Damper rail

A track and body technology, applied in the track field, can solve the problems of limited effective working area of damping materials, limited vibration and noise reduction, and the track cannot achieve the effect of vibration and noise reduction, and achieves good vibration and noise reduction. And the effect of wheel wear and increase of effective contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

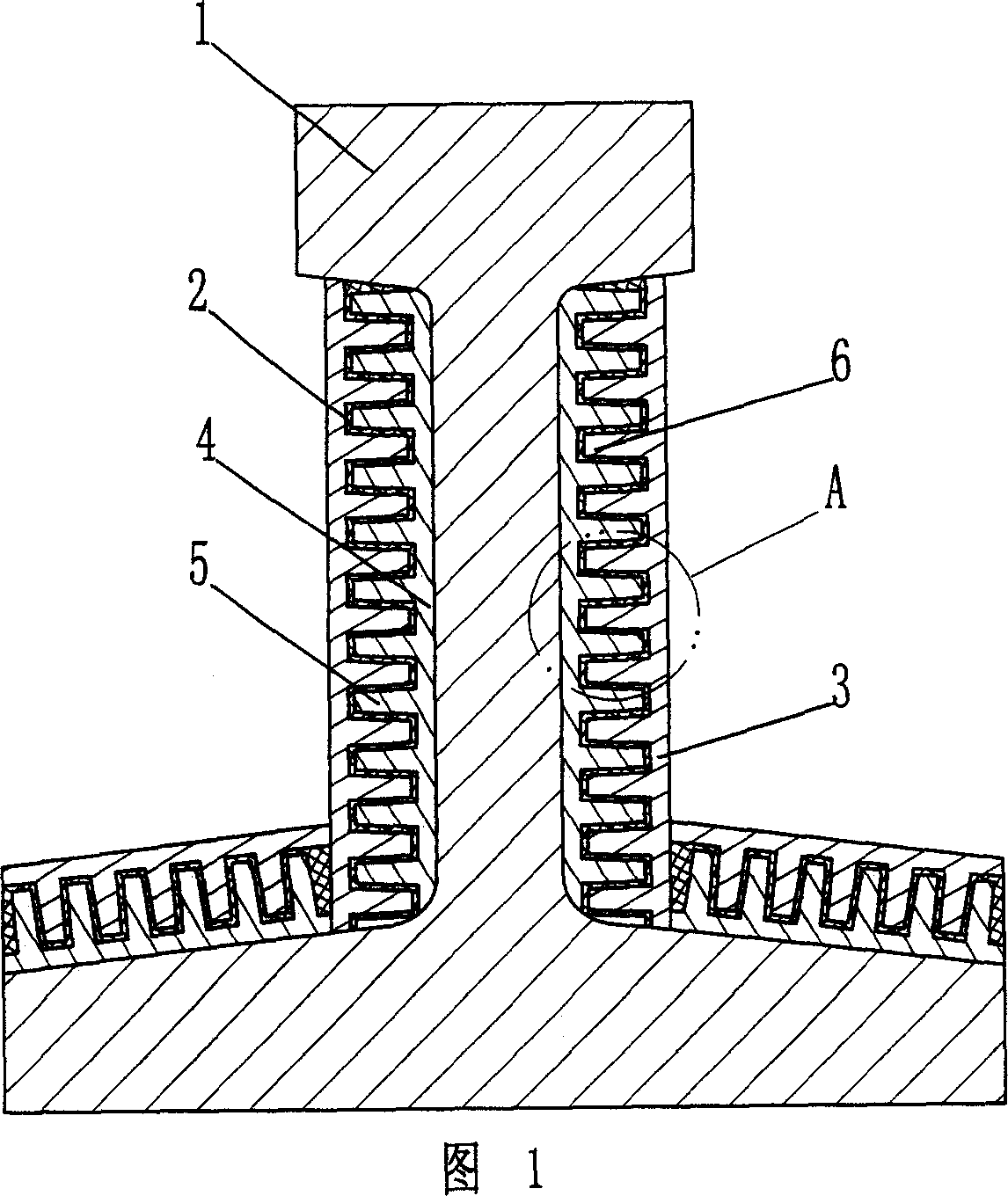

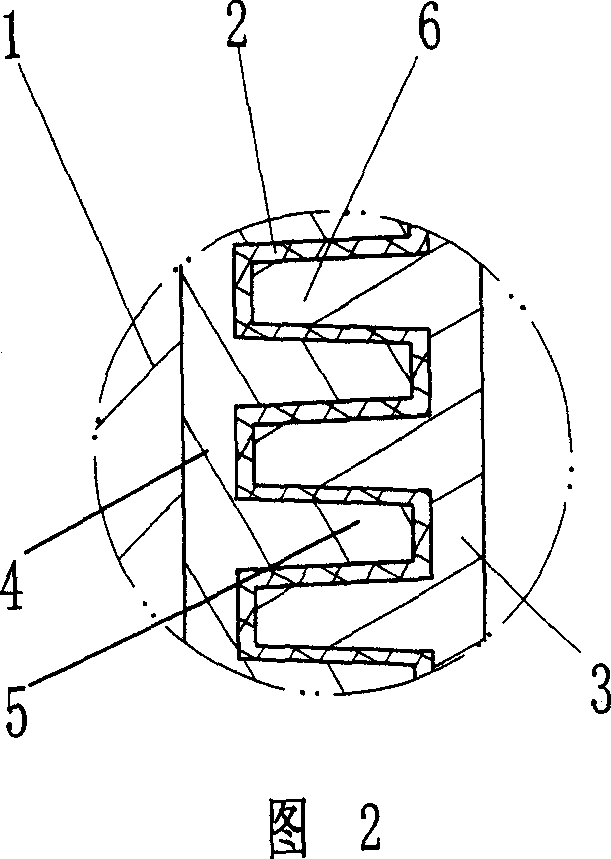

[0031] As shown in Figures 1 and 2, the damping track of the present invention includes a track body 1, a damping body 2 made of high-damping rubber and a steel restraint body 3, and a steel rail is also arranged between the track body 1 and the damping body 2. Connecting body 4, connecting body 4 is multi-point welded on the non-working surface of track body 1 both sides by resistance welding, for the convenience of construction, the connecting body is divided into two sections according to its shape change on each side of track body and installed. The connecting body 4 and the damping body 2 have a trapezoidal rib 5 on the side adjacent to the damping body 2, and the trapezoidal rib 6 interlaced with the connecting body trapezoidal rib 5 is arranged on the side adjacent to the damping body 2, and the damping body 2 It is arranged in the matching gap between the connecting body 4 and the constraining body 3, and the connecting body 4 and the constraining body 3 are vulcanized ...

