Unilateral roll system rolling mill and plate rolling method

A roll system and sheet rolling technology, applied in the field of sheet metal processing equipment, can solve the problems of plastic deformation of rolling pieces affecting product quality and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

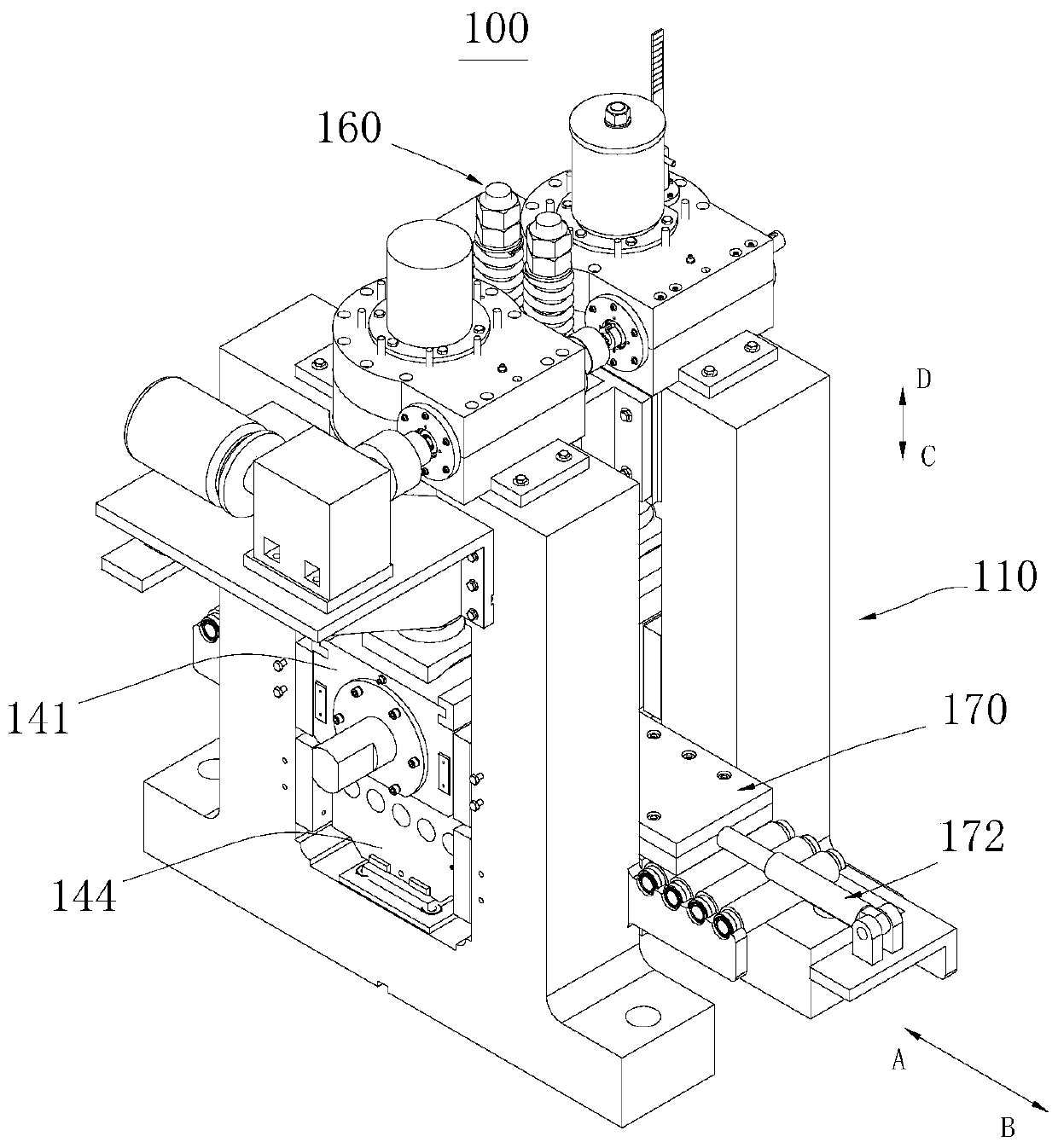

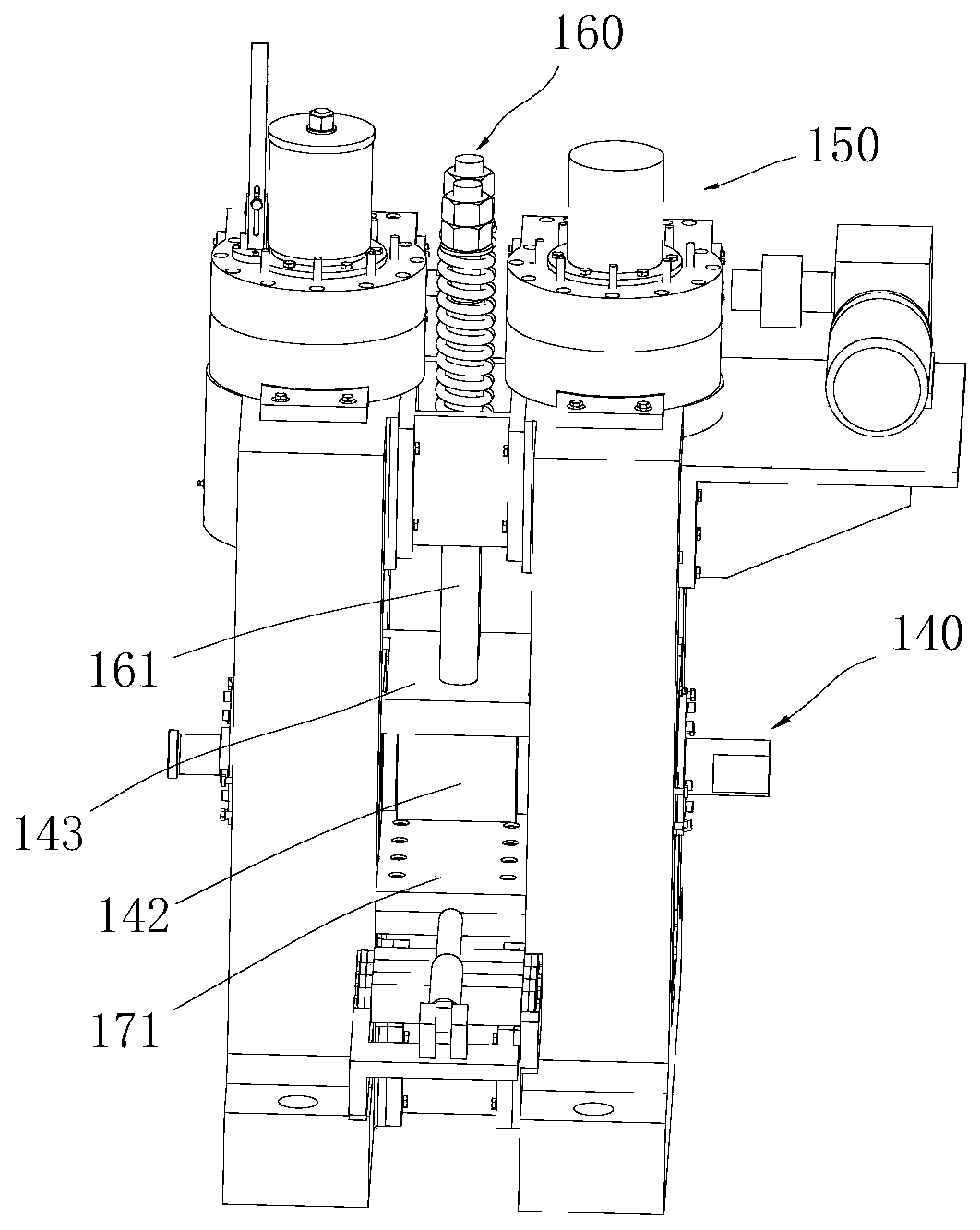

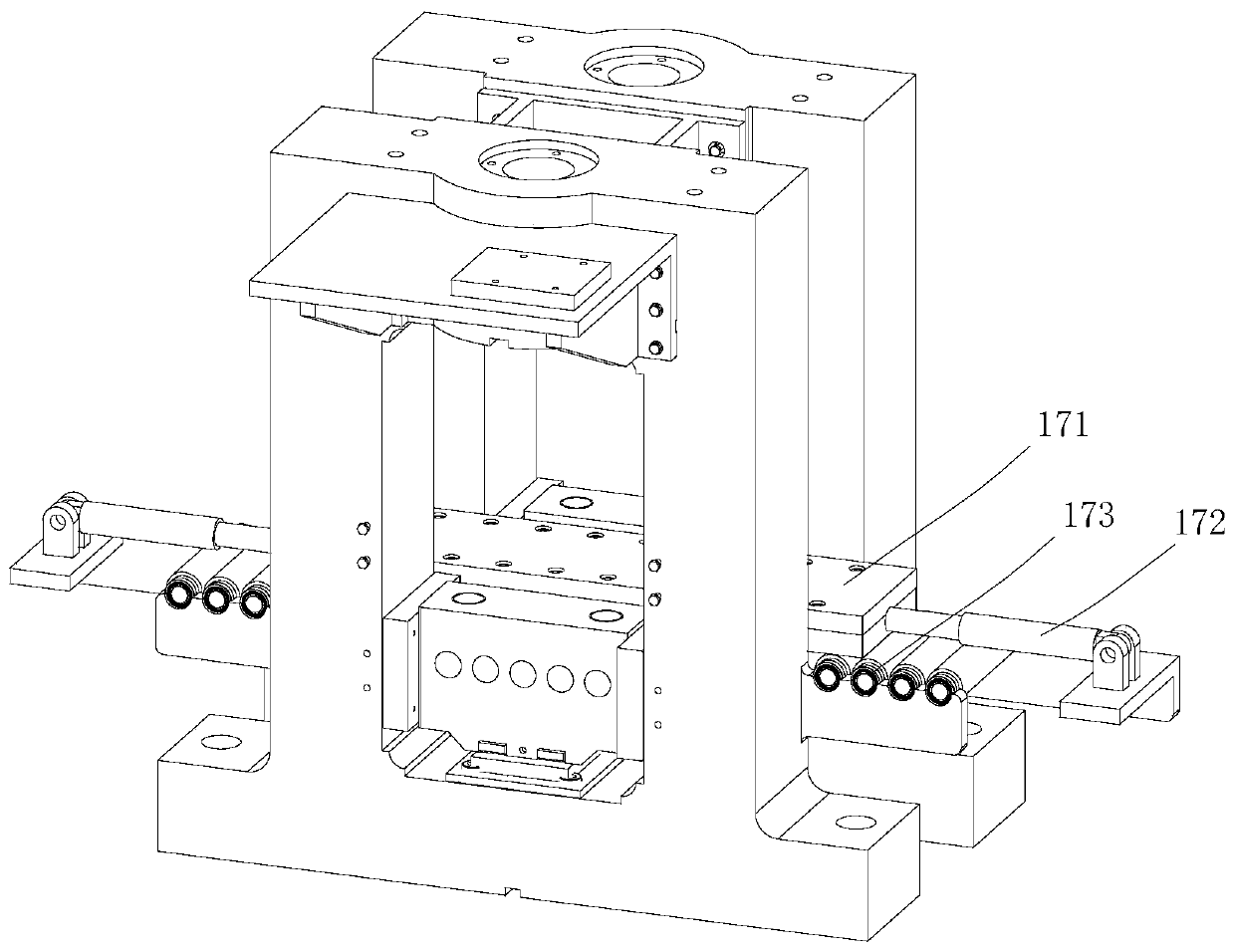

[0048] Please refer to figure 1 with figure 2 , the present embodiment provides a single-side rolling mill 100 , which mainly includes a stand 110 , an upper rolling system 140 and a lower plate rolling device 170 . Wherein, the frame 110 is used for fixedly installing other components of the whole unilateral rolling mill 100, and the upper roller system 140 is horizontally installed