Patents

Literature

41results about How to "Increase shear deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

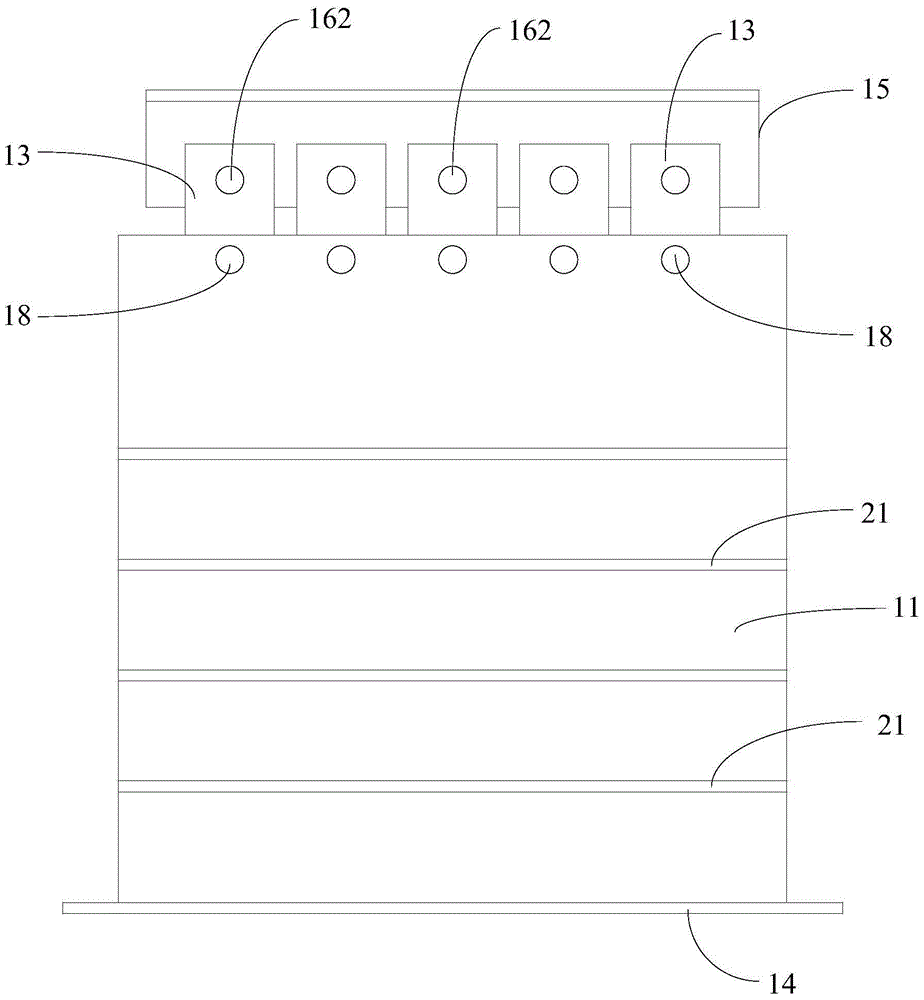

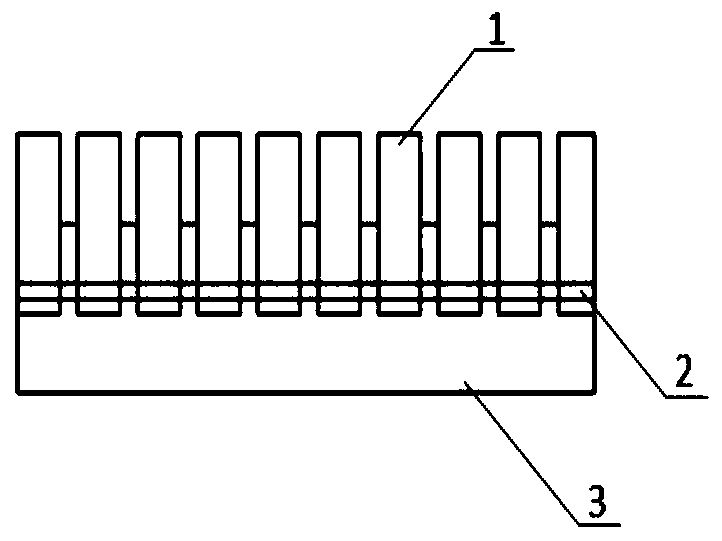

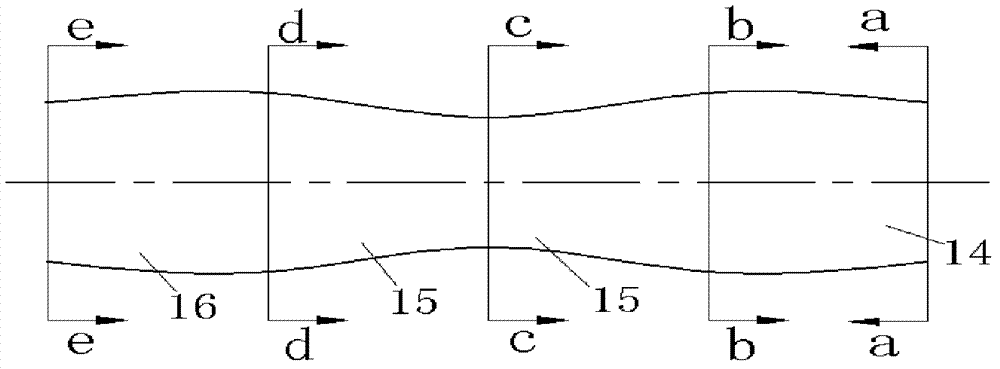

Damping intermediate pillar and damping structure using the same

InactiveUS7076926B2High strengthIncrease shear deformationNon-rotating vibration suppressionProtective buildings/sheltersHorizontal forceViscoelastic damping

