Variable mass dynamic vibration absorber control method

A technology of dynamic vibration absorber and control method, which is applied in the direction of vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc. It can solve the resonance of the main system, which has rarely been studied in depth, the effective vibration reduction bandwidth is narrow, and the vibration of the main system is increased. Large and other problems, to achieve the effect of broadening the effective vibration reduction frequency band, widening the effective frequency range, and broadening the vibration reduction frequency band

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

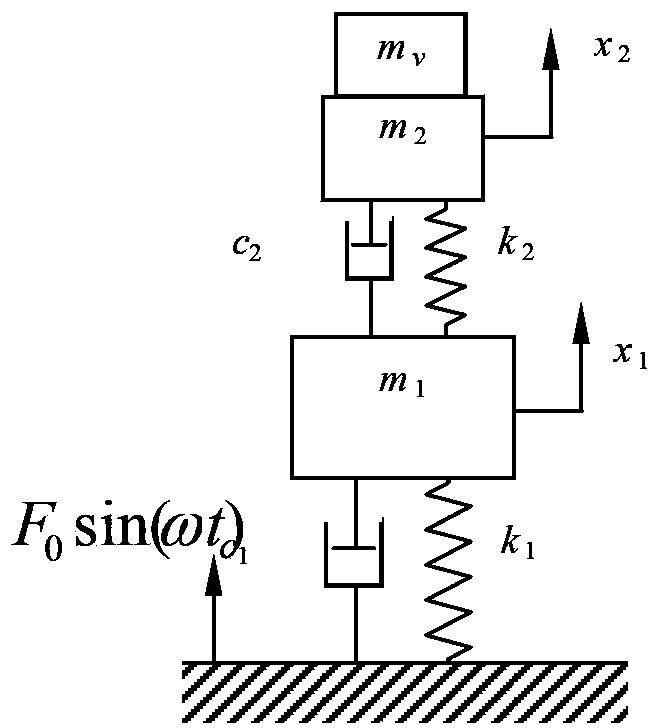

[0061] Such as Figure 5 As shown, the main system is composed of a stainless steel cantilever beam and a vibration acceleration sensor at the end as the elastic element and mass element, and a spring steel sheet and a small glass bottle are used as the elastic element and variable mass unit respectively to form a variable mass dynamic shock absorber. The vibration absorber is installed at the end of the cantilever beam of the main system to form the experimental system. Use tap water as the variable mass medium. The main system is installed on the top of the electromagnetic exciter, and an acceleration sensor is installed on the bottom of the main system to measure the vibration signal input to the main system.

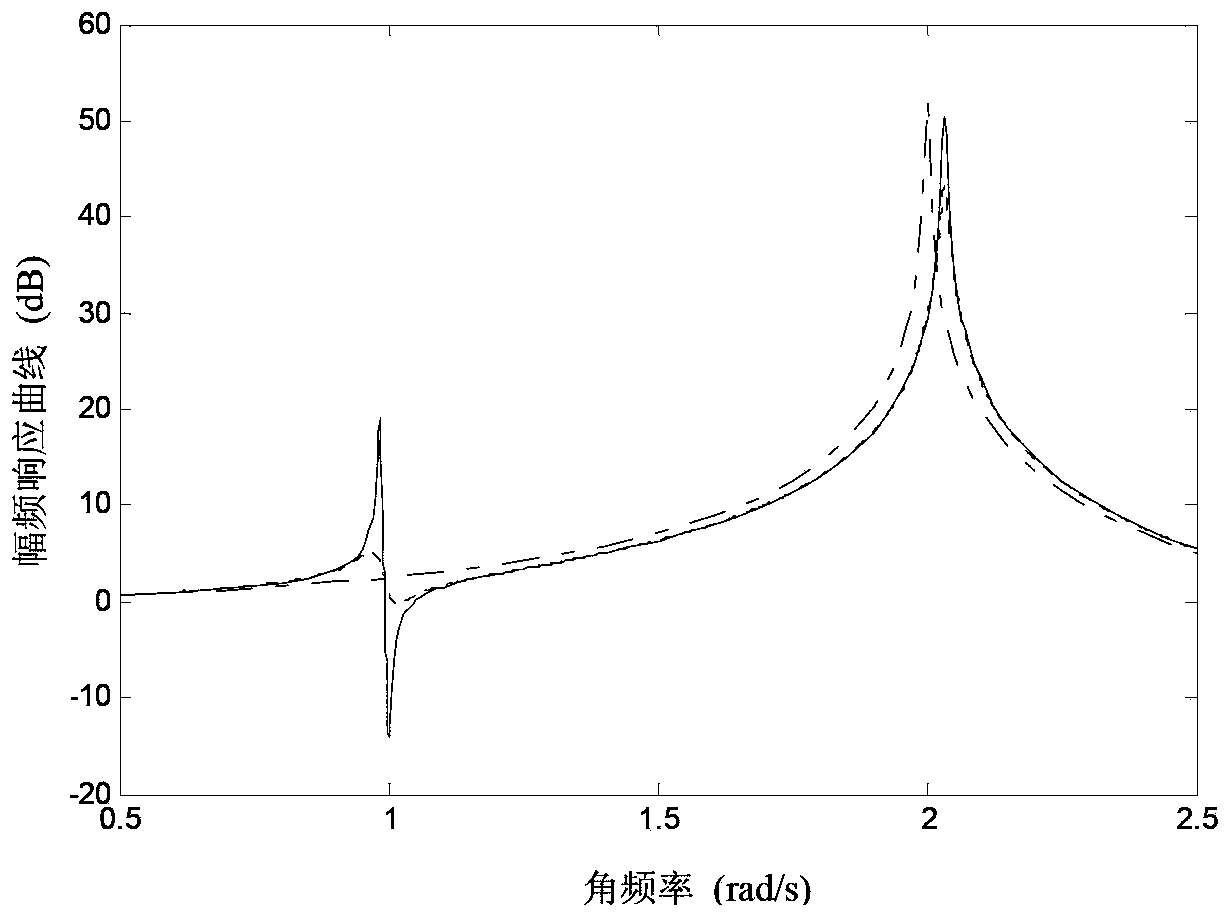

[0062] When the glass bottle is filled with water and not filled with water, the amplitude-frequency response curve of the main system is experimentally tested, such as Figure 6 shown. It can be seen that when the glass bottle is full, the vibration absorber redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com