A method of improving the damping performance of tc4 titanium alloy by magnetron sputtering surface treatment

A surface treatment, magnetron sputtering technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the problems of low damping performance, less deformation, less energy dissipation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the present invention comprises the steps:

[0022] (1) The material is TC4 titanium alloy rod material as the raw material, and the chemical composition of TC4 titanium alloy rod is shown in Table 1-1.

[0023] Table 1-1 Chemical composition of TC4

[0024]

[0025] (2) Vacuum coating was carried out on the samples using a magnetron sputtering coating machine of the model JC400-1 produced by Chengdu Westwork Co., Ltd. Various types of targets were selected, and magnetron sputtering coating was performed on two adjacent surfaces of the substrate TC4; metal films, inorganic non-metal films, composite films and some compound films were formed on the surface of TC4 samples; All anode targets and the specific process parameters of each target are shown in Table 1-2.

[0026] Table 1-2 Magnetron sputtering coating process parameters

[0027]

[0028] (3) The damping performance is characterized by the JN-1 Gerner pendulum tester. The sampl...

Embodiment 1

[0030] The damping test parameters of Cu layer deposited on the surface of TC4 are shown in Table 2

[0031] Table 2 Parameters of damping experiment of samples with Cu layer deposited on TC4 surface

[0032]

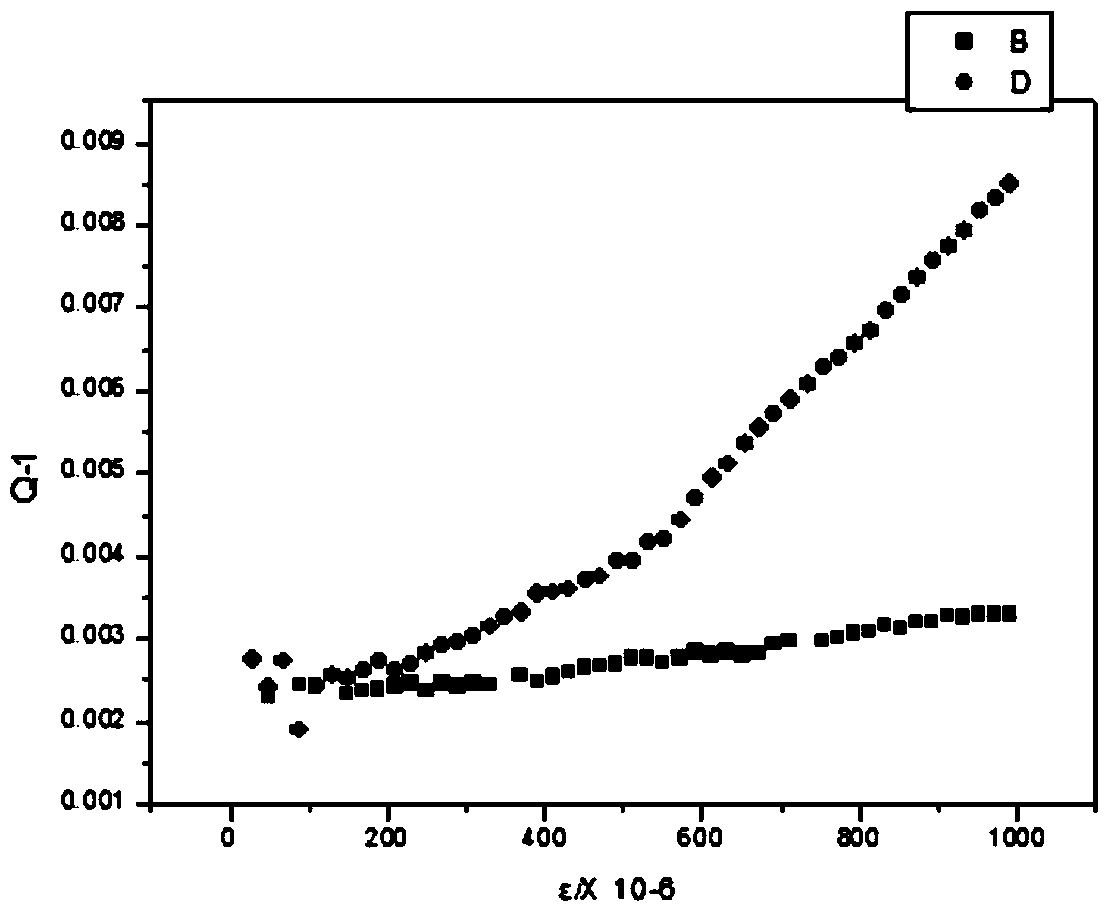

[0033] The results of the sample damping test are as follows: figure 1 shown.