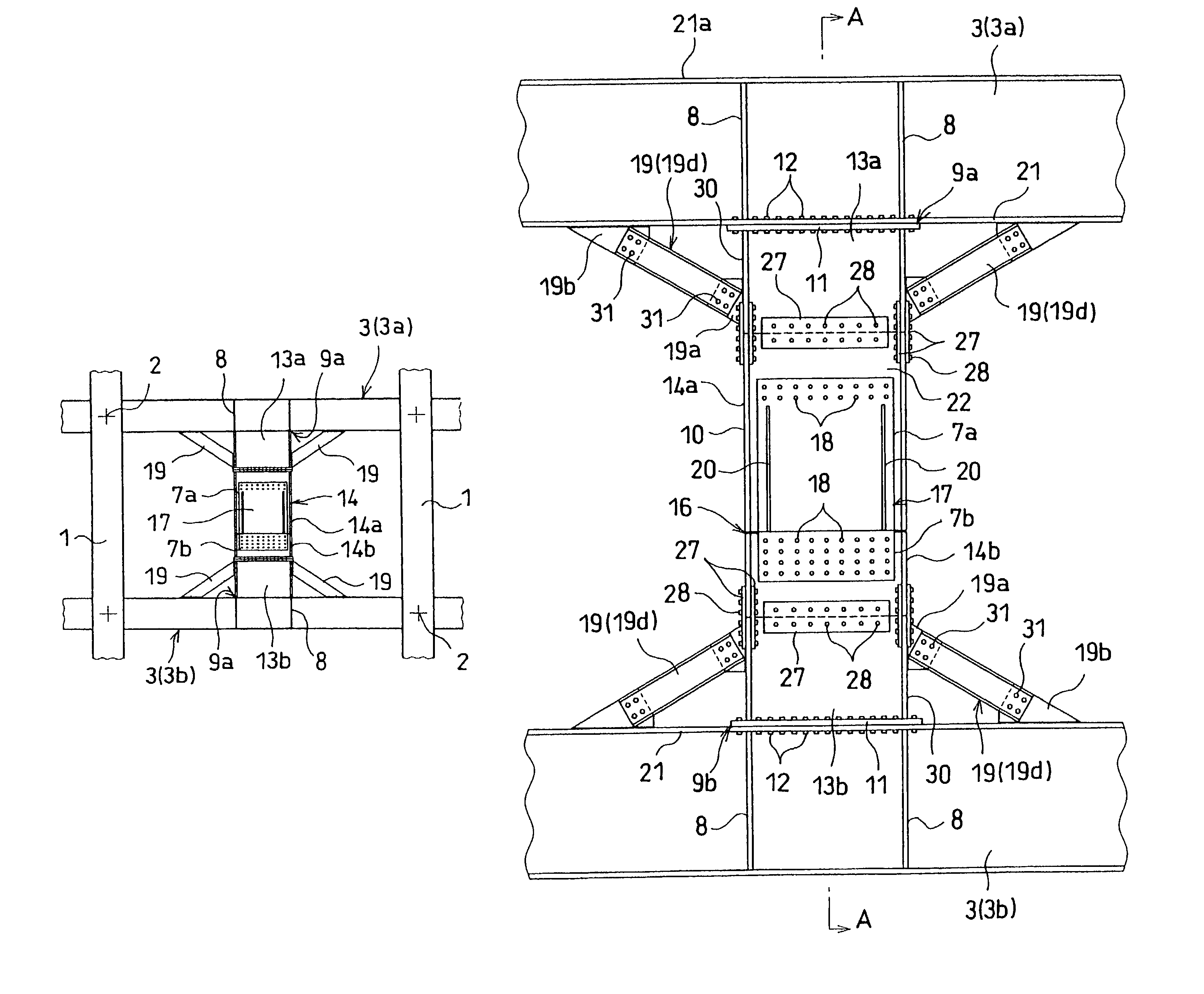

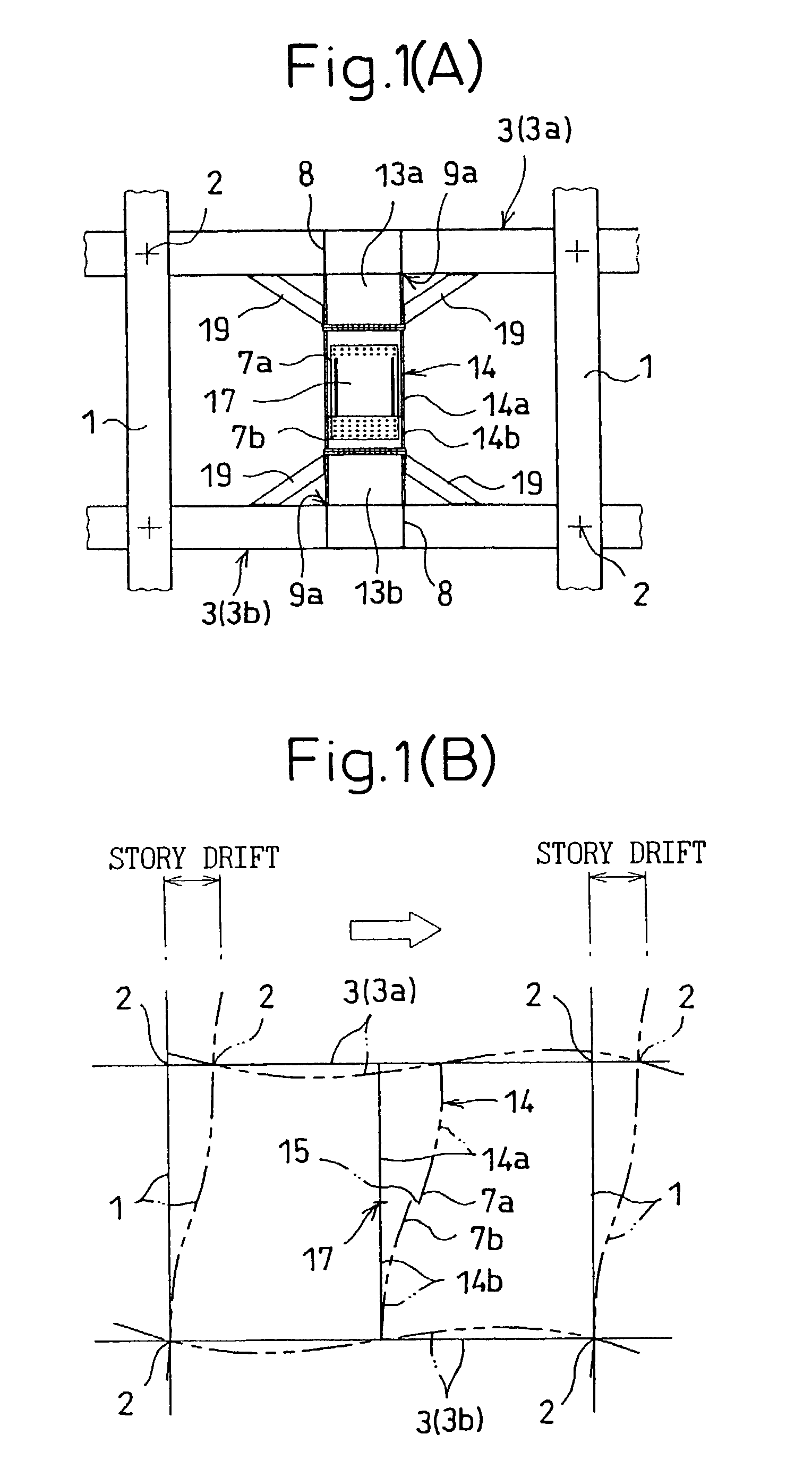

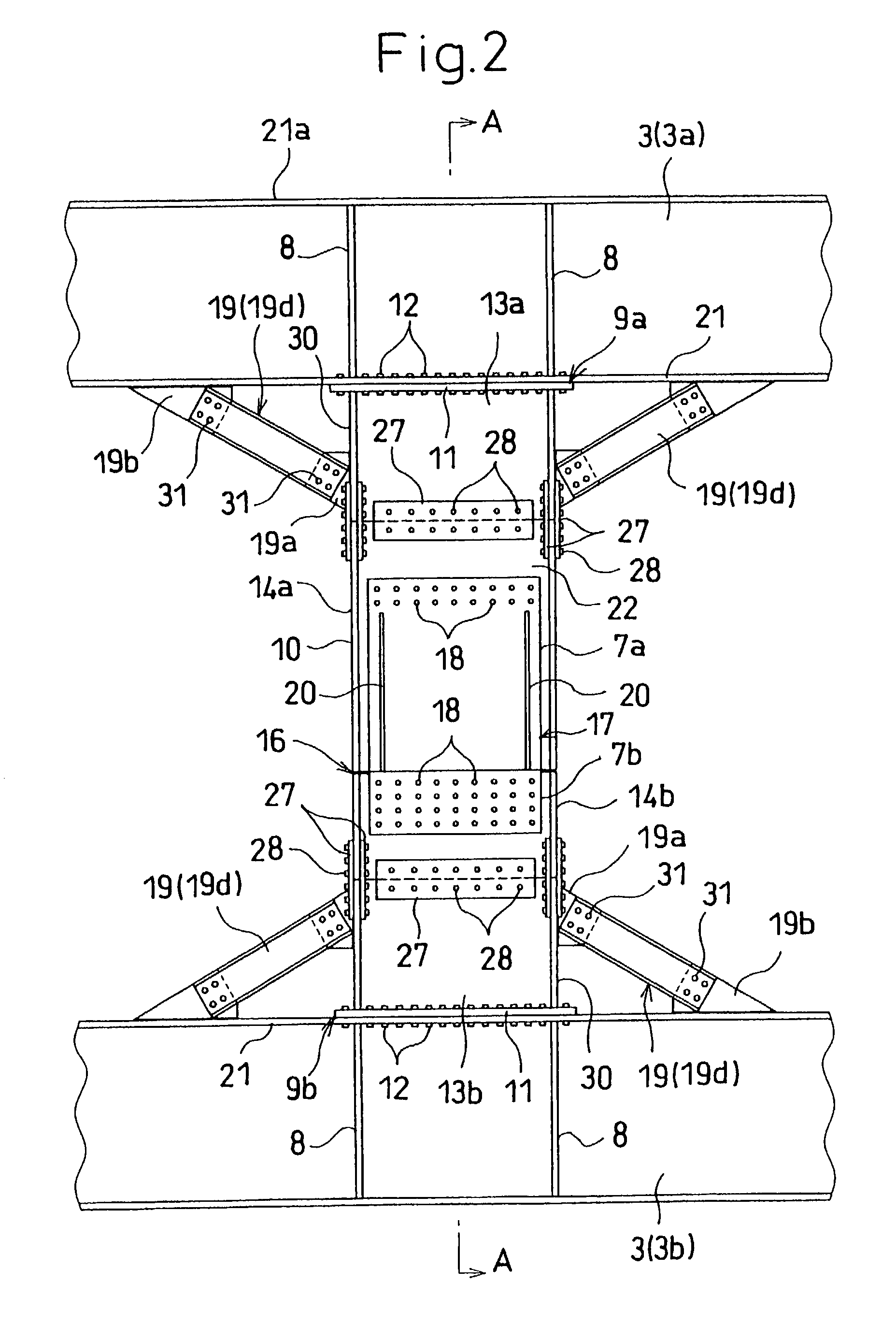

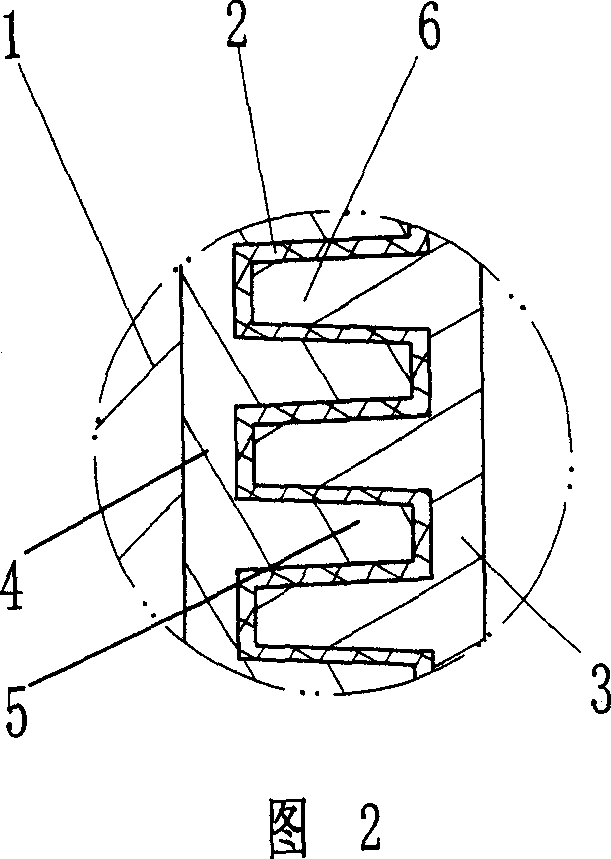

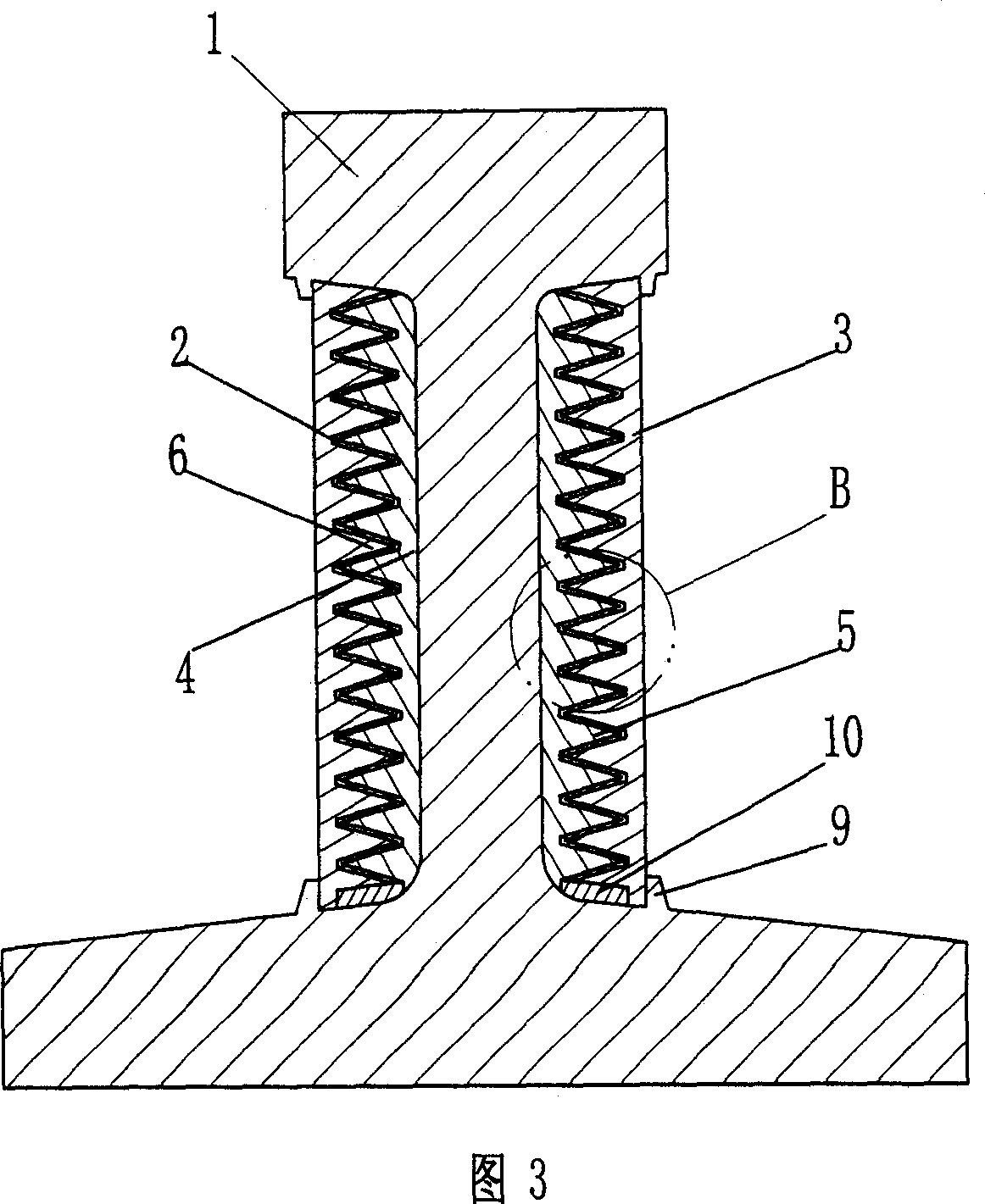

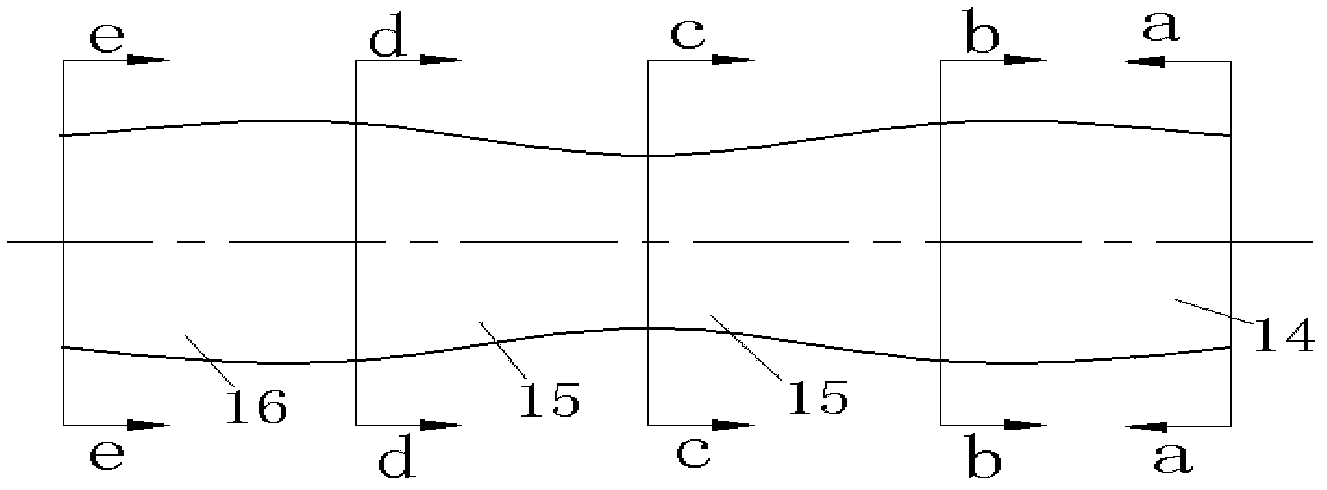

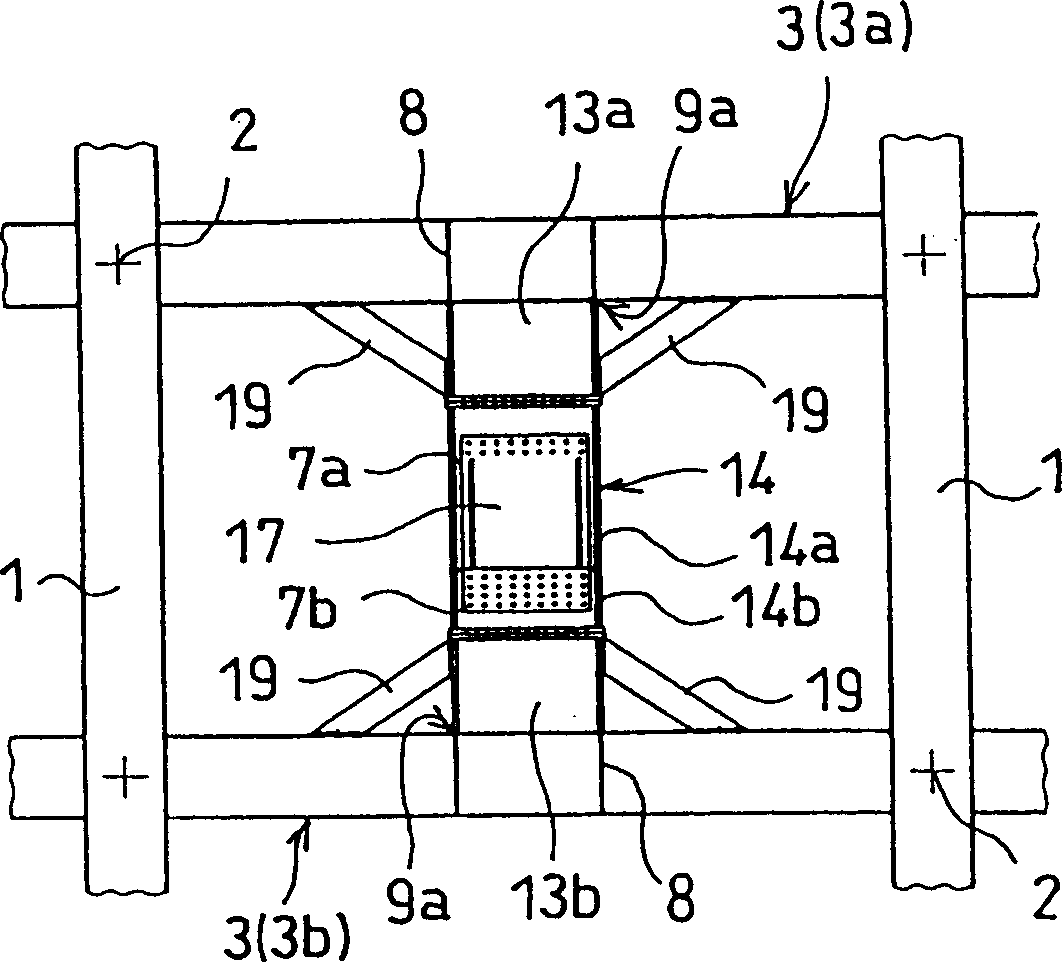

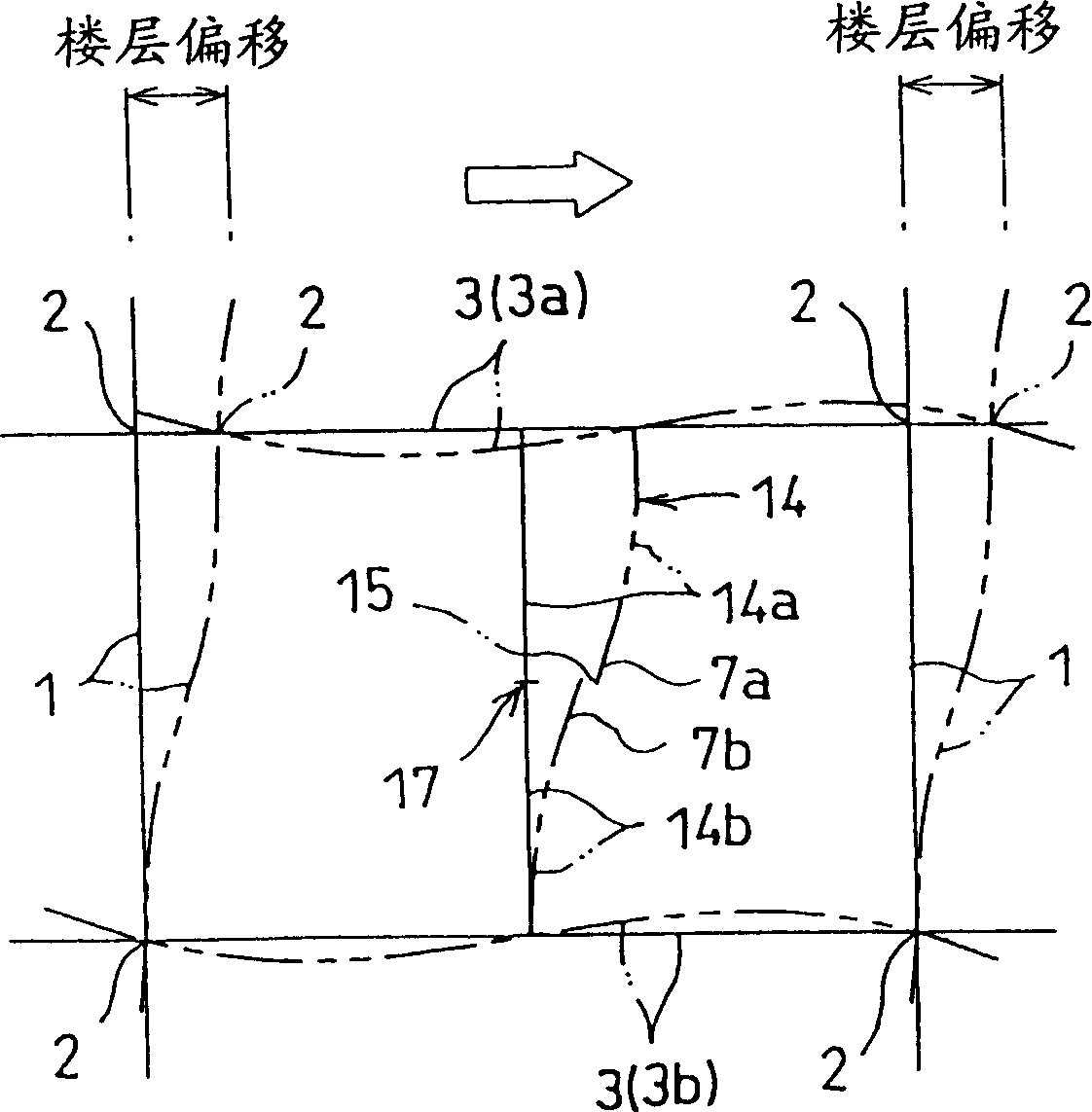

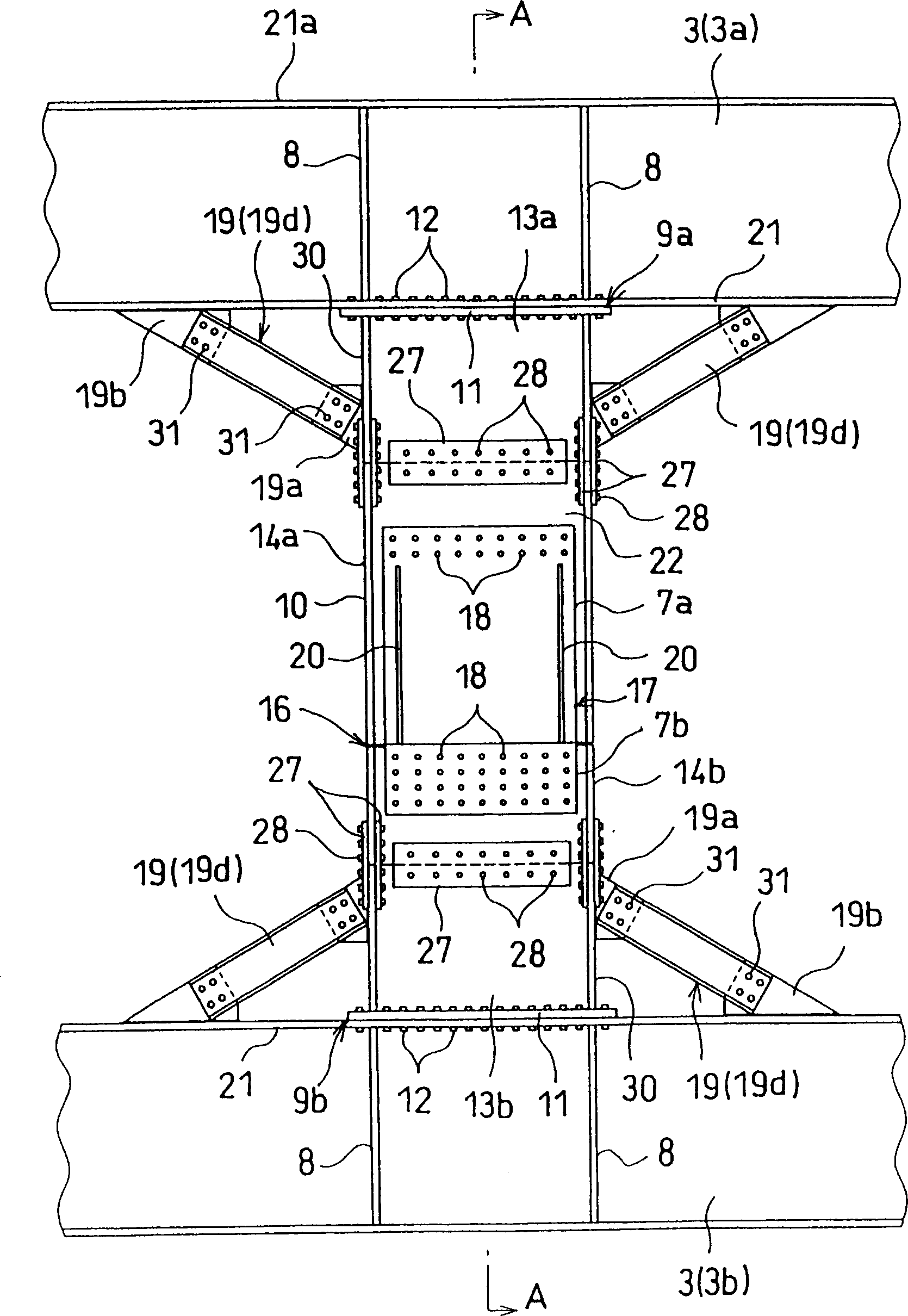

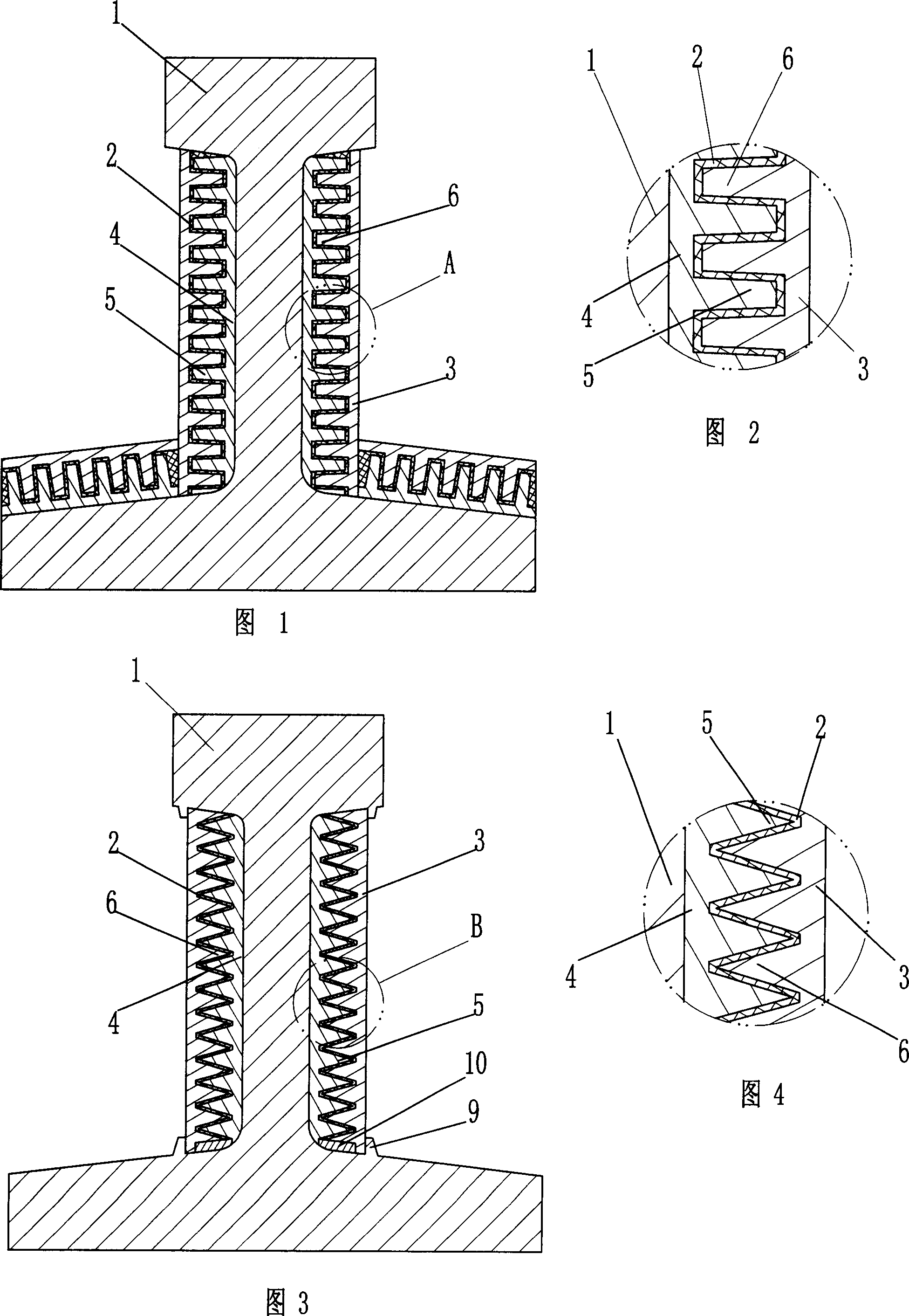

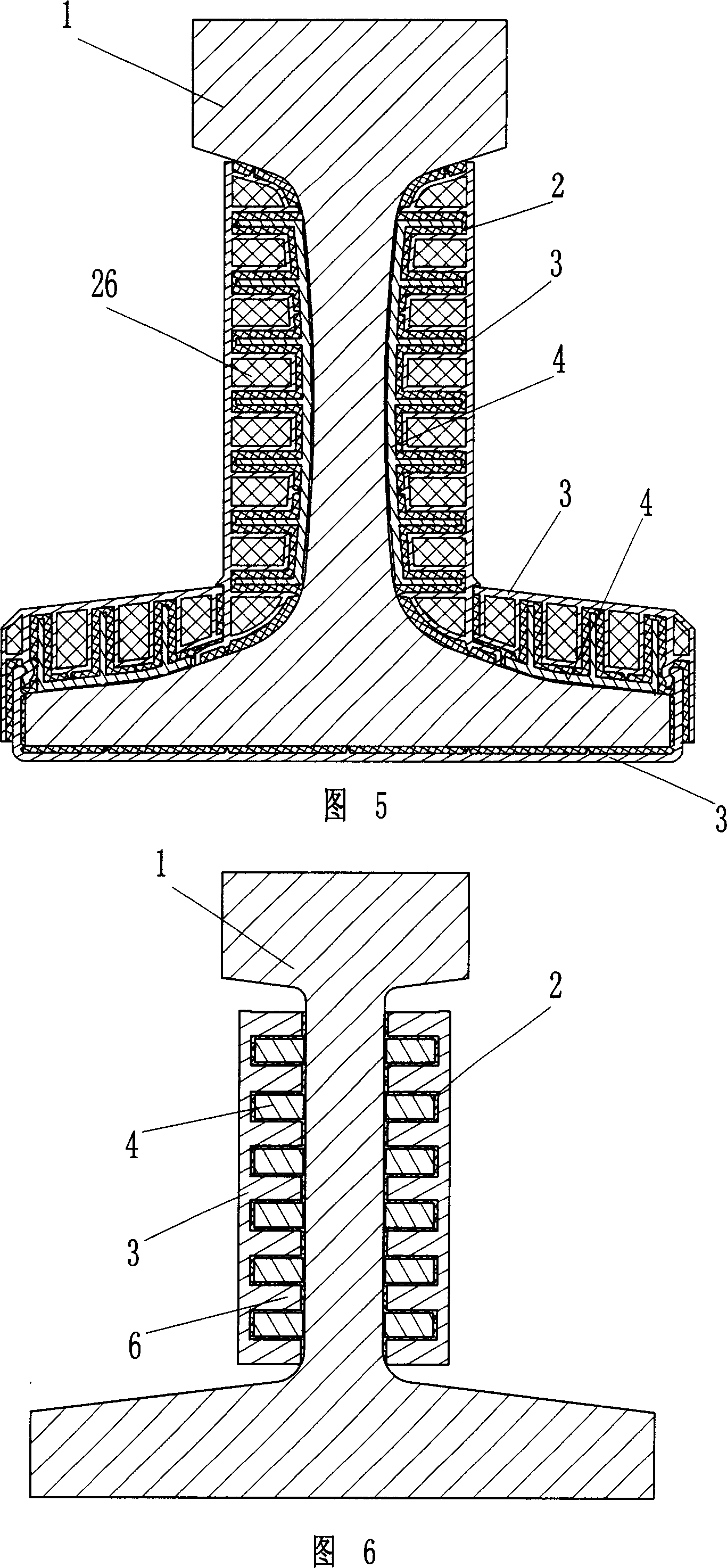

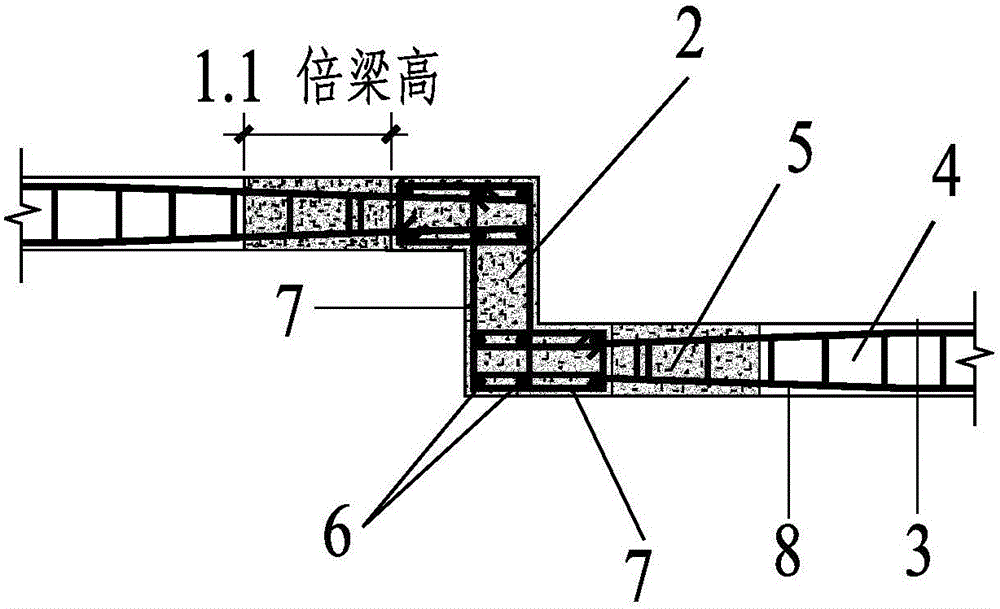

A damping intermediate pillar, which can exhibit a sufficient resistance against the horizontal force of a strong earthquake by reinforcing the joins between the damping intermediate pillar and the upper and lower beams, is disclosed. A damping intermediate pillar 14, used for a building or a structure configured of pillars 1 and beams 3, is divided into upper and lower damping intermediate pillar portions 14a, 14b of H shape steel, and includes a plurality of inner steel plates 7b fixed on the damping intermediate pillar portion 14b and a plurality of outer steel plates 7a fixed on the other damping intermediate pillar portion 14a. The inner and outer steel plates are arranged alternately in a single or a plurality of layers, between which a viscoelastic member 15 is held to make up a viscoelastic damper 17. The coupling end surfaces of the intermediate pillar portions 14a, 14b directed vertically are fixed on the upper and lower floor beams 3a, 3b. Further, one or both sides of each of the damping intermediate pillar portions 14a, 14b (i.e. the coupling members 13a, 13b) and the upper and lower floor beams 3a, 3b are coupled to each other by knee braces 19.

Owner:KAZUHIKO KASAI +1

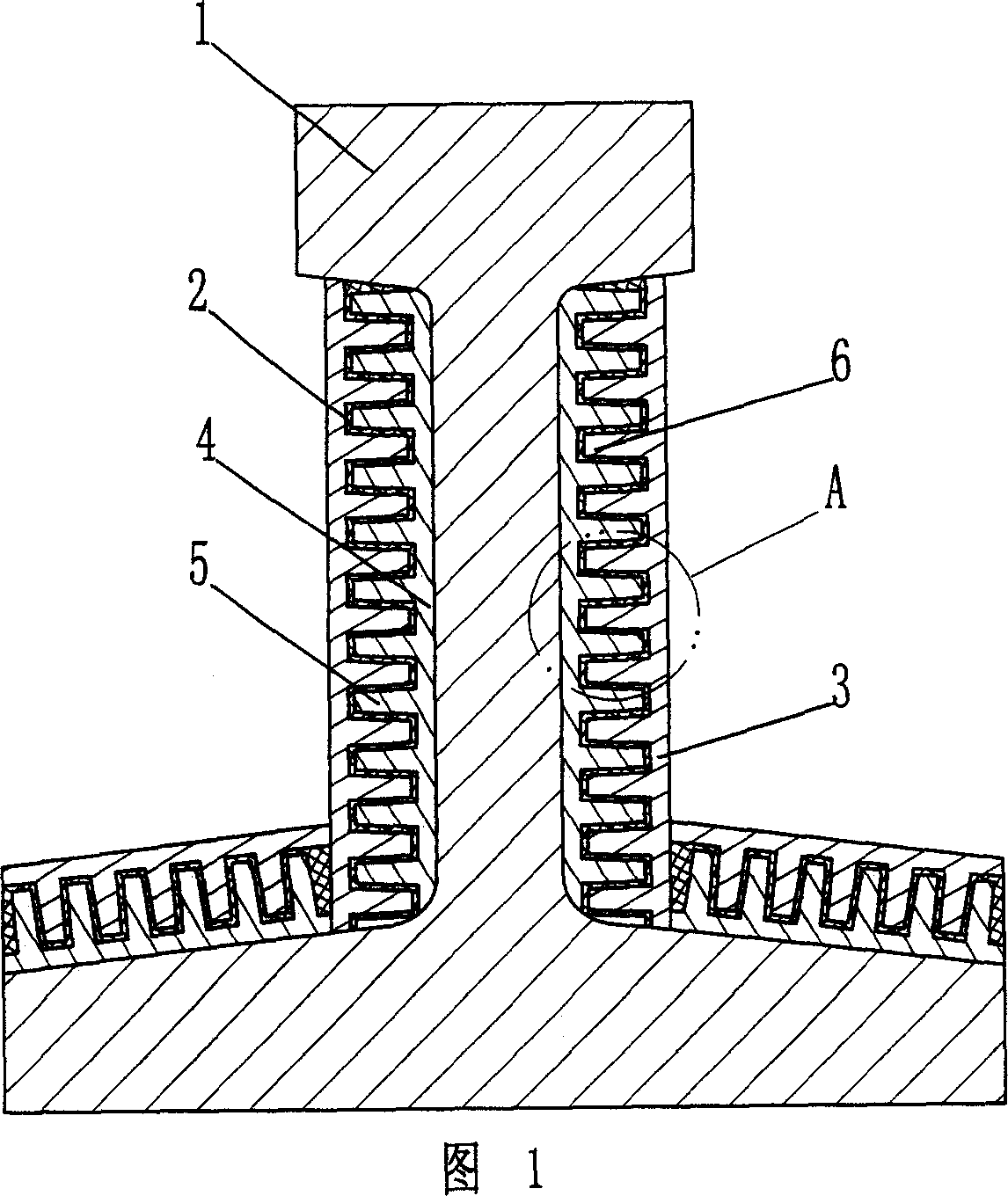

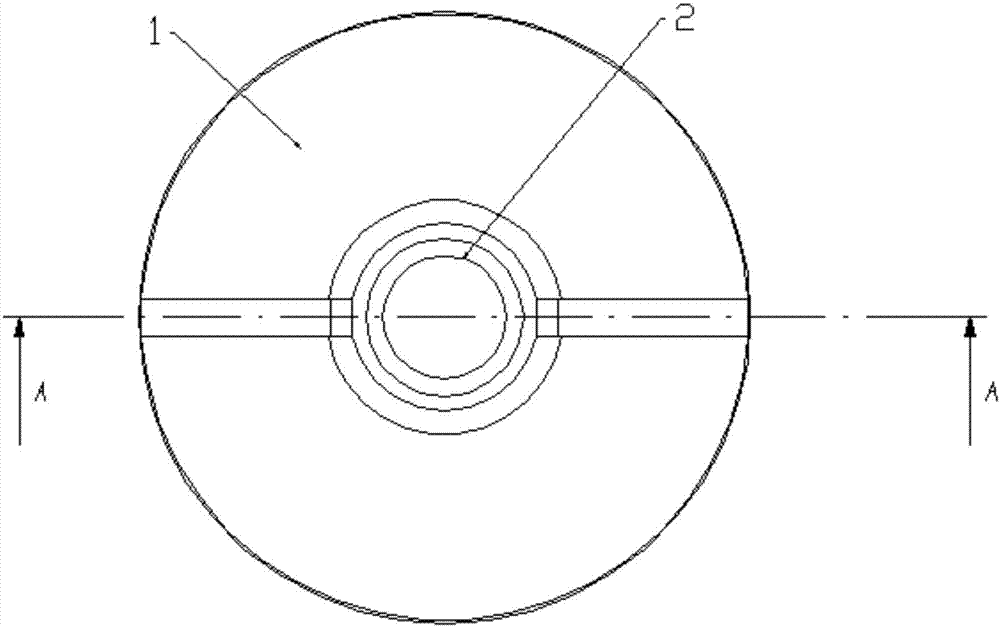

Damper rail

The invention relates to a rail, especially steel rail for railway or electric trolley. Damp rail comprises rail body, on whose non-working surface connector with convex rib or convex-concave structure is set, constraint body connected with rail body, set corresponding to connector, whose inner surface processes convex rib or convex-concave structure and damping body, set between connector and constraint body or among connector, rail body and constraint body, forms labyrinth constraint damping structure, which is set continuously or distantly along length direction of rail body. The rail can decrease shake generated by rail and control the shake and noise of rail in original source, while alleviate availably steel and wheel attrition generated by liberative energy of rail shaking so that there is good damping and noise reduction effect, and operating life of wheel and rail, safety and amenity of train running is largely improved.