Embodiment 2

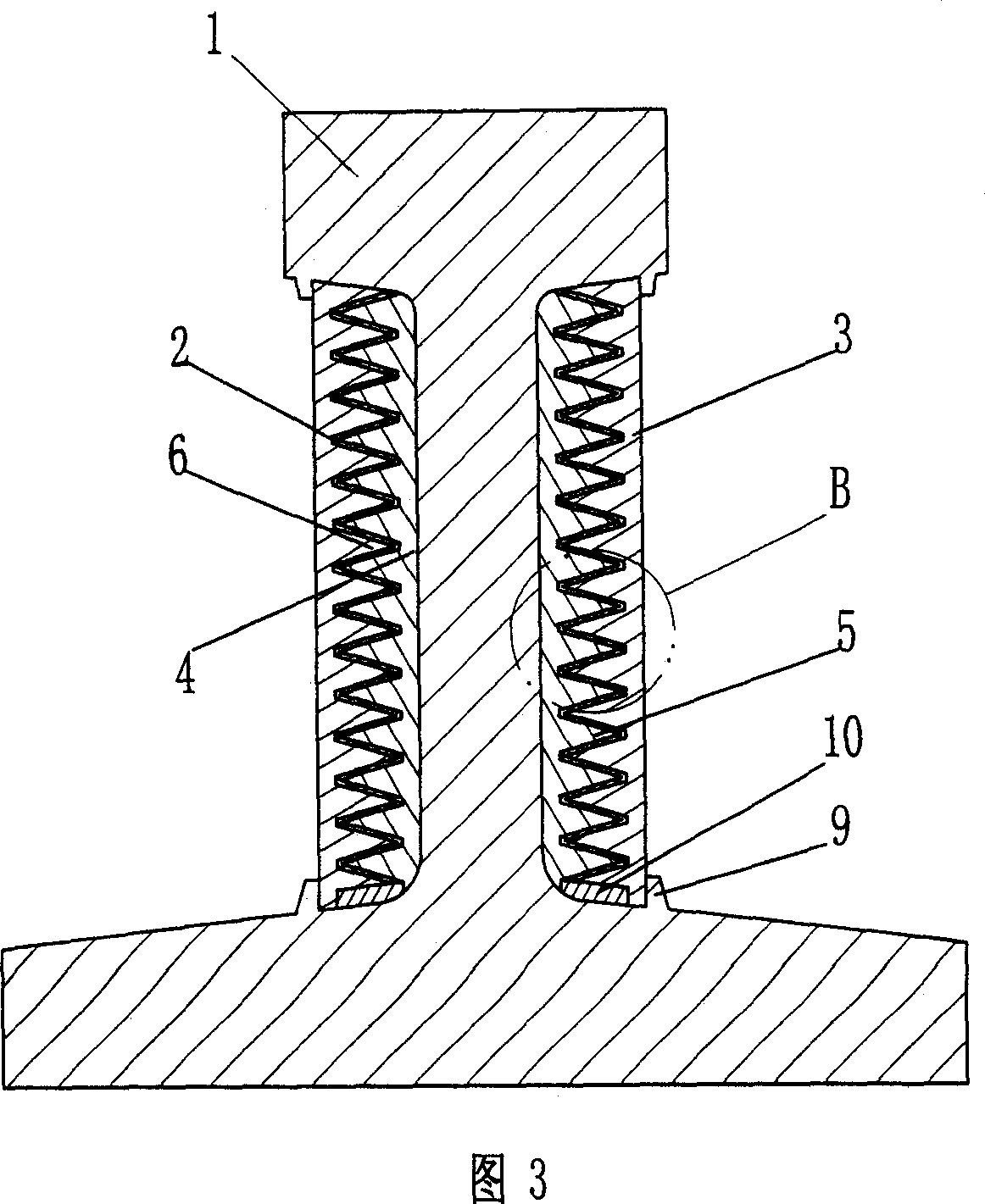

[0035]As shown in Fig. 3 and Fig. 4, the damping track of the present invention comprises a track body 1, a damping body 2 made of modified damping asphalt which is liquid at the working temperature, and an aluminum alloy plate constraining body 3, between the track body 1 and the damping body 2 A connecting body 4 made of aluminum alloy is also provided between them, and the connecting body 4 is firmly bonded to the two sides of the track body 1 by using high-strength damping material. When bonding with high-strength damping materials, the bonding layer should be as thin as possible to ensure high bonding stiffness. The outer surface of the connecting body 4 has triangular ribs 5 , and the side of the constraining body 3 adjacent to the damping body 2 has triangular ribs 6 interlaced with the ribs 5 . The damping body 2 is arranged in the fitting gap between the connecting body 4 and the constraining body 3 . The restraint structure is locked on the rail by means of the groo...

Embodiment 3

[0039] As shown in Figure 5, the damping track of the present invention includes a track body 1, a damping body 2 made of solid modified asphalt, and an aluminum profile constraining body 3, and an aluminum profile connecting body 4 is also arranged between the track body 1 and the damping body 2 , the connecting body 4 is firmly bonded on the track body 1 by using a highly elastic adhesive, and the ribs on the connecting body 4 cross-fit with the hollow rectangular bosses on the constraining body 3, and the damping body 2 is arranged between the connecting body and the restraining body. within the fit gap between bodies.

[0040] In order to facilitate the construction, the corresponding connecting body and restraining body are made in sections according to the shape of the rail. Since the space at the bottom of the rail is small and the plane area of the rail bottom is large, the connecting body is omitted under the rail, and the connecting body is directly installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com