Method for researching mechanical behaviors of soft and hard interbedded rock mass based on 3D printing technology

A 3D printing and rock mass mechanics technology, which is applied in the use of optical devices, the preparation of test samples, and the use of stable shear force to test the strength of materials, which can solve the lack of preparation methods and mechanical properties of layered rock mass materials. The simulation is not perfect, less 3D fine printing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

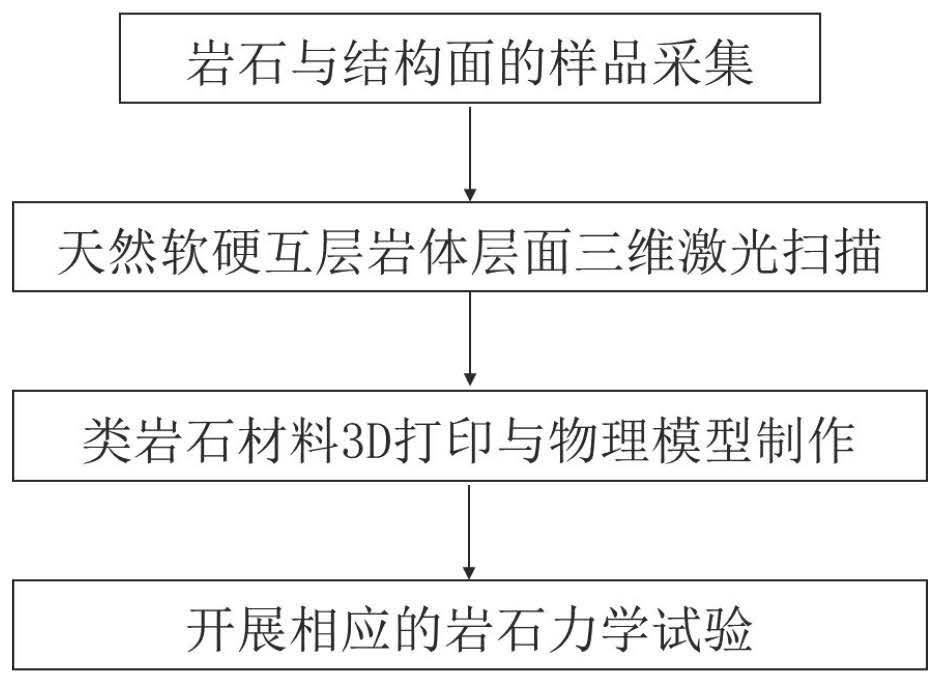

[0042] It is an object of the present invention to provide a method of studying the mechanical behavior of soft and hard mutual layer based on 3D printing techniques, including the following steps: 1. Sample collection of rocks and structural surfaces; 2. Natural soft and hard mutual layer rock mass Level 3D laser scanned; 3. Rock material 3D printing and physical model production; 4. Corresponding rock mechanics test four processes, such as figure 1 Indicated.

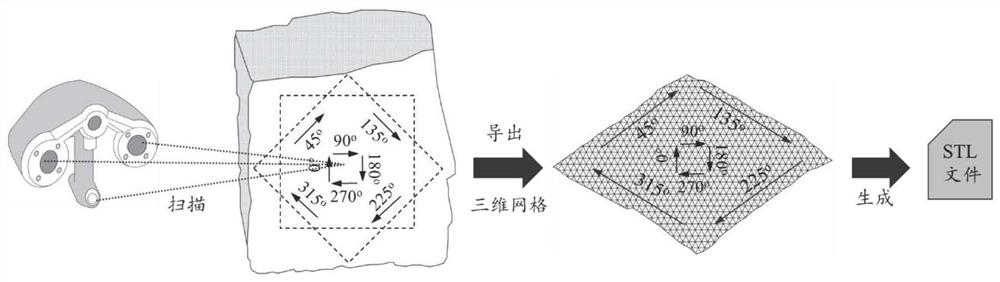

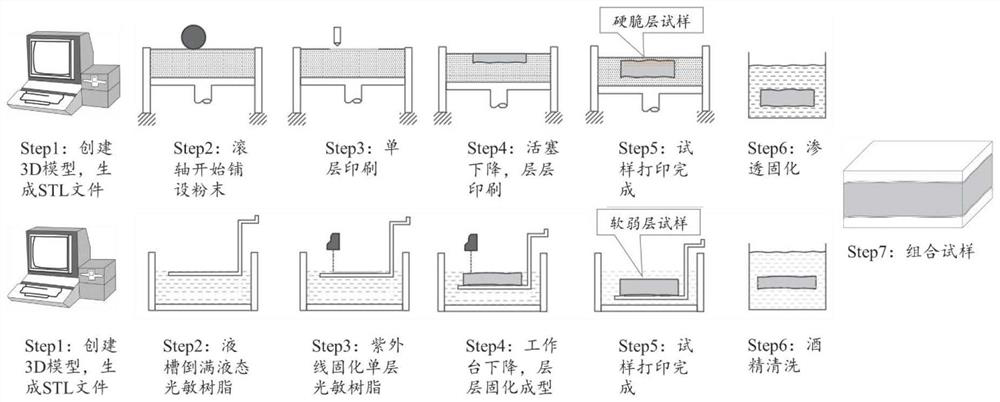

[0043] Among th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com