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH

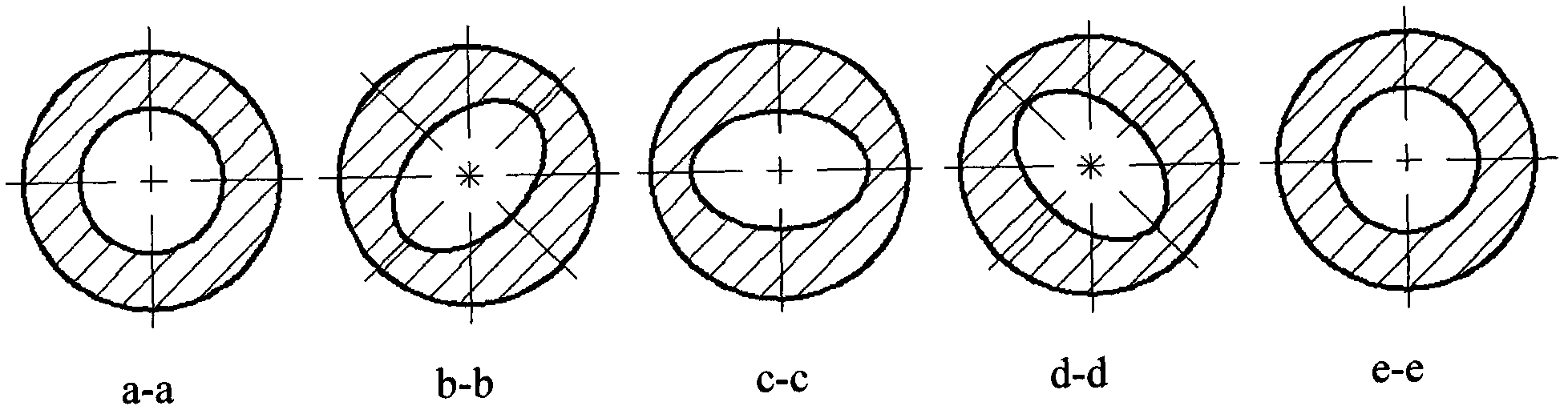

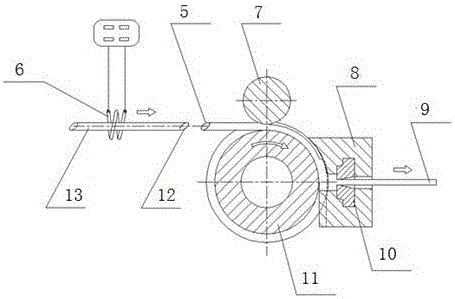

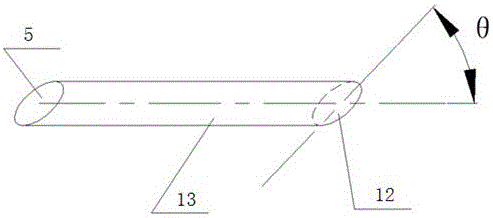

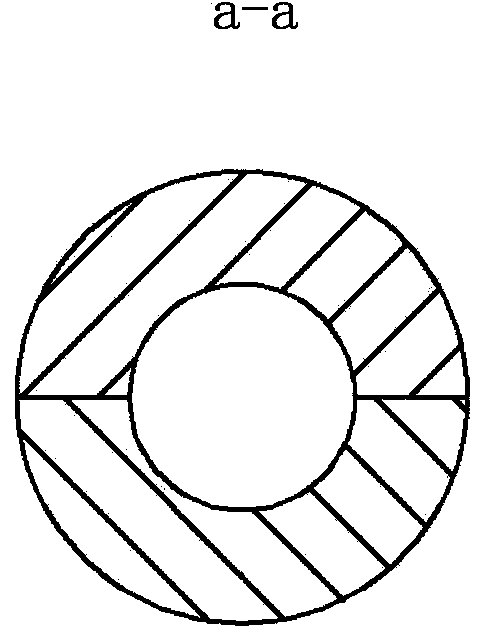

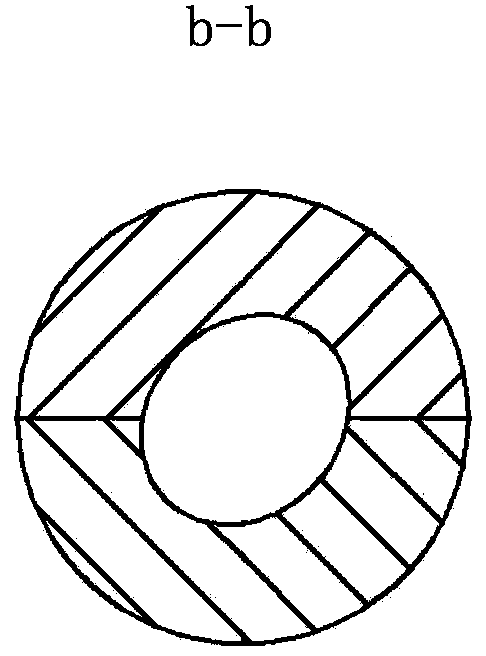

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Deformation-control system and method

A system for selectively controlling deformation. The system includes a first mechanism for resisting deformation about an axis of an accompanying fluid foil. A second mechanism, in communication with the first mechanism, enables deformation along the axis and / or at an angle to the axis. In more a specific embodiment, the axis is a lengthwise axis of the fluid foil, which is a transformable airfoil, and the system includes a bellows device that is approximately concentric with the axis. The bellows device is supported by first base structure at one end and a second base structure at another end. The deformation at an angle to the first axis includes shear deformation or bending deformation. The deformation along the axis includes extension or strain deformation. The deformation about the axis includes torsion deformation.

Owner:COWAN DAVID L +1

Method for producing ultra-thick plate continuous casting blank

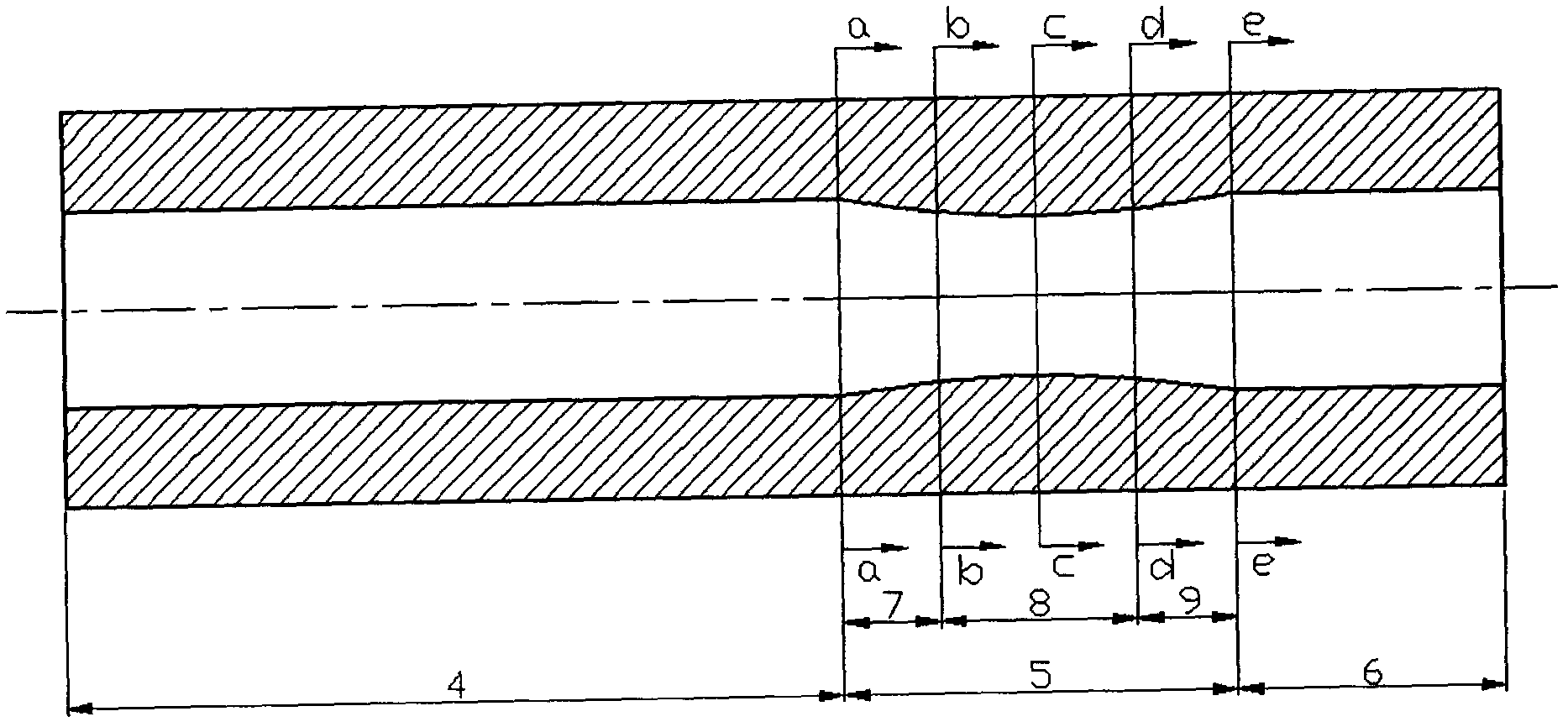

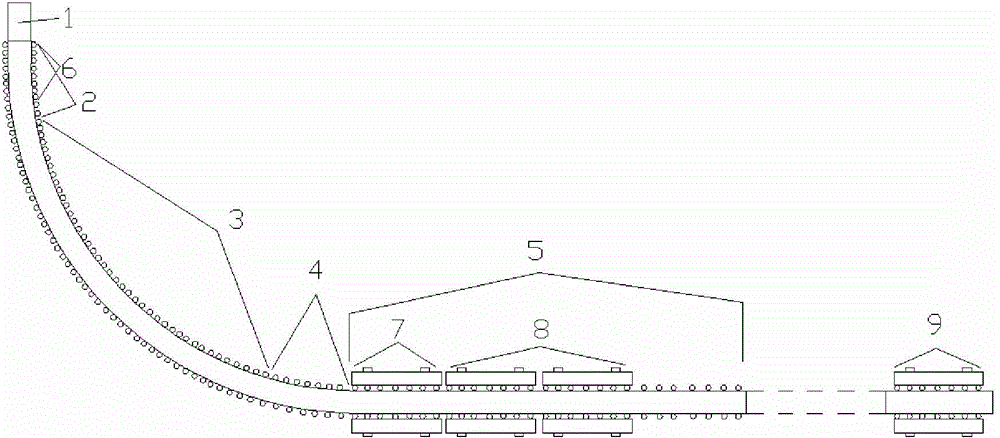

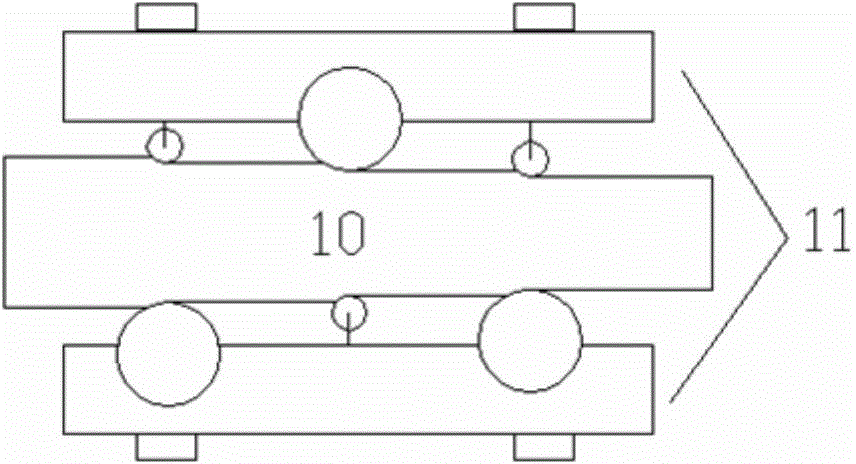

The invention relates to the field of metal continuous casting manufacturing, in particular to a method for producing an ultra-thick plate continuous casting blank by adopting fast cooling and unsymmetrical great pressing-down. According to the method, a continuous casting blank sequentially passes through a vertical section (2), an arc-shaped section (3), a straightening section (4) and a horizontal section (5) under a crystallizer (1), through the implementation of fast cooling and unsymmetrical great pressing-down in a secondary cooling region of a casting machine, the ferritiszation process of the casting blank surface layer is realized before the bending or straightening through the fast cooling process, in addition, the balanced separation of second-phase particles in crystals and at crystal boundaries is ensured, the surface layer tissues of the casting blank are improved, meanwhile, the deformation of a blank core part can be increased through the unsymmetrical great pressing-down process, the occurrence of surface cracks of medium and ultra-thick casting blanks in the bending and straightening process is prevented, and meanwhile, the center segregation and the center looseness of the ultra-thick casting blank is avoided. The method provided by the invention has the advantages that the surface quality and the center quality of the ultra-thick plate continuous casting plate can be better improved, so that the ultra-thick plate continuous casting blank can realize the rolling production of ultra-thick steel plates with the thickness being greater than 120mm at a low compression ratio.

Owner:ZHONG NAT ENG & RES CENT

Tube drawing forming method and forming mould

InactiveCN102423770AImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

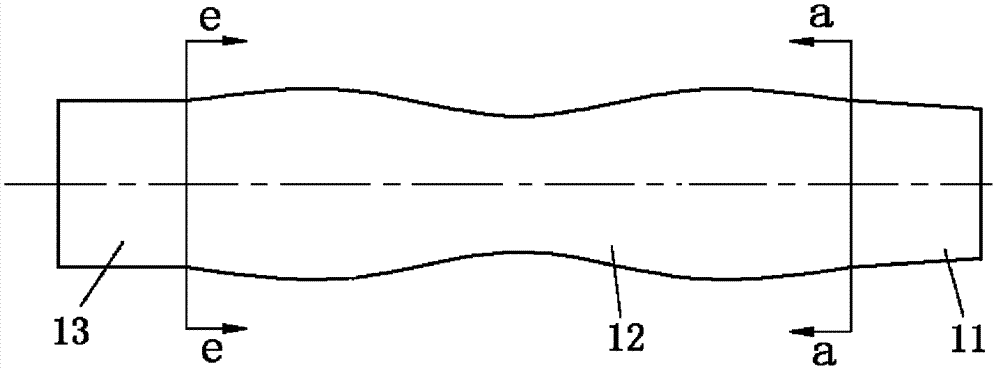

Damping intermediate column and damping structure using same

InactiveCN1401871AHigh strengthIncrease shear deformationNon-rotating vibration suppressionGirdersHorizontal forceViscoelastic damping

Owner:笠井和彦 +1

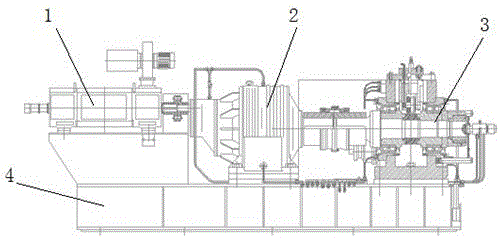

Aluminum alloy plate material continuous extrusion method taking bar materials as blanks, and continuous extrusion machine

The invention discloses an aluminum alloy plate material continuous extrusion method taking bar materials as blanks, and a continuous extrusion machine. The method comprises the following steps: A, dividing the blanks into multiple sections of bar materials, and connecting the head end face of the front-back adjacent bar materials with the tail end face of the front-back adjacent bar materials in each section of bar material; B, performing induction heating on the connected bar materials under the protection of inert gas through an induction device; and C, feeding heated bar materials into a rotary extrusion wheel, pressing the bar materials into a groove of the extrusion wheel through a pressing wheel, driving the bar materials through the groove in the extrusion wheel to enter a cavity and extruding to form a product through an extrusion mold in the cavity. According to the continuous extrusion method and the continuous extrusion machine, the problem that remarkable defects exist at the head-tail connection position of the bar materials during continuous extrusion of the magnesium alloy bar materials is solved; and the temperature of the magnesium alloy is increased by adopting induction heating under the protection of the inert gas, so the problems that the magnesium alloy has low plasticity at normal temperature and is broken when being pressed by the pressing wheel are solved.

Owner:大连康丰科技有限公司

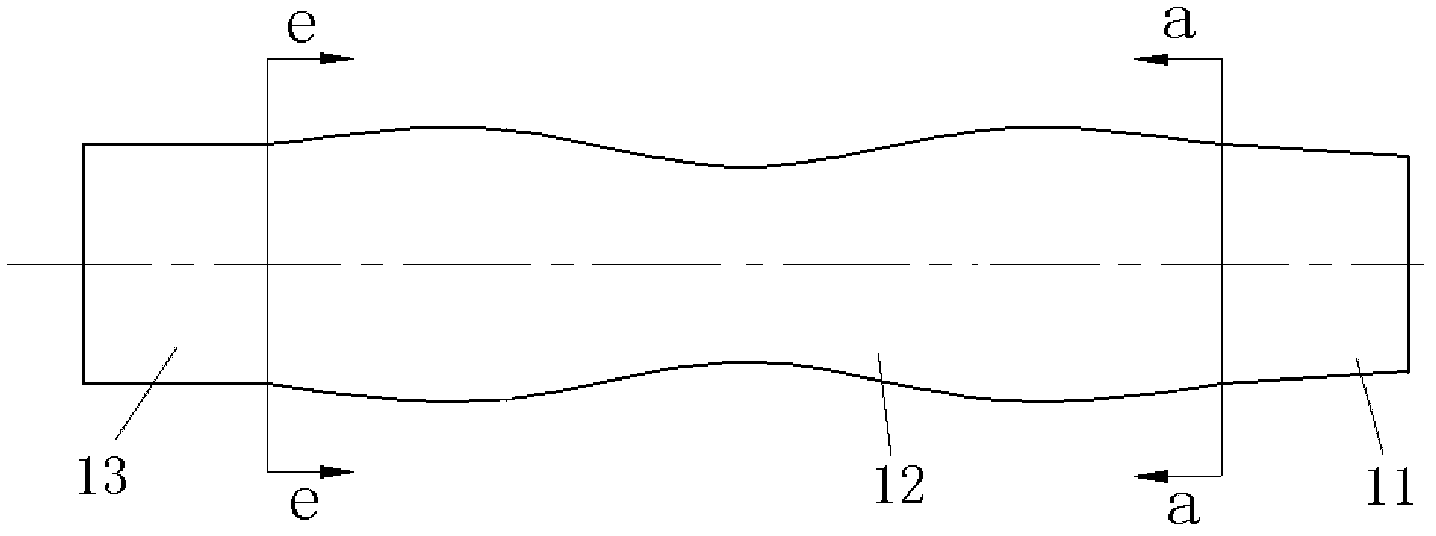

Variable-channel mold for improving drawing toughness of steel bar

The invention discloses a variable-channel mold for improving the drawing toughness of a steel bar. An upper mold and a lower mold are buckled, and the mold forms a mold cavity with variable channel and variable section. The mold cavity comprises a straightening section, a deforming section and a sizing section sequentially, wherein the straightening section is a steel bar drawing front section, and the cross section of the mold cavity is a large circular section; the sizing section is a steel bar drawing rear section, and the cross section of the mold cavity is a small circular section. The mold cavity of the deforming section is partitioned to be a large circle to ellipse traditional twist section and an ellipse to small circle traditional twist section. The section of each section gradually deforms from a large circular section to a twisted elliptic section, and then gradually deforms from the twisted elliptic section to a small circular section, finally a required cold-drawing reinforced steel bar is molded from the sizing section. When the variable-channel variable-section mold is used in a steel bar cold machining, the toughness damage of the mold to the materials is low, the metal grains can be thinned under the condition of multi-section deformation, consequently, a preferable toughness is obtained while the strength of the cold-drawing steel bar is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Unilateral roll system rolling mill and plate rolling method

InactiveCN111389907AIncrease shear deformationImprove deformation abilityMetal rolling stand detailsMetal rolling arrangementsEngineeringStructural engineering

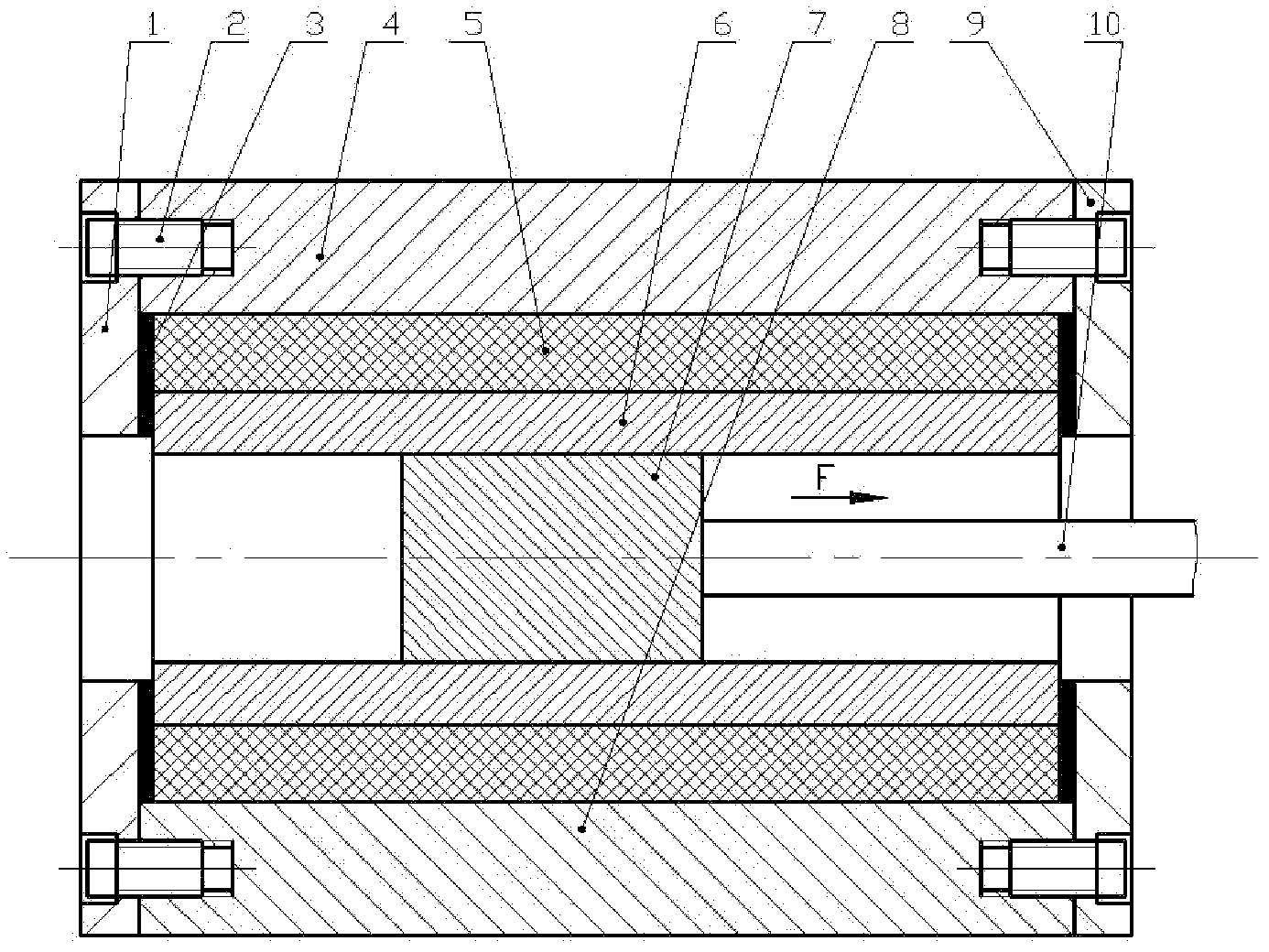

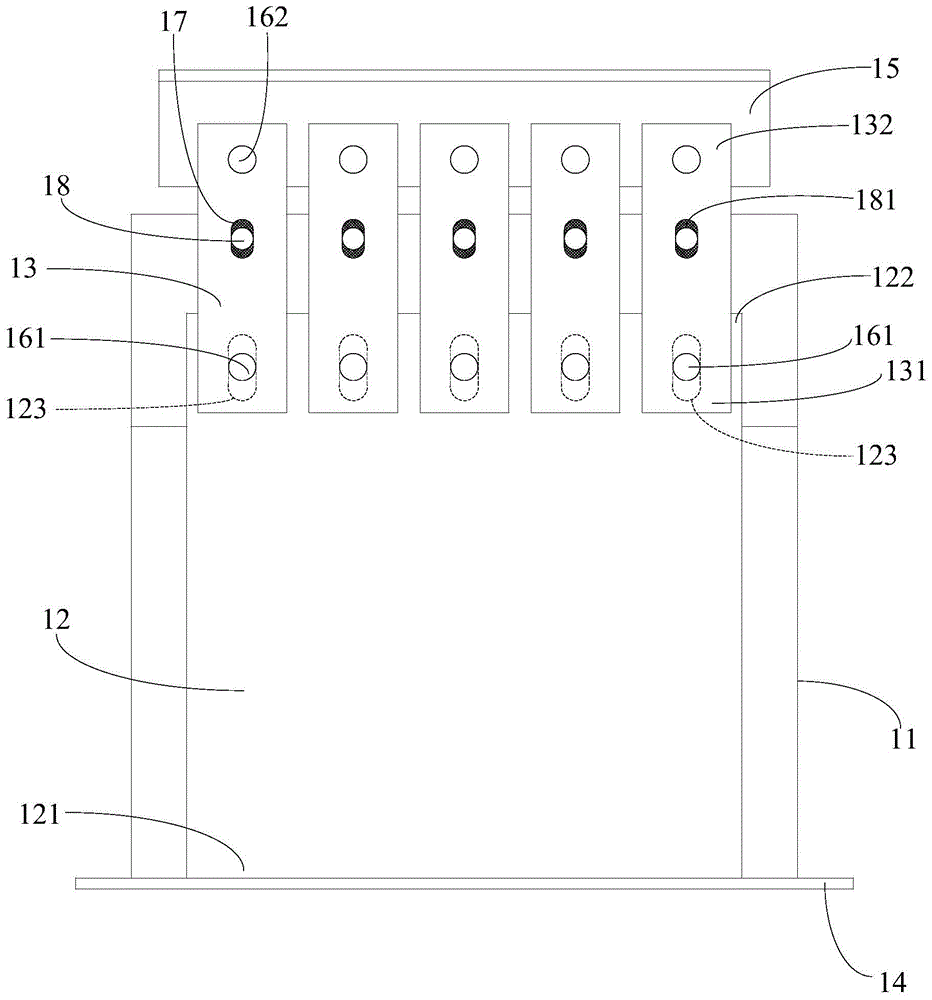

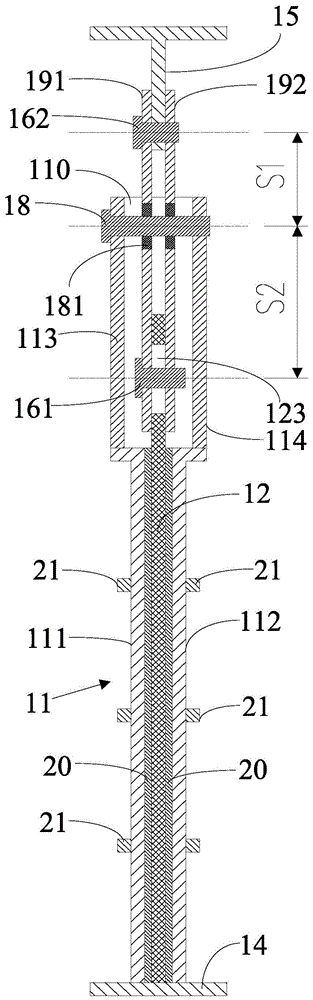

The invention provides a unilateral roll system rolling mill and a plate rolling method, and belongs to the field of plate machining equipment. The rolling mill mainly comprises a rack, an upper rollsystem and a lower plate rolling device. The rack is used for allowing other parts of the whole rolling mill to be fixedly mounted. The upper roll system is horizontally mounted on the rack and comprises an upper roll capable of rotating around the horizontal axis. The lower rolling plate device is arranged below the upper roll, and comprises a lower rolling plate horizontally arranged below the upper roll. A roll gap is arranged between the upper roll and the lower rolling plate, and a rolled piece passes the roll gap to be rolled. According to the rolling mill and the method, the function ofasymmetrical rolling is achieved, the horizontal component of positive pressure is increased, and the stress state of the rolled piece is changed; and rolling force can be reduced, the shearing effect can be enhanced, and the plastic deformation capacity can be improved.

