High damping concrete based on internal structure design and preparation method thereof

An internal structure, concrete technology, applied in building components, manufacturing tools, ceramic molding machines, etc., can solve the problems of reducing mechanical properties, high cost, unsatisfactory damping technology, etc., achieve excellent vibration damping performance, consume vibration energy, increase The effect of shear deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A kind of high damping concrete material preparation method based on internal structure design of the present invention comprises the following steps:

[0032] 1) Accurately weigh 15 to 17 parts of cement, 30 to 35 parts of natural river sand, and 42 to 47 parts of gravel according to the parts by mass, and after mixing evenly, add 4 to 8 parts of water and 1 to 2 parts of polycarboxylic acid Water reducing agent, after manual mixing evenly, forms ordinary concrete constraining layer;

[0033] 2) The ordinary concrete obtained in step 1) is first formed in a part of the test mold;

[0034] 3) Making polymer modified layer: including pure polymer emulsion or polymer modified mortar.

[0035] ①Pure polymer emulsion

[0036] Use 1-2 parts of polymer emulsion (styrene-acrylic emulsion or emulsified asphalt) modified layer as the free layer structure;

[0037] ②Polymer modified mortar

[0038] Mix 3-4 parts of cement, 7-9 parts of river sand, 1 part of water reducing age...

Embodiment 1

[0044] A method for preparing a high-damping concrete material based on internal structure design in this embodiment includes:

[0045] 15 parts of cement, 30 parts of natural river sand, 45 parts of gravel, 8 parts of water, 2 parts of water reducing agent, and 1 part of emulsified asphalt.

[0046] 1) Make ordinary concrete constraining layer:

[0047] Preparation and design process: Accurately weigh the mass of each component according to the above ratio, and mix the components evenly under normal temperature conditions. The mixing time is completed within 5 minutes after adding water. It is formed in a concrete test mold and manually vibrated for 3 minutes to form a common Concrete layer, the thickness of which is about 70mm;

[0048] 2) Make the polymer modified layer: after the initial setting of the concrete, apply the weighed emulsified asphalt with a brush evenly, and the amount of emulsified asphalt should be spread evenly on the entire surface of the test piece, wi...

Embodiment 2

[0052] A method for preparing a high-damping concrete material based on internal structure design in this embodiment includes:

[0053] 15 parts of cement, 30 parts of natural river sand, 45 parts of gravel, 8 parts of water, 2 parts of water reducer, 1 part of styrene-acrylic emulsion.

[0054] 1) Make ordinary concrete constraining layer:

[0055]Preparation and design process: Accurately weigh the mass of each component according to the above ratio, and mix the components evenly under normal temperature conditions. The mixing time is completed within 5 minutes after adding water. It is formed in a concrete test mold and manually vibrated for 3 minutes to form a common Concrete layer, the thickness of which is about 70mm;

[0056] 2) Make the polymer modified layer: after the initial setting of the concrete, apply the weighed styrene-acrylic emulsion with a brush evenly, and the amount of styrene-acrylic emulsion should be evenly spread to the entire surface of the test pie...

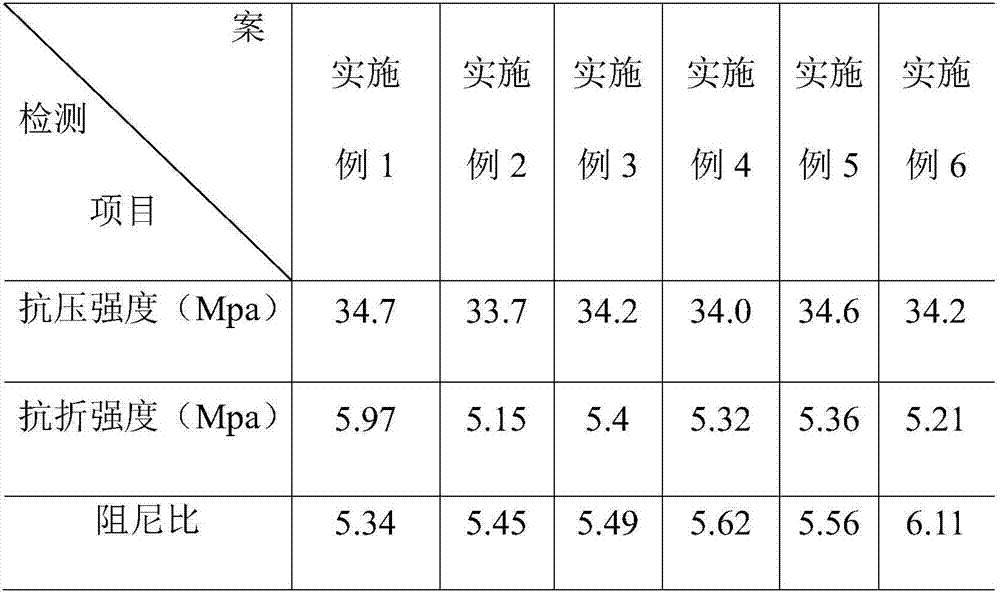

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com