Method for producing ultra-thick plate continuous casting blank

A continuous casting billet and extra-thick plate technology, which is applied in the field of metal continuous casting, can solve the problems of difficult to achieve single pass, cannot completely eliminate the influence of the quality of the central core of the billet, large reduction and deformation rate, etc. Control center segregation and porosity, improve center quality and surface defects, and improve isotropic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

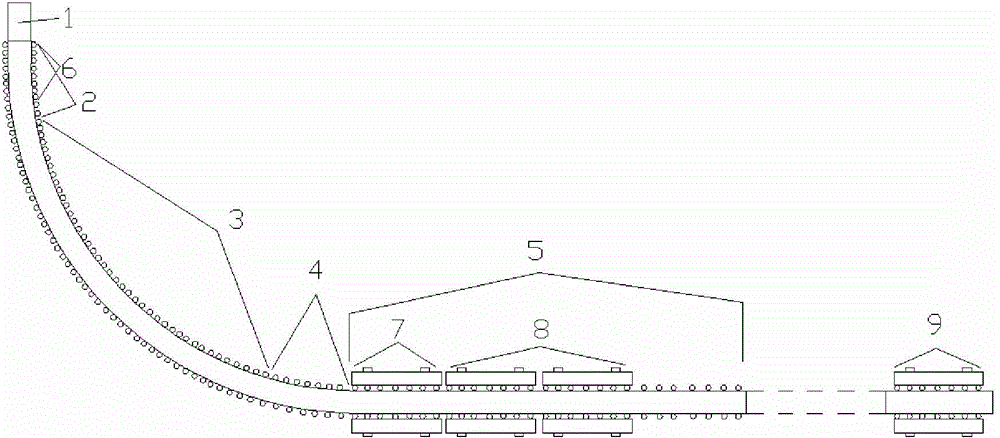

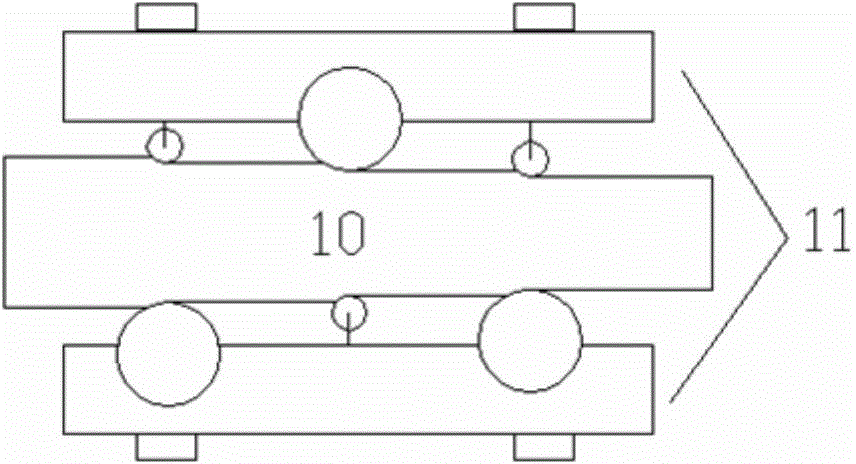

[0043] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, and the present invention is not limited to the following examples.

[0044] In the continuous casting slab rolling process, the temperature inside and outside the slab is usually almost the same, but in the continuous casting machine, the surface temperature of the slab is about 300-400°C lower than the temperature of the core. Therefore, the deformation of the blank during the pressing process tends to concentrate more towards the center. The reduction amount of the conventional slab continuous casting machine solidification end soft reduction process is 4-5mm, the reduction rate is about 0.6-1.0mm / m, the corresponding reduction rate is about 0.01-0.02mm / s, and the extra thick The reduction rate and reduction rate produced by the large reduction process of the plate continuous casting machine can reach 3-15mm / m and 0.025-0.12mm / s respectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com