Owner:TAIYUAN UNIV OF TECH +1

Composite-material energy-dissipation fender and manufacturing process of composite-material energy-dissipation fender

ActiveCN103510491AWide applicabilityProtection securityClimate change adaptationBridge structural detailsShearing deformationEngineering

The invention provides a composite-material energy-dissipation fender which comprises a shell and an energy-dissipation filling body wrapped inside the shell. The energy-dissipation filling body comprises energy-dissipation materials and a plurality of energy-dissipation ribs, the energy-dissipation ribs are distributed inside the energy-dissipation materials and / or between the energy-dissipation materials and the shell, and the energy-dissipation ribs are connected with the shell into a whole. The energy-dissipation ribs of the composite-material energy-dissipation fender form a longitudinally-transversely staggered net structure, the high shearing strength and the certain elastic deformation buffering capacity are achieved, the shell can be protected from large shearing deformation, and the composite-material energy-dissipation fender is good in overall collision avoidance effect, low in manufacturing cost, long in service life and convenient to maintain and repair.

Owner:JIANGSU HONGYUAN TECHNOLOGY ENGINEERING CO LTD

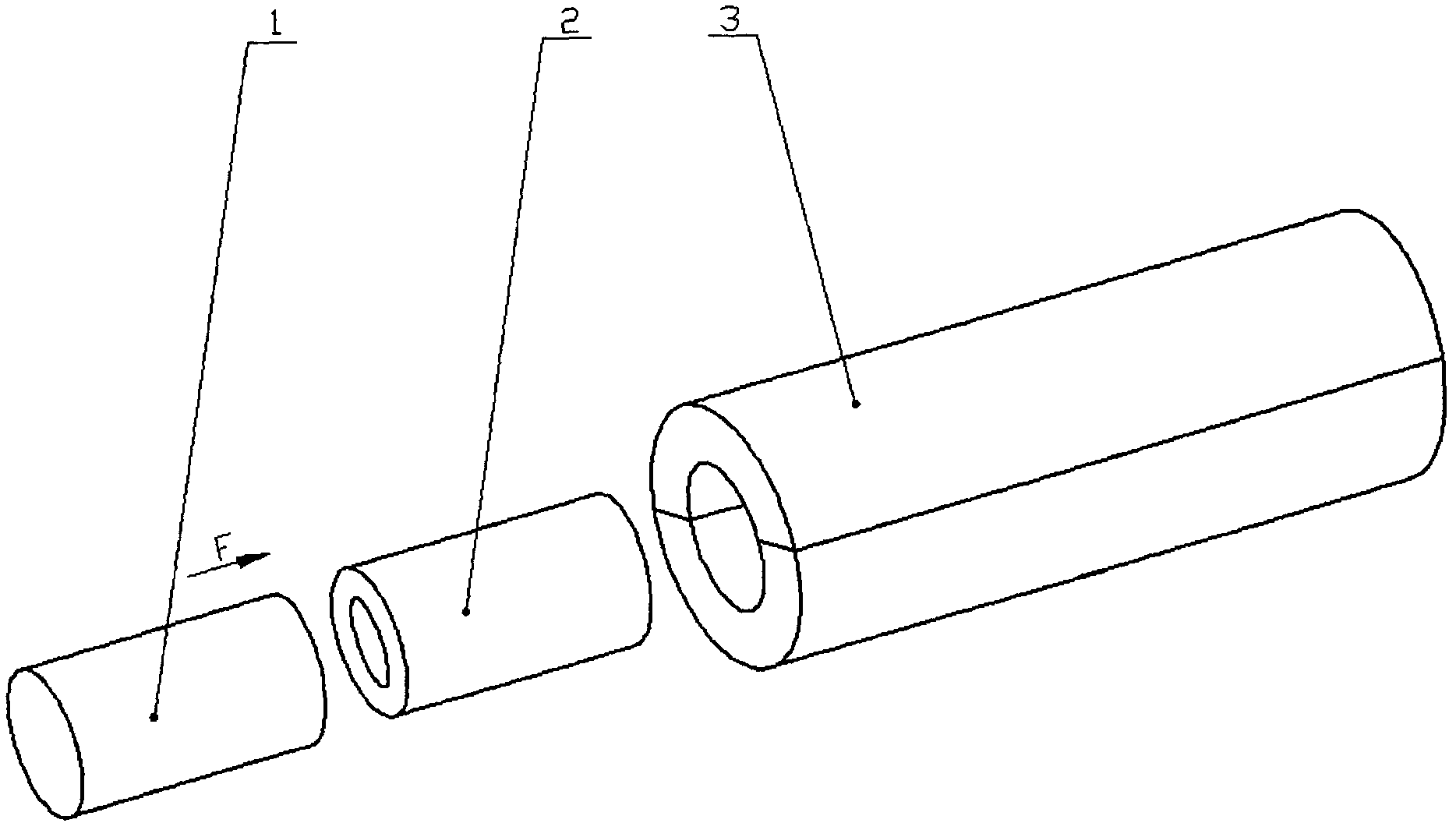

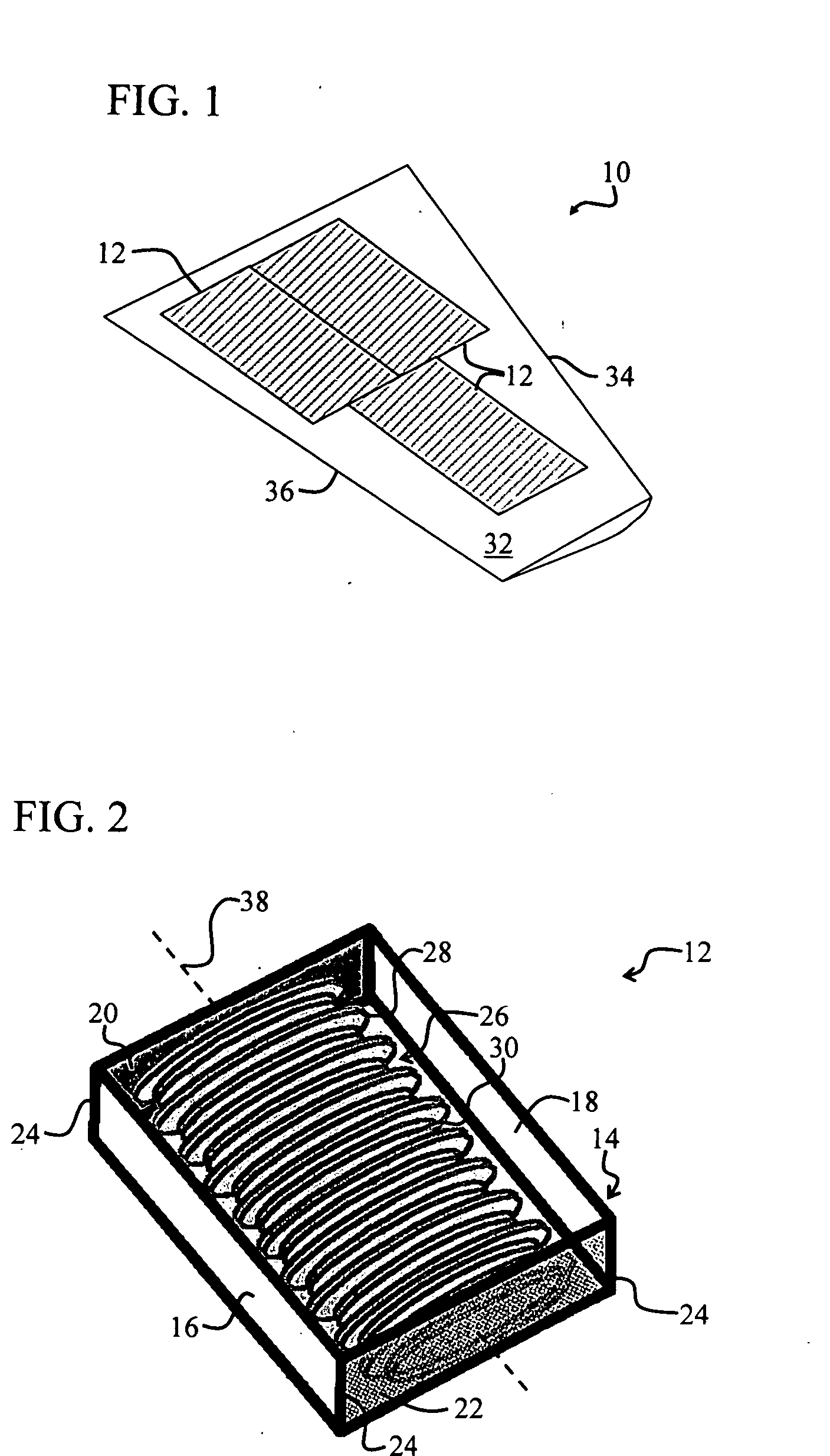

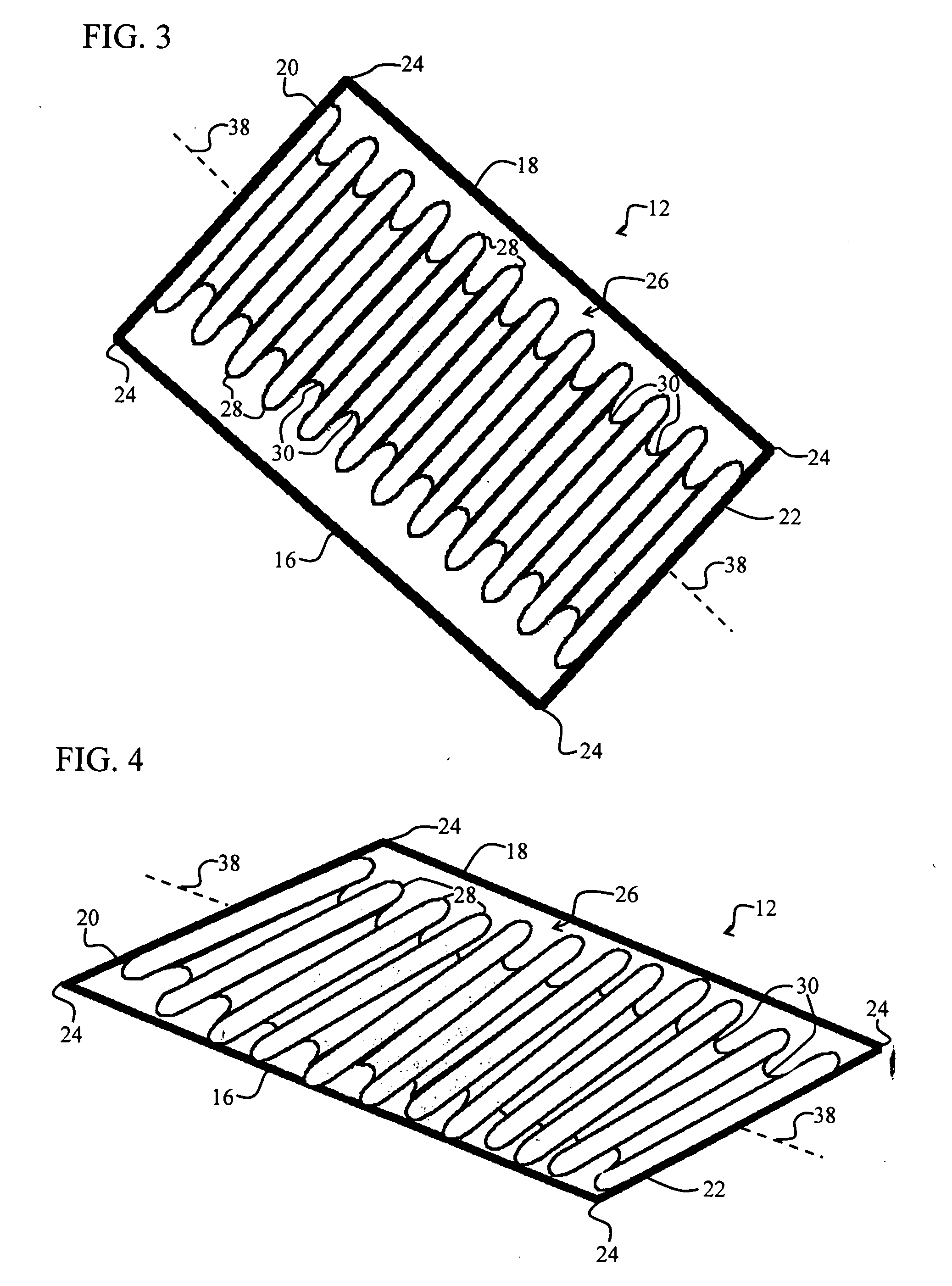

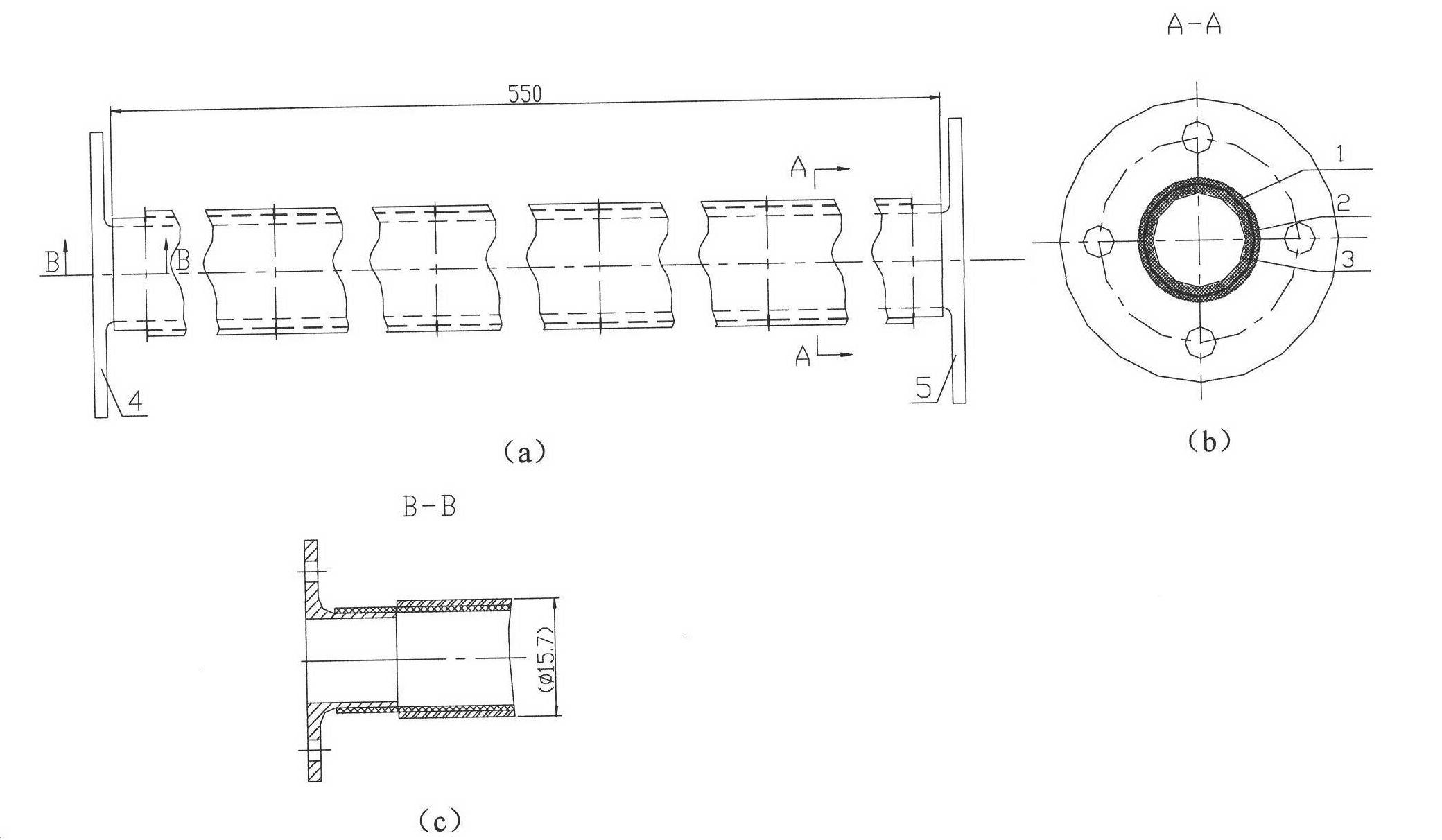

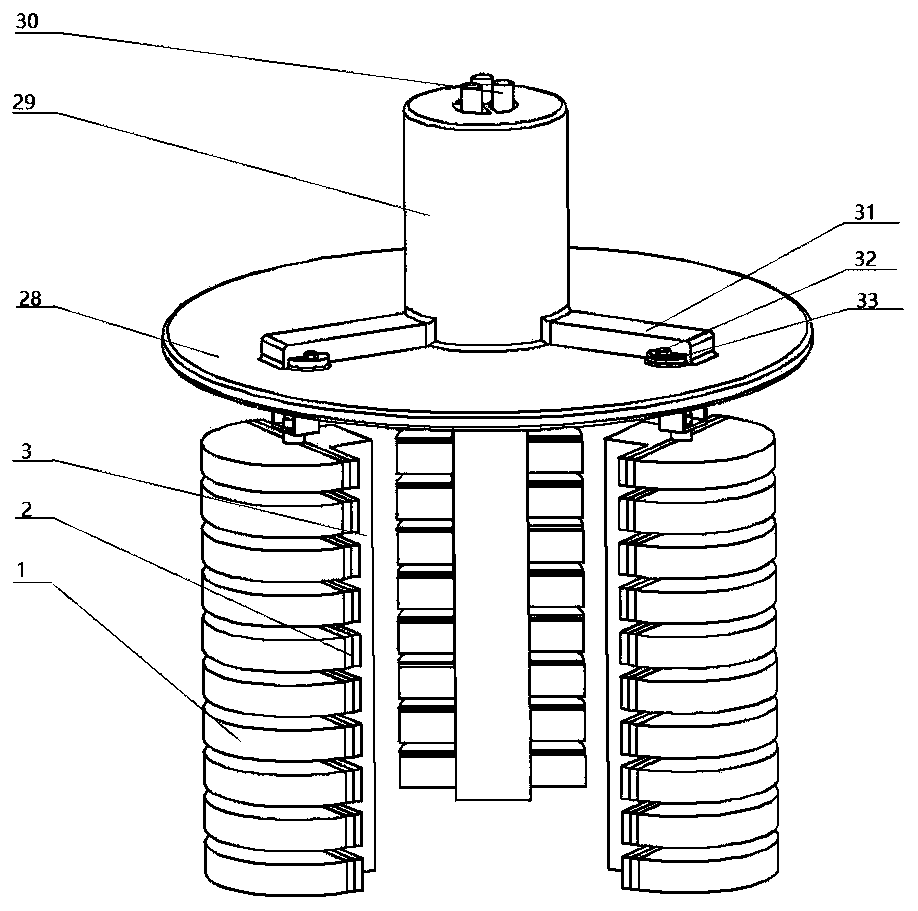

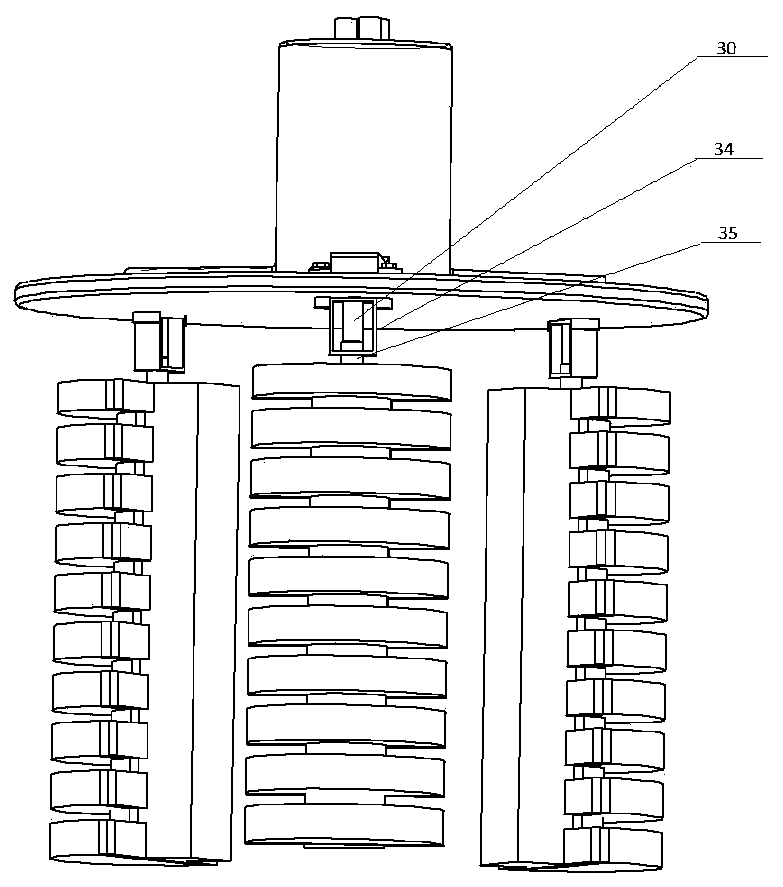

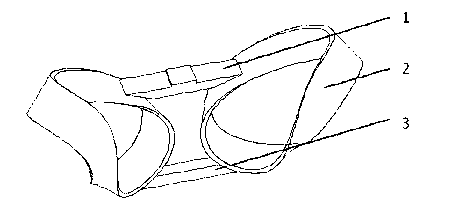

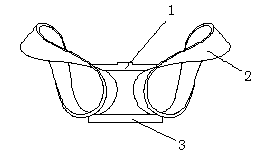

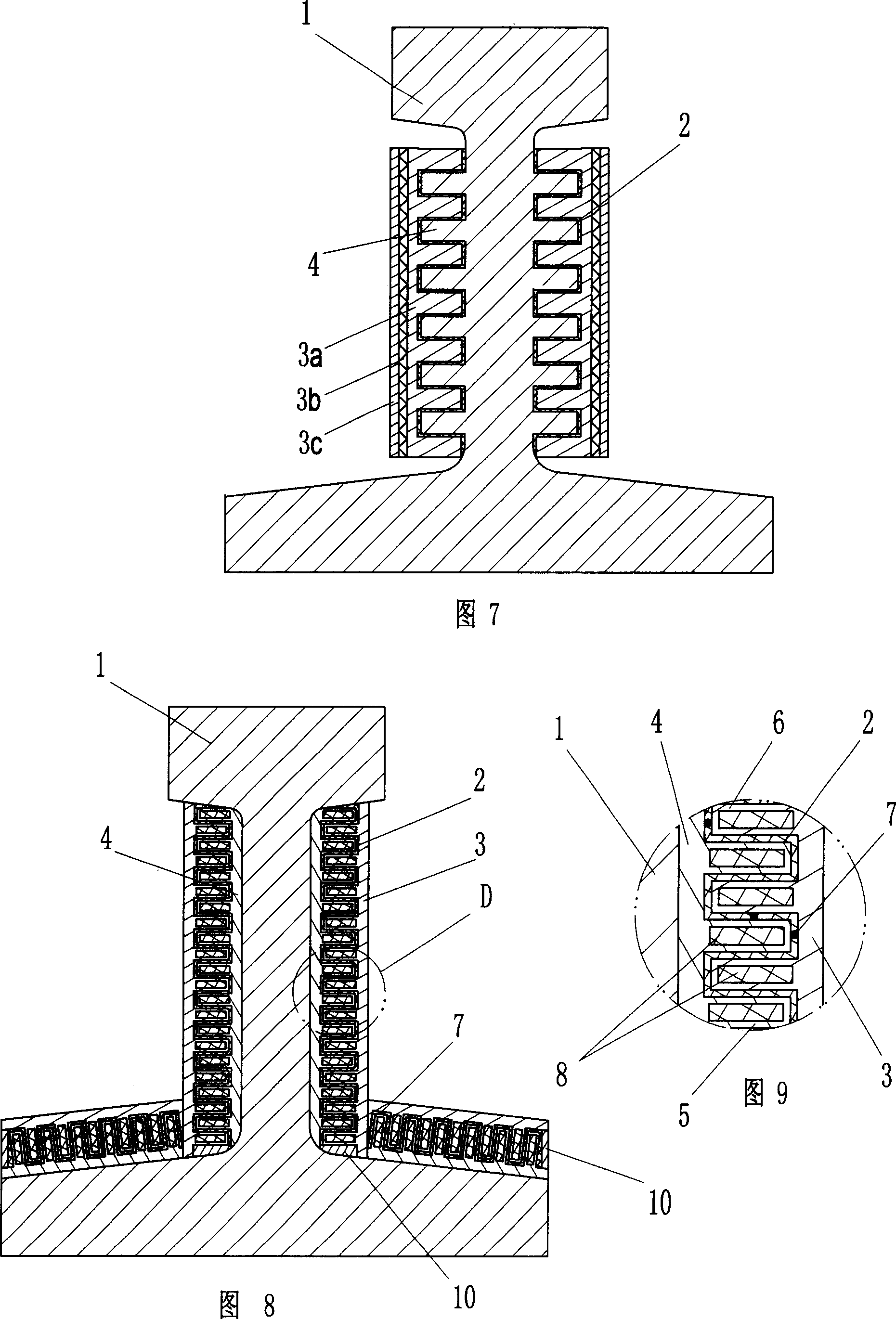

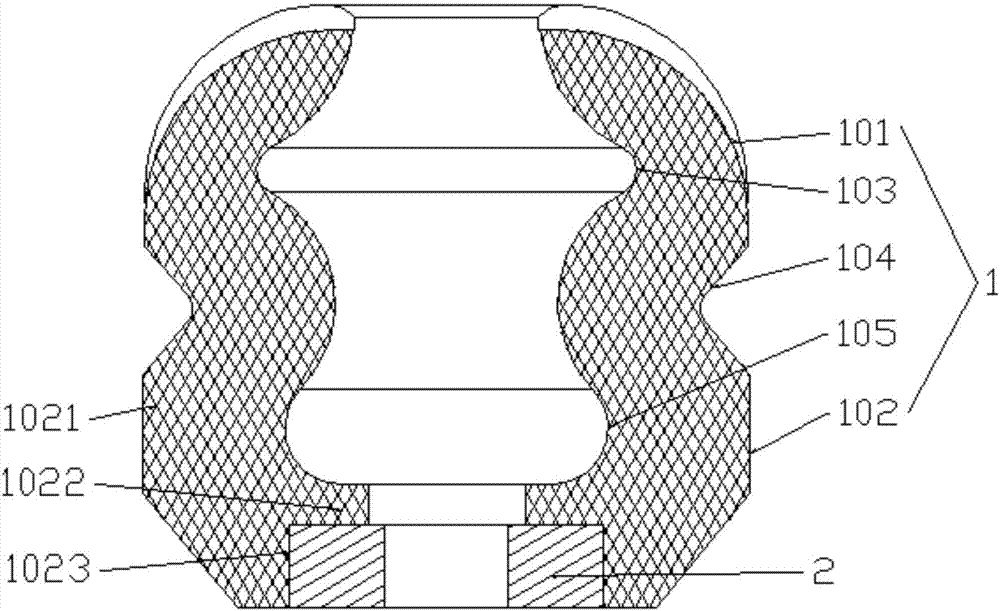

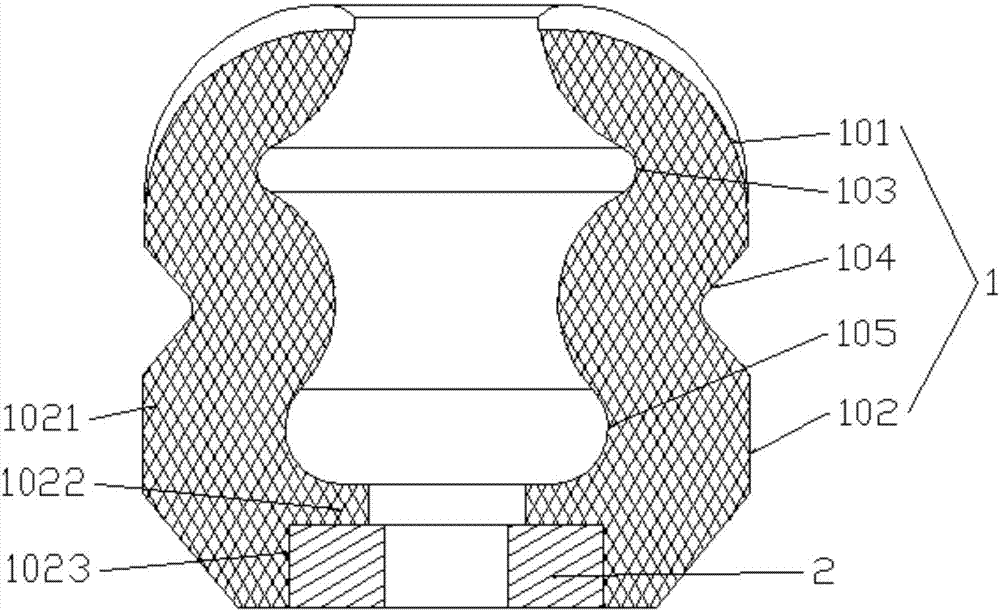

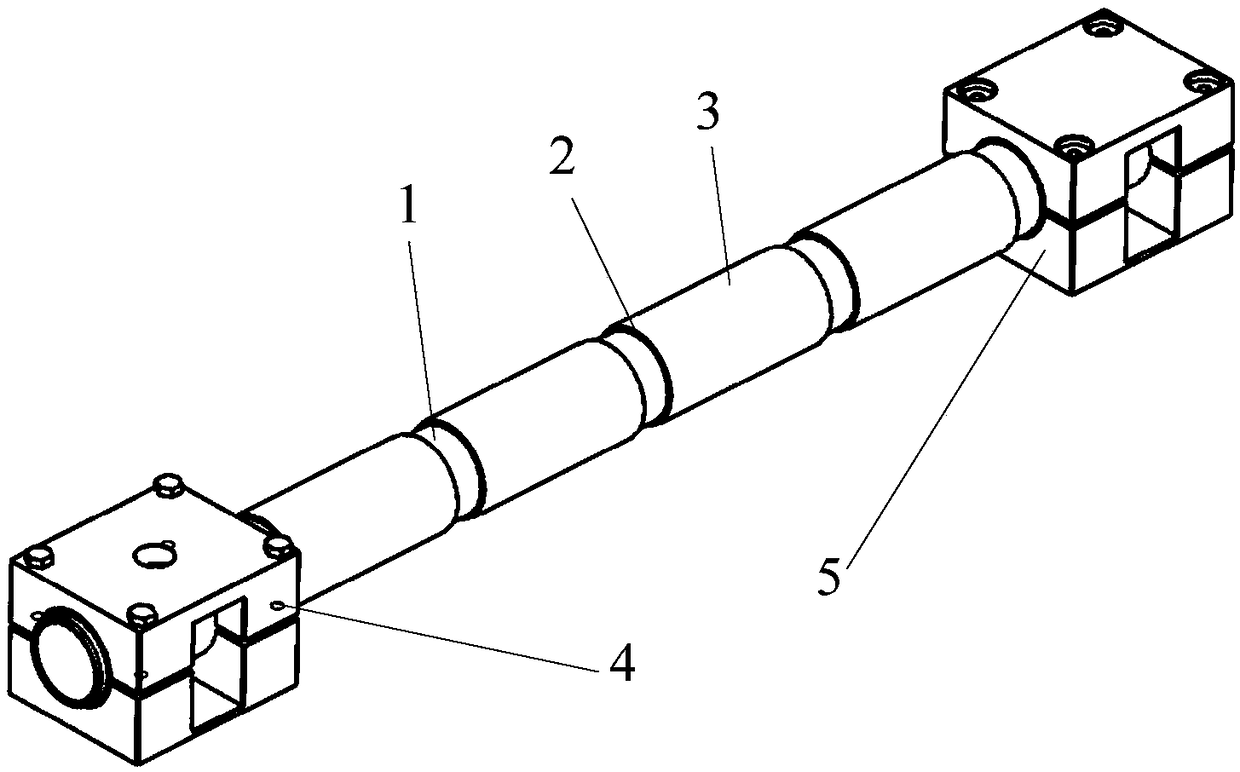

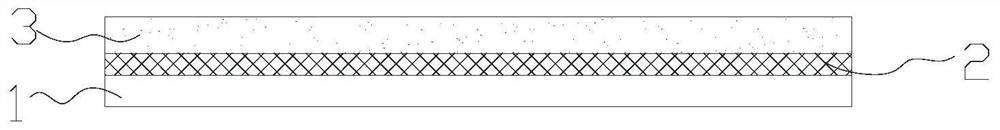

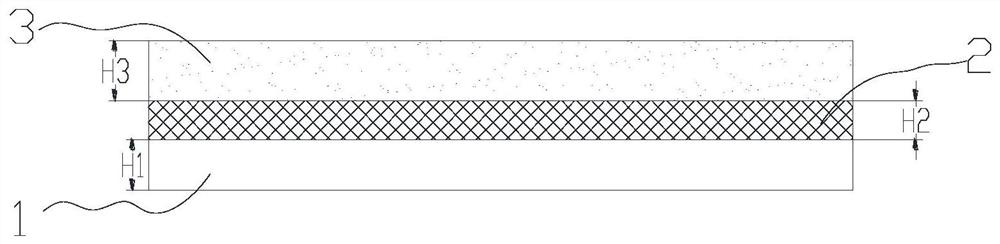

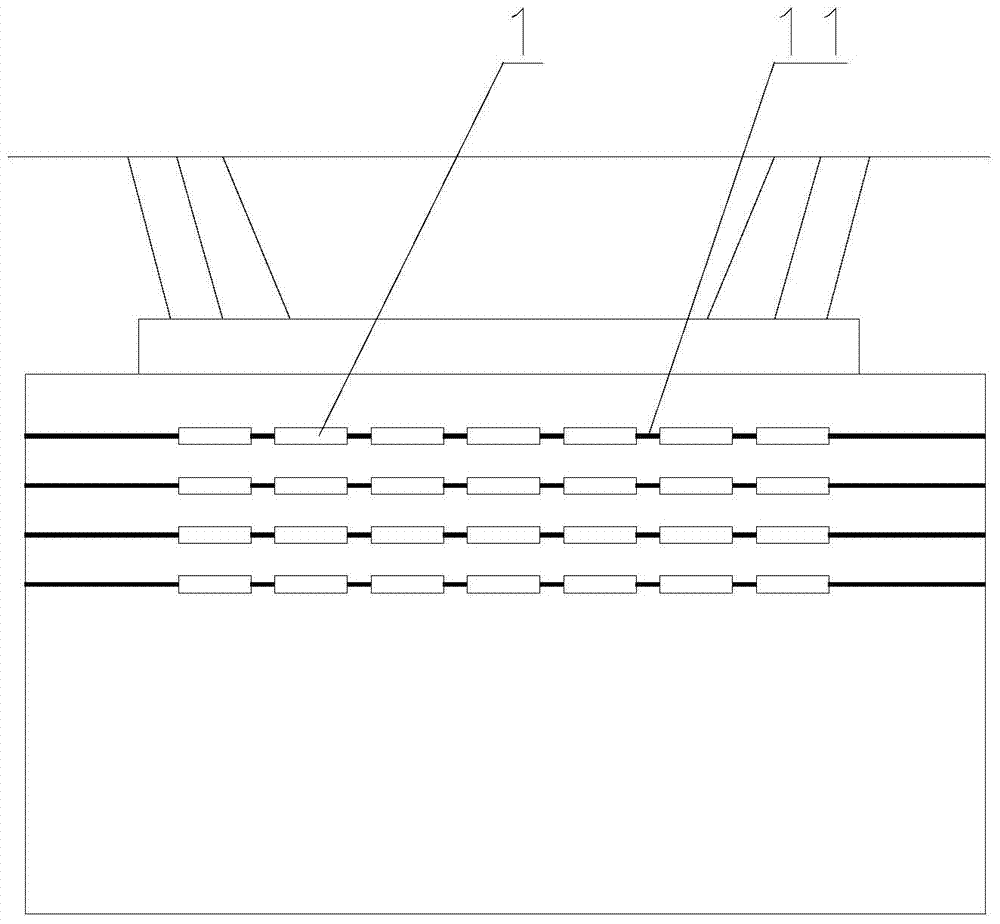

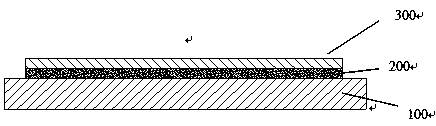

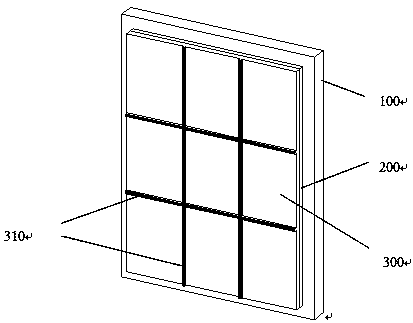

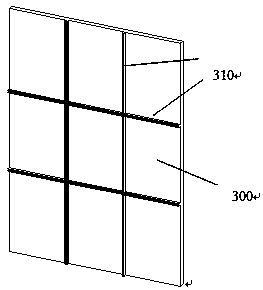

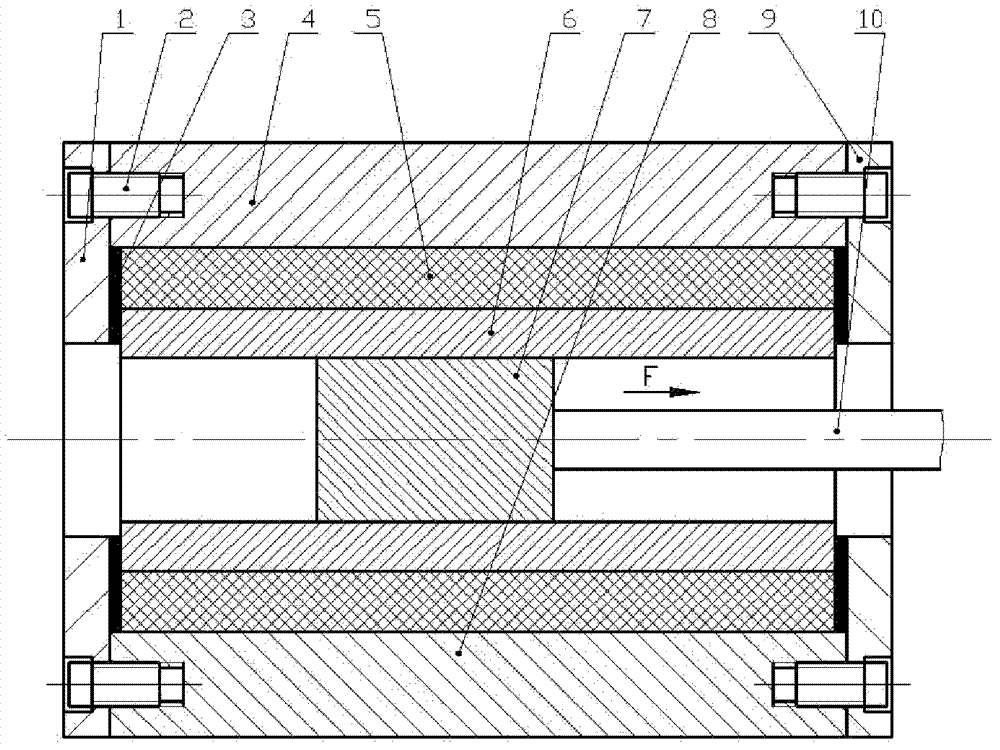

Composite material viscoelastic damping rod

ActiveCN102322493AGuaranteed axial strengthIncreased axial dampingSynthetic resin layered productsRubber-like material springsRubber materialViscoelastic damping

The invention relates to a composite material viscoelastic damping rod which comprises mounting flanges at two ends and an intermediate rod between the mounting flanges, wherein the intermediate rod comprises three layers which are a rod body (1), a viscoelastic damping layer (2) and a restraint layer (3) of T series high-intensity carbon fiber composite materials from inside to outside sequentially, and the length of the intermediate rod is 200-1000mm; a damping rubber material with the dissipation factor greater than 1 is selected for the viscoelastic damping layer (2) to be pasted to the outer part of the rod body (1); M series high-modulus carbon fiber composite materials are selected for the restraint layer (3), and the damping layer (2) and the restraint layer (3) are molded by adopting a co-curing technology; and the intermediate section is divided through opening a U-shaped groove out of the restraint layer (3), and the number of the sections of the intermediate rod at the length direction is 3-12.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

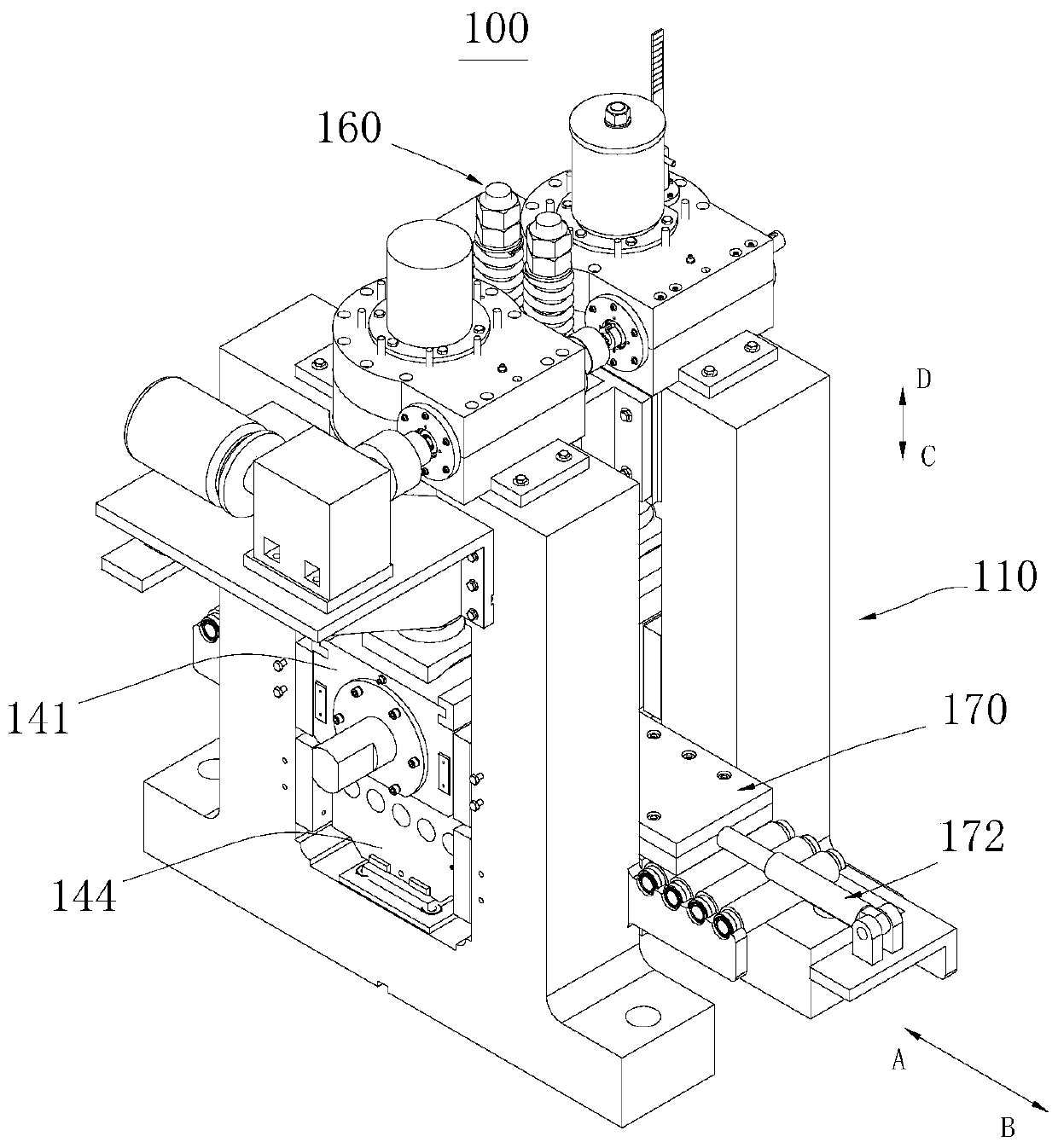

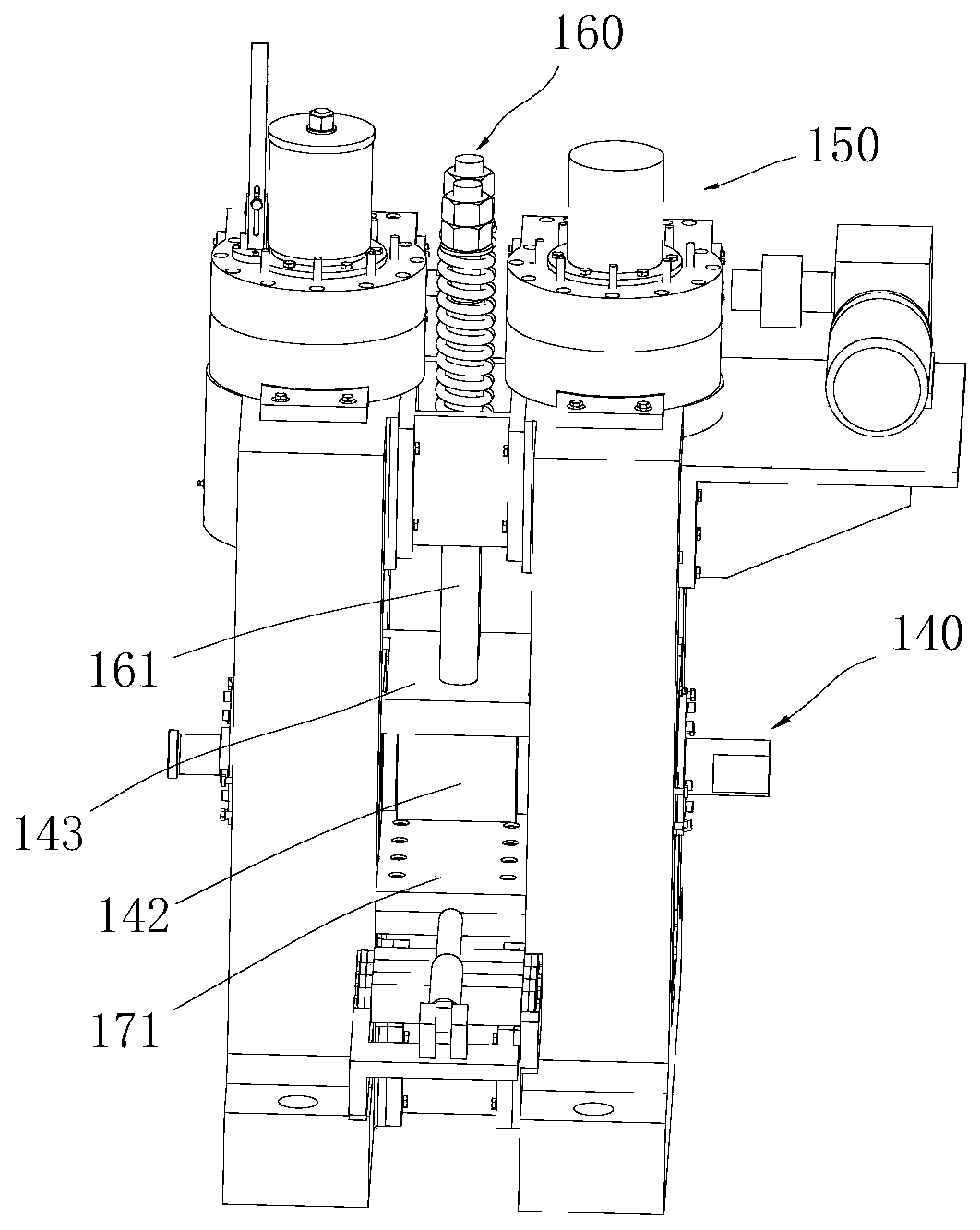

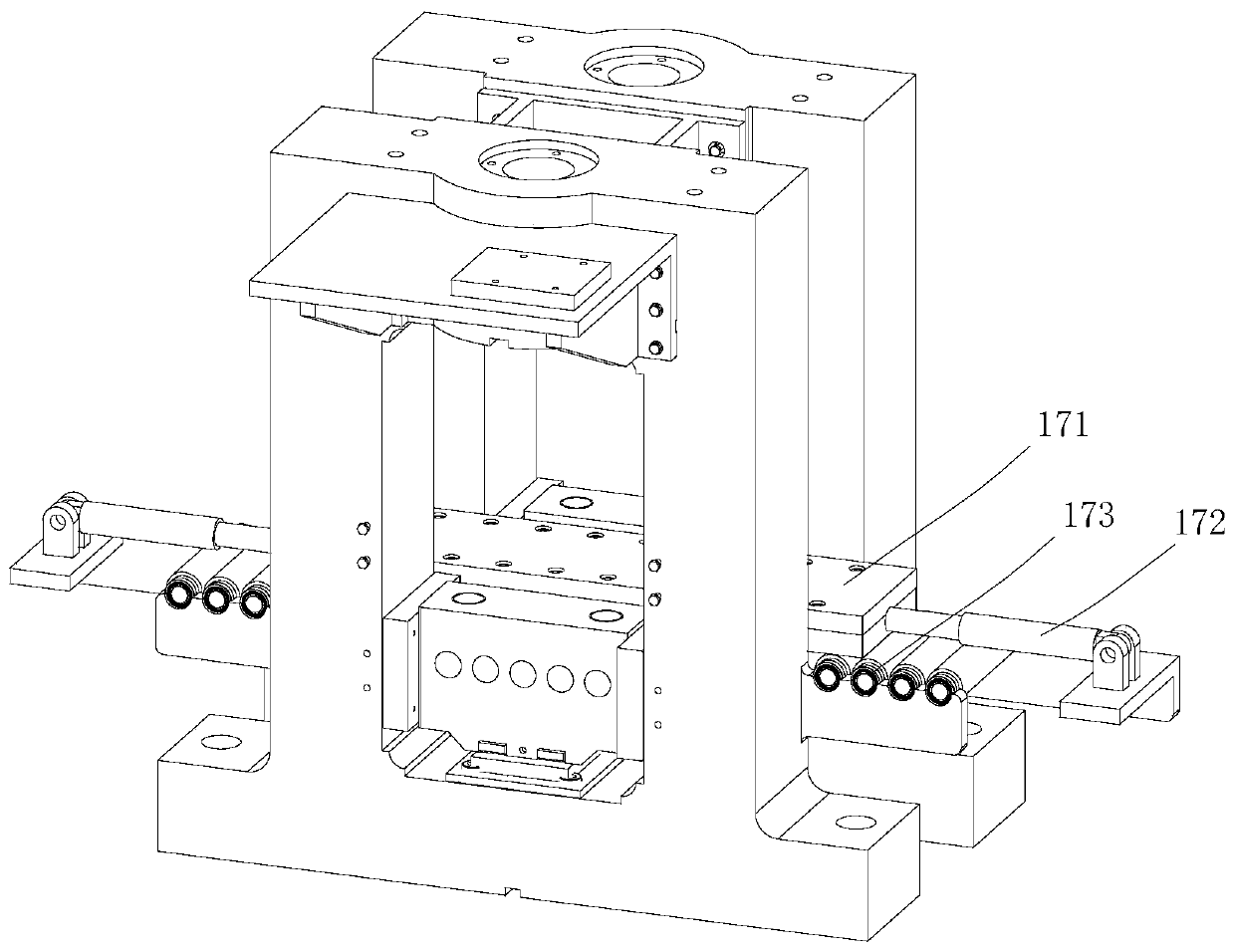

Metal shearing type energy dissipation device with displacement amplifying function

