Composite-material energy-dissipation fender and manufacturing process of composite-material energy-dissipation fender

A composite material and manufacturing process technology, used in bridge parts, climate change adaptation, bridges, etc., can solve the problems of poor anti-collision effect, high cost, difficult repair, etc., to reduce losses, long service life, and anti-collision effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

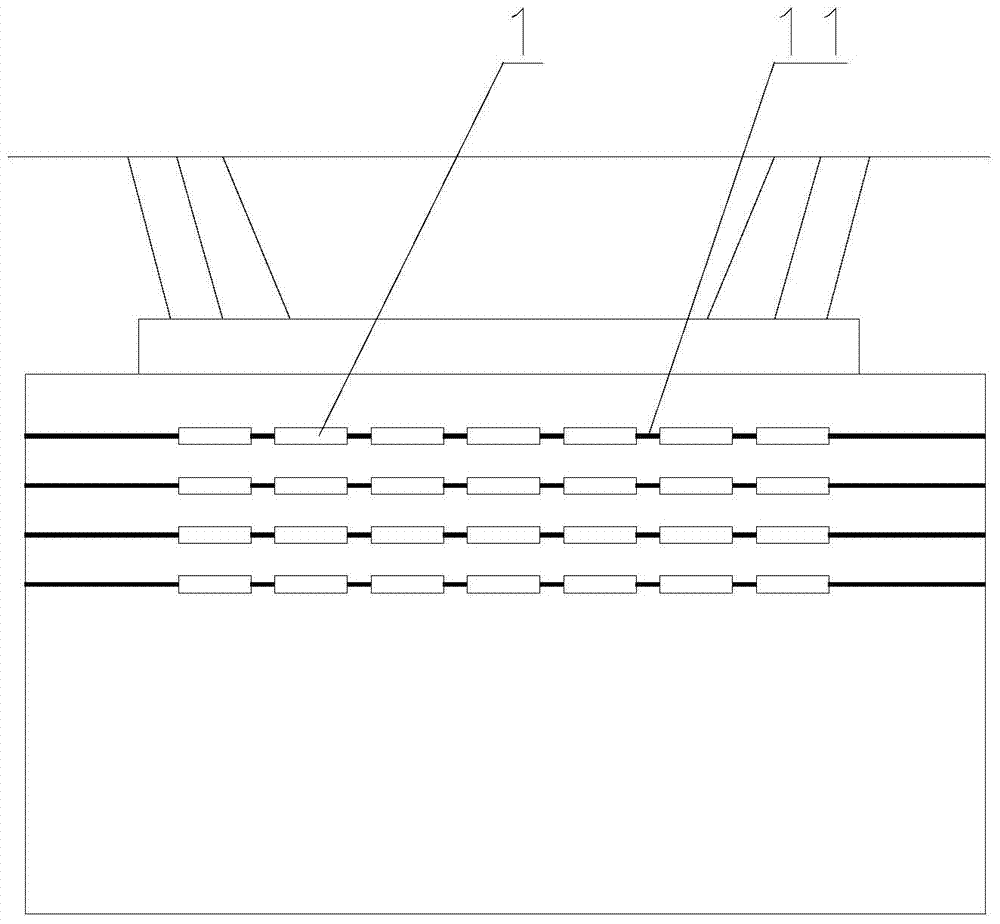

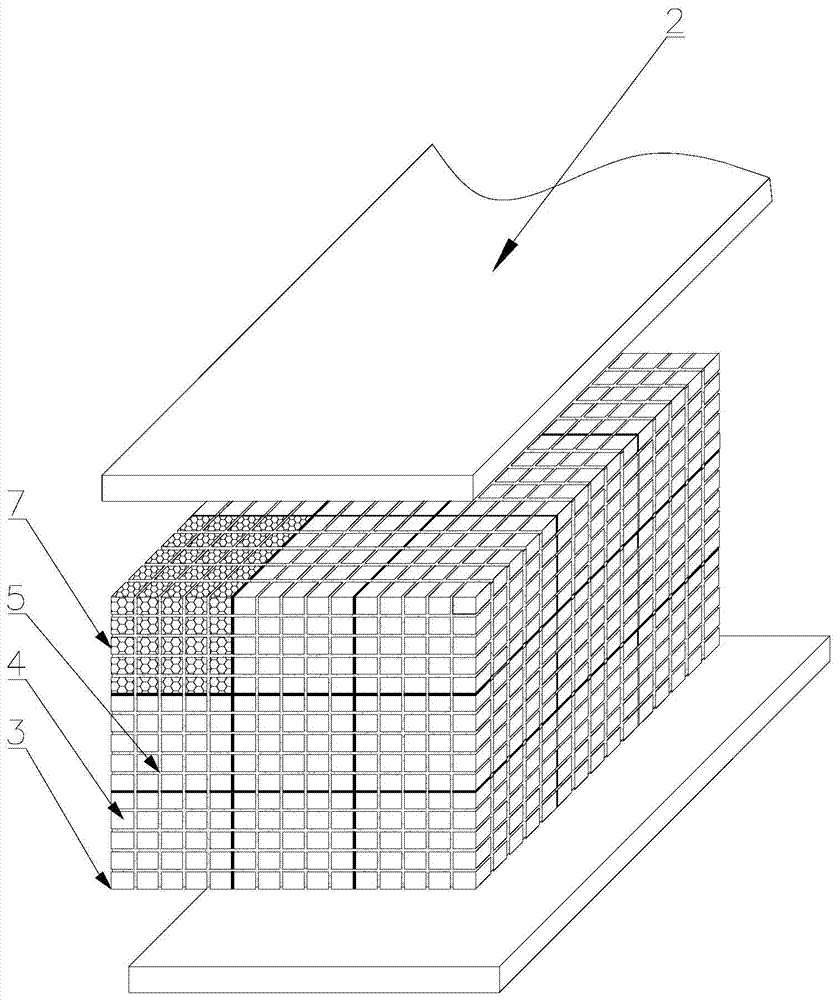

[0043] Such as Figure 4 As shown, a composite energy-dissipating fender 1 includes a shell 2 and an energy-dissipating filler 3 wrapped in the shell 2. The composite energy-dissipating fender 1 is rectangular and is cured by glass fiber and unsaturated resin. A solid shell 2 is formed; the energy-dissipating filling body 3 includes energy-dissipating materials 4 and energy-dissipating ribs 5, and polyurethane foam is used to manufacture several cuboid-shaped unit blocks 7, and several unit blocks 7 are combined to form energy-dissipating materials 4, and the unit blocks 7 have the same shape and size, and the energy-dissipating ribs 5 include glass fiber strands and unsaturated resin; the twelve edges of the unit block 7 are divided into five equal parts, and the endpoints on the six faces are perpendicular to the The ribs are provided with energy dissipation grooves 8, and the energy dissipation grooves 8 on each surface form a rectangular mesh network structure, and the fib...

Embodiment 2

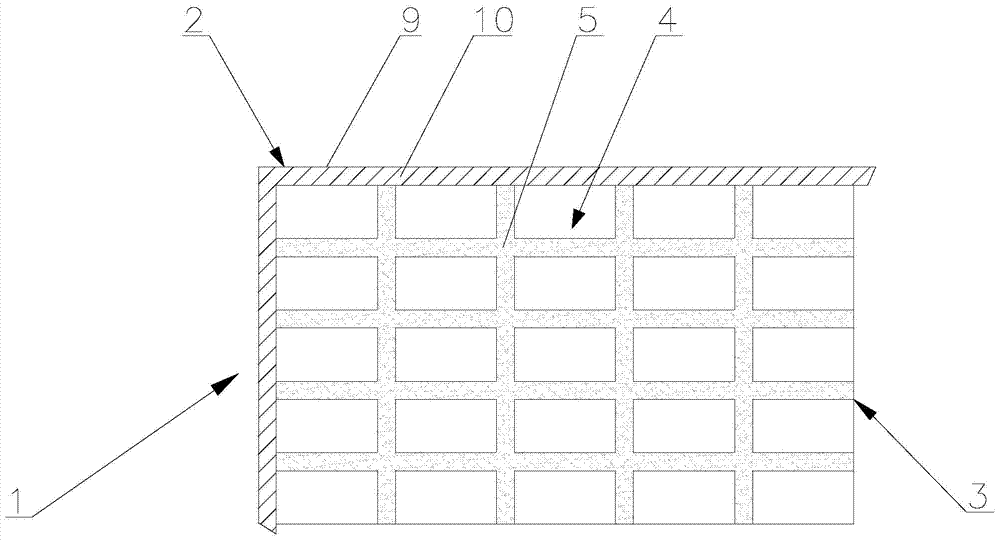

