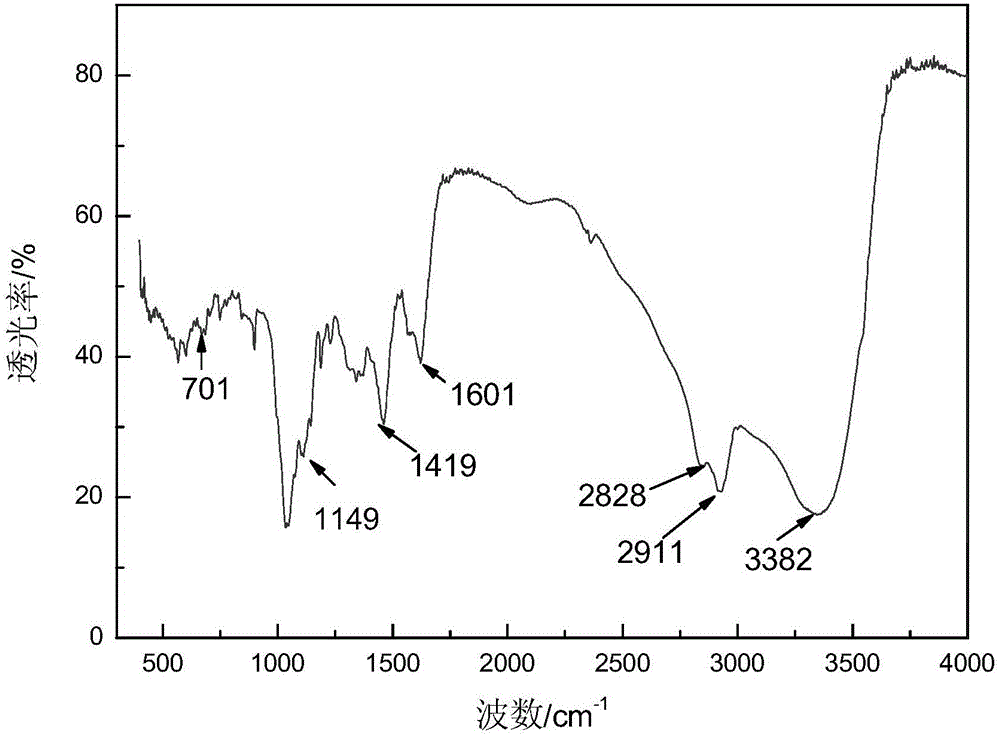

[0074] The polyether aminomethyl glucoside prepared in Example 1 of the present invention was carried out infrared detection, and the detection results were as follows: figure 1 as shown, figure 1 For the polyetheraminomethyl g...

Embodiment 2

[0079] The 1.2-epoxychlorobutane of 11g, the number-average molecular weight of 9g are the polyethylene glycol of 400, the water of 50g, the phosphoric acid of 0.9g join in the four-necked flask that has stirring and condensing reflux device, under normal pressure , Reaction at a temperature of 90°C for 2.0 hours to obtain a reaction product;

[0080] Add 9 g of diethylenetriamine to the reaction product using a dropping funnel at a rate of 20 mL / min, and react at normal pressure and temperature at 50° C. for 3 h to obtain an intermediate product;

[0081] Add 11 g of ethyl glucoside to the intermediate product, react at normal pressure and temperature of 100° C. for 3.0 h, and distill the obtained reaction product to remove water under reduced pressure to obtain polyetheramino ethyl glucoside with a yield of 95.43% .

[0082] Infrared detection was carried out on the polyetheraminoethyl glycoside prepared in Example 2 of the present invention, and the detection result was th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com