ActiveCN105696722AZoom in on the second end deformationIncrease shear deformationBridge structural detailsShock proofingPlastic propertyShock resistance

The invention discloses a metal shearing type energy dissipation device with the displacement amplifying function. The metal shearing type energy dissipation device comprises a restraining box body, a damping core plate and adjusting plate sets. An opening is formed in the top of the restraining box body. A first connecting plate is arranged at the bottom of the restraining box body. The damping core plate is arranged in the restraining box body, and the first end of the damping core plate is connected with the first connecting plate. The first ends of the adjusting plate sets penetrate the opening and are connected with the second end of the damping core plate through first pivot shafts in a pivoted manner. The second ends of the adjusting plate sets are connected with a second connecting plate located outside the restraining box body through second pivot shafts in a pivoted manner. Supporting point shaft holes close to the second pivot shafts is formed in the adjusting plate sets. Supporting point shafts are inserted into the supporting point shaft holes. The two ends of each supporting point shaft are arranged on the side wall of the restraining box body. According to the metal shearing type energy dissipation device with the displacement amplifying function, when the second connecting plate generates horizontal deformation, the adjusting plate sets are driven to rotate around the corresponding supporting point shafts, reversed deformation is applied to the damping core plate, deformation of the upper end of the damping core plate is larger than horizontal deformation generated on the second connecting plate, the damping core plate is accelerated to enter the plastic state, and the energy-dissipating capacity of the damping core plate is brought into full play, so that the structural shock resistance is improved.

Owner:SHANGHAI KUNYI SEISMIC DAMPING ENG TECH CO LTD

Non-Newtonian fluid pneumatic soft touch hand and forming method thereof

InactiveCN110202597AIncrease stiffnessIncrease concentrationGripping headsConvex structureShear stress

The invention discloses a non-Newtonian fluid pneumatic soft touch hand and a forming method thereof. The non-Newtonian fluid pneumatic soft touch hand is composed of a touch hand and a chassis assembly, wherein the upper part of the touch hand is equipped with a strain-layer actuating cavity of a concave-convex structure, the middle part of the touch hand is equipped with a strain limiting layer,the lower part of the touch hand is equipped with a cuboid damping cavity with a separating plate, a gas cavity is arranged between the upper part and the middle part, and non-Newtonian fluid is arranged between the middle part and the lower part; when gas pressure is inflated into the actuating cavity, strain of the middle strain limiting layer part is smaller than that of an upper part actuating cavity unit, and therefore, the touch hand is laterally bent towards the strain limiting layer; and meanwhile, a lower part damping cavity unit is driven to bent, so that non-Newtonian fluid sealedin the damping cavity unit bears shearing stress. Viscosity of the non-Newtonian fluid generates changes along with a shearing rate, so that damping is generated, and therefore, an unstable phenomenongenerated in a bending process of the touch hand bearingexternal disturbance is eliminated. Moreover, stable control can be performed in a complex environment, so that target action is effectively accomplished.