[0045] Such as Figure 5 As shown, a composite energy-dissipating fender 1, a shell 2 and an energy-dissipating filler 3 wrapped in the shell 2, the composite energy-dissipating fender 1 is rectangular, and the shell 2 is a composite surface layer 9 A sandwich shell 2 filled with a sandwich material 10, the composite surface layer 9 is cured by carbon fiber and vinyl resin, the sandwich material 10 is polyurethane foam; the energy dissipation filling body 3 includes energy dissipation materials 4 and energy dissipation ribs 5, Use PMI foam to manufacture several cuboid-shaped unit blocks 7, and several unit blocks 7 are combined to form an energy dissipation material 4. The shape and size of the unit blocks 7 are consistent, and the energy dissipation ribs 5 include carbon fiber tow and vinyl resin; all of the unit blocks 7 are opened Elongated energy-dissipating grooves 8, all the energy-dissipating grooves 8 on each unit block 7 are connected to each other, and the energy-di...

Embodiment 3

[0047] Such as Figure 6 As shown, the difference from Example 2 is that the energy-dissipating fender 1 of composite material is in the shape of "7" and can be directly fixed on the bridge by bolts, and the surface layer 9 of composite material is cured by aramid fiber and epoxy resin. The sandwich material 10 is polyvinyl chloride foam, the energy dissipation material 4 is polyvinyl chloride foam, the filament material is aramid fiber, and the resin material in the energy dissipation rib 5 is epoxy resin. A plurality of through holes 6 are opened, and aramid fiber tows are placed in the through holes 6. All the through holes 6 are connected with the external space of the energy dissipation material 4. Finally, a vacuum introduction process is used to inject molten unsaturated resin into an integrally formed composite material dissipation material. Can fender 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com