A homogeneous high-strength and toughening magnesium alloy cup-shaped member rotary extrusion method

An extrusion method and a technology for component rotation, which are used in the fields of rotary extrusion for forming and toughening, extrusion and modification of magnesium alloy materials, and can solve problems such as large differences in strength in all directions and reduce performance anisotropy. , The effect of refining the organization is significant, and the effect of enhancing the deformation and strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawings and examples.

[0041] The present invention specifically illustrates a rotary extrusion die and method for a homogeneous, high-strength and toughened magnesium alloy cup-shaped member through specific examples.

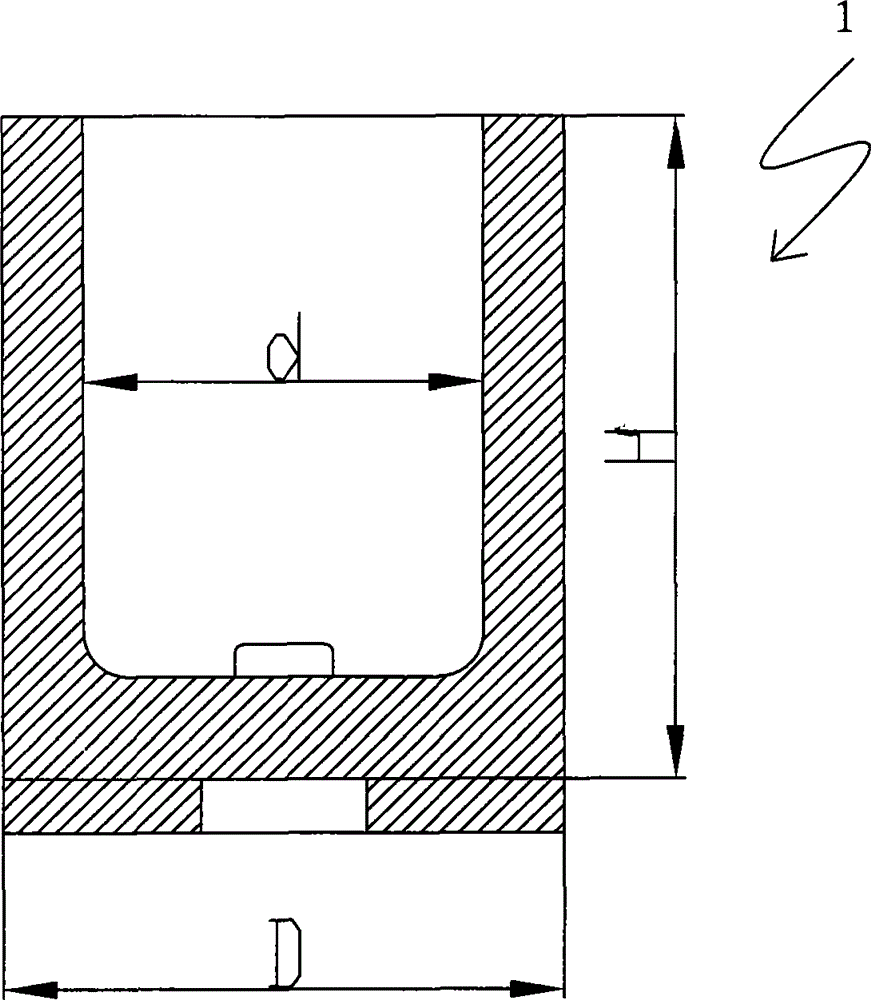