Owner:SHANGHAI UNIV

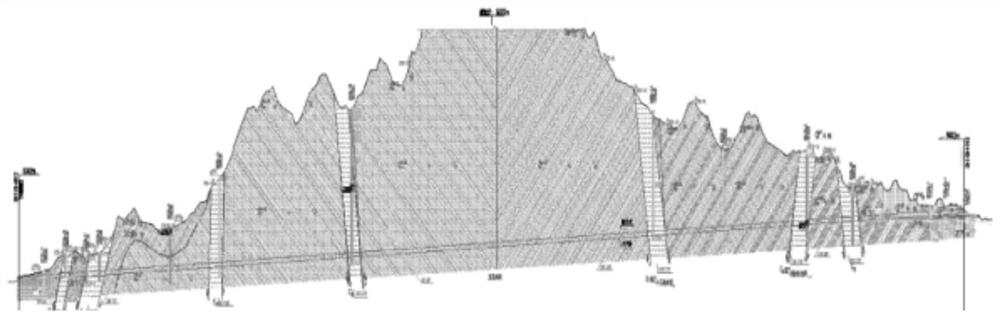

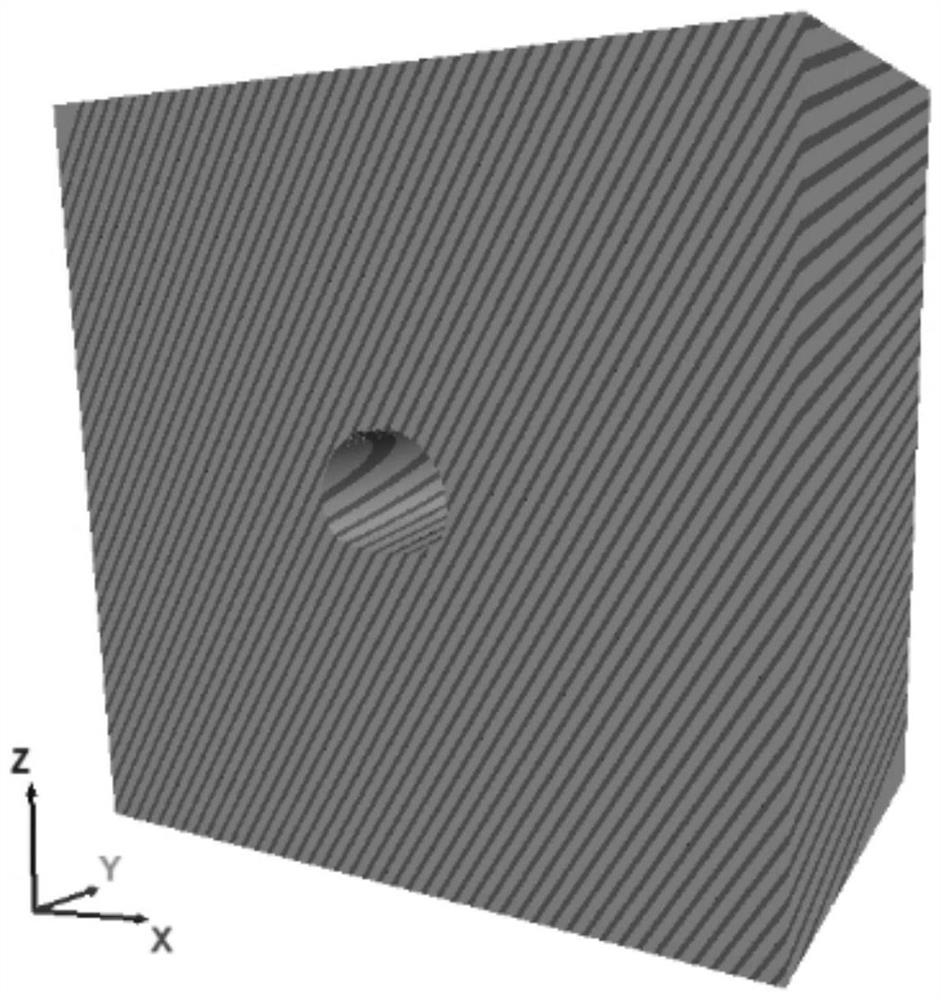

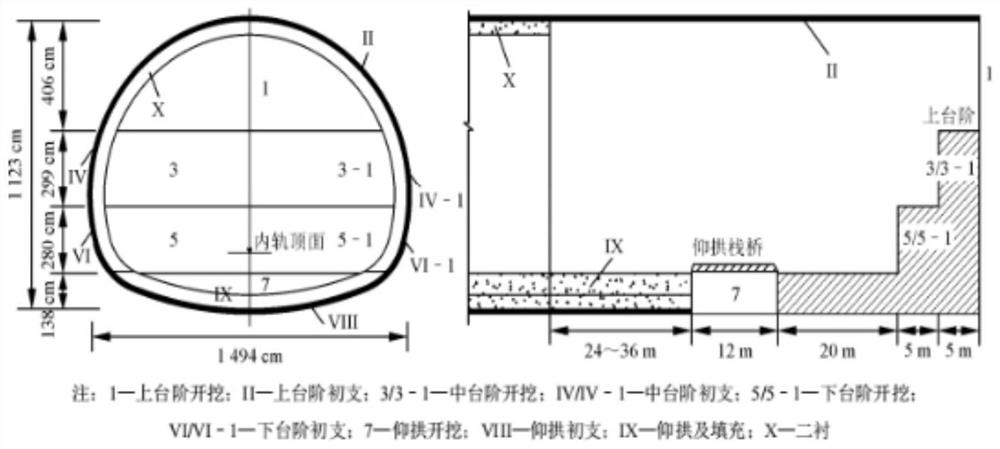

High ground stress interbed soft rock tunnel failure mechanism and construction control research method

PendingCN113094778AIncrease shear deformationSurrounding rock range is smallGeometric CADDesign optimisation/simulationRock tunnelNumerical models

The invention discloses a high ground stress interbed soft rock tunnel failure mechanism and construction control research method. The method comprises the following steps: 1, establishing a numerical model; 2, analyzing the stability of the surrounding rock of the apex mountain tunnel; 3, analyzing the stability of the initial support of the apex mountain tunnel; 4, analyzing a failure mechanism of the high-ground-stress interbed soft rock tunnel; 5, implementing an apex mountain tunnel monitoring and measuring scheme; 6, analyzing a field monitoring and measuring result, wherein the deformation of the surrounding rock generally presents a rule that the horizontal convergence is greater than the vault settlement, the horizontal convergence value and the rate are greater than the vault settlement amount and the settlement rate, and the vault settlement amount tends to be stable earlier than the horizontal convergence value and is consistent with the numerical simulation surrounding rock deformation rule; the overall rules are consistent, so that certain reasonability is achieved, and meanwhile it is verified that the supporting mode of section optimization, advanced reinforcement and variable-section spray layer has a good effect on supporting of the high ground stress interbed soft rock tunnel.

Owner:中国铁路兰州局集团有限公司兰州工程建设指挥部 +2

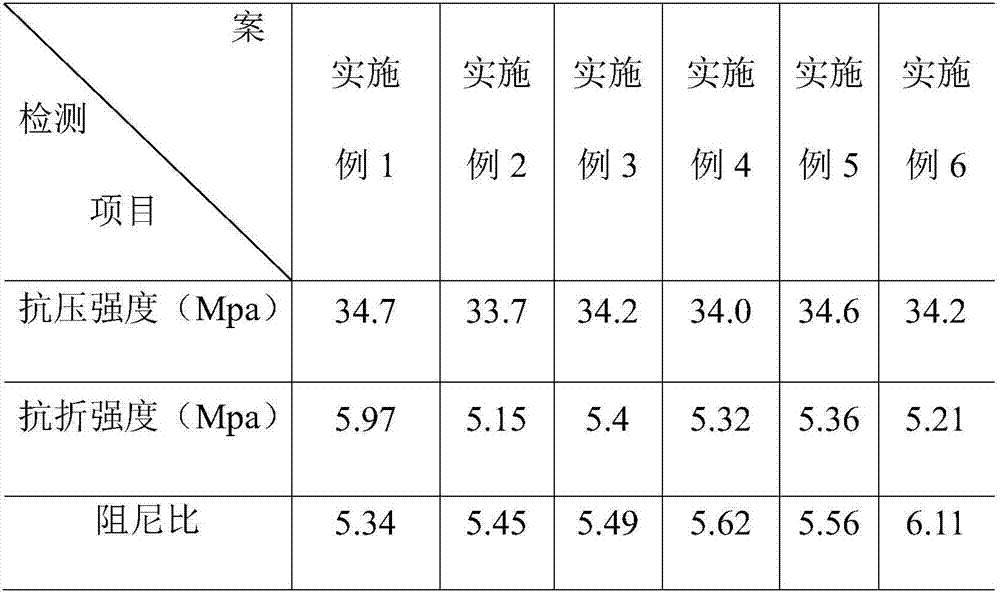

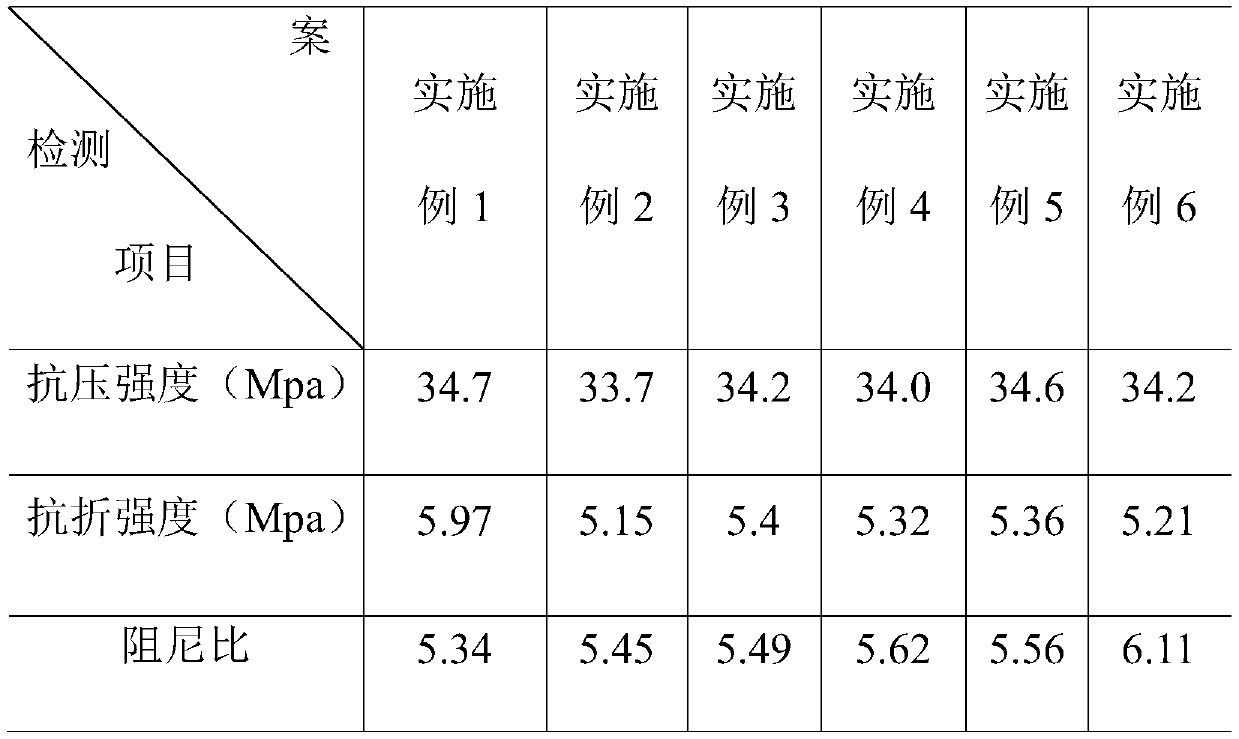

High damping concrete based on internal structure design and preparation method thereof

InactiveCN107473645AGood vibration dampingPlay the role of energy consumptionCeramic shaping apparatusShock proofingPolymer modifiedCompressive strength

The invention discloses a high damping concrete based on internal structure design and a preparation method thereof. The high damping concrete comprises a common concrete restraining layer and polymer modified layers. One or two polymer modified layers are introduced into the common concrete restraining layer so as to form the multiple restraining layer-free layer-restraining layer vibration attenuation unit combination; the common concrete restraining layer comprises 15-17 parts of cement, 30-35 parts of natural river sand, 42-47 parts of macadam, 4-8 parts of water and 1-2 parts of a water reducing agent; each polymer modified layer comprises polymer emulsion or polymer modified mortar. The high damping concrete disclosed by the invention has excellent absorbing and energy-dissipating functions and has excellent vibration attenuation and noise-absorbing properties, and meanwhile, the mechanical properties, such as fracture resistance and compressive strength, are controlled within reasonable scope.

Owner:CHANGAN UNIV

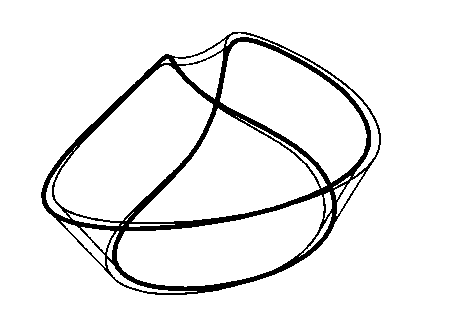

Moebius vibration isolator based on wave mode conversion mechanism and energy local effect

The invention relates to a Moebius vibration isolator based on a wave mode conversion mechanism and an energy local effect. The Moebius vibration isolator is formed by combining multiple Moebius banded structures, and the multiple Moebius banded structures are connected into an integral structure through an upper part bearing force platform and a lower part bearing force platform; and the upper part bearing force platform and the lower part bearing force platform are respectively connected with upper part inclined plane regions and lower part circular arc regions of the Moebius banded structures. The Moebius vibration isolator provided by the invention couples the bending rigidity and torsional rigidity of the Moebius banded structures, the energy local region property is taken as an vibration isolation structure of a vibration isolation mechanism, and the Moebius vibration isolator has the advantages of large load-carrying ability, small static transformation, low inherent frequency, higher damping, and is capable of realizing low-frequency broad band transfer admittance and can not generate creepage, aging and temperature sensibility and the like.

Owner:SHANGHAI JIAO TONG UNIV

Damper rail

Owner:QINGDAO CREATE ENVIRONMENT CONTROL TECH

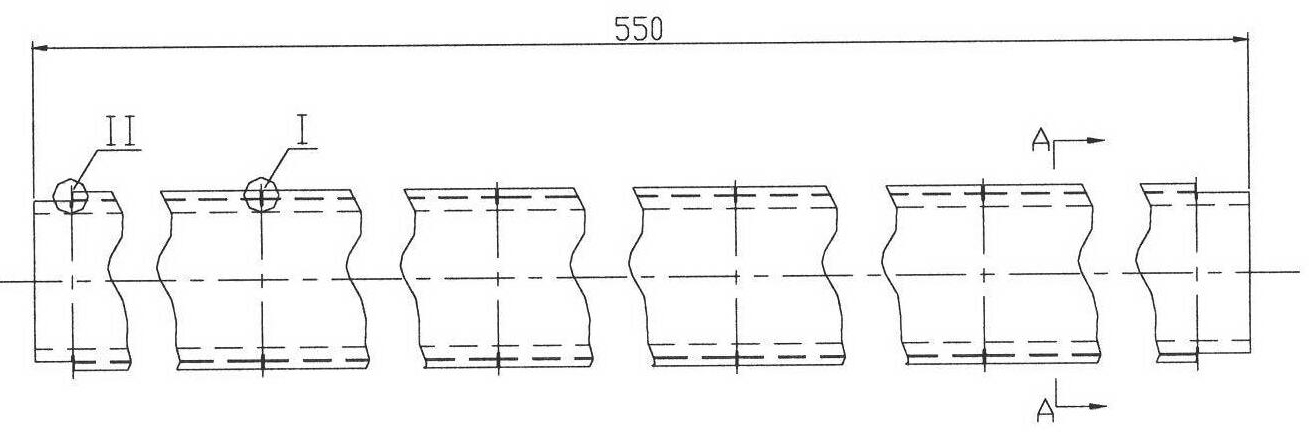

Automobile buffer block

PendingCN108006123AControl deformationSmall compression deformationSpringsWave shapeShearing deformation

The invention discloses an automobile buffer block, which comprises a rubber main spring and a spacer. The spacer is arranged on the lower part of the rubber main spring; a chamber for installing a sleeve pipe is arranged in the rubber main spring; an inner wall and an outer wall of the rubber main spring are in wave shapes; and peak points and peak valleys of the wave-shaped inner wall correspondto peak values and peak valley waving positions of the wave-shaped outer wall. The automobile buffer block has the beneficial effects that the buffer block adopts the wave-shaped structure, so that the deformation of the rubber main spring can be effectively limited, the static rigidity is ensured, the compression deformation of a product is reduced, the shear deformation of the product is increased, and the fatigue strength is effectively improved.

