Rubber bearing

A rubber bearing and rubber technology, applied in the field of rubber, can solve the problems of fast aging and inconvenient replacement, and achieve the effect of good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

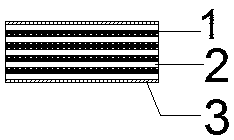

[0009] see figure 1 , The present invention provides a technical solution: a rubber bearing, including multi-layer thin steel plates and multi-layer rubber sheets. The multi-layer rubber sheet is mainly made of rubber. The rubber support is formed by vulcanizing and bonding multi-layer thin steel plates and multi-layer rubber sheets. The surface of the support is glued with a layer of 1.5mm - 3mm thick PTFE plate. Although the present invention has been described in detail with reference to the aforementioned embodiments, those skilled in the art can still modify the technical solutions described in the aforementioned embodiments, or perform equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com