Valve plate, exhaust valve assembly, compressor and air conditioner

A technology for exhaust valves and compressors, which is applied in the field of compressors, and can solve problems such as poor reliability, valve seat impact, and surface wear of valve plates and valve seats, so as to reduce vibration, alleviate valve plate wear, and improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

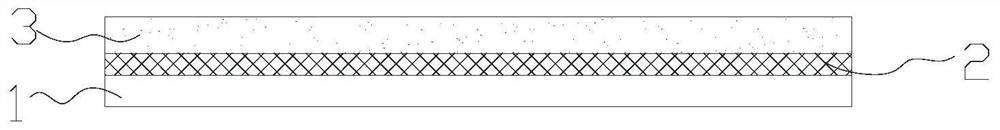

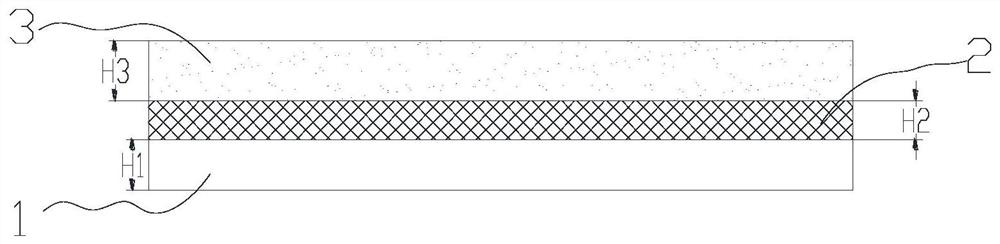

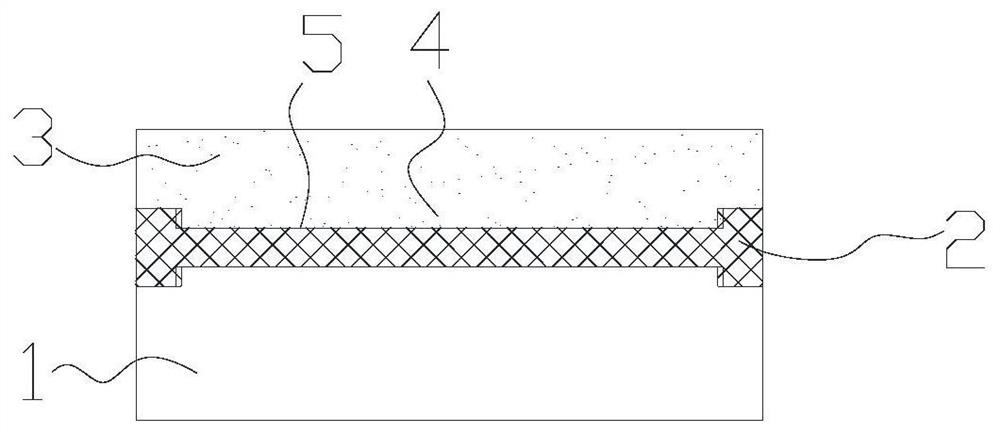

[0028] see in conjunction Figure 1 to Figure 7 As shown, according to the embodiment of the present application, the valve sheet includes a base layer valve sheet 1, a damping layer valve sheet 2 and a constrained layer valve sheet 3, and the damping layer valve sheet 2 is located between the base layer valve sheet 1 and the constraining layer valve sheet 3, and the base layer The valve plate 1, the damping layer valve plate 2 and the constrained layer valve plate 3 are fixedly connected.

[0029] In this embodiment, the valve plate adopts at least three-layer structure, wherein the role of the base valve plate 1 is to directly contact with the valve seat, and the rigidity is relatively high, so as to avoid the direct contact between the damping layer valve plate 2 and the valve seat, so as to avoid the damping layer valve plate 2 Damage occurs under high-frequency impact; the damping layer valve plate 2 acts as a damper and will dissipate part of the vibration energy of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com