Owner:柳州日高汽车减振技术有限责任公司

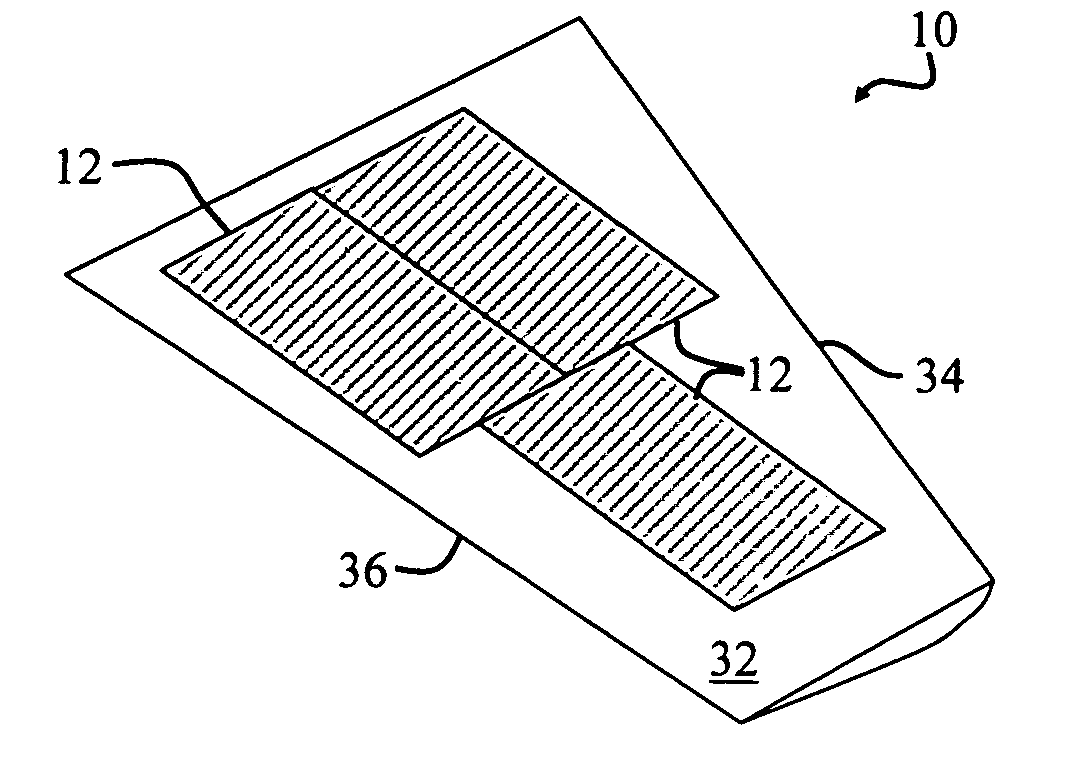

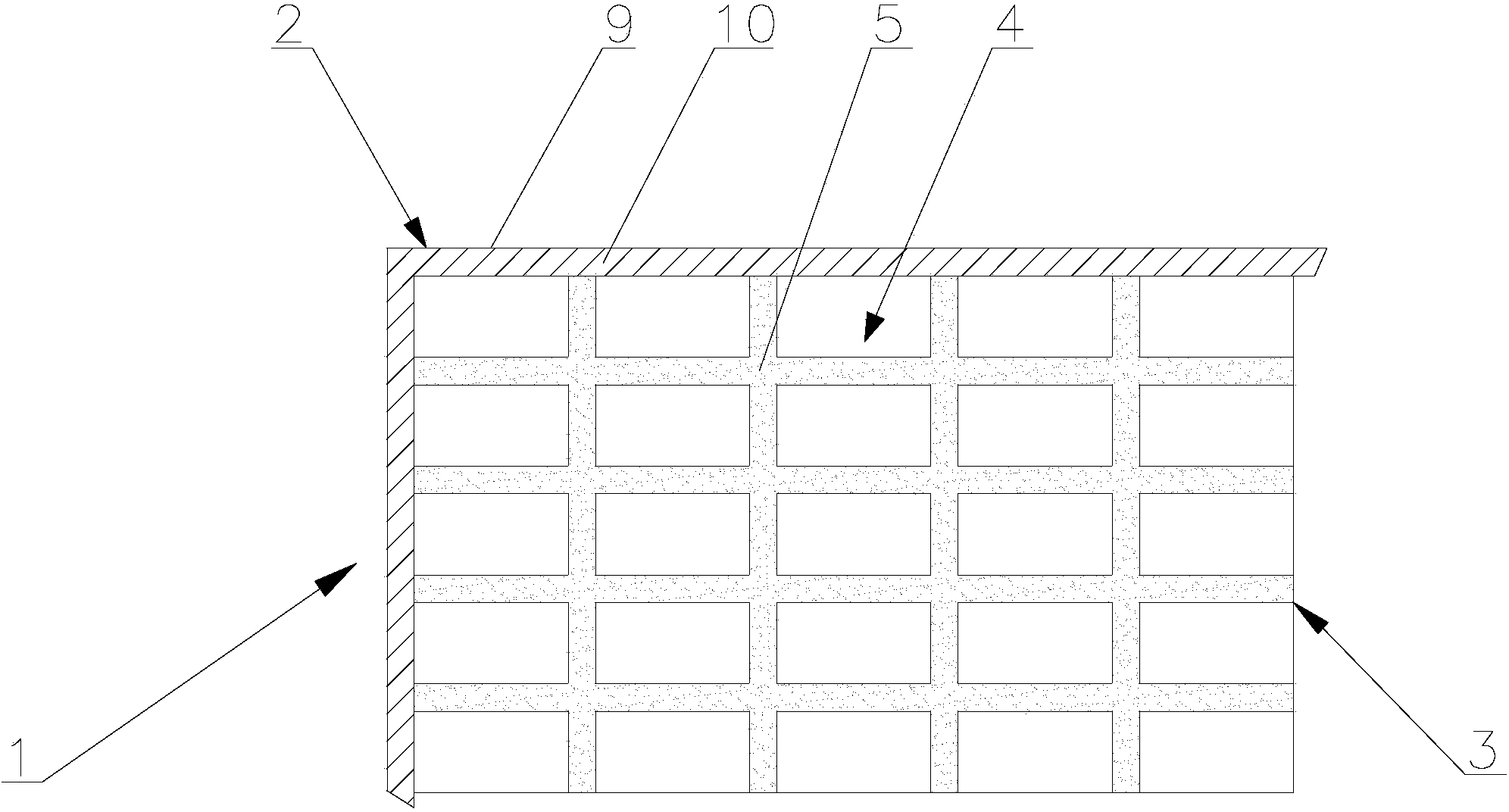

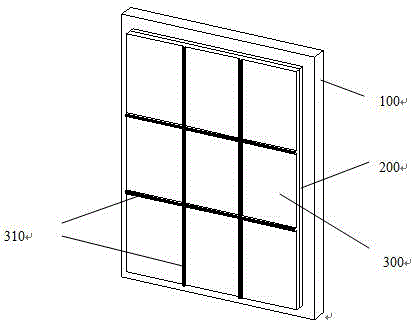

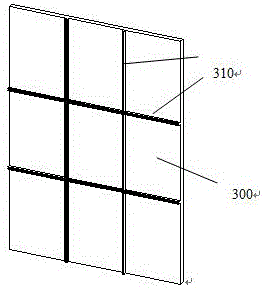

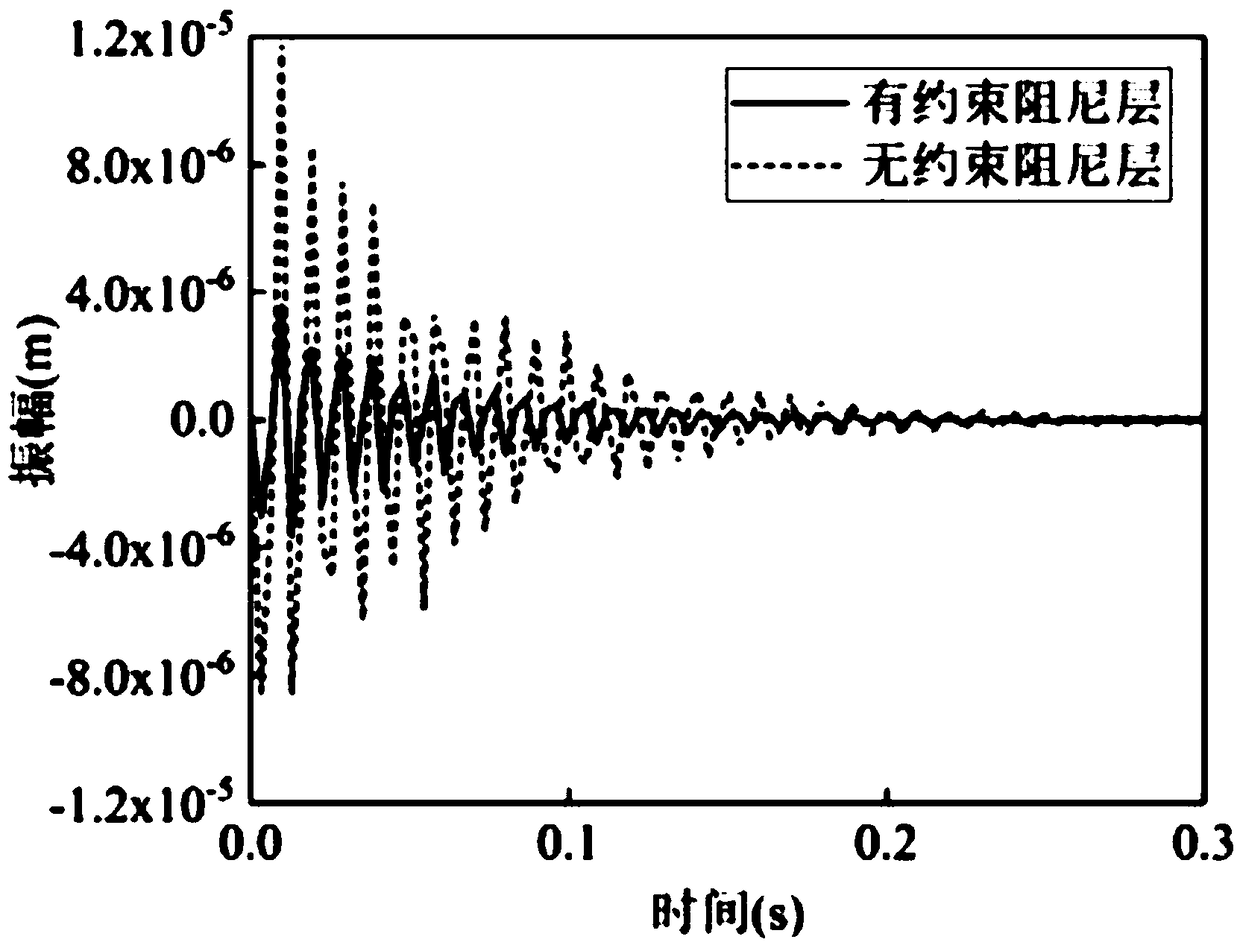

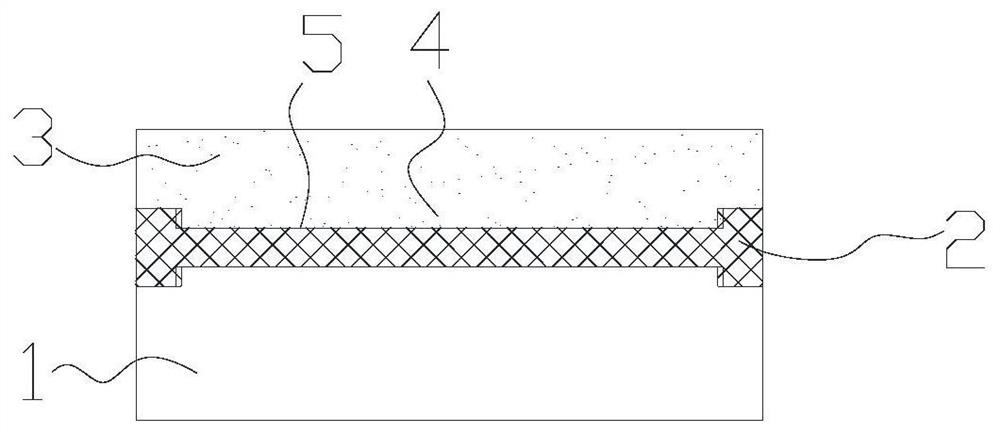

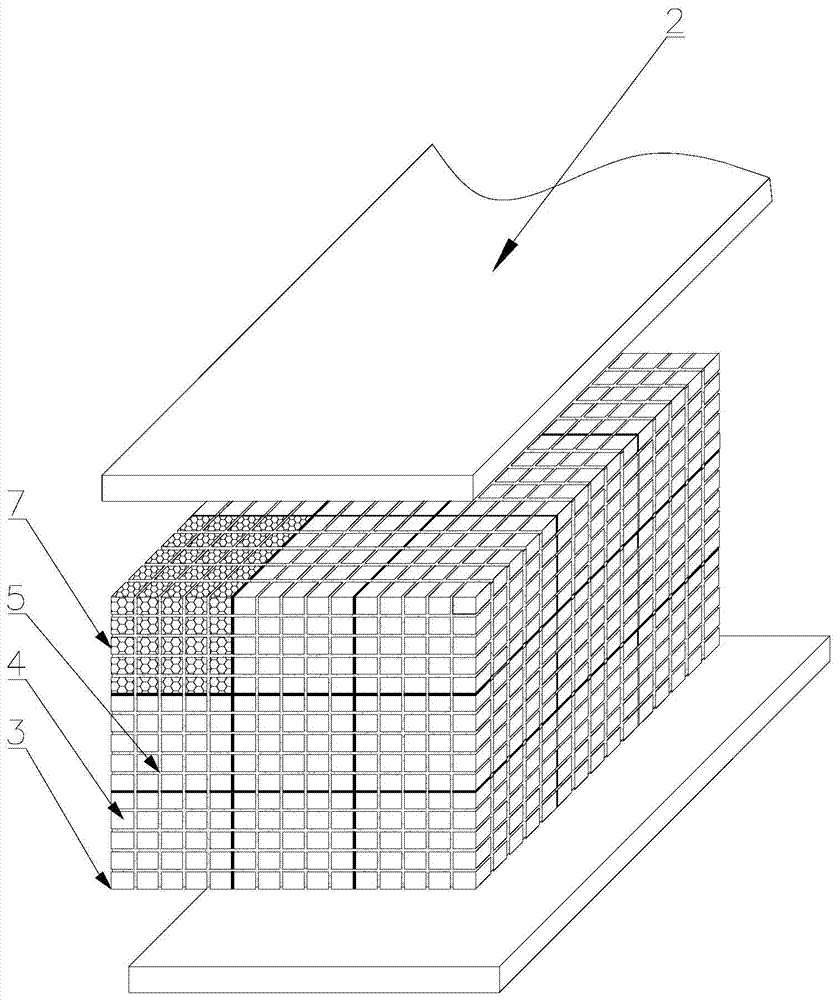

Ribbed constrained damping layer structure

ActiveCN105888093AIncrease stiffnessReduce local deformationShock proofingEngineeringShearing deformation

The invention discloses a ribbed constrained damping layer structure which is characterized in that a structure layer, a damping layer and a constraining layer are superposed in sequence; the damping layer is made of a high-damping viscoelastic material, a ribbed constrained damping layer device is formed in a manner of fitting between the dimpling layer and the ribbed constraining layer and is mounted in a manner of adhesion between the damping layer and the structure layer. The ribbed constrained damping layer structure disclosed by the invention has the advantages that according to the ribbed constrained damping layer structure, the stiffness of the constraining layer is increased, the local deformation of the constraining layer in the transporting and mounting processes is reduced, and the disengaging phenomenon between the constrained damping layer and the structure layer is reduced during mounting, so that a good adhering effect on the constrained damping layer and the structure layer can be realized, and the shear deformation of the damping layer can also be increased. Therefore, the vibration reduction and noise reduction abilities of the ribbed constrained damping layer structure are improved.

Owner:EAST CHINA JIAOTONG UNIVERSITY

A kind of high damping concrete based on internal structure design and preparation method thereof

InactiveCN107473645BGood vibration dampingPlay the role of energy consumptionCeramic shaping apparatusShock proofingPolymer modifiedStructural engineering

The invention discloses a high-damping concrete based on internal structure design and a preparation method thereof, which includes a common concrete constrained layer and a polymer modified layer. According to the introduction of one or two polymer modified layers into the ordinary concrete constrained layer, a combination of multiple constrained layer-free layer-constrained layer vibration damping units is formed; the ordinary concrete constrained layer includes 15-17 parts of cement, natural river sand 30-35 parts, 42-47 parts of gravel, 4-8 parts of water, 1-2 parts of water reducer; the polymer modified layer includes polymer emulsion or polymer modified mortar. The high damping concrete of the present invention has better energy absorption and dissipation functions, has more excellent vibration reduction and noise absorption performance, and the mechanical properties such as flexural resistance and compressive strength are controlled within a reasonable range.

Owner:CHANGAN UNIV

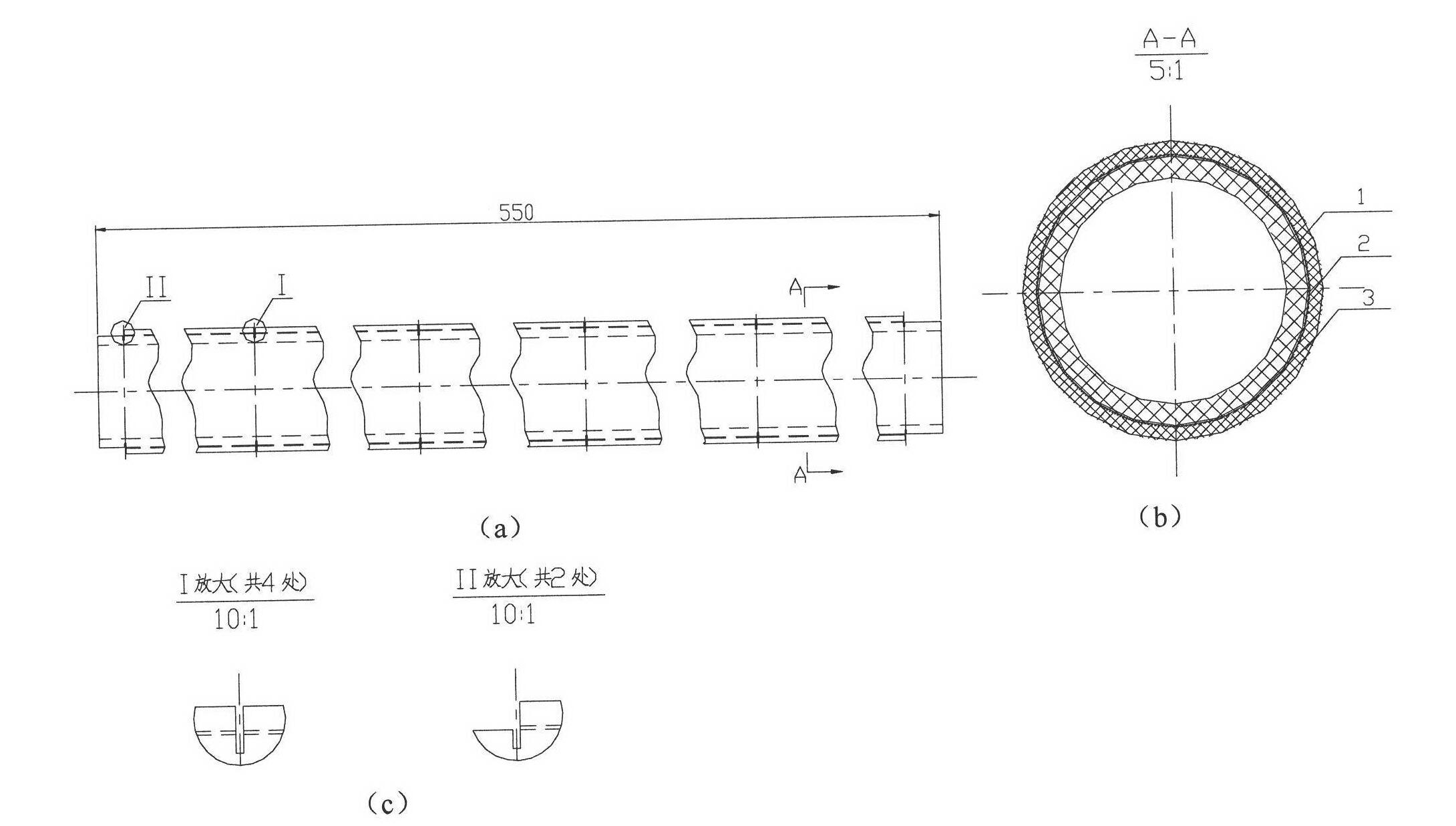

Unmanned aerial vehicle rotor arm structure with outer surface additionally provided with segmented constrained damping layer

InactiveCN109305344AVibration suppression effect is obviousDoes not affect the main structureRotocraftFiberViscoelastic damping

The invention provides an unmanned aerial vehicle rotor arm structure with the outer surface additionally provided with a segmented constrained damping layer. An unmanned aerial vehicle rotor arm comprises a rotor arm body, the constrained damping layer and a viscoelastic damping layer; the rotor arm body is of a hollow cylindrical structure made of a carbon fiber material; the constrained dampinglayer and the viscoelastic damping layer are each of a segmented hollow cylindrical shell structure, and are made of an aluminum alloy and ZN-1 damping rubber correspondingly; and the rotor arm, theviscoelastic damping layer and the constrained damping layer are tightly bonded in sequence from inside to outside. By additionally arranging the segmented constrained damping layer on the outer surface of the unmanned aerial vehicle rotor arm, the viscoelastic damping layer deforms through elastic bending vibration of the rotor arm, and thus vibration energy of the unmanned aerial vehicle rotor arm is dissipated rapidly for vibration reduction. The structure is simple, a main body structure of an unmanned aerial vehicle is not affected, extra additional mass and control device are not needed,the flight stability of the unmanned aerial vehicle is improved, and the vibration suppression effect in practical application is remarkable.

Owner:NORTHEASTERN UNIV

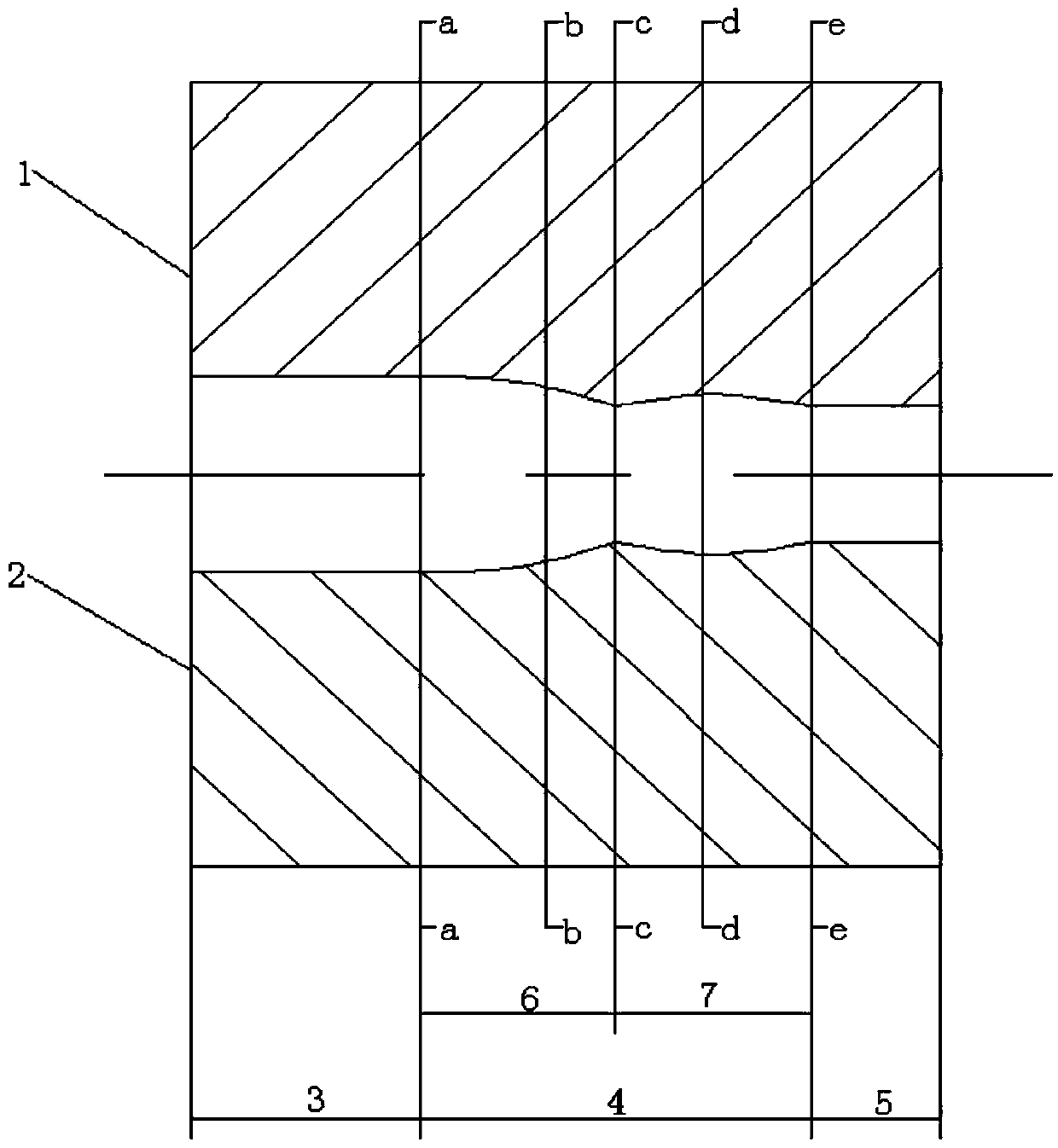

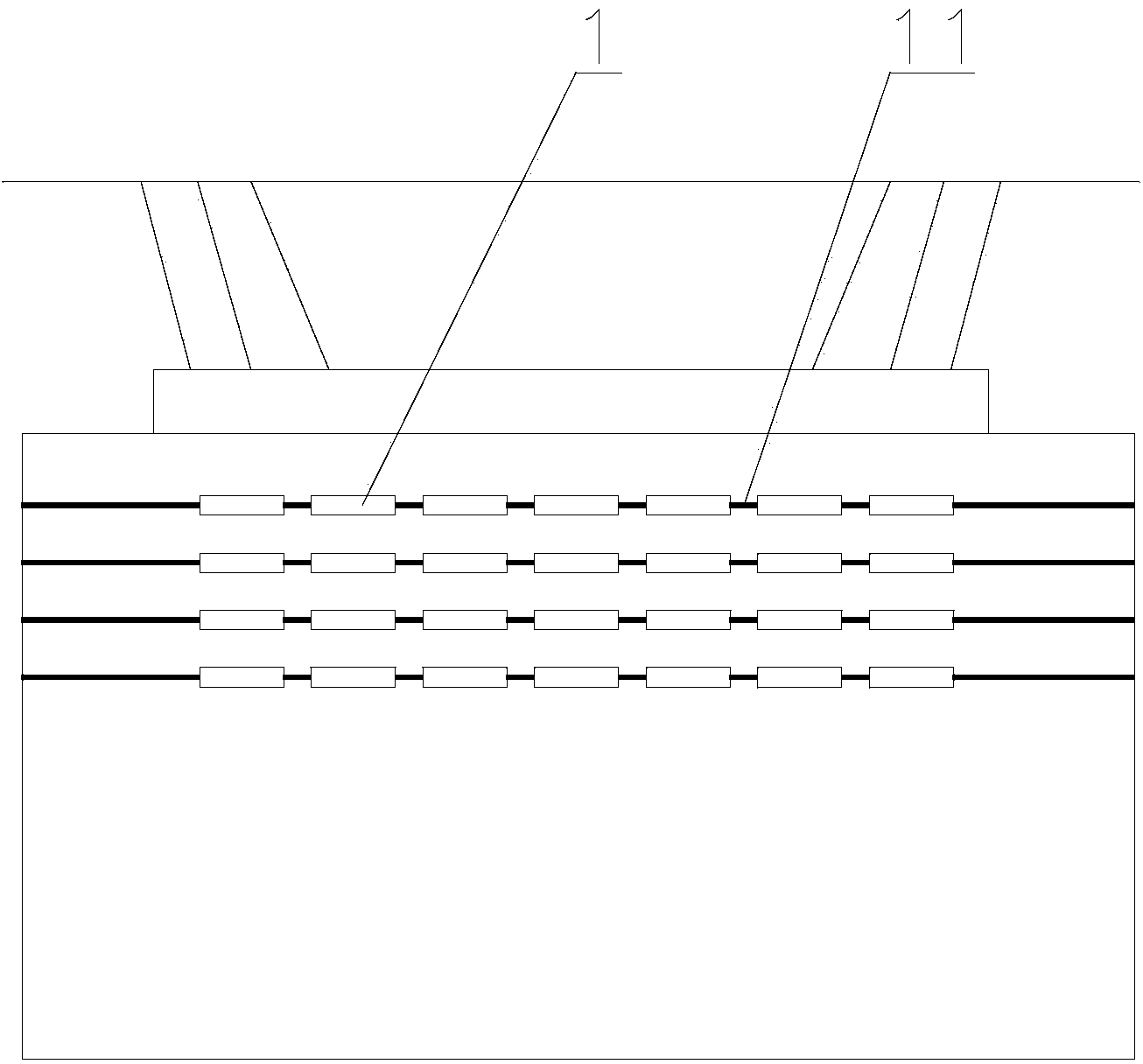

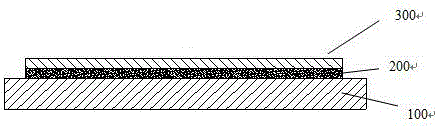

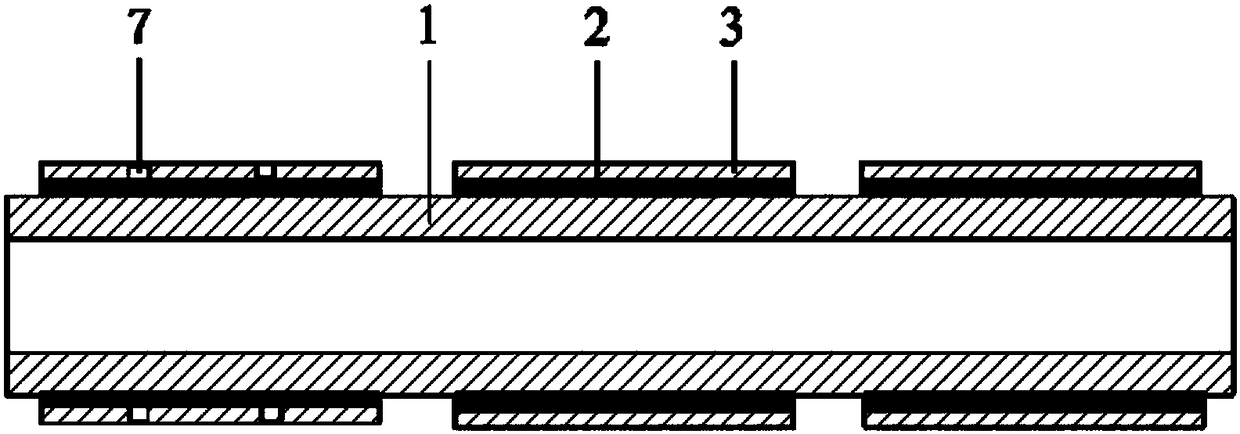

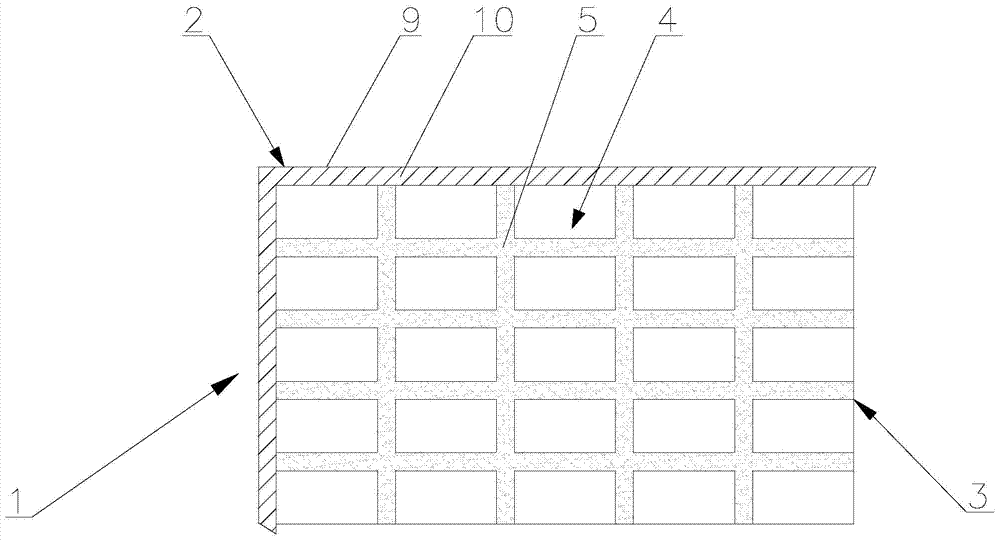

Valve plate, exhaust valve assembly, compressor and air conditioner

PendingCN113864160AAvoid damageDissipate vibrational energyPositive displacement pump componentsSynthetic resin layered productsExhaust valveEngineering

The invention provides a valve plate, an exhaust valve assembly, a compressor and an air conditioner. The valve plate comprises a base layer valve plate (1), a damping layer valve plate (2) and a restraint layer valve plate (3), the damping layer valve plate (2) is located between the base layer valve plate (1) and the restraint layer valve plate (3), and the base layer valve plate (1), the damping layer valve plate (2) and the restraint layer valve plate (3) are fixedly connected. According to the valve plate, part of impact energy can be consumed, abrasion of the valve plate is effectively relieved, and the reliability of the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

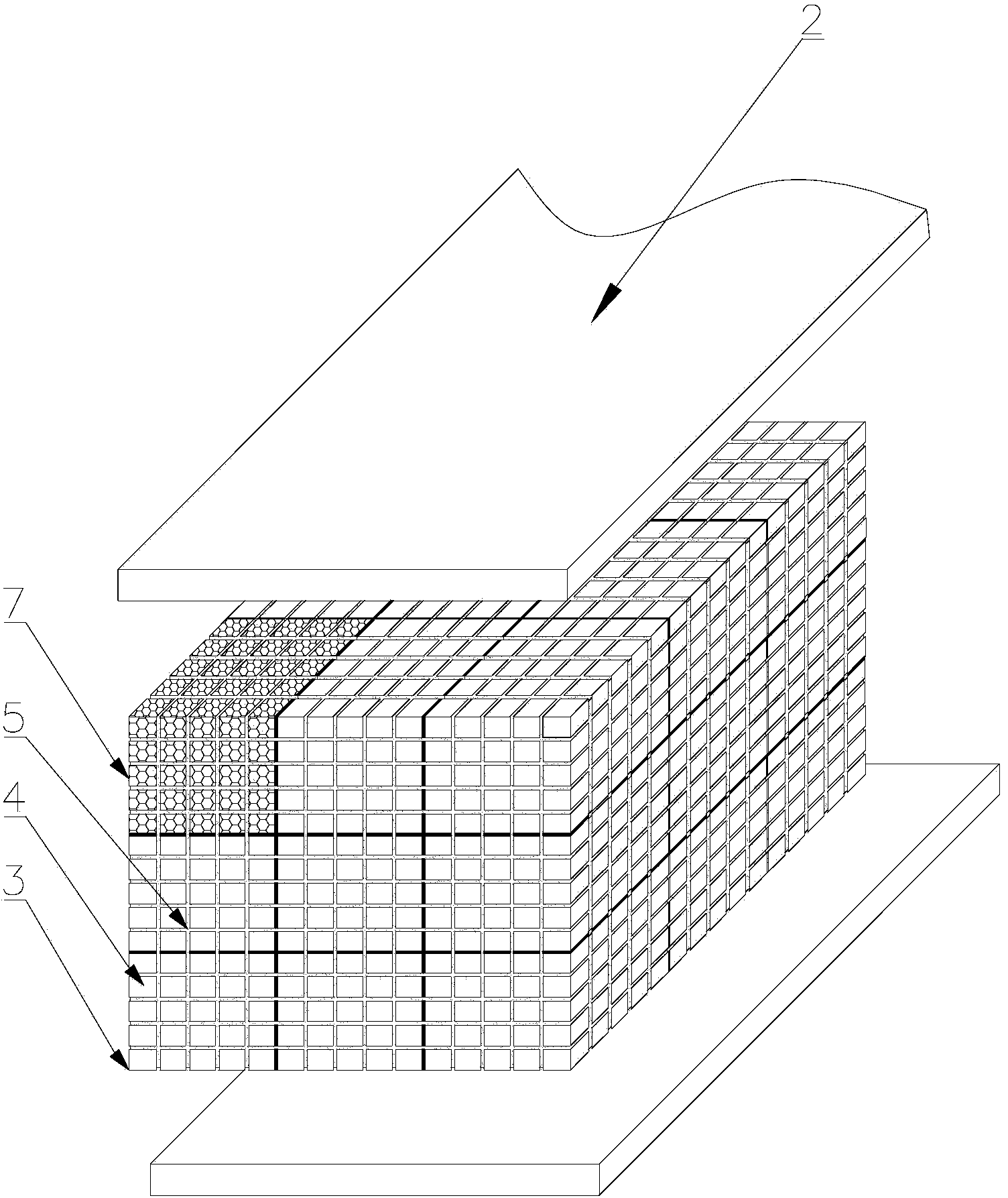

Rubber bearing

InactiveCN109208464AIncrease elasticityIncrease shear deformationBridge structural detailsShearing deformationAbutment

The invention discloses a rubber bearing, comprising a plurality of layers of thin steel plates and a plurality of layers of rubber sheets. The multilayer rubber sheets re mainly rubber, and the rubber bearing is formed by vulcanizing and bonding the multiple layers of thin steel plates and the multiple layers of rubber sheets, and a layer of polytetrafluoroethylene plate 1.5 mm-3mm thick is bonded on the surface of the bearing. The rubber bearing has sufficient vertical rigidity to withstand vertical load and can reliably transmit the pressure of the upper structure to the pier abutment, goodelasticity to accommodate the rotation of the beam end and large shear deformation to meet the upper component.