in the frame 110, and it includes an upper roller 142 that can rotate around a horizontal axis; a lower plate rolling device 170 It is arranged below the upper roller 142 and includes a lower rolling plate 171 horizontally arranged below the upper roller 142 . A roll gap is arranged between the upper roll 142 and the lower rolling plate 171, and rolling is realized after the rolling piece passes through the above-mentioned roll gap.

[0049] Please continue to refer Figure 1-Figure 4 , the upper roller system 140 is installed on the frame 110, and the upper roller system 140 can move along th...

Embodiment 2

[0058] This embodiment provides a plate rolling method, which uses the single-side rolling mill 100 provided in Embodiment 1, and specifically includes the following steps:

[0059] a. Apply lubricating oil or release agent on the lower rolling plate 171;

[0060] b. According to the initial thickness and reduction of the rolled piece, adjust the size of the roll gap through the reduction component;

[0061] c. After driving the upper roller system 140 and making the rotation speed of the upper roller system 140 stable, the lower rolling plate is pushed along the first reference direction through the driving assembly so that the rolled piece smoothly enters the rolling area for rolling. Moreover, the speed of the lower rolling plate 171 and the linear velocity of the upper rolling plate 142 maintain a certain difference, thereby further reducing the rolling force, enhancing the shearing effect, and improving the plastic deformation through the asynchronous manner of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com