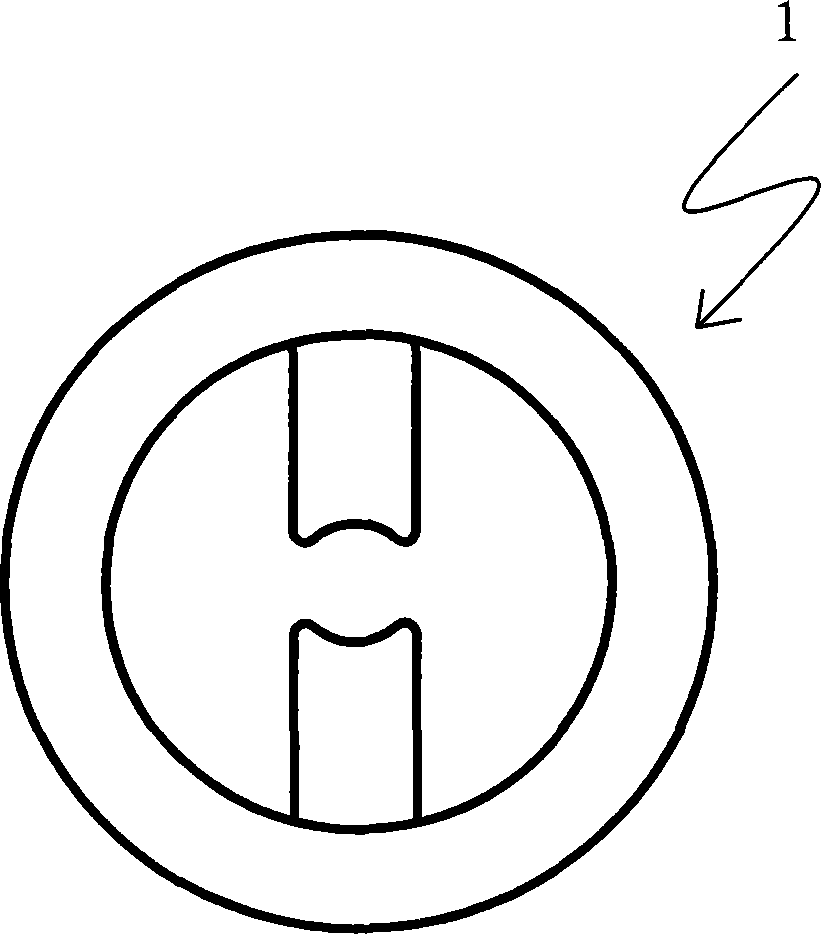

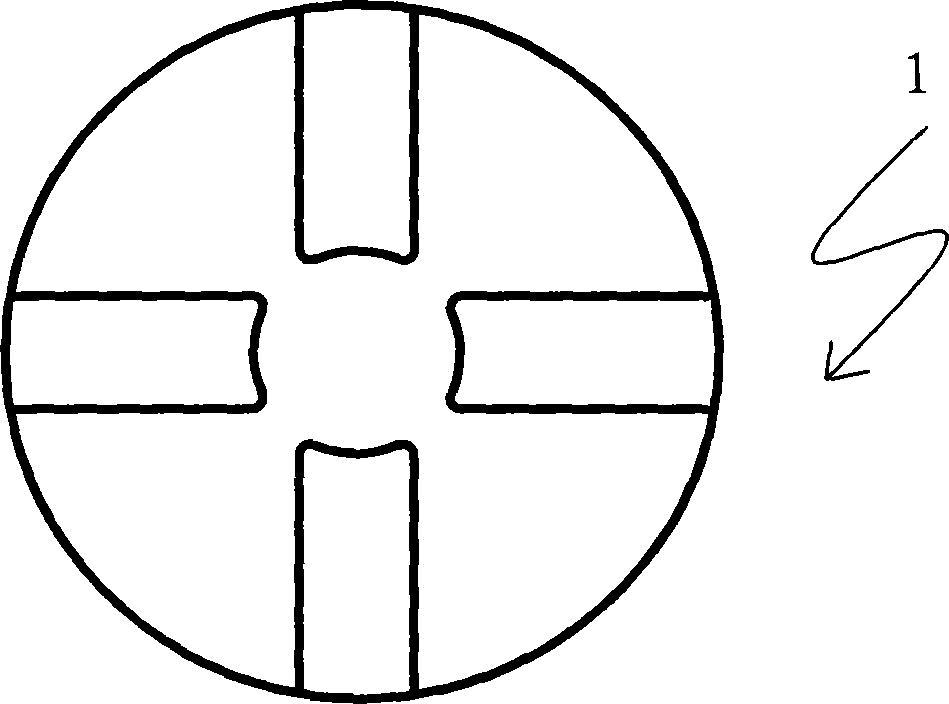

[0042] like Figure 5 , Figures 14 to 17 As shown, a rotary extrusion die 2 of a homogeneous high-strength and toughened magnesium alloy cup-shaped member includes a punch 22 for a rotary-extruded cup-shaped member, a forming die 23, a lower backing plate 27, a lower template 28, and a push rod 29; if Image 6 , Figure 7 , Figure 9 As shown, the punch 22 is an "I" shaped rotary part, and the punch 22 and the extruded blank 41 (such as Figure 5 Shown) that end head 221 that contacts is a cone, and the surface of the cone has a "one" shape, a "ten" shape, or a non-communicating groove 222 in the shape of a certain width and depth (such as Figure 5 ~ Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com