[0034] From the comparison between the Cu-plated sample and the uncoated TC4 sample, it can be seen that the damping performance of the Cu-plated sample is much higher than that of the substrate, and the strain amplitude reaches 10 -3 The damping coefficient of the highest point is close to 0.009, and the damping Q of the sample after Cu plating on the surface -1 increased by about three times. In the figure, the sample damping increases smoothly with the increase of the strain amplitude, and the sample has a strain amplitude of 5.96×10 -4 The speed of the rise of the rear damping becomes faster. The mechanism of the Cu film improving the damping performance of TC4 is mainly divided ...

Embodiment 2

[0036] Table 3 shows the damping test parameters of SiO2 film layer samples deposited on the surface of TC4 alloy.

[0037] Table 3 SiO deposited on the surface of TC4 alloy 2 Parameters of damping experiment of film layer sample

[0038]

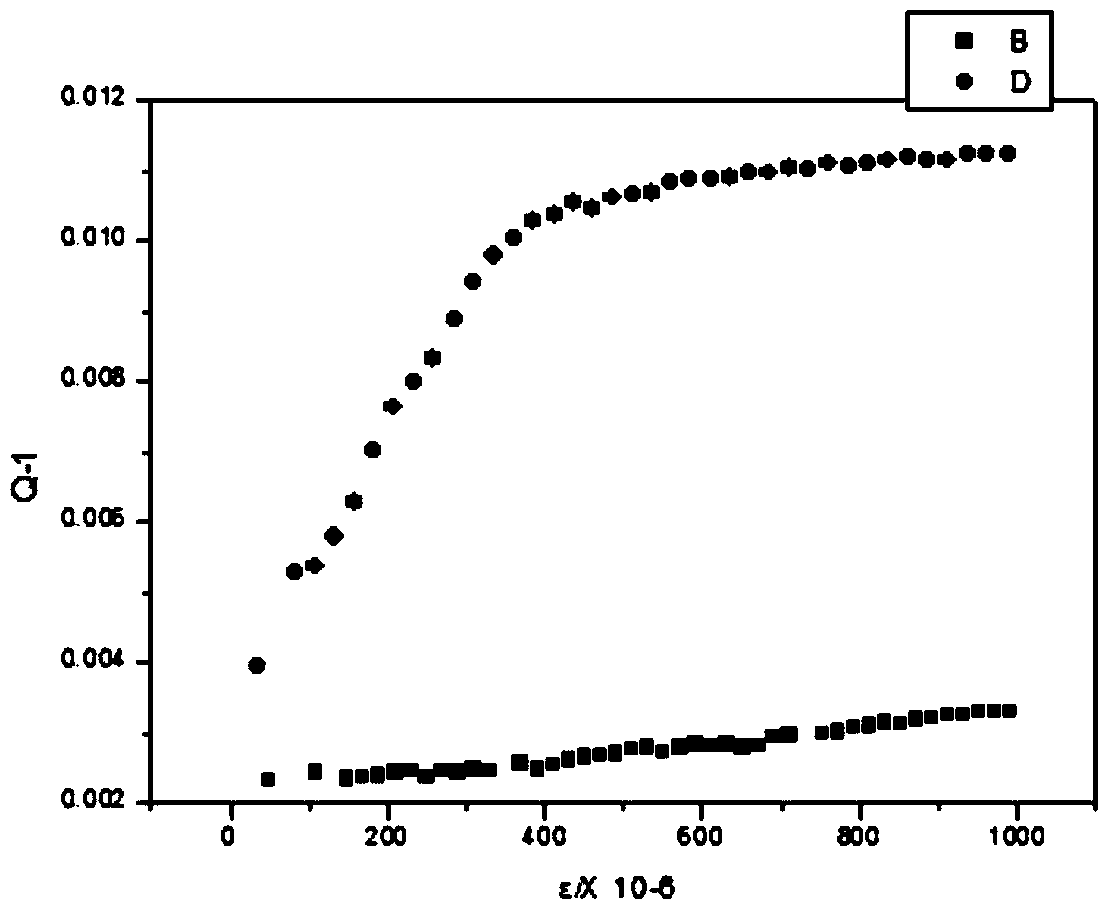

[0039] The results of the sample damping test are as follows: figure 2 shown.

[0040] Depend on figure 2 It can be seen that SiO 2 As an inorganic non-metallic film deposited on the surface of TC4, the strain amplitude ε reaches 10 -3, the damping reaches a maximum of 0.011, which is about four times higher than the inherent damping of TC4. SiO 2 The crystal structure is a regular tetrahedral structure composed of one Si atom and four O atoms with the smallest equal distance around it, where each Si atom forms four covalent bonds with four O atoms, and each O atom forms four covalent bonds with two Si atoms also form two covalent bonds, the whole SiO 2 The crystal is a three-dimensional network structure composed of a Si:O rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com