A Constrained Damping Layer Structure with Ribs

A technology of constrained damping and constrained layers, which is applied to building components, earthquake resistance, etc., can solve problems such as local bonding failure and reduce the vibration and noise reduction ability of the constrained damping layer, so as to reduce local deformation and improve the vibration and noise reduction ability , good paste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

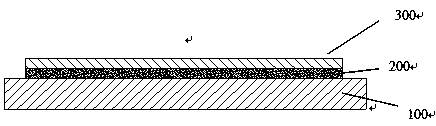

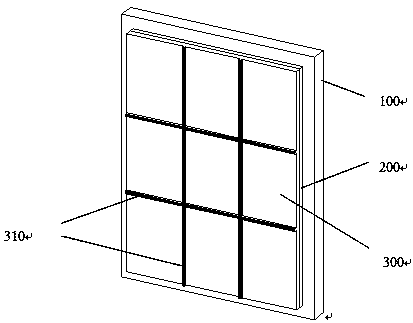

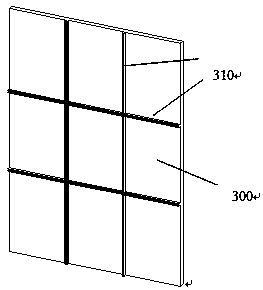

[0020] A restrained damping layer device with ribs is mainly used for vibration and noise control of thin-walled engineering structures. The constrained damping layer is composed of a damping layer 200, a constrained layer 300 and a constrained layer stiffener 310, see figure 2 . Among them, the damping layer 200 is made of high-damping viscoelastic material, and its damping loss factor should not be lower than 0.3 in the frequency range of vibration and noise control; the constrained layer 300 is made of aluminum (70 GPa), steel (200-210 GPa) or carbon fiber (≥210 GPa). The viscoelastic material in the damping layer 200 itself has a certain viscosity, and the damping layer 200 and the constraining layer 300 can be bonded in the factory to form a ribbed constrained damping layer device, and then pass the damping layer 200 and the structural layer on site. The paste between 100 realizes the installation of the ribbed constrained damping layer device, and if necessary, an adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com