Owner:久裕电子科技(江苏)有限公司

Composite-material energy-dissipation fender and manufacturing process of composite-material energy-dissipation fender

ActiveCN103510491BWide applicabilityProtection securityClimate change adaptationBridge structural detailsShearing deformationEngineering

The invention provides a composite-material energy-dissipation fender which comprises a shell and an energy-dissipation filling body wrapped inside the shell. The energy-dissipation filling body comprises energy-dissipation materials and a plurality of energy-dissipation ribs, the energy-dissipation ribs are distributed inside the energy-dissipation materials and / or between the energy-dissipation materials and the shell, and the energy-dissipation ribs are connected with the shell into a whole. The energy-dissipation ribs of the composite-material energy-dissipation fender form a longitudinally-transversely staggered net structure, the high shearing strength and the certain elastic deformation buffering capacity are achieved, the shell can be protected from large shearing deformation, and the composite-material energy-dissipation fender is good in overall collision avoidance effect, low in manufacturing cost, long in service life and convenient to maintain and repair.

Owner:JIANGSU HONGYUAN TECHNOLOGY ENGINEERING CO LTD

A Constrained Damping Layer Structure with Ribs

ActiveCN105888093BIncrease stiffnessReduce local deformationShock proofingEngineeringShearing deformation

Owner:EAST CHINA JIAOTONG UNIVERSITY

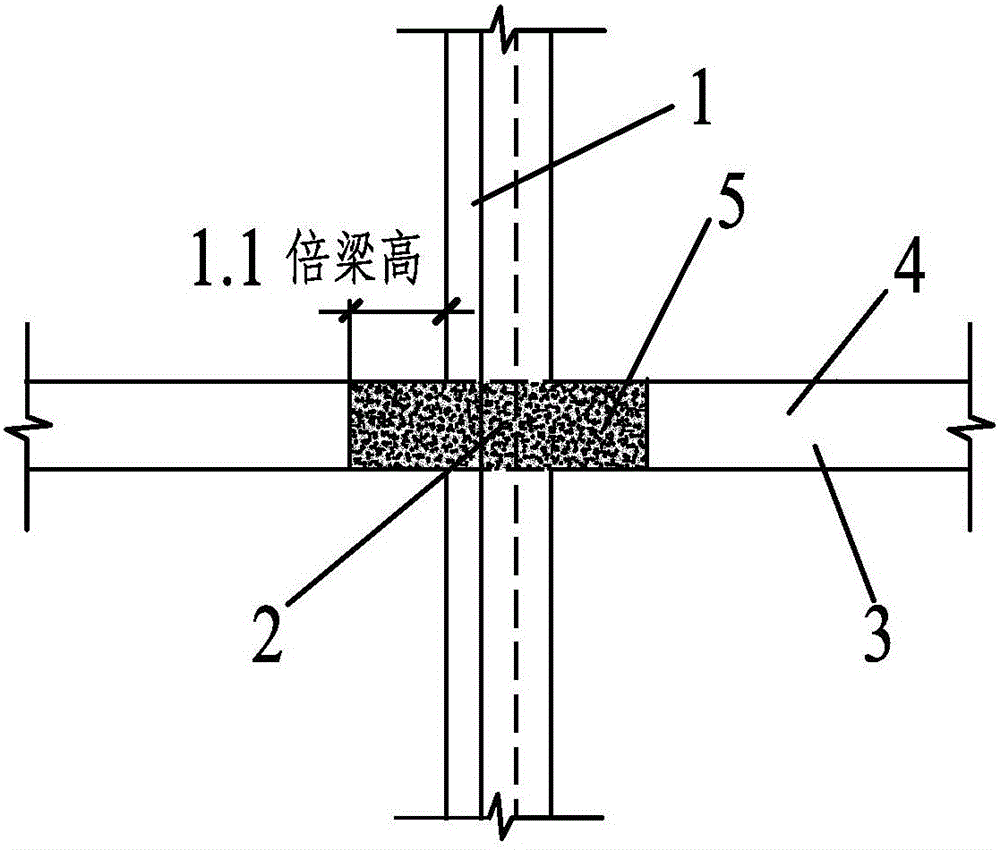

Method for improving anti-seismic property of RC Z-shaped cross section column frame node

InactiveCN105908844AIncrease shear deformationImprove energy consumptionClimate change adaptationBuilding constructionsEngineeringStructural engineering

Owner:ZHEJIANG UNIV OF TECH

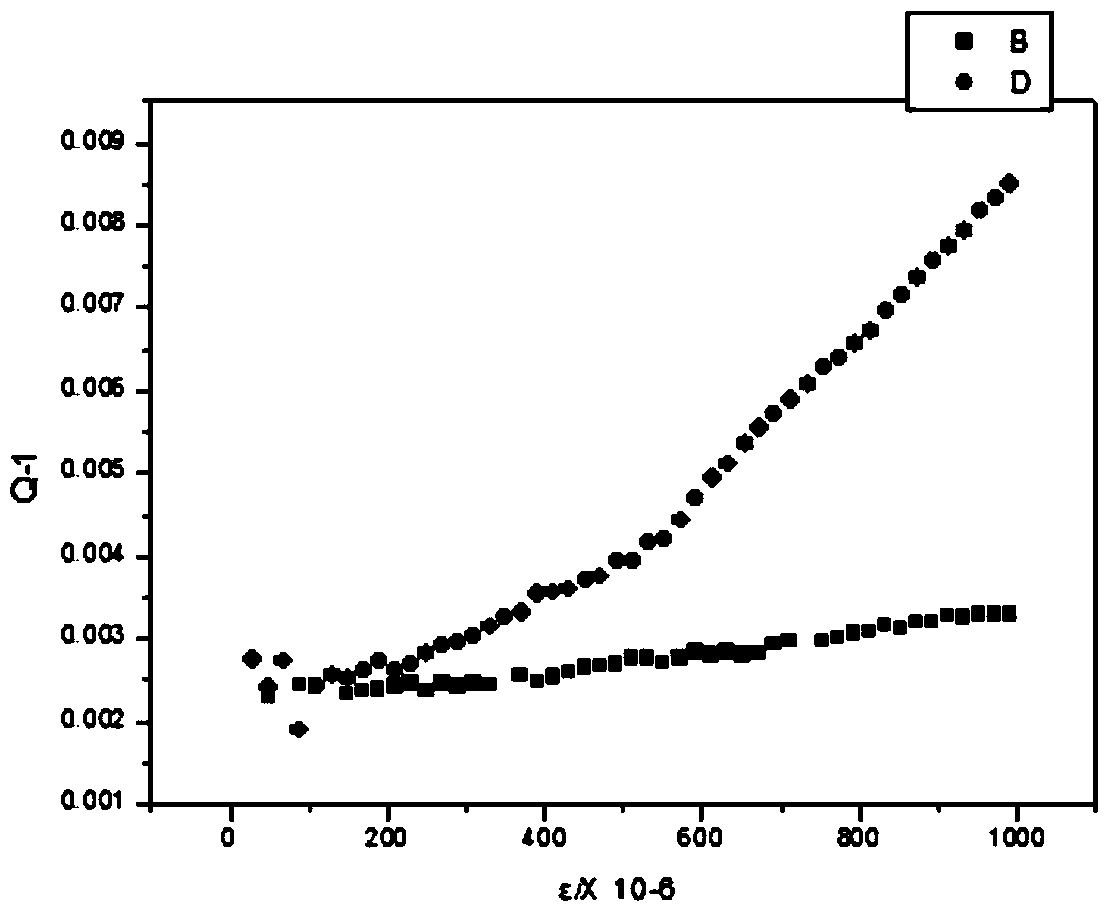

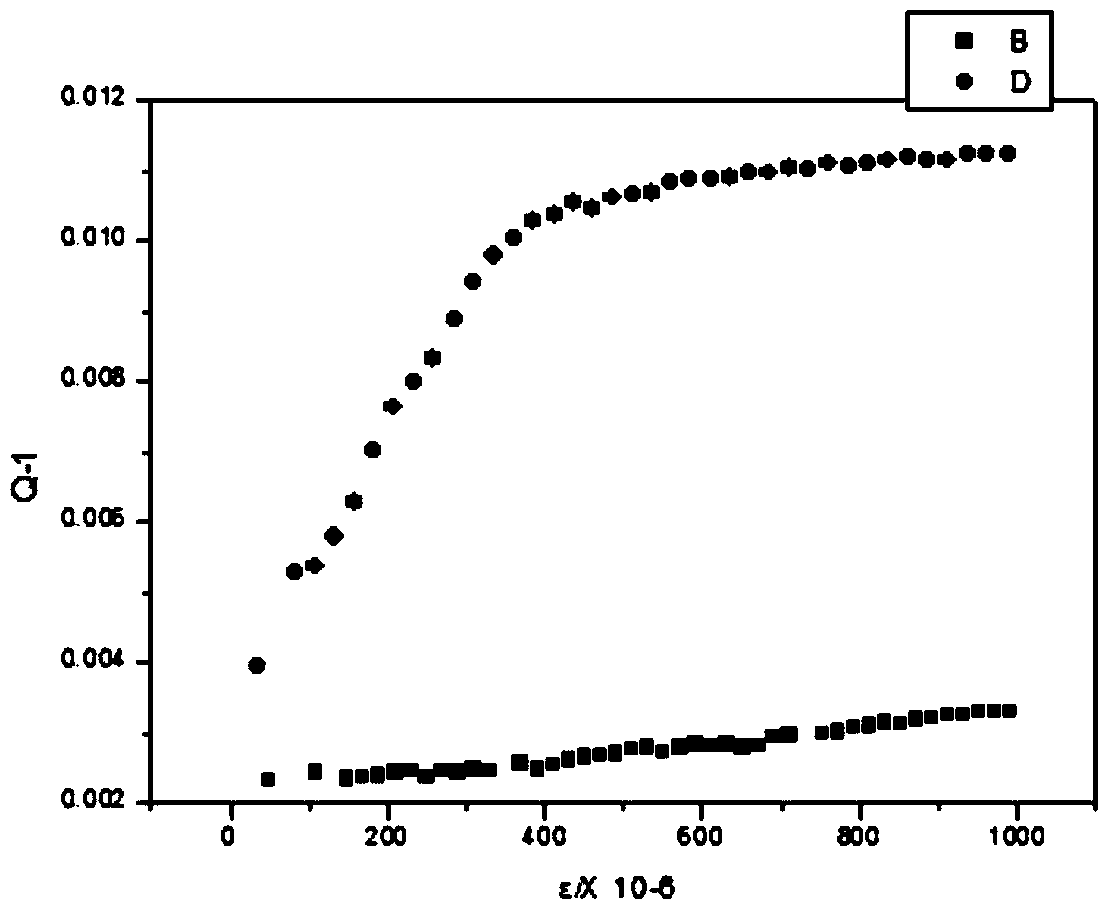

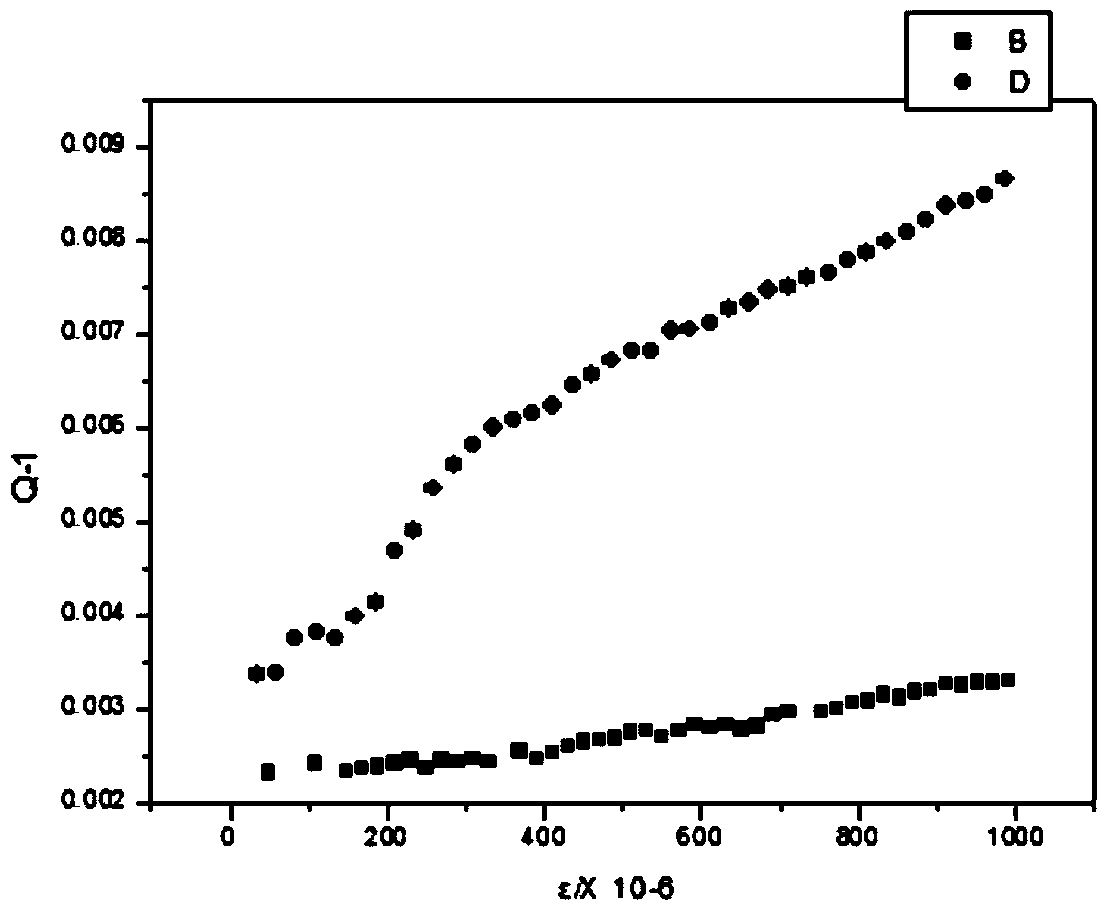

A method of improving the damping performance of tc4 titanium alloy by magnetron sputtering surface treatment

InactiveCN105316633BIncrease dampingIncrease shear deformationVacuum evaporation coatingSputtering coatingTitanium surfaceMicrometer

The invention discloses a technique for improving the damping performance of TC4 titanium alloy through magnetron sputtering surface treatment. The surface treatment of TC4 titanium alloy is carried out to improve the damping performance. Optimum sputtering process parameters to deposit surface films on TC4 samples to improve the damping properties of TC4 titanium alloys. In the invention, a thin film with a thickness of nanometer or micrometer order is formed on the surface of TC4 alloy through magnetron sputtering technology. The interface between the film and the substrate and dislocations near the interface are often the main source of damping in the film material, and energy can often be dissipated through the mechanism of dislocation damping during vibration. Comparing the damping performance of TC4 alloy after surface treatment with that of untreated TC4 alloy, the damping coefficient of TC4 alloy is 0.0034, and the damping coefficient of TC4 alloy can be effectively improved by magnetron sputtering surface treatment technology, so that the damping performance of TC4 alloy can be improved 3-5 times.

Owner:SOUTHWEST JIAOTONG UNIV

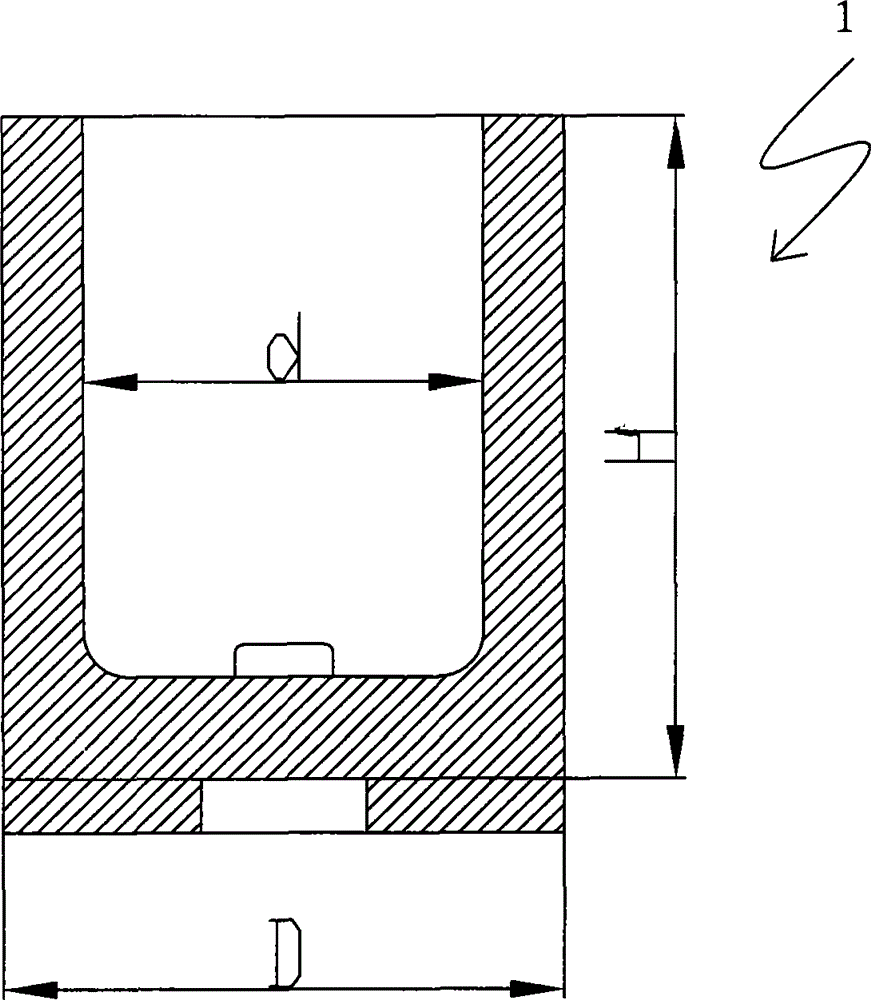

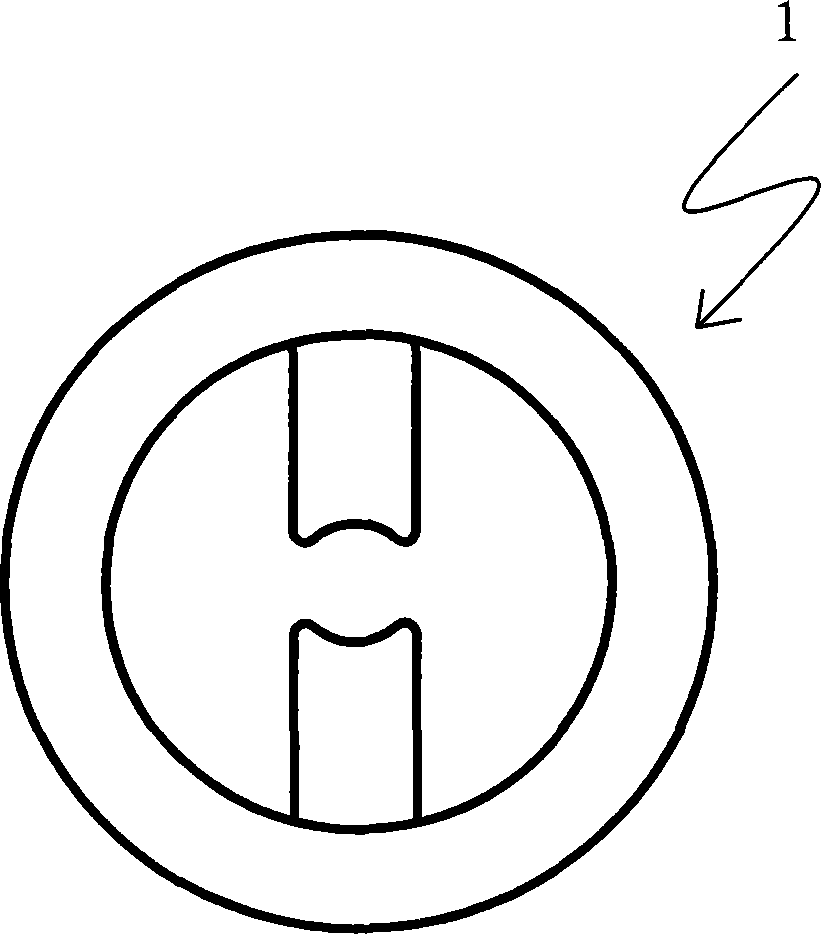

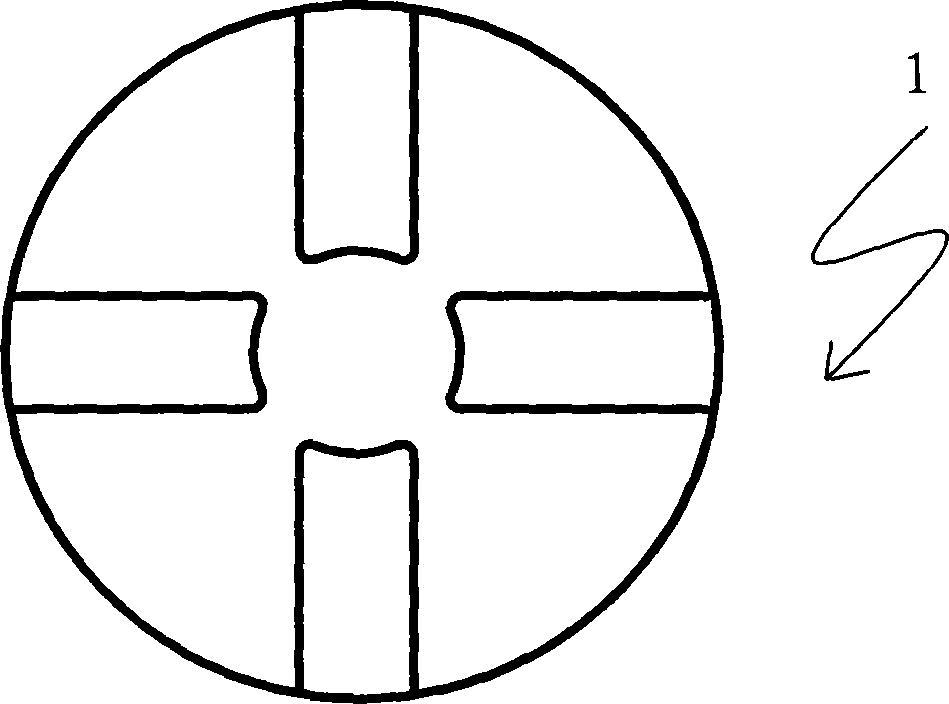

A homogeneous high-strength and toughening magnesium alloy cup-shaped member rotary extrusion method

The invention discloses a rotary extrusion method of a homogenous high-toughness magnesium alloy cup-shaped component. The rotary extrusion method of the homogenous high-toughness magnesium alloy cup-shaped component comprises the following steps: (1) blanking a bar material; (2) carrying out homogenizing thermal treatment; (3) heating the whole rotary extrusion mold, wherein the rotary extrusion mold mainly comprises a punch and a forming concave mold for the rotary extrusion cup-shaped component, the punch is connected with an upper rotary workbench of a hydraulic machine with the upper rotary workbench, the surface of a conical body of the end part of the punch in contact with an extrusion billet is provided with non-communicated grooves with certain widths and depths, and a groove is formed in the plane of the bottom of a mold cavity of the forming concave mold; spraying oiling agent graphitic lubricant for a punch operating belt, the non-communicated grooves, the mold cavity and the blank; installing the blank for extrusion into the mold cavity; (4) moving the upper rotary workbench of the hydraulic machine around a rotary axis, loading the blank around the rotary axis, and filling metal extruded into the non-communicated grooves by the punch when the punch moves around the rotary axis continuously in a smoothing-raising-smoothing-raising mode; (5) processing an extrusion element so as to form the magnesium alloy cup-shaped component.

Owner:ZHONGBEI UNIV

Tube drawing forming method and forming mould

InactiveCN102423770BImproved strain distributionIncrease stressDrawing diesStress distributionShear stress

The invention discloses a tube drawing forming method and forming mould. In the forming method, extrusion-bulging deformation is performed on a tube by using a drawing torsion variable-section core to realize combination of various deformation modes in a primary forming process. The tube wall of the formed tube is subjected to the extrusion-bulging of the core and is in a strong three-way compressive stress state due to the limitation of a polyurethane filling layer; at a deformation stage of circular-elliptical-circular and elliptical torsion change, the tube enters a torsion shearing deformation zone of a metal transition region; under the action of shearing stress, the internal organization of the material is subjected to rotation and shear strain to cause the orientation of a materialorganization structure, namely a new texture is formed, thereby improving deformation texture under the equivalent deformation degree. The drawing variable-section core extrusion-bulging tube deformsto achieve larger deformation degree compared with that of the conventional forming process, so that strain distribution and stress distribution in the tube are improved, the casting organization remained in the broken tube is facilitated, the form and the distribution of inclusion are changed, and the defects of the internal organization of the tube are overcome.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com